The application requires the priority of the U.S. Patent application 11/143,535 submitted on June 2nd, 2005, and described application has required the priority of the U.S. Patent application 60/576,939 submitted on June 4th, 2004, its two incorporated into this paper in full as a reference.

Summary of the invention

In one embodiment, the present invention relates to the method that may further comprise the steps:

A., composition is provided, and it comprises:

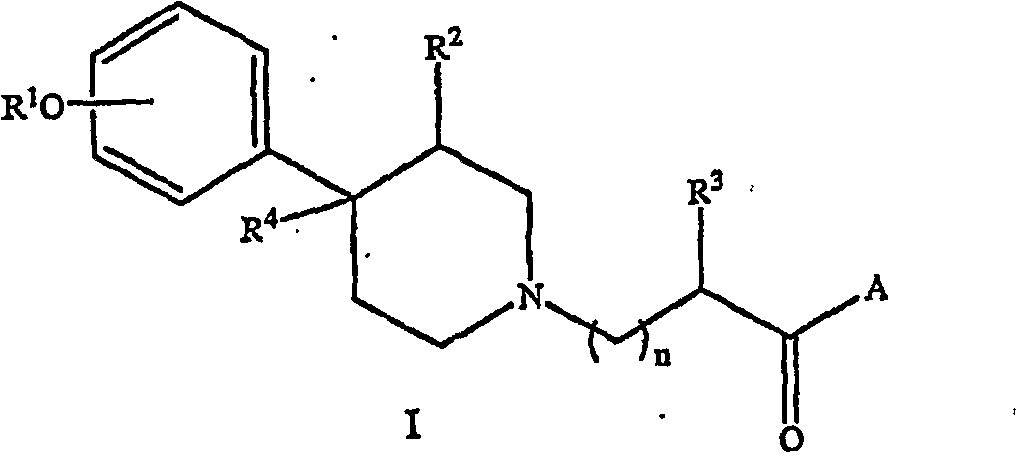

(i) the pharmaceutically acceptable slaine of at least a formula I compound:

Wherein:

R

1Be hydrogen or alkyl;

R

2Be hydrogen, alkyl or alkenyl;

R

3Be the alkyl of hydrogen, alkyl, thiazolinyl, aryl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

4Be hydrogen, alkyl or alkenyl;

A is OR

5Or NR

6R

7

R

5Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

6Be hydrogen or alkyl;

R

7The B that alkyl, aralkyl, aralkyl or the alkylidene that replaces for the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, aryl, cycloalkyl substituted, cycloalkenyl group, cycloalkenyl group replaces, or R

6And R

7Form heterocycle with the nitrogen-atoms that they connected;

B is

C (=O) W or NR

8R

9

R

8Be hydrogen or alkyl;

R

9The alkyl, aryl or the aralkyl that replace for the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl substituted, cycloalkyl, cycloalkenyl group, cycloalkenyl group, or R

8And R

9Form heterocycle with the nitrogen-atoms that they connected;

W is OR

10, NR

11R

12Or OE;

R

10Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

11Be hydrogen or alkyl;

R

12C (=O) the Y, or R that alkyl, aralkyl or the alkylidene that replaces for the alkyl of hydrogen, alkyl, thiazolinyl, aryl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, cycloalkenyl group replaces

11And R

12Form heterocycle with the nitrogen-atoms that they connected;

E is

(C=O) D that alkylidene replaces or-R

13OC (=O) R

14

R

13Alkylidene for the alkyl replacement;

R

14Be alkyl;

D is OR

15Or NR

16R

17

R

15Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

16Be the alkyl of hydrogen, alkyl, thiazolinyl, aryl, aralkyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted or the alkyl of cycloalkenyl group replacement;

R

17Be hydrogen or alkyl, or R

16And R

17Form heterocycle with the nitrogen-atoms that they connected;

Y is OR

18Or NR

19R

20

R

18Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

19Be hydrogen or alkyl;

R

20Be the alkyl of hydrogen, alkyl, thiazolinyl, aryl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces, or R

19And R

20Form heterocycle with the nitrogen-atoms that they connected;

R

21Be hydrogen or alkyl;

With n be 0 to 4;

The (ii) incremental agent of at least a crystallization;

(iii) at least a weak base; With

(iv) water;

Wherein said composition has the initial pH at least about 10.5; With

B. the pH that regulates described composition arrives the final pH that arrive in about 11 scopes about 9;

Wherein, to patient's administration the time, described composition has the dissolution rate and the bioavilability of the improvement that is used for oral or parenterai administration.

In another embodiment, the method that partly relates to of the present invention comprises described composition dries with the described water of removing at least a portion in addition to form the partially or completely step of dry products.

In another embodiment, the method that the present invention relates to comprises in addition by making it organize the step of structure again with the solution that forms described dry products described dry products and the merging of pharmaceutically useful solvent.

In other embodiments, the present invention relates to the product produced by each said method.

In another embodiment, the method that the present invention relates to comprises in addition with the described solution of the described dry products step to patient's administration.

In another embodiment, the present invention relates to composition, it comprises:

The pharmaceutically acceptable slaine of a. at least a formula I compound:

Wherein:

R

1Be hydrogen or alkyl;

R

2Be hydrogen, alkyl or alkenyl;

R

3Be the alkyl of hydrogen, alkyl, thiazolinyl, aryl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

4Be hydrogen, alkyl or alkenyl;

A is OR

5Or NR

6R

7

R

5Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

6Be hydrogen or alkyl;

R

7The B that alkyl, aralkyl, aralkyl or the alkylidene that replaces for the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, aryl, cycloalkyl substituted, cycloalkenyl group, cycloalkenyl group replaces, or R

6And R

7Form heterocycle with the nitrogen-atoms that they connected;

B is

C (=O) W or NR

8R

9

R

8Be hydrogen or alkyl;

R

9The alkyl, aryl or the aralkyl that replace for the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl substituted, cycloalkyl, cycloalkenyl group, cycloalkenyl group, or R

8And R

9Form heterocycle with the nitrogen-atoms that they connected;

W is OR

10, NR

11R

12Or OE;

R

10Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

11Be hydrogen or alkyl;

R

12C (=O) the Y, or R that alkyl, aralkyl or the alkylidene that replaces for the alkyl of hydrogen, alkyl, thiazolinyl, aryl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, cycloalkenyl group replaces

11And R

12Form heterocycle with the nitrogen-atoms that they connected;

E is

(C=O) D that alkylidene replaces or-R

13OC (=O) R

14

R

13Alkylidene for the alkyl replacement;

R

14Be alkyl;

D is OR

15Or NR

16R

17

R

15Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

16Be the alkyl of hydrogen, alkyl, thiazolinyl, aryl, aralkyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted or the alkyl of cycloalkenyl group replacement;

R

17Be hydrogen or alkyl, or R

16And R

17Form heterocycle with the nitrogen-atoms that they connected;

Y is OR

18Or NR

19R

20

R

18Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

19Be hydrogen or alkyl;

R

20Be the alkyl of hydrogen, alkyl, thiazolinyl, aryl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces, or R

19And R

20Form heterocycle with the nitrogen-atoms that they connected;

R

21Be hydrogen or alkyl;

With n be 0 to 4;

B. the incremental agent of at least a crystallization;

Wherein said composition has and is lower than about 1.0g/cm

3Density;

Wherein, to patient's administration the time, described composition has the dissolution rate and the bioavilability of the improvement that is used for oral or parenterai administration.

