CN1129406C - Extensible absortbent articles - Google Patents

Extensible absortbent articles Download PDFInfo

- Publication number

- CN1129406C CN1129406C CN92113184A CN92113184A CN1129406C CN 1129406 C CN1129406 C CN 1129406C CN 92113184 A CN92113184 A CN 92113184A CN 92113184 A CN92113184 A CN 92113184A CN 1129406 C CN1129406 C CN 1129406C

- Authority

- CN

- China

- Prior art keywords

- sanitary towel

- absorbing articles

- equal

- fiber

- top flat

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Landscapes

- Absorbent Articles And Supports Therefor (AREA)

- Orthopedics, Nursing, And Contraception (AREA)

Abstract

The present invention relates to absorbent articles such as sanitary napkins worn by women. More particularly, the present invention relates to absorbent articles, such as thin sanitary napkins, that are extensible, especially in the longitudinal direction.

Description

Technical field

The present invention relates to the absorbent items such as mat that sanitary towel, pantiliner and incontinent person use.More particularly, the present invention relates to extensile sanitary towel, perhaps relate to particularly longitudinally extensile sanitary towel or rather.

Background technology

The absorbing articles such as mat that sanitary towel, pantiliner and incontinent person use are to be used to absorb and preserve liquid and other Excreta that human body discharges and to prevent make dirty health and medicated clothing.Sanitary towel is the class absorbing articles that the women uses, and it is positioned at the wearer usually near the position between two lower limbs of health perineal position.

In general, the disposable absorbent article of most of those types above-mentioned is made by inextensible material, that is to say not tensible under the effect of these materials (thereby making absorbing articles itself) power that produces when normally wearing.

Owing to lacking expansion service, absorbing articles brings a lot of important disadvantages for these absorbing articles.A most serious shortcoming is to feel there be not the comfortable like that of imagination when making these article of user wears.The wearer will experience to the health that makes the wearer and feel comfortably cool and can be fit to difference between extensile absorbing articles of wearer motion and the inextensible absorbing articles.Traditional sanitary towel can not move with wearer's underwear, causes sanitary towel to be offset.If sanitary towel has the stretching, extension performance, the underwear that will make sanitary towel be fit to the wearer better also can remain on the original position.

A lot of patent publications disclose the absorbing articles with extensile various parts.These achievements have been described: No. 2701567 patents of the U.S. of authorizing Smith in following patent, authorize the U.S.'s 3570493 patents of Olsson, authorize the U.S.'s 3653382 patents of people such as Easley, authorize No. 3717150 patents of the U.S. of Schwartz, authorize No. 4013816 patents of the U.S. of people such as Sabee, authorize No. 4041949 patents of the U.S. of Kozak, authorize No. 4166464 patents of the U.S. of Korpman, authorize No. 4533357 patents of the U.S. of Hall, authorize No. 4573991 patents of the U.S. of people such as Pieniak, authorize No. 4578070 patents of the U.S. of people such as Holtman, authorize No. 4596570 patents of the U.S. of people such as Jackson, authorize No. 4655760 patents of the U.S. of Morpman, authorize No. 4731066 patents of the U.S. of Korpman, authorize No. 4847134 patents of the U.S. of people such as Fahrenkrug, authorize No. 4891258 patents of the U.S. of people such as Fahrenkrug, authorize No. 4965122 patents of the U.S. of Morman, authorize No. 4992324 patents of the U.S. of Dube, authorize people's such as Gossens the U.S. 5011480 and the European patent application EP 450541A2 that submits to by people such as Morris.

Above listed publication the absorbing articles with one or more extendable members may be disclosed, and The present invention be directed to absorbing articles, sanitary towel for example, sanitary towel in certain embodiments is made of the parts that can stretch, so that adapt to wearer and wearer's underwear motion.The application also comprises a large amount of embodiment at the fit aspect that utilizes the improved properties absorbing articles that stretches.

Summary of the invention

The purpose of this invention is to provide absorbing articles, quite thin absorbent articles particularly is provided, for example is the sanitary towel that can extend or preferably can stretch.

Specific purposes of the present invention provide when wearing the absorbing articles that can longitudinally extend (preferably can stretch), so that improve comfort and fit.

According to the present invention, provide a kind of attached in the interior crotch district that is wearing, tensile absorbing articles with crotch district extension in described, described absorbing articles is sanitary towel or pantiliner, it has a longitudinal centre line,, a cross central line, an initial length, a transflective liquid side, a liquid-tight side, and absorption piece that is between described transflective liquid side and the described liquid-tight side, described absorption piece has end margin, wherein: described absorbing articles is in the masterpiece time spent that is subjected to being less than or equal to 1000 grams, can be elongated to more than or equal to 110% of its initial length along described longitudinal centre line, and the elongation of at least a portion is that at least a portion absorbing articles by the longitudinal medial of the end margin that is positioned at this absorption piece provides.

By description, can be expressly understood above-mentioned purpose of the present invention and other purpose below in conjunction with accompanying drawing.

The present invention will provide a kind of absorbing articles, for example sanitary towel.Sanitary towel of the present invention can extend.

Certain this sanitary towel can be tensile and/or broad ways (promptly laterally) along the direction of length (promptly vertical), and/or is tensile along other direction.But sanitary towel is elastic elongation preferably.

One embodiment of the present of invention sanitary towel is the top flat that is seen through liquid by a tensile energy, and a tensile absorbent cores and the tensile egative film that can not see through liquid are formed.Absorbent cores is fixed between top flat and the egative film, and top flat and egative film link together along the periphery place of sanitary towel.Sanitary towel comprises that also one is used to make sanitary towel to be attached to the fastener in crotch district in the wearer.Fastener can make the part section of sanitary towel longitudinally extend at least.

The various dissimilar structure of some parts that are suitable for above-mentioned sanitary towel will be described below, also will describe above-mentioned this sanitary towel integrally-built alternative embodiment.

Sanitary towel in several alternative embodiment is made of some tensile parts and some not extending parts.For example the top flat of sanitary towel and egative film are extensile, and the absorbent cores that is clipped between tensile top flat and the tensile egative film then is not extending.As the remodeling of this embodiment, the top flat of sanitary towel can be not extensible equally.

Outside description, specialize and limit claimed scope, be considered to constitute subject content of the present invention, will help to understand better the present invention below in conjunction with the description of accompanying drawing (ratio of these accompanying drawings is inaccurate) with claims.Same label is used for representing substantially the same parts in these figure.

Description of drawings

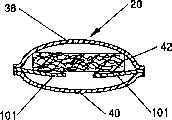

The top view that Fig. 1 is an extensile sanitary towel of the present invention under extended configuration not.

Fig. 2 is the generalized section of the sanitary towel shown in Fig. 1 at decomposing state lower edge Z-Z line.

Fig. 3 is that the sanitary towel shown in Fig. 1 is not with the bottom view of optional adhesive linkage.

Fig. 4 is the top view after the sanitary towel among Fig. 1 stretches.

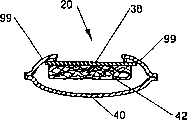

Fig. 5 is the top view that has an extensile sanitary towel of the top flat that two optional limit tongues and and egative film heat merges.

Fig. 6 be health JINYAN 6-6 line among Fig. 5 simplification transverse cross-sectional view.

Fig. 7 is a similar transverse cross-sectional view of having simplified to Fig. 6, a kind of alternative layouts of each several part in the expression sanitary towel.

Fig. 8 shows the preference relation of the size that the amplitude that is applied to the extending force in the sanitary towel and sanitary towel extend corresponding to above-mentioned power.

Fig. 8 A one is illustrated in the plane graph of elongation state of the each several part of the sanitary towel on wearer's underwear.

Fig. 9 shows and makes the sanitary towel with " power barrier " extend the curve of required power.

Figure 10 and 11 schematic side view for the structure that is used for producing the power barrier.

The alternative top layer of Figure 12 for constituting by a kind of non-woven material and a kind of perforated membrane.

Figure 13 is a rough schematic view of a kind of top sheet materials of being made of with the non-woven fibre that tangles a kind of perforated membrane.

