EP0012009A2 - Two-part food container - Google Patents

Two-part food container Download PDFInfo

- Publication number

- EP0012009A2 EP0012009A2 EP79302710A EP79302710A EP0012009A2 EP 0012009 A2 EP0012009 A2 EP 0012009A2 EP 79302710 A EP79302710 A EP 79302710A EP 79302710 A EP79302710 A EP 79302710A EP 0012009 A2 EP0012009 A2 EP 0012009A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- container assembly

- bowl portion

- base portion

- assembly according

- bowl

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47G—HOUSEHOLD OR TABLE EQUIPMENT

- A47G19/00—Table service

- A47G19/30—Other containers or devices used as table equipment

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47G—HOUSEHOLD OR TABLE EQUIPMENT

- A47G19/00—Table service

- A47G19/22—Drinking vessels or saucers used for table service

- A47G19/2205—Drinking glasses or vessels

- A47G19/2255—Details related to the connection between the liquid containing part and the supporting part

Definitions

- This invention relates to improvements to containers particularly suitable for use as food containers.

- the present invention in one form aims to provide an attractive take-away food container which will be economical to produce so as to enable small quantities of food to be dispensed therein, attractive and functional. Other objects and advantages of the invention will hereinafter become apparent.

- this invention resides broadly in a container assembly of the type including a bowl portion supported on an upstanding elongate base portion, characterised in that:

- the food container 10 is a two-part container comprising a top bowl portion 11 and a base portion 12, each of which taper from their outer ends towards their spigot/socket connection assembly 9 so that when dismantled a plurality of the bowls may be stacked within one another and similarly, a plurality of base portions 12 may be stacked within one another to facilitate packaging, storing and transportation.

- the sides of the components are suitably formed with a seven degree taper.

- the bowl portion 11 in the illustrated embodiment has a capacity of approximately six hundred millilitres which is suitable for a take-away food serve. However, this may vary from say five hundred millilitres to a litre as required.

- the bowl portion 11 is formed with a centrally disposed cylindrical socket 13 to receive the upper tapered spigot end 14 of the stem 15 whereby the portions may be pushed firmly together to provide a releasable but firm connection between the parts which may be made and released quickly while at the same tine maintaining a secure connection in use.

- the spigot end 14 is provided with internal stiffening ribs 16 which extend from the upper end of the stem downwardly past the lower edge of the socket 13.

- the open end of the bowl portion is provided with an outwardly extending peripheral flange 17 extending therearound for the purpose of securing thereto a clip-on type lid 18 and in this embodiment the base portion 12 is similarly formed with a peripheral flange 19 having identical proportions to the flange 17 whereby the lid 18 when removed from the bowl portion 11 may be clipped about the base portion 12.

- This has the advantage that in use the person consuming the contents of the container can remove the lid and secure same to the base whereby it remains integral with the container and does not have to be otherwise disposed of. Furthermore, it remains quickly accessible for replacement onto the bowl portion 11 should the contents need to be stored for later consumption.

- a further advantage of the present invention is the formation of the spigot/socket connector assembly 9 adjacent the bottom of the bowl portion 11.

- This arrangement has the advantage that the joint at this point is operatively stable as opposed to say forming the bowl portion and stem integrally and securing the lower end of the stem into a supporting base at which position the dislocation forces are much greater, as a result such connection would be extremely prone to failure.

- the overall height of the container 10 is about 22 cm.

- each component may be formed by injection moulding in general purpose polystyrene using relatively small moulding apparatus as compared with the apparatus which would be necessary to form say the combination bowl and stem in one piece, with say a removable base plate.

- a further disadvantage of forming the container in one piece is that thicker wall sections would be required for the longer flow paths to ensure that the cavity of the mould was completely filled with the polystyrene, and this would add to the material cost of the article.

- the spigot/socket joint at the base of the container it is possible to form the article at a faster production rate on simpler machinery so that the manufacturing costs can be greatly reduced as can the material cost, due to the thinner wall thickness of the moulding which is possible due to the small physical size of each component being moulded.