In other embodiments, the present invention relates to composition, it comprises:

The pharmaceutically acceptable slaine of a. at least a formula I compound:

Wherein: R

1Be hydrogen or alkyl;

R

2Be hydrogen, alkyl or alkenyl;

R

3Be the alkyl of hydrogen, alkyl, thiazolinyl, aryl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

4Be hydrogen, alkyl or alkenyl;

A is OR

5Or NR

6R

7

R

5Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

6Be hydrogen or alkyl;

R

7The B that alkyl, aralkyl, aralkyl or the alkylidene that replaces for the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, aryl, cycloalkyl substituted, cycloalkenyl group, cycloalkenyl group replaces, or R

6And R

7Form heterocycle with the nitrogen-atoms that they connected;

B is

C (=O) W or NR

8R

9

R

8Be hydrogen or alkyl;

R

9The alkyl, aryl or the aralkyl that replace for the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl substituted, cycloalkyl, cycloalkenyl group, cycloalkenyl group, or R

8And R

9Form heterocycle with the nitrogen-atoms that they connected;

W is OR

10, NR

11R

12Or OE;

R

10Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

11Be hydrogen or alkyl;

R

12C (=O) the Y, or R that alkyl, aralkyl or the alkylidene that replaces for the alkyl of hydrogen, alkyl, thiazolinyl, aryl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, cycloalkenyl group replaces

11And R

12Form heterocycle with the nitrogen-atoms that they connected;

E is

(C=O) D that alkylidene replaces or-R

13OC (=O) R

14

R

13Alkylidene for the alkyl replacement;

R

14Be alkyl;

D is OR

15Or NR

16R

17

R

15Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

16Be the alkyl of hydrogen, alkyl, thiazolinyl, aryl, aralkyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted or the alkyl of cycloalkenyl group replacement;

R

17Be hydrogen or alkyl, or R

16And R

17Form heterocycle with the nitrogen-atoms that they connected;

Y is OR

18Or NR

19R

20

R

18Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

19Be hydrogen or alkyl;

R

20Be the alkyl of hydrogen, alkyl, thiazolinyl, aryl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces, or R

19And R

20Form heterocycle with the nitrogen-atoms that they connected;

R

21Be hydrogen or alkyl;

With n be 0 to 4;

B. the incremental agent of at least a crystallization;

C. based on composition total weight, be lower than the solubilizing surfactant of about 1 weight %;

D. based on composition total weight, be lower than the nonaqueous solvents of about 10 weight %; With

E. based on composition total weight, be lower than the cyclodextrin of about 500 weight %;

Wherein, to patient's administration the time, described composition has the dissolution rate and the bioavilability of the improvement that is used for oral or parenterai administration.

In another embodiment, the present invention relates to comprise the injectable dosage formulations of above-mentioned composition.

In another embodiment, the present invention relates to cartridge bag, it comprises:

A. the container that comprises injectable dosage formulations; With

B. be used to prepare the specification of Injectable solution.

In another embodiment, the present invention relates to prevent or treat the method for side effect relevant among the patient with opioid, it step that comprises is:

To the above-mentioned composition of the described patient's effective dosage that needs is arranged.

This method can be used for prevention and treatment intestinal obstruction, scratches where it itches, constipation, the retention of urine, courage spasm, opium bowel dysfunction, angina, n or V or its combination, particularly postoperative ileus, postpartum intestinal obstruction, opium bowel dysfunction, postoperative nausea or postoperative vomiting or its combination.

In other embodiments, the present invention relates to prevent or treat the method for the pain among the patient, it step that comprises is:

To the above-mentioned composition of the described patient's effective dosage that needs is arranged.

In preferred embodiments, composition comprises at least a opioid in addition.

Can make these and other aspect of the present invention become apparent by following detailed description.

Detailed description of the invention

As above-mentioned and to run through the disclosure employed, except as otherwise noted, it should be understood that following term has following implication.

As used in this article, " have the dissolution rate of the improvement that is used for oral or parenterai administration and the composition of bioavilability " and be meant that composition comprises at least a opioid antagonists that is suitable for oral or parenterai administration, owing to the method that forms said composition make said composition with respect to from identical active component and incremental agent preparation but the composition with different final physical character (as density) has higher levels of dissolution rate and bioavilability, preferably make not desired components as being used for prior art to improve the solubilizing surfactant of active component solvability, nonaqueous solvents, cyclodextrin etc. minimize or remove.

As used in this article, " parenterai administration " is meant drug administration outside intestines, and do not pass through digestive tract.The main path that the mammal main body is carried out parenterai administration is in intravenous, the muscle, in subcutaneous, the intracutaneous, intraocular, synovial membrane, in intracardiac, the backbone, in the joint, in the sheath, intra-arterial, through epithelium (comprise in transdermal, the peritonaeum, eye with, hypogloeeis and oral administration), local (comprise eye usefulness, skin, eye, by the snuffing of insufflation go into, aerosol and rectum system) administration.Preferred parenterai administration approach is for passing through in intravenous, the muscle and the hypodermic injection administration.

As used in this article, " bioavilability " be meant medicine or other material after administration by available ratio of target tissue and degree.In situation of the present invention, bioavilability is meant that opioid antagonists is by central nervous system or the available degree of its periphery.

As used in this article, " alkyl " is meant to have about 1 hydrocarbon to optional substituted saturated straight chain, side chain or the ring-type of about 20 carbon atoms (with all combinations and the recombinant and the concrete carbon number of scope in scope), preferably is referred to herein as the alkyl that arrive about 8 carbon atoms containing of " low alkyl group " about 1." side chain " is meant wherein has low alkyl group such as methyl, ethyl or propyl group to be connected in the alkyl of linear alkyl chain.In some preferred embodiment, alkyl is C

1-C

5Alkyl promptly, has 1 branched-chain or straight-chain alkyl to about 5 carbon.In other preferred embodiment, alkyl is C

1-C

3Alkyl promptly, has 1 branched-chain or straight-chain alkyl to about 3 carbon.Exemplary alkyl comprises methyl, ethyl, n-pro-pyl, isopropyl, butyl, isobutyl group, sec-butyl, the tert-butyl group, amyl group, hexyl, heptyl, octyl group, nonyl and decyl." low alkyl group " is meant to have 1 alkyl to about 6 carbon atoms.Preferred alkyl comprises 1 low alkyl group to about 3 carbon.Alkyl includes but not limited to methyl, ethyl, n-pro-pyl, isopropyl, normal-butyl, isobutyl group, the tert-butyl group, n-pentyl, cyclopenta, isopentyl, neopentyl, n-hexyl, isohesyl, cyclohexyl, ring octyl group, adamantyl, 3-methyl amyl, 2,2-dimethylbutyl and 2, the 3-dimethylbutyl.

As used in this article, " alkylidene " is meant and has general formula-(CH

2) divalent alkyl of n-, wherein n is 1 to 10, and all combinations and the recombinant of the scope in this scope.Alkylidene can be straight chain, side chain or ring-type.Non-limitative example comprises methylene, methylene (CH

2-), ethylidene (CH

2CH

2-), propylidene ((CH

2)

3-), trimethylene, pentamethylene and hexa-methylene.May randomly insert one or more oxygen, sulphur or optional substituted nitrogen-atoms along alkylidene, wherein the substituting group of nitrogen is foregoing alkyl.Alkylidene can be chosen wantonly and be substituted.Term herein " low-grade alkylidene " is meant to have about 1 those alkylidenes to about 6 carbon atoms.Preferred alkylidene has about 1 to about 4 carbon.

As used in this article, " thiazolinyl " is meant the monovalent alkyl that comprises at least one carbon-to-carbon double bond and have 2 to about 10 (and combination and the recombinant of the scope in this scope) carbon atoms in chain.Thiazolinyl can be chosen wantonly and be substituted.In some preferred embodiment, thiazolinyl is C

2-C

10Thiazolinyl promptly, has 2 side chain or straight-chain alkenyls to about 10 carbon.In other preferred embodiment, thiazolinyl is C

2-C

6Thiazolinyl promptly, has 2 side chain or straight-chain alkenyls to about 6 carbon.In other preferred embodiment, thiazolinyl is C

3-C

10Thiazolinyl promptly, has 3 side chain or straight-chain alkenyls to about 10 carbon.In other preferred embodiment, thiazolinyl is C

2-C

5Thiazolinyl promptly, has 2 side chain or straight-chain alkenyls to about 5 carbon.Exemplary thiazolinyl comprises for example vinyl, acrylic, cyclobutenyl, pentenyl, hexenyl, heptenyl, octenyl, nonene base and decene base.

As used in this article, " aryl " is meant to have about 5 to about 50 carbon atoms optional substituted monocycle of (with all combinations and the recombinant and the concrete carbon number of scope in scope), two rings, three rings or the fragrant loop systems of other many cyclophanes, preferably contains about 6 aryl that arrive about 10 carbon atoms.Non-limitative example comprises for example phenyl, naphthyl, anthryl and phenanthryl.

As used in this article, " aralkyl " is meant and has aryl substituent and have about 6 to about 50 carbon atoms alkyl of (with all combinations and the recombinant and the concrete carbon number of scope in scope), preferably contain about 6 aralkyl to about 10 carbon atoms.Aralkyl can randomly be substituted in aryl or moieties.Non-limitative example comprises for example phenyl methyl (benzyl), benzhydryl, trityl, phenylethyl, diphenyl-ethyl and 3-(4-aminomethyl phenyl) propyl group.