Figure 14 is the top view that has a kind of sanitary towel of a top flat, and described top flat is by a kind of non-woven fleece sheet and roughly constituted along the fiber (part in the fiber only is shown among the figure) of horizontal orientation.

Figure 15 is the photo in a cross section of an embodiment sanitary towel of an expression, and wherein Xia Mian fibrous layer has extended and bonded on the perforated membrane.

Figure 16 is a top view that has a kind of sanitary towel of a top flat, and described top flat is made of the fiber of a kind of elastic fabric and described fabric mat that (fabric is exaggerated manyfold in the drawings, and only shows the part of fabric among the figure.)

Figure 17 illustrated and has been used for the sheet of an extensible materials being cut into a kind of common process of one, and a kind of extensible materials bar of sending into operation with the certain angle direction of (or be with machine direction " oblique line ") by cutting prepares the technology of the top flat that multi-directionally stretches.

Figure 17 A is the plane graph of a film topsheet of sanitary towel, has on the top flat a plurality ofly to make it have ductile hole.

Figure 17 B is the floor map of a kind of cross section top sheet materials of can reversibility shrinking.

The perspective view of the decomposition of situation assembles in Figure 18 has the absorbent cores of slit for expression extensile sanitary towel.

Figure 18 A is a kind of plane graph that is coated onto the preferred sticker pattern of sanitary napkin topsheet downside shown in Figure 18 of signal.

Figure 19 is positioned at the middle part rather than at the plane graph of the absorbent cores slit of end.

Figure 20 is the plane graph that has the absorbent cores in diamond hole.

Figure 21-23 is respectively one and crooked core is housed and the thick sanitary towel of a shaped profile is arranged along the top view of 22-22 line and 23-23 line, sectional view and the profilograph simplified.

Figure 23 A and 23B are respectively a kind of top view and schematic cross-section of the sanitary towel that is made up of some tensile parts and some not extending parts.

The serve as reasons schematic cross-section of the another kind of sanitary towel that some tensile parts and some not extending parts form of Figure 23 C.

The specific embodiment,

1. the overall characteristic of absorbent.

The overall characteristic of absorber of the present invention at first is discussed.

Fig. 1-3 shows a preferred embodiment of disposable adsorption object of the present invention.The present invention relates to absorbing articles, such as sanitary towel.More particularly, the present invention relates to extensile (particularly longitudinally) thin sanitary towel.

" absorbing articles " speech is meant the article that can absorb and preserve the human body effluent herein.Say that more clearly this speech is meant and touch in order to absorb or maintain the various discharge liquors that human body discharges or the article of contiguous wearer's body.Summarize sanitary towel, pantiliner and incontinence pad (or be through other article of the underwear crotch region) with " assimilate " speech.

" disposable " speech refers to plan to use once promptly abandon, and preferably reclaims, becomes compost certainly or reclaim in the mode compatible with environmental conservation.That is to say, do not plan again they to be washed or preserve in addition again and reuse again.In the preferred embodiment of being given, absorbing articles is with 20 sanitary towels that represent.

" sanitary towel " speech confession under directions woman herein is through near the article of pudendum, is used to absorb and maintain the various ejections (as blood, menstruation and urine) that health is discharged.But the present invention is not limited only to the absorbing articles of particular type shown in the accompanying drawing or configuration.

There are two faces in sanitary towel 20, and promptly liquid a face (perhaps claiming " medial face " 20A) and a liquid permeable and Body contact can not be through the face 20B towards underwear.Sanitary towel 20 shown in Fig. 1 is observed from its direction towards health face 20A.Health face 20A will paste wearer's health when wearing.Sanitary towel 20 is in the back side towards underwear face 20B (as shown in Figure 2), and this face is pressed close to wearer's underwear when wearing sanitary towel 20.

There are two centrages in sanitary towel 20, i.e. a longitudinal centre line L and a transverse centerline." vertically " speech refers to a line in sanitary towel 20 planes herein, axle or direction, the same vertical plane of this direction are calibrated (the promptly approximate vertical plane that is parallel to) this plane mutually and roughly a wearer who stands who wears sanitary towel 20 are divided into health left side and right-hand part." horizontal " or " level " can exchange herein, refers to be positioned at the plane of sanitary towel 20, and basically with a vertical vertical line, axle or direction.

Fig. 1 also shows, it is horizontal or be referred to as end margin (or be referred to as " end ") 24 that sanitary towel 20 also has that two longitudinal edges that separate 22 and two separate, and these edges have constituted the periphery 26 of sanitary towel 20 together.When using sanitary towel 20, one in the end margin 24 towards the place ahead of user, and another in the end margin 24 is towards the rear of user.That end margin 24 towards user the place ahead is called 24A, and that end margin towards the user rear is called 24B.

There are two petiolareas in sanitary towel, is called first petiolarea 28 and second petiolarea 30.Center 32 is between petiolarea 28 and 30.32 edge stretches out petiolarea 28 and 30 from the center, and elongation is about 1/8 to 1/3 of sanitary towel's length.Authorized in 1st in the United States Patent (USP) 4690680 of Higgins JIUYUE in 1987 detailed narration has been done in center 32 and two petiolareas 28 and 30.

Sanitary towel also has one to be oriented to longitudinal center district 34 longitudinally, at least a portion length of its seat longitudinal centre line L, and also has a vertical lateral areas 36 that is positioned at the lateral outer side in longitudinal center district 34.

The thickness of sanitary towel 20 can be selected arbitrarily, and it can be quite thick, also can quite approach even very thin.The embodiment of the sanitary towel 20 shown in Fig. 1 in the accompanying drawing-3 is the examples as a sanitary towel (preferably as " ultrathin type " sanitary towel) that approaches.But be understood that when seeing these figure, the number of plies of material shown in the figure makes sanitary towel 20 look much thicker than itself.The thickness of " ultrafine " sanitary towel 20 is preferably less than about 3mm.Thin sanitary towel 20 shown in the figure is preferably flexible, thereby user is felt comfortably cool.

Fig. 2 shows each building block of sanitary towel.Sanitary towel 20 of the present invention is made of at least four critical pieces usually, comprise that a top flat that sees through liquid 38, one do not see through 40, one absorbent cores 42 of the egative film of liquid (or claim " barrier layer ") and one and be used for sanitary towel is connected to fastener 44 on the user underwear.Absorbent cores 42 is between top flat 38 and egative film 40.

Fig. 4 shows the extending characteristic of sanitary towel 20." tensile " speech is meant on article at least one yardstick in the x-y plane herein can be increased.The x-y plane is meant and is arranged essentially parallel to plane positive in the sanitary towel 20." tensile " but a speech comprises those extensile and (below will further limit) article elastic stretch.Sanitary towel 20 shown in Fig. 4 is preferably all extending along length and width.But, sanitary towel 20 can be only along a direction elongation in these directions in other embodiments.Preferably sanitary towel 20 can prolong longitudinal tensile strain at least.

In some preferred embodiments, sanitary towel 20 can also stretch except extending.Described article remained tensile when " extensible " speech referred to again stretching, extension be caused certain resistance herein after stretching force acts on absorbing articles.

Preferablely be that sanitary towel 20 can elastic stretch, " but elastic stretch " and " but elastic elongation " same meaning.Fig. 4 for example understands their meaning.These speech are with representing herein that when removing the stretching force of usefulness " F " expression sanitary towel tends to get back to the yardstick (getting back to " initial " yardstick in other words) Lu and the Wu that do not stretch in other words that it does not extend.But, sanitary towel 20 needn't get back on its yardstick that does not stretch fully.As shown in Figure 4, it may only turn back to (or stretched dimensions) yardstick Ls of its yardstick that does not stretch and elongation and the loose yardstick between the Ws (such as L

RAnd W

R) on.

But make sanitary towel's elastic stretch will help to reduce and do not wish vertical contraction (vertically gathering) that sanitary towel occurs when making the power that sanitary towel tends to stretch when removing.This point particular importance that when wearer's underwear shrinks, seems.