- FIG. 2 to 4 Further embodiments of the invention are shown in Figs. 2 to 4.

- the socket connector portion 13a extends upwardly within the bowl portion 11a so as to conceal the joint, while in the embodiment illustrated in Fig. 4, the spigot end 14b is stepped inwardly from the stem 15b so that the external diameter of the socket portion 13b may be substantially identical to the external diameter of the upper end of the stem 15b.

- the shape and size of the bowl may be varied as may the stem, but it is preferred that several bowl variations be provided each of which may connect to the common stem.

- the consumer may support the container by the stem instead of having to hold a hot food container by the actual container portion itself which, of course, can be very hot and uncomfortable to hold.

- the container is formed of G.P. styrene which is a clear plastic having a glass-like appearance to enhance the appearance of the container but of course, it may be made of other materials as desired.

- the connection between the base portion and the bowl portion may be a push-in connection as shown or it may include possible locking means such as a bayonet connection or a threaded connection.

Abstract

A container assembly, particularly suitable for take-away food, has a bowl portion and an elongated base portion releasably connectable to the bowl portion to provide a.support. Releasable connector means are disposed substantially centrally between the top and bottom of the assembly and the bowl and base portions each taper inwardly towards the releasable connector means.

Description

- This invention relates to improvements to containers particularly suitable for use as food containers.

- It is well known that in merchandising, packaging of the product to be sold is extremely important and good packaging can greatly increase the demand for the article. This applies equally to the food industry, especially the take-away food industry, where it is very important to provide attractive containers for take-away food.

- The present invention in one form aims to provide an attractive take-away food container which will be economical to produce so as to enable small quantities of food to be dispensed therein, attractive and functional. Other objects and advantages of the invention will hereinafter become apparent.

- With the foregoing and other objects in view, this invention resides broadly in a container assembly of the type including a bowl portion supported on an upstanding elongate base portion, characterised in that:

- (1) releasable connector means interconnect said bowl portion and said base portion;

- (2) said releasable connector means is disposed substantially centrally between the under and lower extremities of said container assembly, and

- (3) said bowl portion and said base portion each taper inwardly from their respective operative upper and lower ends towards said releasable connector means.

- In order that the invention may be more readily understood and put into practical effect, reference will now be made to the accompanying drawings which illustrate preferred embodiments of this invention and wherein:-

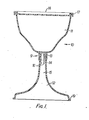

- Fig. 1 is a cross-sectional view of a two-part container made in accordance with the present invention;

- Fig. 2 and Fig. 3 are exploded views of a further embodiment of the invention from below and above respectively, and

- Fig. 4 is a side view of yet a further embodiment of the invention.

- As shown in Fig. 1, the

food container 10 is a two-part container comprising a top bowl portion 11 and a base portion 12, each of which taper from their outer ends towards their spigot/socket connection assembly 9 so that when dismantled a plurality of the bowls may be stacked within one another and similarly, a plurality of base portions 12 may be stacked within one another to facilitate packaging, storing and transportation. For this purpose, the sides of the components are suitably formed with a seven degree taper. The bowl portion 11 in the illustrated embodiment has a capacity of approximately six hundred millilitres which is suitable for a take-away food serve. However, this may vary from say five hundred millilitres to a litre as required. - The bowl portion 11 is formed with a centrally disposed

cylindrical socket 13 to receive the uppertapered spigot end 14 of thestem 15 whereby the portions may be pushed firmly together to provide a releasable but firm connection between the parts which may be made and released quickly while at the same tine maintaining a secure connection in use. For this purpose, thespigot end 14 is provided with internalstiffening ribs 16 which extend from the upper end of the stem downwardly past the lower edge of thesocket 13. - The open end of the bowl portion is provided with an outwardly extending peripheral flange 17 extending therearound for the purpose of securing thereto a clip-on