As used in this article, " heteroaryl " is meant and comprises that at least one and preferred 1 optional substituted monocycle, two rings, three that arrive the annular atoms of about 4 sulphur, oxygen or nitrogen heteroatoms encircle or the aromatic rings system of other many rings.Heteroaryl can have for example about 3 to about 50 carbon atoms (and all combinations and recombinant and the concrete carbon number of the scope in this scope), preferably contains about 4 heteroaryls to about 10 carbon.The non-limitative example of heteroaryl comprises for example pyrrole radicals, furyl, pyridine radicals, 1,2,4-thiadiazolyl group, pyrimidine radicals, thienyl, isothiazolyl, imidazole radicals, tetrazole radical, pyrazinyl, pyrimidine radicals, quinolyl, isoquinolyl, thienyl, benzothienyl, isobenzofuran-base, pyrazolyl, indyl, purine radicals, carbazyl, benzimidazolyl He isoxazolyl.

As used in this article, " cycloalkyl " is meant to have about 3 optional substituted, the alkyl that have one or more rings in its structure to about 20 carbon atoms (with all combinations and the recombinant and the concrete carbon number of scope in scope), preferably contain about 3 to about 10 carbon atoms, more preferably contain about 3 to about 8 carbon atoms, more preferably contain about 3 to about 6 carbon atoms.Multiring structure can be bridged ring or condensed ring structure.Cycloalkyl can be randomly by for example alkyl (preferred C

1-C

3Alkyl), alkoxyl (preferred C

1-C

3Alkoxyl) or halo replace.Non-limitative example comprises for example cyclopropyl, cyclobutyl, cyclopenta, cyclohexyl, suberyl, ring octyl group and adamantyl.

As used in this article, " alkyl of cycloalkyl substituted " is meant that carbon is by cycloalkyl (preferred C endways

3-C

8Cycloalkyl) straight chained alkyl of Qu Daiing (preferred low alkyl group).Non-limitative example comprises for example cyclohexyl methyl, cyclohexyl ethyl, cyclopenta ethyl, cyclopenta propyl group, cyclopropyl methyl or the like.

As used in this article, " cycloalkenyl group " is meant and has the about 4 undersaturated cycloalkyl of olefinic to about 10 carbon (and all combinations and the recombinant of the scope in this scope).In preferred embodiments, cycloalkenyl group is C

5-C

8Cycloalkenyl group promptly, has 5 cycloalkenyl groups to about 8 carbon.

As used in this article, " alkyl-cycloalkyl " is meant the optional substituted loop systems that comprises the cycloalkyl with one or more alkyl substituents.Non-limitative example comprises for example alkyl-cycloalkyl, comprises 2-methylcyclohexyl, 3,3-dimethylcyclopentyl, trans-2,3-diformazan basic ring octyl group and 4-methyl decahydronaphthalenes base.

As used in this article, " heteroarylalkyl " is meant to have the about 2 optional substituted alkyl that replaced by heteroaryl to about 50 carbon atoms (and all combinations and recombinant and the concrete carbon number of the scope in this scope), preferably contains about 6 to about 25 carbon atoms.Non-limitative example comprises 2-(1H-pyrroles-3-yl) ethyl, 3-pyridylmethyl, 5-(2H-tetrazole radical) methyl and 3-(pyrimidine-2-base)-2-methyl cyclopentane base.

As used in this article, " Heterocyclylalkyl " is meant and comprises that at least one and preferred 1 optional substituted monocycle, two rings, three that arrive the annular atoms of about 4 sulphur, oxygen or nitrogen heteroatoms encircle or the aliphatic loop systems of other many rings.Cycloalkyl can have for example about 3 to about 20 carbon atoms (and all combinations and recombinant and the concrete carbon number of the scope in this scope), and preferred about 4 to about 10 carbon.Heterocyclylalkyl can be undersaturated, and also can condense in aromatic rings.Non-limitative example for example comprises also [c] pyranose, 1 of tetrahydrofuran base, tetrahydro-thienyl, piperidyl, pyrrolidinyl, isoxazole alkyl, isothiazole alkyl, pyrazolidinyl, oxazole alkyl, thiazolidinyl, piperazinyl, morpholinyl, piperidyl, decahydroquinolyl, octahydro benzopyranyl, octahydro pentamethylene, 2,3,4-tetrahydric quinoline group, octahydro [2] pyridine radicals, octahydro cyclooctane be [c] furyl and imidazolidinyl also.

As used in this article, term " spirane base " is meant optional substituted alkylidene double-basis, and its two ends are incorporated into the same carbon atom of female group to form the volution group.As defined herein, spirane base group female with it has 3 to 20 annular atomses.Preferably, it has 3 to 10 annular atomses.The non-limitative example of group female with it spirane base together comprises 1-(1-methyl-cyclopropyl)-propane-2-ketone, 2-(1-phenoxy group-cyclopropyl)-ethamine and 1-methyl-spiral shell [4.7] dodecane.

As used in this article, term " alkoxyl " is meant optional substituted alkyl-O-group, and wherein alkyl defines as described above.Non-limitative example for example comprise methoxyl group, ethyoxyl, positive propoxy, isopropoxy, n-butoxy and heptan the oxygen base.

As used in this article, term " aryloxy group " is meant optional substituted aryl-O-group, and wherein aryl defines as described above.Non-limitative example comprises for example phenoxy group and naphthoxy.

As used in this article, term " aralkoxy " is meant optional substituted aralkyl-O-group, and wherein aralkyl defines as described above.Non-limitative example comprises for example benzyloxy, 1-phenyl ethoxy, 2-phenyl ethoxy and 3-naphthyl oxygen in heptan base.

As used in this article, term " aryloxy group aryl " is meant to have the substituent aryl of aryloxy group, and wherein aryloxy group and aryl define as described above.The aryloxy group aryl can be chosen wantonly and be substituted.Non-limitative example comprises for example Phenoxyphenyl and naphthoxy phenyl.

As used in this article, term " heteroaryl aryl " is meant to have the substituent aryl of heteroaryl, and wherein heteroaryl and aryl define as described above.The heteroaryl aryl can be chosen wantonly and be substituted.Non-limitative example comprises for example 3-pyridine radicals phenyl, 2-quinolyl naphthyl and 2-pyrrole radicals phenyl.

As used in this article, term " alkoxy aryl " is meant the aryl that has alkoxy substituent, and wherein alkoxyl and aryl define as described above.Alkoxy aryl can be chosen wantonly and be substituted.Non-limitative example comprises for example p-methoxyphenyl, tert-butoxy phenyl and methylenedioxyphenyl.

As used in this article, " carboxyl " is meant-C (=O) OH group.

As used in this article, " alkanoyl " be meant-C (=O)-and alkyl group, wherein alkyl defines as described above.Exemplary alkanoyl comprises acetyl group, positive propiono, positive bytyry, 2-methylpropionyl, positive valeryl, 2-methylbutyryl base, 3-methylbutyryl base, 2,2-dimethyl propylene acyl group, heptanoyl group, capryl and palmityl.

As used in this article, " heterocycle " is meant the carboatomic ring atom group of monocycle or multi-loop system, it comprises about 4 all combinations and recombinants to about 10 atoms and the scope in scope, and wherein one or more atoms are the atom that is different from carbon, as nitrogen, oxygen or sulphur.Heterocyclic group can be aromatic or non-aromatic.Non-limitative example comprises for example pyrroles and piperidines group.

As used in this article, " halo " is meant fluoro, chloro or bromo.

Typically, substituted chemical part comprises the substituting group of one or more replacement hydrogen.Exemplary substituting group for example comprise halo (as, F, Cl, Br, I), alkyl, cycloalkyl, alkyl-cycloalkyl, thiazolinyl, alkynyl, aralkyl, aryl, heteroaryl, heteroarylalkyl, spirane base, Heterocyclylalkyl, hydroxyl (OH), nitro (NO

2), cyano group (CN), amino (NH

2) ,-amino that N-replaces (NHR ") ,-N, the dibasic amino of N-(N (R ") R "), carboxyl (COOH) ,-C (=O) R " ,-OR " ,-C (=O) OR " ,-NHC (=O) R ", amino carbonyl (C (=O) NH

2) ,-amino carbonyl that N-replaces (C (=O) NHR ") ,-N, the dibasic amino carbonyl of N-(C (=O) N (R ") R "), mercaptan, sulfenyl (SR "), sulfonic acid (SO

3H), phosphonic acids (PO

3H), S (=O)

2R ", S (=O)

2NH

2, S (=O)

2NHR ", S (=O)

2NR " R ", NHS (=O)

2R ", NR " S (=O)

2R ", CF

3, CF

2CF

3, NHC (=O) NHR ", NHC (=O) NR " R ", NR " C (=O) NHR ", NR " C (=O) NR " R ", NR " C (=O) R " etc.For above-mentioned substituting group, each part R " can be any in H, alkyl, cycloalkyl, thiazolinyl, aryl, aralkyl, heteroaryl or the Heterocyclylalkyl for example independently.