2. the percentage elongation of the preferred embodiment of sanitary towel

A. introduce

For ease of discussing, can be divided into four classes to these concrete sanitary towels substantially at least.The first kind is that the used power of sanitary towel's elongation that makes is discussed.The first kind can be divided into two groups again: (a) elongation depends on the sanitary towel of user action, and (b) this two classes sanitary towel of sanitary towel of elongation those important power effects of only depending in use to be run into all within the scope of the invention.

Second class is according to for making sanitary towel extend whether a considerable amount of power of needs are divided.The second class sanitary towel can be divided into again: (a) sanitary towel that could extend of the sizable power of needs; And power that (b) only need be very little is with regard to tensile sanitary towel.This two classes sanitary towel also within the scope of the invention.

Which parts that the 3rd class relates to sanitary towel can extend.The 3rd class sanitary towel can be divided into two basic groups again: (a) all tensile sanitary towel of all building blocks; (b) sanitary towel that together constitutes by some tensile building blocks and some not extending building blocks.It is extending and top flat and absorbent cores are not extending that the example of the second group sanitary towel includes, but is not limited to the egative film of (i) sanitary towel; (ii) the top flat of sanitary towel and egative film are all extending, and have constituted a tensile sack, have encased not extending absorbent cores.

The 4th class sanitary towel relates to be tensile basically or to be not extending sanitary towel substantially, (but is connected with the extendible member of some types.) the 4th class can be divided into two groups at least: the sanitary towel that (a) has extending building block; (b) couple together by extendible member and the sanitary towel that can extend with some type.Second group for example can be that those have tensile attachment sanitary towel.Equally, this sanitary towel of two types is also all at this

In the scope of invention.

The content of the theme of these classes may comprise the content that other class covered.Other class and group also have this situation.To narrate comprehensive elongation characteristics below.But, be understood that comprehensive elongation characteristics often depends on which group described sanitary towel belongs to.

B. elongation property

(1) elongation

Elongation extensible amount best and the user underwear adapts.Promptly use the elongation of sanitary towel 20 preferably identical with the span of user underwear.Have been found that 20% span can be adapted to consider the maximum extension amount of user underwear that body kinematics causes.

Compiled in the form of Fig. 8 make the required power of sanitary towel elongation and with other relevant parameters of elongation of some preferred embodiments of sanitary towel 20.Power in the table 1 and other parameter (as mentioned above) obtain from several preferred embodiment of sanitary towel.

Certainly, those absorbing articles of dropping on beyond the described scope of table 1 of parameter in some cases also may be in scope of the present invention.In addition, be understood that: all ultimate values defined herein and scope comprise all that narrower ultimate value and scope within the ultimate value of above-mentioned qualification and scope.If such as institute's restricted portion is between about 125% to about 150%; all narrower scopes (such as between about 130-140% and between about 130%-150% etc.) within protection domain of the presently claimed invention, also are like this even these ultimate values and scope are not listed separately all.These force measurements carry out according to this description the 5th part described " method of testing ".

This heading has provided the size that makes sanitary towel extend longitudinally required power earlier.Sanitary towel causes when user moves preferably that its underwear stretches and moves under the effect of spontaneous power and produces elongation.This will make sanitary towel stretch with the underwear of user.The size of these power of numeric representation in the table.

The percentage ratio of longitudinal tensile strain amount recited above (and other measured value in the table 1) is that the longitudinal centre line L along sanitary towel 20 records.But, the elongation of some part of sanitary towel 20 may bigger than the part that is positioned at longitudinal centre line L in the sanitary towel (perhaps forming a power barrier) after bigger elongation.

Fig. 8 A shows, longitudinally that part of elongation at edge 22 can be than being positioned at that part of bigger on the longitudinal centre line L in the sanitary towel 20.In the present embodiment, sanitary towel is attached in the user underwear near on the elastic cord of shank, particularly near the elastic cord the angular region 27 tightly towards the underwear fastener 44 on that side of underwear.When the span of user underwear leg elastic when being positioned at the span of underwear appropriate section below sanitary towel's longitudinal centre line, the bigger situation of above-mentioned elongation will appear.

Fig. 8 A shows, longitudinally that part of sanitary towel elongated distance " C " of centre line L.Sanitary towel 20 is that part of one section bigger distance " D " of having extended at edge 22 longitudinally.Sanitary towel 20 longitudinally these parts at edge 22 can be stretched to its not extended length 175% to 200%.

Form among Fig. 8 shows that sanitary towel can also the elongation of (or as another kind of mode) broad ways.In addition, Fig. 8 also shows: can have an elasticity " barrier " (or " power barrier ") in the sanitary towel thus on a certain specified point, make sanitary towel along length/or width further the required power of elongation sharply increase.Below these parameters will be discussed at length.

Those parts that can reach the sanitary towel of described elongation preferably contain some absorbing material.The liquid maintenance dose of absorbing material preferably can reach 0.05g/cm at least

2This amount is to measure by following method: absorbing material is immersed in the distilled water, sample is taken out from water again, and make the sample drip-dry reach for 30 seconds.This absorbing material can be used as the material of absorbent cores.The absorbing material that can extend preferably is made of the top flat absorbing material more than one deck.

An example that does not contain among the embodiment of the absorbing material that can extend is: top flat and egative film can extend (but can not absorb liquid), but not tensible of absorbent cores.Because tensile ingredient does not comprise absorbing material, so such an embodiment is not to be preferred.But, such structure still can provide the additional areas of a little for covering the user underwear when elongation.

(2) extending force

That group digitized representation on the 2nd hurdle makes sanitary towel longitudinally extend the size of required power in the table 1.This group numeral is to record sanitary towel being extended reach under 25% to 40% the situation.

The 25% o'clock required power that sanitary towel's elongation reaches its length at least should be less than or equal to about 800g, preferably is less than or equal to about 400g, the most preferably is less than or equal to about 300g.

But the elongation of sanitary towel reaches about the stressed value of its length at 40% o'clock for being less than or equal to about 1250g.The elongation of sanitary towel more preferably is less than or equal to 800g for about 40% o'clock suffered power of its length.The elongation of sanitary towel is to be less than or equal to about 600g for about 40% o'clock the most desirable (though not limiting in table 1) of suffered power of its length.

The size of required power when listed that group numeral stretches sanitary towel's broad ways in the third column in the table (result who is done experiment according to the wide strip sample of the following employing 2.54cm that will narrate).Should read this table according to understanding longitudinally extending explanation.

Also have the embodiment of some sanitary towels of the present invention not drop in the scope in the table.But the embodiment of these sanitary towels still may drop within the category of the present invention, even their parameter has some to exceed listed range of parameter values in the table.

(3) the required minimum force of elongation

Required minimum force when making sanitary towel be stretched to any remarkable length (as 5% or be preferably 10%) for one will have a suitable value, thereby make user be easy to handle sanitary towel.User is difficult to handle the low excessively sanitary towel's (such sanitary towel stretches too easily) of elastic modelling quantity.User is difficult to handle and such sanitary towel is positioned in the underwear, and it becomes and " is clamminess " as taffy.

Preferably make sanitary towel extend about 25% o'clock needed power and be at least about 50 grams, making sanitary towel extend about 40% o'clock needed power is about 100 grams.In embodiment more preferably, making sanitary towel extend about 25% o'clock required power is about 100 grams.

(4) power barrier

The load-deformation curve of sanitary towel's 20 vertical or horizontal extensions is preferably similar with curve shown in Figure 9.

Sanitary towel preferably can more easily reach the elongation of an expectation, can form a power barrier then, and this power barrier can prevent that sanitary towel's suffered power when normally using and taking off from causing that sanitary towel further extends.

Be not among all embodiment sanitary towel all need a power barrier.In addition, in the embodiment of strong barrier, the effect of power barrier only limits to avoid the length of sanitary towel and width further to increase.

Usually, the more important thing is the further power barrier that increases of length that will provide can prevent sanitary towel.This is because sanitary towel may be maximum along the suffered stretching force of its length direction.