type lid 18 and in this embodiment the base portion 12 is similarly formed with a peripheral flange 19 having identical proportions to the flange 17 whereby thelid 18 when removed from the bowl portion 11 may be clipped about the base portion 12. This has the advantage that in use the person consuming the contents of the container can remove the lid and secure same to the base whereby it remains integral with the container and does not have to be otherwise disposed of. Furthermore, it remains quickly accessible for replacement onto the bowl portion 11 should the contents need to be stored for later consumption. - A further advantage of the present invention is the formation of the spigot/socket connector assembly 9 adjacent the bottom of the bowl portion 11. This arrangement has the advantage that the joint at this point is operatively stable as opposed to say forming the bowl portion and stem integrally and securing the lower end of the stem into a supporting base at which position the dislocation forces are much greater, as a result such connection would be extremely prone to failure. Furthermore, in order to achieve the required physical size as outlined above, the overall height of the

container 10 is about 22 cm. and the formation of the joint at the base of the bowl reduces the overall length of each component to approximately one-half the overall length of the assembly whereby each component may be formed by injection moulding in general purpose polystyrene using relatively small moulding apparatus as compared with the apparatus which would be necessary to form say the combination bowl and stem in one piece, with say a removable base plate. - In addition, it is very difficult to cool the inside core of a mould say 20 cm. long as the heat build- up requires extra curing time which in turn slows down the production cycle. This causes the unit cost to be increased. If the long curing time is not provided then the possibilities of producing deformities will be greatly increased and this will further add to the unit cost of the article.

- A further disadvantage of forming the container in one piece is that thicker wall sections would be required for the longer flow paths to ensure that the cavity of the mould was completely filled with the polystyrene, and this would add to the material cost of the article. Thus, by forming the spigot/socket joint at the base of the container it is possible to form the article at a faster production rate on simpler machinery so that the manufacturing costs can be greatly reduced as can the material cost, due to the thinner wall thickness of the moulding which is possible due to the small physical size of each component being moulded.

- Further embodiments of the invention are shown in Figs. 2 to 4. In the embodiment shown in Figs. 2 and 3 the

socket connector portion 13a extends upwardly within thebowl portion 11a so as to conceal the joint, while in the embodiment illustrated in Fig. 4, the spigot end 14b is stepped inwardly from thestem 15b so that the external diameter of the socket portion 13b may be substantially identical to the external diameter of the upper end of thestem 15b. - These embodiments also illustrate obvious variations in the shape of the bowl portion.

- Of course,the shape and size of the bowl may be varied as may the stem, but it is preferred that several bowl variations be provided each of which may connect to the common stem. In use, when the container is used as a hot food container, the consumer may support the container by the stem instead of having to hold a hot food container by the actual container portion itself which, of course, can be very hot and uncomfortable to hold.

- Preferably, the container is formed of G.P. styrene which is a clear plastic having a glass-like appearance to enhance the appearance of the container but of course, it may be made of other materials as desired. Additionally, the connection between the base portion and the bowl portion may be a push-in connection as shown or it may include possible locking means such as a bayonet connection or a threaded connection.

- It will of course be realised that while the above has been given by way of illustrative example many modifications of constructional detail and design may be made to the above described embodiment by persons skilled in the art without departing from the broad scone and ambit of the invention as is defined in the appended claims.

Claims (9)

1. A container assembly of the type including a bowl portion supported on an upstanding elongate base portion, characterised in that;

(1) releasable connector means interconnect said bowl portion and said base portion;

(2) said releasable connector means is disposed substantially centrally between the upper and lower extremities of said container assembly, and

(3) said bowl portion and said base portion each taper inwardly from their respective operative upper and lower ends towards said. releasable connector means.

2. A container assembly according to Claim 1, wherein said releasable connector means comprises a socket and spigot assembly, one said portion being provided with a socket and the other said portion being provided with a complimentary spigot and said socket and said spigot being adapted to be joined together to form said socket and spigot assembly.

3. A container assembly according to Claim 2, wherein said bowl portion is provided with a cylindrical socket extending downwardly from the underside thereof, and wherein the spigot on said base portion tapers inwardly towards its operative upper end.

4. A container assembly according to Claim 2, wherein said bowl portion has a capacity of between 500 millilitres and one litre.

5. A container assembly according to Claim 4, wherein said bowl portion and said base portion are moulded from a plastics material.