As used in this article, " side effect " is meant the result that the result is used in described medicine or measure that is different from as the side effect that is produced by medicine, particularly to not being the tissue pursued of administration or the harmful effect of tract.In the situation of for example opioid, term " side effect " can be meant such as intestinal obstruction for example, scratches where it itches, the situation of constipation, the retention of urine, courage spasm, opium bowel dysfunction, angina, n or V or its combination.

As used in this article, " intestinal obstruction " is duodenum 12 or the pylorus obstruction to the intestines between rectum, particularly colon.Referring to for example, Dorland ' s Illustrated Medical Dictionary, p.816,27th ed. (W.B.Saunders Company, Philadelphia 1988).Intestinal obstruction should be different from constipation, and constipation is meant seldom or very difficult defecation.Referring to for example, Dorland ' s IllustratedMedical Dictionary, p.375,27th ed. (W.B.Saunders Company, Philadelphia 1988).Intestinal obstruction can cause intestinal contents to advance diagnosing malfunction by the destruction of the normal coordinated movement of various economic factors of digestive tract.Referring to for example, Resnick, J.Am.J.ofGastroenterology, 1992,751 and Resnick, J.Am.J.of Gastroenterology, 1997,92,934.In some cases, particularly to perform the operation after (comprising abdominal operation), bowel dysfunction may be quite serious, continues to surpass a week and influences GI more than a part.This situation often is called postoperative ileus, and the most continually (referring to Livingston, E.H.and Passaro, E.D.Jr., Digestive Diseases and Sciences, 1990,35,121) takes place after laparotomy.Similarly, postpartum, the intestinal obstruction common problem that is the women after childbirth in a period of time and thought that the similar fluctuation of the natural opioid level that stress be caused by childbirth causes.

As used in this article, " effective dose " is meant the amount of the described compound herein of the symptom that can suppress, prevent or treat specified disease, illness or side effect on acology effectively.Described disease, illness and side effect (for example include but not limited to those pathological conditions relevant with the administration opioid, with treatment of pain and/or prevent relevant), wherein the treatment or the prevention comprise for example by making compound exposing cell of the present invention, tissue or acceptor suppress its activity.Therefore, for example, term " effective dose " is being used for being meant when relevant with the opioid of for example treating pain treating and/or preventing the situation of pain.Term " effective dose " treats and/or prevents typically the side effect relevant with opioid being used for being meant when relevant with the peripheral mu opioid antagonists, comprises such as intestinal obstruction for example, scratches where it itches, the side effect of constipation, the retention of urine, courage spasm, opium bowel dysfunction, angina, n or V or its combination.

As used in this article, " with ... combination ", " therapeutic alliance " and " combination product " are meant simultaneously administration antiemetic and peripheral mu opioid antagonists (comprising for example compound of formula I) to the patient in certain embodiments, or to patient's while administration antiemetic, peripheral mu opioid antagonists and opioid.When combination medicine-feeding, the administration simultaneously of each component or at different time points with random order administration continuously.Therefore, each component discriminably but the time on fully closely administration, so that required curative effect to be provided.

As used in this article, " dosage unit " is meant the discrete unit of physics that is suitable as the unit dose that is used for the particular patient of being treated.Each unit can comprise the reactive compound that being intended for use in of combining with required pharmaceutical carrier produces the scheduled volume of required curative effect.The specification of unit dosage forms of the present invention can by the specific characteristic of (a) reactive compound and the specific therapeutical that will realize and (b) the intrinsic limitation of this in the art reactive compound stipulate.

As used in this article, term " pharmaceutically useful " be meant those compounds, material, composition and/or formulation in rational medical judgment scope, be suitable for contacting human and animal's tissue and do not have too much toxicity, excitant, allergy or with rational interests/risk than the other problem complication that matches.

As used in this article, " pharmaceutically acceptable slaine " is meant the derivative of compound disclosed herein, and wherein parent compound carries out modification by being prepared into its alkali salt.The example of officinal salt includes but not limited to the alkaline residue for example inorganic acid or the organic acid salt of amine, alkali etc.Officinal salt comprises the nontoxic salts of the routine that parent compound and for example nontoxic inorganic base or organic base form.The acceptable salt of these physiology prepares by method as known in the art, for example, and by will free amine alkali dissolving in aqueous alcohol with excessive acid or with alkali metal base such as hydroxide or with in the amine and the carboxylic acid that dissociates.

Running through the compound of describing herein can alternative use or preparation.Law of isomorphism type, all chirality and racemization shape, N-oxide, hydrate and solvate have also been considered within the scope of the invention.

Some acidity of the present invention or alkali compounds can be used as amphion and exist.The form of ownership of compound comprises that free acid, free alkali and amphion all are considered within the scope of the invention.As known in the art is that the compound that comprises amino and carboxyl simultaneously often exists with its zwitterionic form.Therefore, any compound described herein that runs through that for example comprises amino and carboxyl simultaneously also comprises their corresponding amphions.

As used in this article, " patient " is meant and comprises mammal by animal, and be preferred human.

As used in this article, " prodrug " is meant the maximized compound of amount of the active substance that is designed to reach required response location especially, itself for required activity normally non-activity or have lowest activity, but become the metabolite of biologic activity by biological transformation.

As used in this article, " stereoisomer " be meant have identical chemical composition but on the spatial arrangements of atom or group different compound.

As used in this article, " N-oxide " is meant that the oxidized formation of basic nitrogen atom of heteroaryl ring wherein or tertiary amine has the quaternary nitrogen of a form positive charge and the oxygen atom that has the form negative electrical charge that is connected.

When any variable occurs surpassing one time in any composition or in any formula, have nothing to do in its definition in each situation and other situation.The combination of substituting group and/or variable only is only permission when this combination results stable compound.

Formula I explanation can be used for 3-that the piperidine derivative in method of the present invention, composition and the cartridge bag can be used as at piperidine ring and the trans and cis three-dimensional chemical isomer of 4-position exists.In the compound of most preferred formula I, R

2Substituting group and R

4Substituting group is " trans " orientation on piperidines.

R except formula I

2Substituting group and R

4Outside substituent " cis " and " trans " orientation, have R among the formula I

2Substituting group and R

4The absolute stereo chemistry of substituent carbon atom also uses " R " of common employing and " S " to define (people such as Orchin, The Vocabulary of OrganicChemistry, John Wiley and Sons, Inc., page 126, and it is merged in this paper as a reference).R on the piperidine ring that preferred compound of the present invention is its Chinese style I

2Substituting group and R

4Substituent configuration all is those of " R ".

In addition, depend on R

4Structure, can in molecule, introduce asymmetric carbon atom.Therefore, these compounds categories can be used as at independent " R " or " S " of these chiral centres stereoisomer and exist, or exist as the racemic mixture of isomer, and it is considered within the scope of the invention all.Preferably, use the pure basically stereoisomer of compound of the present invention, that is, the isomer that is configured as " R " or " S " of chiral centre wherein, that is, wherein the configuration at three chiral centre I is preferably 3R, 4R, S or 3R, 4R, those compounds of R.

As used in this article, " periphery " or " periphery works " is meant that medicine works outside central nervous system.

As used in this article, " maincenter works " is meant that medicine works in central nervous system.

Method of the present invention, composition and cartridge bag relate to periphery opioid antagonists compound.Term " periphery " is meant that this compound mainly acts on department of physiology beyond the central nervous system key element of unifying.In a preferred form, the periphery opioid antagonists compound that is used for the inventive method shows the high level activity with respect to peripheral tissues such as stomach intestinal tissue, and shows the CNS activity of reduction and preferably do not have the CNS activity basically.As used in this article, phrase " does not have the CNS activity " and is meant to show about 20% of the pharmacological activity that is lower than the inventive method compound used therefor basically in CNS, preferably be lower than about 15%, more preferably less than about 10%, more preferably less than about 5%, most preferably in CNS, show about 1% of the pharmacological activity that is lower than the inventive method compound used therefor.