Sanitary towel is the process of taking off from the user underwear, and the effect of the stretching force that it vertically is subjected to is bigger.The power barrier can prevent that excessive stretching, extension from appearring in sanitary towel the process of taking off from the user underwear.In addition, because the length of sanitary towel is greater than its width, so just can there be a power barrier in sanitary towel than horizontal bigger also hope at span longitudinally like this.

Such power barrier can include, but is not limited to the intrinsic power barrier of the material that adopts in sanitary towel's building block, and owing to the structure of sanitary towel forms the power barrier, in described structure, place " stop " on the mechanical meaning sanitary towel to be stretched to beyond the specified point to prevent it.

First type of power barrier can exist in the thin film of a for example hypothesis, and this film approaches may produce a power barrier when being stretched over a certain ultimate value.For example this thin film reaches certain in stretching, extension and may extend about 10% (be its initial length 110%) before a bit, and described that feature is: when the thin film elongation reaches the state of this point, not can not further extend by the effect of significant forces.But common situation is, if thin film is not according to such elongation described herein, thin film have to be subjected to surpassing for reaching the effect of this initial elongation of 10% in those power of this defined so.

Figure 10 shows the example of a mechanics " stop " 54.Described a tensile building block 56 in this sketch map.Extensible member 56 (as an indefiniteness example) is made of a tensile absorbent cores, a tensile egative film.Post on the extensible member 56 one both can be not extending also can be the very little buffer element of elongation 58.Because with buffer element 58, just for sanitary napkin topsheet provides loose or soft material, it can make absorbent cores or egative film when being stretched to a length-specific only otherwise be subjected to a sizable power effect, just can further not extend.

Figure 11 shows an example that can make the laminar structure of the sanitary towel that is formed with stop or power barrier in the sanitary towel.Shown example can be an egative film.Egative film 40 can be to stretch the laminated product that adjustment means constituted (such as an extensile adhesive film 60 being laminated on the polyethylene film 62 after giving stretching, extension) by one.When the film 62 after giving stretching, extension is loose, two retes are pressed onto together.When egative film 40 is stretching, be easy to make film 60 to extend to polyethylene film 62 and give that length that stretched, but afterwards as not then can further not stretch by effect quite energetically.

The laminated construction that is used to make sanitary towel form stop or power barrier there is no need along bonding on the whole interface between each parts of lamination.

Such as, laminatedly can constitute by a kind of material (as a kind of elastica and a kind of absorbing material) of stretching of giving.Can be attached to absorbing material by spells and be in giving on the stretching, extension film under the state of stretching.Can be at many lines, a plurality of speckles or other locate mode are bonded together two building blocks.Can these building blocks be combined with the associated methods of glue, hot press or any other suitable type.

These last laminated goods that form can form some rugae areas under relaxed state.It can stretch or multi-direction stretching, extension to stretching, extension, twocouese by folk prescription.Laminated can extend to elastica that give the size that stretched.But as be not subjected to act on quite energetically then and can further do not extend, that makes like this laminatedly can be used as a combinative structure, is used on one or more building blocks of sanitary towel.

(5) amount of recovery (or set rate)

The recovery rate of sanitary towel can be different different because of embodiment.Be stretched under 125% to 140% the situation of its initial length, after removing the elongation load, sanitary towel needn't be back on its initial length.But, can return back to as sanitary towel and to be less than 110% of its initial length, then will be desirable, and it will be replied along with the motion of the loose of underwear material and/or user health when sanitary towel extends like this, and can be not pleating.Show in the table 1 that in not good enough embodiment, when removing when load elongation, sanitary towel may only be returned to and be less than or equal 125% of its initial length.

(6) regeneration rate

If sanitary towel has the ability that returns to the size that does not stretch, it preferably has lower regeneration rate.Expect to have low regeneration rate several reasons arranged:

After stretching, sanitary towel when lentamente towards size restoration that it does not stretch, will little by little touch the health of user.Sanitary towel can lightly, cosily touch the health of user under the effect of the power of the size restoration that does not extend towards it.Also contain some zones in the sanitary towel and can not be returned to its initial size owing to its material generation plastic deformation.These zones also have the applying that helps with health.Therefore, sanitary towel is just in time opposite with the material (as LYCRA) with the elastic property commonly used that is tending towards basically shrinking.

From consumer this point being taken off from underwear in sanitary towel considers not wish that also the regeneration rate of sanitary towel is too fast.User often is very fast after using sanitary towel it to be torn it down from the underwear crotch region, if recovery rate speed is too high, in removing the process of sanitary towel, sanitary towel may be easy to bullet to user (promptly as rubber band) when sanitary towel's elongation radially more than or equal to about 20% the time, this point of control regeneration rate particular importance that seems.

But, length or width after regeneration rate should be high enough to make sanitary towel's (be shorter than or equal 5 seconds) in several seconds to return it to recover.

The length that sanitary towel turns back to it after recovering or the speed of width are preferably in about 1.3cm//s (about 0.5 inch/second) extremely between about 5cm/s (about 2 inch/seconds).

3. each independent building block of sanitary towel

With reference to figure 1-3, can more clearly understand each building block of the various embodiment that are applicable to sanitary towel 20 of the present invention.

A. top flat

(1) general performance of preferred top sheet materials

Top flat 38 is made of permeable first parts of liquid.When using sanitary towel 20, top flat 38 is close on the skin of user.Top flat 38 is preferably submissive, soft feel, and preferably as far as possible user skin is not stimulated.Top flat 38 also should have the performance of well wearing permeability and reducing rewetting, and it can make the interior Excreta rapid permeability of body cross and flow to absorbent cores 42, but does not allow these Excretas to flow back on the skin of user by top layer 38.

Two sides (or title face or claim surface) are arranged on the top flat 38, comprise towards a side 38A of human body and towards a side (perhaps being a the side) 38B of underwear towards absorbent cores.Top flat 38 constitutes in the sanitary towel 20 a part with the contacted surface of human body (" surface ") 20A usually at least towards a side 38A of human body.Top flat 38 has two longitudinal edge 38C and two end margin 38D.

Other building block of sanitary towel can be described with similar label system.That is to say, represent with the numbering and the letter " A " of this building block towards that side of user health in a certain building block.That side towards the user underwear is represented with the numbering of this building block with letter " B ".Lateral edge and end margin use the numbering of building block and letter " C ", " D " to represent respectively.

The top flat 38 that is fit to can be made by the very wide various materials of scope, and these materials include, but is not limited to textile material and non-woven material, porous formed thermoplastic film, plastic film, wet-formed thin film, perforated foams, reticulated foam, weblike heat plastic films and thermoplasticity woven scrim.

Weaving that is suitable for and non-woven material by natural fiber (as the wood fiber or cotton fiber) synthetic fibers or modification natural fiber (as polymer fiber, such as polyester, polypropylene fibre and polyethylene or polyvinyl alcohol, starch-based resin, polyurethane, cellulose esters, nylon and rayon fiber) or combine by natural fiber and staple fibre.

When top flat 38 comprised a kind of nonwoven sheet, described material piece can be used the spunbond method, and the method for combing method, wet-laying, molten blowing method, hydraulic pressure entanglement method, said method combination etc. is made.

Usually make preferred top flat 38 with porous membrane, because they can make liquid see through, and if the hole processes to such an extent that suitably can also reduce liquid return, thereby reduced the probability of the user skin of getting wet again.The porous membrane that is suitable for can be made with any material defined in the publication of description thin film of being quoted here and preparation film process.

Narrated the thin film that is suitable in the following patent: Decembers in 1975 were authorized the US 3929135 of Thompson on the 30th, authorize people's such as Mullane US 4324426 April 13 nineteen eighty-two, the US that authorizes people such as Radel August 3 nineteen eighty-two authorized people's such as Ahr US 4463045 and the US 5006394 that authorized Baird on April 9th, 1991 on July 31st, 4342314,1984.Narrated in the following patent other that be shaped with suitable thin film hydroforming: the US4609518 that authorizes people such as Curro, US 4629643, US 4695422, and US 4772444, US4778644 and US4839216 and the US4637819 that authorizes people such as Ouelletle.