6. A container assembly according to Claim 5, wherein said plastics material is general purpose polystyrene.

7. A container assembly according to Claim 4, wherein said base portion includes a lower part having a configuration substantially identical to the top part of said bowl portion.

8. A container assembly according to Claim 7, wherein said lower part and said top part are each provided with an outwardly extending flange therearound to enable a covering lid to be clipped to either said bowl portion. or said base portion.

9. A container assembly substantially as hereinbefore described with reference to the accompanying drawings.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AUPD696878 | 1978-11-30 | ||

| AU6968/78 | 1978-11-30 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0012009A2 true EP0012009A2 (en) | 1980-06-11 |

| EP0012009A3 EP0012009A3 (en) | 1980-12-10 |

Family

ID=3767859

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP79302710A Withdrawn EP0012009A3 (en) | 1978-11-30 | 1979-11-28 | Two-part food container |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP0012009A3 (en) |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5996825A (en) * | 1996-08-01 | 1999-12-07 | Wna Comet East, Inc. | Bi-nestable container for consumables |

| EP1314383A1 (en) * | 2001-11-27 | 2003-05-28 | Vetrerie Di Empoli S.p.A. | Modular drinking glass with interchangeable parts |

| US6640989B2 (en) * | 2001-02-08 | 2003-11-04 | Inoac Packaging Group Inc. | Composite container with integral support, related method and mold |

| DE102006062169A1 (en) * | 2006-12-22 | 2008-06-26 | Kuhlmann, Manuel | Glass container for accommodating beverages, has base detatachably inserted in glass body, and seal-clamping units adapted to arrange base in glass body in clampable manner and to seal base and glass body |

| EP1987745A2 (en) * | 2007-04-16 | 2008-11-05 | Armando Diaz Alonso | Model of beverage container |

| US7612565B2 (en) | 2004-07-14 | 2009-11-03 | Schlumberger Technology Corporation | Apparatus and system for well placement and reservoir characterization |

| US7755361B2 (en) | 2004-07-14 | 2010-07-13 | Schlumberger Technology Corporation | Apparatus and system for well placement and reservoir characterization |

| US7861888B2 (en) | 2006-10-26 | 2011-01-04 | Solo Cup Operating Corporation | Stackable stemware |

| AT13464U1 (en) * | 2012-09-20 | 2014-01-15 | Gls Bau Und Montage G M B H | Packaging for food |

| US8736270B2 (en) | 2004-07-14 | 2014-05-27 | Schlumberger Technology Corporation | Look ahead logging system |

| US11187402B1 (en) | 2021-01-22 | 2021-11-30 | James Haug | Illumination assemblies using magnetic attachment and activation |

| US11540653B2 (en) | 2021-01-22 | 2023-01-03 | James Haug | Multi-piece stemware |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3051303A (en) * | 1960-04-07 | 1962-08-28 | Sylvester J Daanen | Combined container and serving dish |

| US3089605A (en) * | 1961-06-09 | 1963-05-14 | Frank A Buonauro | Convertible container construction |

| DE1486225A1 (en) * | 1964-06-05 | 1969-06-12 | Bellaplast Gmbh | Thin-walled vessel, deep-drawn from thermoplastic plastic film, with a closure lid, for example ice cream cups, Schuettelbecher or the like. |

| FR2040049A5 (en) * | 1969-03-28 | 1971-01-15 | Zach Ludwig | |

| US3586277A (en) * | 1968-12-26 | 1971-06-22 | Standard Oil Co | Stackable base |

| GB2007198A (en) * | 1977-11-07 | 1979-05-16 | Dart Ind Inc | Container Closure |