In addition, give therein in drug compound certain embodiments of the present invention with the periphery side effect of antagonism opioid, preferably this compound is gone up substantially not by blood-brain barrier, thereby does not reduce the favorable activity of opioid.As used in this article, phrase " basically not by " is meant that the about 20 weight % of being lower than of the inventive method compound used therefor pass through blood-brain barrier, preferably be lower than about 15 weight %, more preferably less than about 10 weight %, more preferably less than about 5 weight %, and most preferably the compound of 0 weight % passes through blood-brain barrier.By measuring the CNS permeability of the intravenous administration evaluation of the level in blood plasma and brain afterwards selected compounds.

US-B-6,451,806 and US-B-6,469,030 disclose such method and composition, and it comprises opioid and opioid antagonists, comprises the peripheral mu opioid antagonists, and it is open is incorporated into this paper as a reference in full.This method and composition especially can be used for preventing and treats pain and the side effect that is used for the treatment of and/or prevention is relevant with opioid, comprise intestinal obstruction, scratch where it itches, constipation, the retention of urine, courage spasm, opium bowel dysfunction, angina, feel sick or its combination, particularly postoperative ileus, postpartum intestinal obstruction, opium bowel dysfunction, postoperative nausea or postoperative vomiting.Method of the present invention, composition and cartridge bag relate to the peripheral mu opioid antagonists, and relate to the antiemetic that antiemetic that peripheral mu opioid antagonists and maincenter work and maincenter work and the combination of opioid, be used for the treatment of and prevent for example pain and/or the side effect relevant with opioid, comprise intestinal obstruction, scratch where it itches, constipation, the retention of urine, courage spasm, opium bowel dysfunction, angina, vomiting or feel sick its combination, particularly postoperative or postpartum intestinal obstruction, opium bowel dysfunction, postoperative nausea or postoperative vomiting.

Therefore, in one embodiment, the invention provides the method that may further comprise the steps:

A., composition is provided, and it comprises:

(i) the pharmaceutically acceptable slaine of at least a formula I compound:

Wherein:

R

1Be hydrogen or alkyl;

R

2Be hydrogen, alkyl or alkenyl;

R

3Be the alkyl of hydrogen, alkyl, thiazolinyl, aryl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

4Be hydrogen, alkyl or alkenyl;

A is OR

5Or NR

6R

7

R

5Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

6Be hydrogen or alkyl;

R

7The B that alkyl, aralkyl, aralkyl or the alkylidene that replaces for the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, aryl, cycloalkyl substituted, cycloalkenyl group, cycloalkenyl group replaces, or R

6And R

7Form heterocycle with the nitrogen-atoms that they connected;

B is

C (=O) W or NR

8R

9

R is a hydrogen or alkyl;

R

9The alkyl, aryl or the aralkyl that replace for the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl substituted, cycloalkyl, cycloalkenyl group, cycloalkenyl group, or R

8And R

9Form heterocycle with the nitrogen-atoms that they connected;

W is OR

10, NR

11R

12Or OE;

R

10Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

11Be hydrogen or alkyl;

R

12C (=O) the Y, or R that alkyl, aralkyl or the alkylidene that replaces for the alkyl of hydrogen, alkyl, thiazolinyl, aryl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, cycloalkenyl group replaces

11And R

12Form heterocycle with the nitrogen-atoms that they connected;

E is

(C=O) D that alkylidene replaces or-R

13OC (=O) R

14

R

13Alkylidene for the alkyl replacement;

R

14Be alkyl;

D is OR

15Or NR

16R

17

R

15Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

16Be the alkyl of hydrogen, alkyl, thiazolinyl, aryl, aralkyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted or the alkyl of cycloalkenyl group replacement;

R

17Be hydrogen or alkyl, or R

16And R

17Form heterocycle with the nitrogen-atoms that they connected;

Y is OR

18Or NR

19R

20

R

18Be the alkyl of hydrogen, alkyl, thiazolinyl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces;

R

19Be hydrogen or alkyl;

R

20Be the alkyl of hydrogen, alkyl, thiazolinyl, aryl, cycloalkyl, cycloalkenyl group, cycloalkyl substituted, alkyl or the aralkyl that cycloalkenyl group replaces, or R

19Form heterocycle with 20 with the nitrogen-atoms that they were connected;

R

21Be hydrogen or alkyl;

With n be 0 to 4;

The (ii) incremental agent of at least a crystallization;

(iii) at least a weak base; With

(iv) water;

Wherein said composition has the initial pH at least about 10.5; With

B. the pH that regulates described composition arrives the final pH that arrive in about 11 scopes about 9;

Wherein, to patient's administration the time, described composition has the dissolution rate and the bioavilability of the improvement that is used for oral or parenterai administration.

Method of the present invention especially can be used for formation and has the dissolution rate of improvement and the composition of bioavilability with respect to prior art combinations (but comprising the composition that contains identical or different component be not processed into final preparation (for example pH regulator, original place form pharmaceutically acceptable slaine, freeze drying and/or the kneading (anneal) of active component) in the same way or do not have same physical properties (for example density or porosity)), particularly by injectable formulation, as at those of intravenous administration.

In the preferred embodiment of this method, when organizing structure again, solution forms in less than about five minutes under environmental condition, more preferably, under environmental condition in less than about one minute, and more preferably, under environmental condition, in less than about 30 seconds, form, preferably by simply shaking, stir or mixing and organize structure again.As used in this article, " under environmental condition " is meant under normal atmospheric pressure and about 10 ℃ of room temperatures that arrive in about 50 ℃ of scopes, and not directly heating or cooling.The formation of solution can be by for example measuring, measure by Ku Erte suspended matter determination instrument mensuration or by the light scattering instrument by the existence of visualization (the preferred use by diaphragm projects microscope light in the solution) clear solution when mixing.

In the preferred embodiment of this method, initial pH is adjusted at least about 11.Preferably, initial pH is no more than about pH 12, because high like this pH can cause the composition instability.Initial pH can regulate with any suitable pharmaceutically acceptable pH regulator agent, comprise strong or weak acid or alkali, preferred pharmaceutically useful metal carbonate, pharmaceutically useful alkali metal bicarbonate salt, pharmaceutically useful metal hydroxides or, hydrochloric acid, more preferably wherein pharmaceutically useful metal is a sodium, and more preferably sodium carbonate or sodium bicarbonate, and more preferably sodium carbonate.Preferred sodium carbonate and sodium bicarbonate are because they produce carbonic acid gas, thereby help required lower composition density.

In the preferred embodiment of this method, regulating final pH is about 9.5 to about 10.5.Final pH can be regulated with any suitable pharmaceutically acceptable pH regulator agent, comprises strong or weak acid or alkali, preferred sodium hydroxide or hydrochloric acid.

In some preferred embodiment of this method, the original place prepares the pharmaceutically acceptable slaine of at least a formula I compound.

In some preferred embodiment of this method, the pharmaceutically acceptable slaine of the compound of formula I is formed by at least a weak base, and wherein said weak base is to join in the compound of described formula I at least about equimolar amounts.Preferably, do not use big excessive weak base, because this excessive high pH (greater than about 12) that does not expect that causes, it can help the composition instability.

In some preferred embodiment of this method,, add the compound of described formula I and prepare composition to described mixture then by at first the pharmaceutically acceptable slaine of described incremental agent and described weak base being mixed in water.

In some other preferred embodiment, by side by side the pharmaceutically acceptable slaine of the compound of described formula I, described incremental agent and described weak base being mixed with composition in water basically.As mixing under the background employedly, " basically side by side " be meant each other in about five minutes, preferably in about one minute, more preferably in about 30 seconds each component is mixed.

In a preferred embodiment of the invention, pharmaceutically acceptable metal is an alkali metal, as sodium, potassium or lithium; Or alkaline earth metal, as calcium or magnesium, or its combination.Preferred sodium, calcium and magnesium.More preferably sodium.For parenterai administration, preferably avoid using potassium.

This method can comprise described composition dries with the described water of removing at least a portion in addition to form the step of partially or completely dry product.In preferred embodiments, in the drying steps process, composition is mediated.As used in this article, " kneading " is meant the process that the material heating is slowly cooled off then, comprises the heating and cooling circulation of repetition.Suitable drying means comprises freeze drying (freeze-drying), atomized drying, vacuum drying and combination thereof.Preferred drying means is freeze drying.