Narrated the material that other is applicable to top flat in the following patent: the US4775579 that authorized people such as Hagy on October 4th, 1988, authorized the US4798604 of Carter on January 17th, 1989, on June 11st, 1991 was authorized the US5023124 of Kobayashi, and the people's such as Suda that published on March 1st, 1989 European patent application EP 0304617 A2.

In the different embodiment of other, can prepare the thin film described in other document with the material described in more above-cited files (such as the extensile polymeric material described in the U.S. Pat 4798604 of authorizing Carter).The plastic foil that can be used for preparing the three-dimensional grand existing elongation that has not shinny basically surface described in the US4463045 such as the extensible polymeric material described in the US4798604.

In another embodiment shown in Figure 12, the member that top flat 38 can be made up of non-woven material or fabric 64 and a kind of for example three-dimensional porous plastic foil 66.Non-woven material decreases the plastic sense of top flat, thereby becomes more comfortable.

In a preferred embodiment embodiment illustrated in fig. 12, the pivot weight of non-woven material 64 can be about 1-40g/m

2, be preferably about 8-12g/m

2A kind of preferred non-woven material is made of a kind of thermal point bond polypropylene foil of combing.Some preferred nonwoven fibrous webs can be that the Fiherweb Group company of South Carolina Simpsonville produces, and trade mark is the product of CELESTRA and HOLMESTRA.

This plastic foil 66 is a kind of thermoplastics with capillary tube 39 of a large amount of similar tapers, has described capillary size, structure and the orientation of this material in authorizing the US3939135 of Thompson.This thin film needs a kind of surfactant (ATMER645 that I C I SpecialtyChlmicals produces) to handle.Preferably surfactant is joined in the vistanex granule of forming thin film.

Can use a kind of vacuum lamination process, by adhesive-bonded fabric than the mode in the thermoplastic film of imbedding under the molten condition, adhesive-bonded fabric 64 and porous plastic film 66 are formed a whole composite construction as shown in figure 12.On January 9th, 1991 was narrated such top flat in the U.S. Patent application 07/794745 by people such as Aziz proposition in more detail.In an alternative embodiment, can place adhesive-bonded fabric and thin film Face to face, in those embodiment of back, these two building blocks are connected to each other.The usability methods that these two building blocks are connected includes, but is not limited to Method for bonding, fusion method (comprising thermally coupled and/or pressure connection method), ultrasonic method and dynamic power machine connection method.

Figure 13 shows other embodiment, and wherein top flat 38 can have the film of fiber to constitute by an entanglement." entanglement has the film of fiber " speech is meant that one includes the perforated membrane of fiber, and wherein fiber tangles in the hole of thin film and tangles on every side in these holes.

The perforated membrane 68 of such top flat can described from here any thin film or bare cloth formation.Disclose a kind of perforated membrane 68 that is specially adapted to a kind of like this top flat among the US4463045, and this film encircled ingot rolls so that it has extensibility to a certain degree.Can encircle ingot to film 68 before or after tangling rolls.

Can be with Mechanical Method or heated mechanical processing method perforated membrane 68 and non-woven fibre 70 loosely mats.Fiber 70 is tangled towards health one side 38A or towards the direction of absorbent core layer one side 38B along (or from).

Can adopt any suitable technology, fiber 70 and film 68 be tangled with Mechanical Method or heated mechanical method.Such as, can moltenly blow to fiber 70 on the film, centrifugally bond on the film, combing is intertwined or melts to film, with heated mechanical method and the film of clogging short fiber and blow on the plastic foil that still is in molten state, perhaps be intertwined with hydraulic method with film.Authorize in people's such as Buntin the U.S. Pat 3978185 of Exxon company and disclose a kind of suitable molten blow moulding.

In a preferred embodiment, fiber 70 is a kind of thermoplastic synthetic fibers.The ASPUN that the polyethylene fibre that is suitable for can select for use Dow chemical company to produce, and polypropylene fibre can be selected the commodity of Exxon company ESCORENE 3400 by name and 3500 series of products for use.

After having prepared the membrane structure of fibre matting, preferably come membrane structure is handled so that its possess hydrophilic property with any known method immediately.The hole 39 that this technology will make film is treat liquid better.After these treatment process, can encircle ingot to composite construction and roll.

The material of the top flat 38 of fibre matting makes the contact between perforated membrane 68 and the non-woven fibre 70 tightr.This will bring and improve the advantage that liquid passes film 68 arrival fibers 70 and following each layer conveying capacity.Arrange towards health one side 38A along top flat 38 as fruit fiber, can also improve comfortableness.Among can the slit of shift-in user health because film 68 parts of top flat 38 are difficult for and following entangled fiber 70 separates, so as fruit fiber arrange further its comfortableness of raising along that side 38B of top flat 38 towards absorbent core layer.

(2) make top flat have alternative mode of extensibility

Can make above-mentioned top sheet materials have extensibility in several ways.These modes are not limited to following several.

A kind of mode for preparing tensile top flat 38 is to carry out one-time mechanical operation (rolling as pleating, wrinkling or ring ingot) on the top sheet materials so that form openable fold when top flat stretches in top flat.This technology can be carried out on above-mentioned a variety of top sheet materials.

In a preferred embodiment of the invention, after top flat 38 is made by the method in the U.S. Pat 4463045, roll through the ring ingot again, so that it has longitudinal extension to a certain degree.

Narrated a kind of like this top flat in the patent application that on July 23rd, 1 submitted to, people's such as Thompson U.S. Patent application 07/734404, people's such as people's such as Thompson U.S. Patent application 07/734292 and Buenger U.S. Patent application 07/734405.Can be these patent applications together as the reference of " capillary channel fiber " aspect.

Narrated in the following document and be used to encircle that ingot rolls or the suitable technology of " giving wrinkling ": authorized the U.S. Pat 4107364 of Sisson on August 15th, 1978, the US4834741 of the Sabee of approval on May 30th, 1989, and await the reply jointly, common three U.S. Patent applications transferring the possession of be people such as Gerald on February 28th, 1991 submit to 07/662536, people such as Kenneth B.Buell on February 28th, 1991 submit to 07/662537, people such as Gerald M.Weber on February 28th, 1991 submit to 07/662543.The reference paper of these patent applications conduct together " the ring ingot rolls " aspect.

The orientation that the ring ingot rolls the fold line in the corrugation structure of top flat is along laterally, so that make the top flat can be at longitudinal extension.In other embodiments, the orientation of fold line also can be longitudinally, both direction and/or other direction.The prolonging direction of top flat 38 is vertical with the direction of fold line.

Figure 14 shows that in other embodiments, top flat 38 can be made of a kind of non-woven material, contains fiber 78 in this non-woven material, and the orientation of fiber 78 is general vertical with the direction of desired stretching, extension.Can be roughly horizontal fiber by orientation as top flat and constitute, thereby it can longitudinally be extended.

Figure 15 shows an alternative top flat embodiment.In Figure 15, the fused portion 72 discrete with each shown in Fig. 5 is attached to top flat 38 on the following collecting layer 46.In the embodiment shown in fig. 15, collecting layer 46 just produced before being fused on the top flat 38 and stretches.So top flat 38 and collecting layer 46 have constituted a lamination.When the lamination after stretching is in loose attitude, between a plurality of fused portions 72, form a plurality of bunches of shape zones 74 in the lamination, and formed a plurality of valley point district 76 at the place, fusion area.

Embodiment described in Figure 15 has a very important advantage.This embodiment (and multiple alternative embodiment) allows with it seems that usually inextensible material makes extensile lamination.As it has been generally acknowledged that porous plastic film top flat 38 is exactly inextensible.But, if a top flat 38 being fixed on one deck for example on the collecting layer 46, make the material of these two building blocks be in loose attitude after the elongation on the collecting layer 46, top flat 38 has just possessed extensibility to a certain degree.

In other alternative embodiment, top flat 38 and collecting layer 46 the two in fusion for all extensible before the one.

In other embodiments, top flat 38 can be with tensile (perhaps preferably extensile) material, so that it has extensibility.As top flat 38 can with the porous membrane (for example can be the Exx-7 Exxon thin film of having bought from Exxon company) that polyethylene/the Kraton mixture is made, just obtain a kind of without any mechanical treatment with regard to extensile material.

In other embodiments, top sheet materials can comprise that the lower non-woven material of those pivot weights (is that pivot weight is about 18-25g/m

2Non-woven material).For example, so a kind of non-woven material can be the P-8 product that Veratec company (it is the branch company of Massachusetts Walpole International Paper Company for Veratec, Inc) produces.

In other embodiments, top flat can be made of the non-woven material that heat treated intensive fiber or hydraulic pressure tangle.

Figure 16 shows that in other embodiment, top flat 38 can elastic structural member.An example of this structure is a net, sieve or the scrim 80 that is made of elastic rib 82.December in 1977 was authorized an example that discloses a kind of like this structure in the U.S. Pat 4062995 of Korpman on the 13rd.Square or diamondoid hole 84 is arranged between each rib in the net.Such structure is generally all extensible in all directions.Can be added to elasticity or stiff fiber 86 in the net or bond to online.

In the alternative embodiment of other, can make a kind of structure that can stretch along all directions to top flat 38 with the material that only can stretch along direction.

An example that can be used for a kind of technology of this purpose shown in Figure 17.The left side of Figure 17 shows a kind of traditional handicraft, can be used for the net 88 of an extensible materials is cut into several top flats that separate 38.Net 88 is along direction (MD) motion of processing.This direction also is the direction of extension of net 88.

The right side of Figure 17 shows a kind of by (perhaps having one with machine direction from an angle

" deflection " angle) mode of cutting extensible materials net make a kind of can be along the technology of the top flat of multi-direction stretching, extension.In a modification of this technology, can make net send into machine at an angle also along cutting with the equidirectional shown in traditional technology.Resulting cutting top flat 38 can be along stretching near the both direction shown in the arrow of cutting top flat.

Figure 17 A shows in other alternative embodiment, a plurality of holes 39 are arranged on the perforated membrane top flat 38, and the geometric arrangement in hole 39 helps to make top flat 38 to stretch along specific direction.

In other some embodiment, can on top flat 38, be cut into slit so that absorbent cores has following elongation characteristics.

In other embodiment (as shown in Figure 17 B), top flat 38 can be made of a kind of reversible expanded material.Reversible expanded material material that generally width increases (rather than reducing) when longitudinally extending constitutes.Such material is applicable to sanitary towel because when above-mentioned material stretches, these materials topped in the user ability in the crotch district do not reduce, in fact can increase topped ability in the fork district on the contrary.As shown in Figure 17 B,, can make the structure that when stretching, plays the tongue effect of similar limit of sanitary towel of these materials if the increase of this width is enough big.

Authorize October 23 nineteen ninety and narrated a kind of can reverse a kind of suitable method of material of constriction of making in the U.S. Pat 4965122 of Morman.

(3) additional step

Except foregoing, in the preferred embodiment of the invention, be a part 38 of handling top flat at least with surfactant.This can finish by any routine techniques well-known to those skilled in the art.

All narrated the method that is suitable for of handling top flat 38 with surfactant in a lot of piece of writing documents, these documents comprise the U.S. Pat 4950264 and 5009653 of authorizing Osborn, and by the U.S. Patent application 07/794745 of people such as Aziz in application on November 19th, 1991.Back one piece of patent application has pointed out how to handle with a kind of surfactant a kind of perforated membrane parts of formed film top flat of non-woven material/porous thermoplastic.Preferably surfactant is mixed in the used resin of thermoplastic forming thin film into.

Handling top flat 38 with surfactant makes top flat 38 more hydrophilic.Can make flowing fluid ratio pass undressed surface like this and see through top layer 38 quickly.So just reduced body fluid and overflowed the possibility of top flat 38, thereby prevented the probability of discharging by top flat 38.

In addition, in a preferred embodiment, the inner surface 38B of top flat 38 closely contacts with following absorbed layer and combines.This contact relation is not passed flowing fluid ratio and is penetrated top flat 38 better with the contacted top flat of absorption portion.Yet, be not that the surface of top flat 38 and the surface of following absorbed layer are bonded together.

The mode that top flat 38 and following absorption piece are kept in touch has: top flat and below building block between applying adhesive, the fiber of surface layer is tangled mutually with top layer, with many discrete separately fusion parts top flat 38 is fused on the following absorbed layer, perhaps uses the known any other method of those skilled in the art.

Fig. 5 and Fig. 7 show a kind of fusion part that can form the preferred type of fusion area, and described fusion area has constituted to have for liquid and sees through and the structure of the required apocenosis passage of absorbing material below arriving.Narrate these in more detail in the U.S. Patent application 07/810774 by people such as Cree submission on 17th at December in 1991 and preferably fused part.

B. absorbent cores

(1) fundamental characteristics of preferred absorbent core structures

The absorptive capacity of absorbent cores 42 needn't be far longer than the fluidic total amount that the phase of giving absorbs.Absorbent cores generally can compress, and has comfort, and the skin of user is not stimulated.It can be made of the known any material that is used for this occasion.The example of indefiniteness comprises natural material (such as being commonly referred to pulverous art slurry of airfelt chemical fibre dimension, corrugated cellulose wadding), can form the polymeric gelling agent of hydrogel, any suitable combination of the cross-linked cellulosic of modification (below will introduce in detail), capillary channel fiber, absorbent foam materials, absorption sponge, synthetic staple fibre, polymer fiber, peat moss floss or any effect identical materials and these materials.

Also can call " absorbability gel rubber material " or " superabsorbent material " to top listed polymeric gelling agent.To be exactly those will suck in these liquid and form the material of hydrogel contacting with liquid (as water or other body fluid) polymeric gelling agent.Adopt this mode, polymeric gelling agent can be collected and be maintained the liquid that enters in the absorbent cores 42, thereby makes these absorbing articles have higher absorptive capacity and/or liquid-maintaining capacity.

The polymeric gelling agent that is adopted in the absorbent cores 42 generally by a kind of water-fast basically, have the polymeric material granule 41 that a little is crosslinked, part is neutral, can form hydrogel to constitute." granule " speech used herein can refer to the granule of Any shape (as ball shape, lamellar or shape such as fibrous).

The polymeric material of the preferred type that the absorbent cores 42[that has narrated a kind of fundamental type in those patents of authorizing the U.S. Pat 5009653 of Osboyn and being quoted in more detail includes, but is not limited to here to be adopted, and the method that can be used for preparing those preferred types of these polymer beads], quote all these description as a reference at this.But, absorbent cores 42 described herein needn't comprise particles of superabsorbent material.

Described the suitable cross-linked cellulose fibres that are used for absorbent cores in the following document: Decembers in 1989 were authorized people's such as Cook U.S. Pat 4888093 on the 19th, authorized people's such as Dear US4822543 on April 18th, 1989, Decembers in 1989 were authorized people's such as Schoggen US4889595 on the 26th, authorize people's such as Moor US4898642 February 6 nineteen ninety, authorize people's such as Lash US4935022 June 19 nineteen ninety, May in 1991 people such as disclosed Herron on the 15th european patent application 0427316A2 and 0427317A2, and May in 1991 people such as disclosed Herron on the 29th european patent application 0429112A2.

Be suitable in the example that the capillary channel fiber [fiber that promptly has passage (preferably on the outer surface of fiber)] of absorbent cores provides below detailed description being arranged, these examples be documented in October 10 nineteen ninety disclosed european patent application 0391814 and the patent application of above-mentioned those relevant capillary channel fibers in.

At U.S. Patent application 07/743839,07/743950,07/743947,07/830159 (P﹠amp; G case numbers 4451,4452,4453 and 4453R) in narrated the absorbent cores that is fit to that constitutes by foam-like material.First, the third and fourth listed application is submitted to people such as Des Marais.Second listed application submitted to people such as Young.First three application was submitted on August 12nd, 1991, and the 4th application submitted on February 12nd, 1992.Introduced other absorbent cores that constitutes by foam-like material among the european patent application 0293208B1.