This method can comprise in addition by making it organize the step of structure again with the solution that forms described dry products described dry products and the merging of pharmaceutically useful solvent.

In the preferred embodiment of this method, weak base is bicarbonate or carbonate, more preferably carbonate.Preferred these weak base are because they produce carbonic acid gas, thereby help required lower composition density.

In the preferred embodiment of this method, pharmaceutically useful solvent is moisture, preferred water, isotonic sodium chlorrde solution, ringer's solution (Ringer ' s solution), dextrose solution or Lactated Ringer'S Solution (lactated Ringer ' s solution).

In preferred embodiments, the inventive method comprises in addition with the described solution of the described dry products step to patient's administration.Composition can be before art, in the surgical procedure and/or administration under the situation that is not having operation.

In preferred embodiments, composition is by drug administration by injection, particularly hypodermic injection, intramuscular injection or intravenous injection.

In composition of the present invention, can use any pharmaceutically useful incremental agent of crystallization.As used in this article, " incremental agent " is meant inert diluent or the additive that plays as the carrier function of medicine (being the compound of formula I in situation of the present invention).Suitable incremental agent can be at Handbook of Pharmaceutical Excipients, 3rd Ed.Washington, and D.C:American Pharmaceutical Association finds in 1998, and it openly is merged in this paper as a reference.In some other preferred embodiment, incremental agent is a polyalcohol, as carbohydrate or sugar alcohol.Suitable carbohydrate comprises sucrose, trehalose, lactose, maltose and composition thereof.Suitable sugar alcohol comprises mannitol, xylitol, erythrite, lactitol, isomalt, polyalditol, maltitol and composition thereof.Preferred especially mannitol.

Though be not wishing to be bound by theory, believe that the incremental agent generation of crystallization has the required pie structure of good mechanical properties.These character are for guaranteeing that it is important organizing structure speed rapidly again.In addition, the incremental agent of crystallization in freezing dry process rapidly nucleation produce and have the more pie of high surface area, thereby produce higher diffusion flux and rate of sublimation faster.The drying of amorphous incremental agent needs high-energy and can not produce required pie structure.Because the primary crystallization size depends on nucleation rate and growth rate, the brilliant generation of the brief summary that forms in comprising the system of amorphous solid has the more hole of low surface area of every volume.This lower surface area produces lower diffusion flux and lower rate of sublimation.

In certain embodiments, the present invention relates to composition, it comprises:

The pharmaceutically acceptable slaine of a. at least a formula I compound;

B. the incremental agent of at least a crystallization;

Wherein said composition has and is lower than about 1.0g/cm

3Density;

Wherein, to patient's administration the time, described composition has the dissolution rate and the bioavilability of the improvement that is used for oral or parenterai administration.

Preferably, composition has the 0.5g/cm of being lower than

3Density, more preferably be lower than about 0.2g/cm

3, more preferably be lower than about 0.15g/cm

3, more preferably about 0.05g/cm

3To about 0.12g/cm

3Density in the scope, more preferably from about 0.06g/cm

3To about 0.08g/cm

3Density in the scope.

In certain embodiments, the present invention relates to composition, it comprises:

The pharmaceutically acceptable slaine of a. at least a formula I compound;

B. the incremental agent of at least a crystallization;

C. based on composition total weight, be lower than the solubilizing surfactant of about 1 weight %;

D. based on composition total weight, be lower than the nonaqueous solvents of about 10 weight %; With

E. based on composition total weight, be lower than the cyclodextrin of about 0.5 weight %;

Wherein, to patient's administration the time, described composition has the dissolution rate and the bioavilability of the improvement that is used for oral or parenterai administration.

These compositions provide for oral or dissolution rate and the bioavilability of parenterai administration for improving, because they allow the compound of formula I more easily to dissolve in other situation that is compared to the compound of formula I when dry products is organized structure again (it is low-down water-soluble owing to zwitterionic character has).

Preferably, the pharmaceutically acceptable slaine of the compound of formula I exists with the level at least about 0.1mg/mL, more preferably exists with the level at least about 1mg/mL, more preferably exists with the level at least about 2mg/mL.

Preferably, composition of the present invention comprises at least a pharmaceutically useful solvent in addition.In the preferred embodiment of said composition, pharmaceutically useful solvent is moisture, preferred water, isotonic sodium chlorrde solution, ringer's solution, glucose solution or Lactated Ringer'S Solution.

Preferably, composition has the pot-life at least about 18 months.As used in this article, " pot-life " be meant after the production of preparation and packing up to its chemistry or biologic activity and be no less than the time that predeterminated level (common about 90%) that mark renders a service and its physical property do not have appreciable or harmful variation.

In some preferred embodiment, composition of the present invention can comprise the prodrug and/or the pharmacological activity metabolite of opioid, opioid, and condition is dissolution rate or the bioavilability that its inclusion does not hinder formula I compound.Suitable opioid comprises alfentanil, buprenorphine, butorphanol, codeine, dezocine, Dihydrocodeine, fentanyl, hydrocodone, Hydromorphone, levorphanol, meperidine(pethidine), methadone, morphine, Nalbuphine, Oxycodone, Oxymorphone, pentazocine, propiram, dextropropoxyphene, sufentanil, tramadol and composition thereof.Preferred opioid comprises morphine, codeine, Oxycodone, hydrocodone, Dihydrocodeine, dextropropoxyphene, fentanyl and tramadol.

Composition of the present invention can comprise in addition that one or more are generally used for other active component of pain relieving and/or cough-flu-pectoral combination product, and condition is dissolution rate or the bioavilability that its inclusion does not hinder formula I compound.The component of this routine comprises for example aspirin, cox 2 inhibitor, paracetamol, phenylpropanolamine, neo-synephrine, chlorphenamine, caffeine and/or gualfenesin.Typical or the conventional composition that can comprise is at for example Physicians ' Desk Reference, describes in 2004, and it is open is incorporated into this paper as a reference in full.

In addition, composition of the present invention can comprise in addition that one or more are designed to can strengthen the pain relieving effectiveness of opioid and/or be designed to reduce the compound that forms the anodyne tolerance, and condition is dissolution rate or the bioavilability that its inclusion does not hinder formula I compound.This compound for example comprises dextromethorphan or other nmda antagonist, and (Pain 1996 for Mao, people such as M.J., 67,361), L-364,718 and other CCK antagonist (Dourish, CT. wait people, Eur.J.Pharmacol., 1988,147,469), no inhibitor (Bhargava, people such as H.N., Neuropeptides, 1996,30,219), pkc inhibitor (Bilsky, EJ. wait people, J.Pharmacol.Exp.Ther.1996,277,484) and dynorphin antagonist or antiserum (Nichols, M.L. wait people, Pain, 1997,69,317).The open quilt of aforementioned each document is incorporated this paper into as a reference in full.

Except that above-mentioned illustrational those, the pain relieving that can be used for being used in the method and composition of the present invention and increase opioid is renderd a service and/or the opioid component and the optional compound that are used to reduce other opioid of forming the anodyne tolerance, optional routine is conspicuous for the those skilled in the art that grasped instruction disclosed by the invention.

Preferred 4-aryl-piperidine derivative for example comprises at US-A-5,250,542, US-A-5,159,081, US-A-5,270,328 and US-A-5,434,171, US-B-6,451, disclosed compound in 806 and US-B-6,469,030, it is open is incorporated into this paper as a reference in full.

In preferred embodiments, the compound of formula I is trans 3, the 4-isomer.

In some embodiment of the compound that adopts formula I, preferred

R

1Be hydrogen;

R

2Be alkyl;

N is 1 or 2;

R

3Be benzyl, phenyl, cyclohexyl or cyclohexyl methyl; With

R

4Be alkyl.

In some embodiment of the compound that adopts formula I, preferred

A is OR

5With

R

5Be hydrogen or alkyl.

In some embodiment of the compound that adopts formula I, preferred

A is NR

6R

7

R

6Be hydrogen;

R

7B for the alkylidene replacement; With

B is C (O) W.

In some embodiment of the compound that adopts formula I, preferred

R

7Be (CH

2) q-B;

Q is about 1 to about 3;

W is OR

10With

R

10The alkyl of alkyl, cycloalkyl or the cycloalkyl substituted that replaces for hydrogen, alkyl, phenyl.

In some embodiment of the compound that comprises formula I, preferred

W is NR

11R

12

R

11Be hydrogen or alkyl; With

R

12The C that replaces for hydrogen, alkyl or alkylidene (=O) Y.