U.S. Pat 3512530 and 3954493 and French Patent (FRP) FR2203827 in introduced the absorbent cores that constitutes by spongy material.

Introduced other suitable absorbent cores in the following list of references: the U.S. Pat 4773903 of authorizing people such as Weismon on the 12nd respectively at JIUYUE in 1988 27 days and JIUYUE in 1989, and US4865596 with extensibility.Disclose in these patents by microfibre sheet, the staple fibre goods of non-absorbent band wrinkle, and the various composite absorbent structure that granule constituted that can form the polymeric gelling agent of hydrogel basically that tangle, blowing with a kind of hydrophilizing agent.

Other absorbent core material that is suitable for is made of the mixture of molten playing wind and stringing instruments property fiber and absorbing material.Such material is made of cotton fiber and the melt blown fiber composite after hydraulic method is tangled, and described composite is and can have bought from the Fiber web ofSimpsonville company of the South Carolina

#The 7102-102 product.In other embodiments, can replace cotton fiber with other absorbing material (such as the 101 or 102 type FSA fibers that can buy from the Courtaulds fiber company limited of England West Midlands).Another kind of alternative plan is, two layers of material (as above-mentioned

#The 7102-102 product) is superimposed together with a kind of granulated polymer gel in the centre, and makes it have extensibility, thereby prepare a kind of tensile lamination of high absorption.

In addition, absorbent cores 42 can describedly from here be suitable for use as a lot of materials formations of top flat.But, for the purpose of practicality, these materials must be absorbable or use with some absorbing materials.Can be adhered in the bare cloth absorbing fiber by a kind of and the similar structure of elasticity bare cloth shown in Figure 16 such as, absorbent cores 42.

(2) make absorbent cores have extensibility

The present invention has a lot of tensile absorbent cores embodiment that are suitable for.They include, but is not limited to following embodiment.Also can combine the parts of following embodiment in any suitable manner and constitute other embodiment.

(a) lamination

In a preferred embodiment shown in Figure 2, absorbent cores is a lamination.This lamination by the tissue layer of two air-flows weavings of super polymeric material (as being the shape of the granule 41) quantum that absorbs of one deck (be respectively first and second tissue layer or title " on " and the D score tissue layer) constitute between 43 and 47.

First and second tissue layer 43 and 47 contain super-absorbent polymer materials, and it can promote the effluent that is absorbed to pass the horizontal siphonic process of absorbent cores 42 and have the certain absorption ability.Tissue layer 43 and 47 can be accompanied the piece of cloth behind particles of superabsorbent material 41 folding and constituted by a centre, perhaps two discrete lamellas also can making for identical (or different) fabric.

The super lamination (WATER-LOCK is the trade mark of Grain Processing Corporation registration) that absorbs of the WATER-LOCK L535 that the Girain ProcessingCorporation Of Muscatine that a kind of suitable lamination is Iowa Muscatine produces.Disclose so super absorption lamination in the following patent: the U.S. Pat of authorizing people such as Peterson on August 20th, 1984 was authorized people's such as Lindsay US4260443 on April 7th, 4467012,1981 and was authorized people's such as Kramer US4578068 on March 25th, 1986.

By using elongation in that (tissue paper that stretches between can the about 120%-300% at its initial length prepares lamination absorbent cores 42, can make this absorbent cores have extensibility between the 20%-200%.Can prepare such piece of cloth with kinds of processes.In one embodiment, tissue paper can be conventional, corrugated fabric.As tissue paper can be BOUNTY fabric through a creping.

In other embodiments, preparing this kind fabric can adopt and carried out suitable improved a kind of technology to ratifying on March 4th, 1980 to technology described in the US4191609 of Trokhan, perhaps adopt technology described in the U.S. Pat 4529480 of authorizing Trokhan on July 16th, 1985 has been carried out suitable improved a kind of technology, perhaps adopt technology described in the U.S. Pat 4529480 of authorizing Trokhan on July 16th, 1985 has been carried out suitable improved a kind of technology, perhaps adopt disclosed european patent application WO92/00414 on January 9th, 1992, the technology described in WO92/00415 and the WO92/00416.In the latter case, it is tensile fabric to be become with following one or more steps: the angle of regulating scraping blade is so that can form different fold; Change paper mesh-like area performance so that its can stretch to a certain extent; Perhaps before gauze is subjected to further drying, from the Yankee heat drier, take out gauze, thereby obtain effective fold.

In the embodiment that can Gong select for use, originally there was not fold or fold fabric seldom to occur fold later at lamination yet, the technology that forms wrinkle in this case is to make laminated fabric acquire a ripple laminated fabric by the roll of two couplings, and the extending range of this fabric (can stretch between the 120%-300% at its initial length) between the 20%-200%.The ripple direction should be vertical with desirable direction of extension.

In a relevant alternative embodiment, the mode that makes lamination fold occur is: can make lamination break away from this surperficial method again and make lamination wrinkling by lamination being adhered on the surface.This can be with finishing with the similar mode of the step that shifts out paper from a Yankee exsiccator described in the above-mentioned european patent application.

In another relevant embodiment, can be at the lamination place in one plane the time, the mode of compressing into this lamination with a mould makes it wrinkling.As can with to the similar mode of mode described in the U.S. that authorizes people such as Kramen No. 4578068 patents, adopt pair of plates that a mould is compressed into lamination.

In alternative embodiment, can suitably cut or cut out slit to lamination and form a tensile absorbent core structures.Show among Figure 18 that in a specific preferred embodiment, absorbent cores 42 is laminations that help longitudinal tensile strain that cut out slit in a manner described or partly cut out slit.Figure 19 shows one in central region rather than have the other absorbent cores of slit at petiolarea.A kind of other absorbent cores of wherein cutting the diamond hole has been shown among Figure 20.Also can adopt the hole of any or multiple other suitable shapes.

On July 24th, 1991, disclosed Lion company publication number was the absorbing material that has slit of having introduced other type in the european patent application of 0293208B1.

Preferably the longitudinal edge of sanitary towel and end margin 22 and 24 seal with prevent sanitary towel when the elongation liquid or the superabsorbent material that contains liquid from sanitary towel by siphon or eject.Another kind of situation is can make the edge 42c and the 42d sealing of absorbent cores 42 rather than the edge of whole sanitary towel is sealed.Such as, can get up the edge roll of absorbent cores 42 or cover with a tissue layer.In other alternative embodiment, can or otherwise handle with the particles of superabsorbent material 41 that prevents liquid or contain liquid to be come out or eject the edge fold of this tissue layer by siphon from absorbent cores 42.All sealed-for-lives of sanitary towel's 20 peripheries are in sanitary towel's should not break when elongated (that is to say that between the operating period, any sealing all should be remained valid in sanitary towel).

In above-mentioned any lamination absorbent cores embodiment, can be with another any other known absorption material, include, but is not limited to the cross-linked cellulose fibres of peat moss floss, modification or synthetic fibers and replace cellulose fibre in one or more tissue layer.The pivot weight of each tissue layer also can be different.

(b) contain the mixture structure of absorbing material and superabsorbent material.

Such as, can prepare the thin slice fabric with the mixture that the absorbing material that has airfelt chemical fibre dimension, improved cross-linked cellulose fibres, crosslinked carboxymethyl cellulose (authorize as on October 9th, 1984 Gellert US4475911 described in) peat moss floss or other absorbing material are formed.Can carry out wrinkle, joint-cutting or carry out other operation described here these thin slice fabrics then, to produce tensile absorbent cores 42.

Can distribute particles of superabsorbent material 41 with any known mode among any embodiment described here.Can be particles of superabsorbent material 41 and absorbing material uniform mixing described here.In other embodiments, can distribute particles of superabsorbent material to such an extent that the concentration in gradient of superabsorbent material in sanitary towel distributed.Realize the mode that this Concentraton gradient distributes, the people's such as Duenk that announce on October 22nd, 1986 european patent application was authorized people's such as Kellenbdrger US4699823 and authorized on April 23rd, 1991 among the US5009650 of Bernardin on October 13 in 0198683,1987 introduction.

(c) contain the structure of all kinds fibre blend.

(i) " mixing " absorbent cores

A kind of specific preferred absorbent cores 42 that will be called as " mixing " absorbent cores afterwards has been shown among Figure 21-23.This specific absorbent core structures has been shown in thicker sanitary towel 20.But also it can be prepared into a kind of thin layer for the product that is used for approaching.

Blended absorbent core 42 is made of one deck fiber (preferably making the homogeneous mixture of fiber).Mixed core 42 is made of at least two groups (two types) fiber.The short hydrophilic fibers that comprises the low denier of first group (or type), and by second group of (or type) fiber of the synthetic fibers formation high danier, long of about 5%-90% (preferably being about 10%).Can change the mixing ratio of two groups of fibers, to produce product with the required character of dissimilar absorbing components.Except that specializing, all percentage ratios that limited here all are percentage by weights.

First group of fiber can comprise that natural fiber is (such as cotton fiber, cellulose fibre or other natural fiber.) first group of fiber also can (or additional) also comprise synthetic fibers (such as superabsorbent material fiber, capillary pipe fiber, with the natural fiber of Mechanical Method or chemical method modification).These fibers comprise paper pulp (or title " CTMP " or " TMP "), the wood fiber or the cross-linked cellulosic of (but being not limited to) artificial silk, chemi thermo mechanical processing.In one embodiment, first group of fiber is made of airfelt chemical fibre dimension.Those fibers in first group or hydrophilic, perhaps can with any aforesaid method of hydrophilizing they handle possess hydrophilic property.

A kind ofly can maintain an incompressible essential part when the moistening by selecting for use, have the performance that quite inflexible fiber can improve product.(be that this fiber should have higher coefficient of compressibility.) preferably selected fiber wet resilience and dried resilience (promptly when being compressed they not only tend to resist compression but also be inclined to bullet be back to its original shape) can incompressiblely be arranged again.For satisfying these requirements, cross-linked cellulosic is that special recommendation is adopted.But should be pointed out that these cellulose fibres are to have passed through certain modification to handle, and can not be considered as cellulose fibre or natural fiber itself to them again.

Second group of fiber should have higher coefficient of compressibility equally, and still can keep quite high coefficient of compressibility when moistening.Second group of fiber preferably also has wet resilience and in resilience.Useful fiber include, but is not limited to by those that limit below be suitable as fiber in the collecting layer 46 the synthetic fibers that material constituted (but, two groups of fibre lengths, yarn deniers etc. needn't be all identical.To introduce parameters such as some preferred fibre lengths below.)

The fibre length of fibre length in second group in first group.Preferably, the fibre length in second group more than or equal to about 0.6cm (about 1/4 inch) and more preferably greater than or equal about 1.3cm (about 1/2 inch).The fiber denier number of fiber denier number in second group of fiber in first group of fiber.Preferably in second group every danier number of fiber between about 6-40.Preferable is that the danier number is preferably between about 15-about 25 between about 15-about 30.

Fiber in second group can be hydrophilic, hydrophobic, also can be that part is hydrophilic and part is hydrophobic.Fiber in second group preferably has a certain hydrophilic means (preferably cellulose parts) at least.Can make the fiber in second group have a hydrophilic means with several suitable methods.These methods include, but is not limited to fiber is applied or handles, so that their (or being their surface at least) possess hydrophilic properties.

The synthetic fibers that are fit to can be KODEL 200 and 400 series of products that the Eastman Kodak TextileFibers Division Kingsport of Tennessee State produces.A kind of synthetic fibers of suitable model are KODEL 410 fibers.

A kind of synthetic fibers that are particularly suitable for type that are used in second group of fiber are polyester fibers of handing over wrinkle.A kind of suitable polyester fiber is KODEL 431 fibers.When being carried out cockle, these KODEL fibers can be undertaken by the standard that 5-7 fold appears in every 2.5cm straight length (per 1 inch) approximately, preferable is about 6 fold of every 2.5cm air line distance, and about 6.3 fold of the most every 2.5cm air line distance are better.Cockle angle during the fiber cockle between about 70 °-Yue 91 ° better, for about 88 ° better.Cockle has been improved the resilience of one of desired various character of the conduct of fiber.The danier number of fiber is every single fiber 15 daniers, and fibre length is about 1.3cm (about 0.5 inch).Can on fiber, be coated with any suitable method that those skilled in the art were familiar with and be covered with a hydrophilic or hydrophobic coating.

In an alternative embodiment, may replace first group of fiber in the fiber with a kind of synthetic fibers (having water-wetted surface) very short, the low denier number.Blended absorbent core 42 is combined into second of fiber (scribbling the polyester fiber that one deck is called a kind of patented permanent wettable coating of CELWET such as those) and long, high danier number by hydrophilic first of short, low denier number and is combined into fiber and constitutes in this case.The polyester fiber that scribbles CELWET can have been bought from the HoechestCelanese company of North Carolina state Charlotte.

A kind of blended absorbent core like this can also contain the polymeric gelling agent granule that can form hydrogel, so that improve the absorptive capacity of core.

In a kind of preferred embodiment, can form the gel rubber material formation of the polymeric gelling agent of hydrogel by " absorbing at a high speed ".The gel rubber material that " absorbs at a high speed " is meant herein can be to reach about 40% of its absorptive capacity at least in 10 seconds or within 10 seconds.(reach at least about 50% better, preferably can reach about 90% at least) absorb ejection with such speed those absorb gel rubber materials.

In the U.S. Patent application 07/637090 and 07/637571 that proposes by people such as people such as Noel and Feist respectively, introduced a kind of percentile usability methods of absorptive capacity that is used for measuring.In alternative embodiment, may mix use to (or speed) the usually absorption gel rubber material that absorbs at a high speed gel rubber material and other type mutually equally.

Among the embodiment that has just introduced in the above, absorbing gel rubber material preferably makes fibrous material at a high speed.Authorize on August 8th, 1989 among people's such as Bourland the US4855179 than having introduced fibrous superabsorbent material (absorbing gel rubber material) in more detail though need not to be fibrous high speed.

" fibrous absorption gel rubber material " is to comprise fully by absorbing fibrous absorption gel rubber material that gel rubber material constitutes and scribbling the bicomponent fibre that some other material of absorbing gel rubber material constitutes by the surface at least partially.A kind of useful fiber shape absorbs the formal FIBERSORBSA7000 that produces of Arco chemical company that gel rubber material is Pennsylvania Newton Square at a high speed.The super at a high speed fiber that absorbs of other useful fiber shape is the polyacrylate based fiber that is claimed 101,102,111 or 112 type FSA fibers that Courtlauds fiber company limited is produced.

It is believed that, the polymeric gelling agent that can form hydrogel is used in such blended absorbent core can improves its effectiveness.Certainly, also may use the polymeric gelling agent that can form hydrogel of higher concentration.

Preferably blended absorbent cores 42 is compressed to density and is at least about 0.09g/cm

3(about 1.5g/ inch

3).Can be compressed to density to blended absorbent core 42 at least up to about 0.25g/cm

3(about 4.0g/ inch

3), so that still can keep its improved flexibility and flexible its fluidic siphon level that improves simultaneously.The density value of top defined does not count the quality of any absorption gel material particle.Can or only carry out compacting to whole absorbent cores 42 to wherein selected part.Can make the adjustment of its fluid handling properties can satisfy specific needs to its compacting that figure is arranged.Such as, the density in the fluid target area can be very low, so that fluid collection speed reaches top level, and the density of the marginal portion of close core can be very high so that fluid siphon level reaches the highest.

In a particularly preferred embodiment, the absorbent cores of having improved 42 is hybrid yams of a kind of air lay, it is long by 15% 1.27cm, the polyester fiber of crossing through fold of every ultimate fibre 15 daniers and about 85% cross-linked cellulose fibres constitute, and it is compacted to density at last and is about 0.06g/cm

3(about 1g/ inch