In some embodiment of the compound that adopts formula I, preferred

R

12Be (CH

2) mC (O) Y;

M is 1 to 3;

Y is OR

18Or NR

19R

20With

R

18, R

19And R

20Be hydrogen or alkyl independently.

In some embodiment of the compound that adopts formula I, preferred

W is OE;

E is CH

2C (=O) D;

D is OR

15Or NR

16R

17

R

15Be hydrogen or alkyl;

R

16Be methyl or benzyl; With

R

17Be hydrogen.

In some embodiment of the compound that adopts formula I, preferred

W is OE;

E is R

13OC (=O) R

14

R

13For-CH (CH

3)-or-CH (CH

2CH

3)-; With

R

14Be alkyl.

In some embodiment of the compound that adopts formula I, preferred

A is OR

5With

R

5Be hydrogen.

In some embodiment of the compound that adopts formula I, 3 of preferred piperidine ring and 4 s' the configuration R type of respectively doing for oneself.

The compound of preferred formula I comprises:

Q-CH

2CH(CH

2(C

6H

5))C(O)OH、

Q-CH

2CH

2CH(C

6H

5)C(O)NHCH

2C(O)OCH

2CH

3、

Q-CH

2CH

2CH(C

6H

5)C(O)NHCH

2C(O)OH、

Q-CH

2CH

2CH(C

6H

5)C(O)NHCH

2C(O)NHCH

3、

Q-CH

2CH

2CH(C

6H

5)C(O)NHCH

2C(O)NHCH

2CH

3、

G-NH(CH

2)

2C(O)NH

2、

G-NH(CH

2)

2C(O)NHCH

3、

G-NHCH

2C(O)NH

2、

G-NHCH

2C(O)NHCH

3、

G-NHCH

2C(O)NHCH

2CH

3、

G-NH(CH

2)

3C(O)OCH

2CH

3、

G-NH(CH

2)

3C(O)NHCH

3、

G-NH(CH

2)

2C(O)OH、

G-NH(CH

2)

3C(O)OH、

Q-CH

2CH(CH

2(C

6H

11))C(O)NHCH

2C(O)OH、

Q-CH

2CH(CH

2(C

6H

11))C(O)NH(CH

2)

2C(O)OH、

Q-CH

2CH(CH

2(C

6H

11))C(O)NH(CH

2)

2C(O)NH

2、

Z-NHCH

2C(O)OCH

2CH

3、

Z-NHCH

2C(O)OH、

Z-NHCH

2C(O)NH

2、

Z-NHCH

2C(O)N(CH

3)

2、

Z-NHCH

2C(O)NHCH(CH

3)

2、

Z-NHCH

2C(O)OCH

2CH(CH

3)

2、

Z-NH(CH

2)

2C(O)OCH

2(C

6H

5)、

Z-NH(CH

2)

2C(O)OH、

Z-NH(CH

2)

2C(O)NHCH

2CH

3、

Z-NH(CH

2)

3C(O)NHCH

3、

Z-NHCH

2C(O)NHCH

2C(O)OH、

Z-NHCH

2C(O)OCH

2C(O)OCH

3、

Z-NHCH

2C(O)O(CH

2)

4CH

3、

Z-NHCH

2C(O)OCH

2C(O)NHCH

3、

Z-NHCH

2C (O) O-(4-methoxyl group cyclohexyl),

Z-NHCH

2C (O) OCH

2C (O) NHCH

2(C

6H

5) and

Z-NHCH

2C(O)OCH(CH

3)OC(O)CH

3;

Wherein: Q represents

G represents

Z represents

The compound of preferred formula I comprises:

(3R,4R,S)-Z-NHCH

2C(O)OCH

2CH(CH

3)

2、

(+)-Z-NHCH

2C(O)OH、

(-)-Z-NHCH

2C(O)OH、

(3R,4R,R)-Z-NHCH

2C(O)-OCH

2CH(CH

3)

2、

(3S,4S,S)-Z-NHCH

2C(O)OCH

2CH(CH

3)

2、

(3S,4S,R)-Z-NHCH

2C(O)OCH

2CH(CH

3)

2、

(3R, 4R)-Z-NHCH

2C (O) NHCH

2(C

6H

5) and

(3R,4R)-G-NH(CH

2)

3C(O)OH。

Wherein Q, Z and G define as described above.

The compound of preferred formula I comprises (+)-Z-NHCH

2C (O) OH and (-)-Z-NHCH

2C (O) OH, wherein Z defines as described above.At described compound is (+)-Z-NHCH

2Preferred especially during C (O) OH.Particularly preferred compound is [[2 (S)-[[4 (R)-(3-hydroxy phenyl)-3 (R), 4-dimethyl-piperidyl] methyl]-1-oxo-3-phenyl propyl] amino] acetate dihydrate (USAN title, Aiweimopan).

The compound of preferred formula I comprises Q-CH

2CH (CH

2(C

6H

5)) C (O) OH, wherein Q defines as described above.At described compound be (3R, 4R, S)-Q-CH

2CH (CH

2(C

6H

5)) preferred especially during C (O) OH.This compound is the active metabolite of Aiweimopan, but when oral administration, it has the tendency of the reverse analgesia do not expected more much bigger than Aiweimopan.When parenterai administration, particularly during intravenous administration, but the much lower dosage of administration is to reduce this tendency.

Work, have efficient and have the compound of the formula I of Orally active particularly preferably in the enteron aisle part.Particularly preferred embodiment of the present invention is (+)-Z-NHCH

2C (O) OH, that is, and with the compound of following formula (II):

The compound of formula (II) has low aqueous solubility, unless under low or high pH condition.Zwitterionic character may be that this compound is intrinsic, and the system that can produce the difference of desirable character after for example oral absorbs and in gastral lasting local action.

In particularly preferred embodiments, the compound of formula I is pure basically stereoisomer.

In another embodiment, the present invention relates to comprise the injectable dosage formulations of above-mentioned composition.In preferred embodiments, with respect to the pain that is caused by venipuncture, injectable dosage formulations helps to have minimum pain or does not have other pain, prepares under the pH higher than physiology pH although comprise composition of active components.

In another embodiment, the present invention relates to prevent or treat the method for side effect relevant among the patient with opioid, it step that comprises is:

To the above-mentioned composition of the described patient's effective dosage that needs is arranged.

This method can be used for prevention and treatment intestinal obstruction, scratches where it itches, constipation, the retention of urine, courage spasm, opium bowel dysfunction, angina, n or V or its combination, particularly postoperative ileus, postpartum intestinal obstruction, opium bowel dysfunction, postoperative nausea or postoperative vomiting.

In other embodiments, the present invention relates to prevent or treat the method for the pain among the patient, it step that comprises is:

To the above-mentioned composition of the described patient's effective dosage that needs is arranged.

In preferred embodiments, composition comprises at least a opioid in addition.

In another embodiment, the present invention relates to cartridge bag, it comprises:

A. the container that comprises injectable dosage formulations; With

B. be used to prepare the specification of Injectable solution.

Preferably, cartridge bag comprises syringe in addition.Preferably, injectable dosage formulations comprises at least a opioid in addition.Composition can randomly comprise conventional medicinal cartridge bag component.

The present invention relates to comprise method, composition and the cartridge bag of opioid compound.As mentioned above, this opioid compound can be used for for example treating and/or preventing pain.Yet, also as mentioned above, undesirable side effect for example comprises intestinal obstruction, scratches where it itches, constipation, the retention of urine, courage spasm, opium bowel dysfunction, angina, vomiting or feel sick or its combination, particularly postoperative and postpartum intestinal obstruction, opium bowel dysfunction, feel sick and/or vomiting and possible frequent other side effect that takes place in the patient who accepts the opioid compound.Rely on method of the present invention, composition and cartridge bag, can advantageously realize effective and desirable inhibition is carried out in undesirable side effect that may be relevant with the opioid compound.Therefore, wherein method, composition and the cartridge bag of opioid with the combination of combination of suitable peripheral mu opioid antagonists compound or co-administered can be provided than independent compound and the more favourable effectiveness of medicine.

In this respect, as mentioned above, often patient's administration opioid is used for the treatment of for example pain condition.Yet, as mentioned above, undesirable side effect such as intestinal obstruction for example, scratch where it itches, constipation, the retention of urine, courage spasm, opium bowel dysfunction, angina, n or V or its combination may cause by the administration opioid.But these undesirable side effects can be used as with to the amount relative restrictions factor of patient's administration opioid.That is to say, can the amount of the opioid of patient's administration can be restricted owing to the generation of undesirable above-mentioned side effect.The degree that can reduce pain relief again unfriendly that is restricted to the amount of the opioid of patient's administration.The method and composition of combination of the present invention can advantageously increase the amount to the opioid of patient's administration, thereby increases the degree of pain relief, thus make may be relevant with opioid undesirable side effect reduce, minimize and/or avoid.The peripheral mu opioid antagonists that is preferred for method and composition of the present invention does not have the central nervous system activity basically, and therefore, the pain relieving that does not influence opioid is as required renderd a service.

Though do not wish to be bound by any theory or theory of operation, estimate opioid side effect such as intestinal obstruction, scratch where it itches, constipation, the retention of urine, courage spasm, opium bowel dysfunction, angina, vomiting or feel sick or its combination can be caused by the interaction of not expecting of opioid and peripheral mu acceptor.The μ opioid antagonists that the method according to this invention administration is worked in periphery can be blocked the interaction of opioid compound and μ acceptor, thereby prevention and/or suppress side effect, particularly postoperative or postpartum intestinal obstruction, opium bowel dysfunction, feel sick and/or vomiting.

Except that above-mentioned illustrational those, other μ opioid antagonists compound that can be used for method and composition of the present invention is conspicuous for the those skilled in the art that learned instruction of the present invention.

The compound that is used for method of the present invention can be used as prodrug forms and exists.As used in this article, " prodrug " is intended to comprise any covalently bound carrier, and with this prodrug during to the administration of mammal main body, it discharges the active parent drug of formula I used in the inventive method for example in vivo.Because the character of many needs of known prodrug raising medicine (as, dissolution rate, bioavilability, production etc.), if expectation, the inventive method compound used therefor can be sent by prodrug forms.Therefore, the present invention has considered to send the method for prodrug.Be used for the functional group that the prodrug of compound of the present invention (suc as formula I) can exist by modified compound, make this be modified in the conventional treatment or be cracked into parent compound in vivo.

Therefore, prodrug for example comprises that wherein hydroxyl, amino or carboxyl are incorporated into the described compound of any group herein, in the described linking group cracking during to the administration of mammal main body with prodrug, forms free hydroxyl, free amino or carboxylic acid respectively.Its example includes but not limited to acetic acid esters, formic acid esters and the benzoic ether of alkohol and amine functional group; With ester alkyl, carbocyclic ring, aryl and alkylaryl, as the ester of methyl, ethyl, propyl group, isopropyl, butyl, isobutyl group, sec-butyl, the tert-butyl group, cyclopropyl, phenyl, benzyl and phenethyl, or the like.

Compound used in the inventive method can be by well known to a person skilled in the art the several different methods preparation.Compound can pass through method for example as described below or the method variant is synthetic as understood by a person skilled in the art.Estimate that all methods disclosed by the invention put into practice with any scale, comprise milligram, gram, number gram, kilogram, thousands of gram or commercial scale.

Go through as above-mentioned, the inventive method compound used therefor can comprise the carbon atom of one or more asymmetric replacements, and separable be the form of optically active or racemization.Therefore, be intended to comprise all chiralitys, diastereomer, racemization form and all geometrical isomerism forms, unless specifically show concrete spatial chemistry or isomeric form.Known in the artly how to prepare and separate this optical activity form.For example, can be by the mixture separation of standard technique with stereoisomer, described standard technique includes but not limited to the fractionation, positive of racemization form and anti-phase and chirality chromatography, preferential salt formation, recrystallization etc., or it is synthetic, or synthetic by the chirality of the careful target chiral centre of planning by the chirality that begins from active initiation material.

Can easily understand, the functional group of existence can comprise protecting group in building-up process.Protecting group is known chemical functional group itself, can be optionally removes with its affix with from degree of functionality such as hydroxyl and carboxyl.These groups are present in the compound, make that this degree of functionality is an inertia to the chemical reaction condition of compound contact.The present invention can use any in the kinds of protect base.Preferred protecting group comprises benzyloxycarbonyl and tertbutyloxycarbonyl.Can be used for other preferred protecting group of the present invention can be as Greene, T.W. and Wuts, P.G.M., Protective Groups inOrganic Synthesis 2d.Ed., Wiley ﹠amp; Sons is described in 1991.

4-aryl-piperidine derivative of formula I of the present invention can adopt at for example US-A-5, and 250,542, US-A-5,434,171, US-A-5,159,081, US-A-5,270,328, US-B-6,451,806, US-B-6,469,030 and WerneR, people's such as J.A. Journal ofOrganic Chemistry, 61, the method of instruction is synthetic among the 587-597 (1996), and its open quilt is separately incorporated this paper into as a reference in full.For example; be used as in The compounds of this invention synthetic that the 3-of initiation material replaces-4-methyl-4-(3-hydroxyl-or alkanoyl oxygen base phenyl) piperidine derivative can be by at US-A-4; 115; 400 and US-A-4; 891; the conventional method of instruction preparation in 379, its open quilt is separately incorporated this paper into as a reference in full.Be used for the synthetic initiation material (3R of described compound herein, 4R)-4-(3-hydroxy phenyl)-3, the 4-lupetidine can pass through at US-A-4,581, the method preparation of describing in 456 and US-A-5,136,040, it is openly incorporated into this paper as a reference in full, but is adjusted into preferred β-spatial chemistry as described.

The first step of this method can relate to by making the reaction of 3-alkoxyl bromobenzene and alkyl lithium reagents form 3-alkoxyl phenyl lithium reagent.This reaction can be carried out under inert conditions and in the presence of suitable non-reactive solvent such as absolute ether or preferred anhydrous tetrahydro furan.The preferred alkyl lithium reagents that is used for this method is n-BuLi, particularly s-butyl lithium.Usually, add the slight excessive alkyl lithium reagents of arriving of about equimolar amounts to reactant mixture.Reaction can be carried out under about-20 ℃ to about-100 ℃ temperature, preferably carries out under about-50 ℃ to about-55 ℃ temperature.

After forming 3-alkoxyl phenyl lithium reagent, to the 1-alkyl-4-piperidones of the about equimolar amounts of mixture adding, holding temperature is between-20 ℃ to-100 ℃ simultaneously.Reaction was typically finished after about 1 to 24 hour.At this moment, can make the reactant mixture room temperature of rising again gradually.The separation of product can be by adding saturated nacl aqueous solution with any residual lithium reagent of cancellation to reactant mixture.Separate organic layer, and if expect and can be further purified, suitable 1-alkyl-4-(3-alkoxyl phenyl) piperidines 01 derivatives obtained.

The dehydration of the 4-Phenylpiperidine alcohol of above-mentioned preparation can be finished with strong acid according to known method.Take place with different amounts though dewater, preferably dewater and carry out, particularly the p-methyl benzenesulfonic acid in toluene or benzene with phosphoric acid with any of several strong acid example hydrochloric acids, hydrobromic acid etc.This reaction typically can under refluxad be carried out, and is more typically between about 50 ℃ to 150 ℃.The product of Xing Chenging can be by with the acidic aqueous solution alkalization of the salt form of product and with suitable separating with the immiscible solvent extraction of water thus.The residue that will obtain after will evaporating as required then is further purified.

1-alkyl-4-methyl-4-(3-alkoxyl phenyl) tetrahydrochysene piperidine derivative can be by metal enamine alkylation preparation.Preferred this reaction uses the n-BuLi in oxolane (THF) to carry out under inert atmosphere such as nitrogen or argon gas.Usually, slight excessive n-BuLi is joined in the 1-alkyl-4-in THF (3-the alkoxyl phenyl)-tetrahydrochysene piperidines that is cooled to-50 ℃ to about 0 ℃ approximately (more preferably being cooled to-20 ℃ to-10 ℃ approximately) of stirring.With this mixture stir about 10 to 30 minutes, in solution, add the halide of about 1.0 to 1.5 equivalents subsequently, keep the temperature of reactant mixture to be lower than 0 ℃ simultaneously.After about 5 to 60 minutes, can add entry and collect organic facies to reactant mixture.Product is according to the standard method purifying, but preferred crude product by it distill under vacuum or with it at hexane: ethyl acetate (65: 35, v: v) with in the silica gel pulled an oar about two hours and carry out purifying.According to a kind of method in back, then can be by filtering and under reduced pressure filtrate being evaporated and separated product subsequently.