-

1979

- 1979-11-28 EP EP79302710A patent/EP0012009A3/en not_active Withdrawn

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3051303A (en) * | 1960-04-07 | 1962-08-28 | Sylvester J Daanen | Combined container and serving dish |

| US3089605A (en) * | 1961-06-09 | 1963-05-14 | Frank A Buonauro | Convertible container construction |

| DE1486225A1 (en) * | 1964-06-05 | 1969-06-12 | Bellaplast Gmbh | Thin-walled vessel, deep-drawn from thermoplastic plastic film, with a closure lid, for example ice cream cups, Schuettelbecher or the like. |

| US3586277A (en) * | 1968-12-26 | 1971-06-22 | Standard Oil Co | Stackable base |

| FR2040049A5 (en) * | 1969-03-28 | 1971-01-15 | Zach Ludwig | |

| GB2007198A (en) * | 1977-11-07 | 1979-05-16 | Dart Ind Inc | Container Closure |

Cited By (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5996825A (en) * | 1996-08-01 | 1999-12-07 | Wna Comet East, Inc. | Bi-nestable container for consumables |

| US6640989B2 (en) * | 2001-02-08 | 2003-11-04 | Inoac Packaging Group Inc. | Composite container with integral support, related method and mold |

| EP1314383A1 (en) * | 2001-11-27 | 2003-05-28 | Vetrerie Di Empoli S.p.A. | Modular drinking glass with interchangeable parts |

| US8736270B2 (en) | 2004-07-14 | 2014-05-27 | Schlumberger Technology Corporation | Look ahead logging system |

| US7924013B2 (en) | 2004-07-14 | 2011-04-12 | Schlumberger Technology Corporation | Apparatus and system for well placement and reservoir characterization |

| US9442211B2 (en) | 2004-07-14 | 2016-09-13 | Schlumberger Technology Corporation | Look ahead logging system |

| US7612565B2 (en) | 2004-07-14 | 2009-11-03 | Schlumberger Technology Corporation | Apparatus and system for well placement and reservoir characterization |

| US7755361B2 (en) | 2004-07-14 | 2010-07-13 | Schlumberger Technology Corporation | Apparatus and system for well placement and reservoir characterization |

| US7786733B2 (en) | 2004-07-14 | 2010-08-31 | Schlumberger Technology Corporation | Apparatus and system for well placement and reservoir characterization |

| US8933699B2 (en) | 2004-07-14 | 2015-01-13 | Schlumberger Technology Corporation | Apparatus and system for well placement and reservoir characterization |

| US7861888B2 (en) | 2006-10-26 | 2011-01-04 | Solo Cup Operating Corporation | Stackable stemware |

| DE102006062169A1 (en) * | 2006-12-22 | 2008-06-26 | Kuhlmann, Manuel | Glass container for accommodating beverages, has base detatachably inserted in glass body, and seal-clamping units adapted to arrange base in glass body in clampable manner and to seal base and glass body |

| EP1987745A2 (en) * | 2007-04-16 | 2008-11-05 | Armando Diaz Alonso | Model of beverage container |

| EP1987745A3 (en) * | 2007-04-16 | 2008-11-12 | Armando Diaz Alonso | Model of beverage container |

| AT13464U1 (en) * | 2012-09-20 | 2014-01-15 | Gls Bau Und Montage G M B H | Packaging for food |

| US11187402B1 (en) | 2021-01-22 | 2021-11-30 | James Haug | Illumination assemblies using magnetic attachment and activation |

| US11540653B2 (en) | 2021-01-22 | 2023-01-03 | James Haug | Multi-piece stemware |

| US11614223B2 (en) | 2021-01-22 | 2023-03-28 | James Haug | Illumination assemblies using magnetic attachment and activation |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0012009A3 (en) | 1980-12-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US4235557A (en) | Dispenser | |

| US6325229B1 (en) | Container coil having multiple discreet compartments | |

| CA1093029A (en) | Megaphone cup | |

| EP0012009A2 (en) | Two-part food container | |

| US2575770A (en) | Nesting kitchen canister set | |

| US5405030A (en) | Dual-compartment drinking cup | |

| CN1321864C (en) | Suspended containers | |

| US4073397A (en) | Fowl-shaped container | |

| IE800860L (en) | Nestable beverage tray | |

| US4800934A (en) | Device for pouring drinks having layers of different densities | |

| US3799493A (en) | Mold for congealable foodstuffs and the like | |

| US4678149A (en) | Support | |

| US3607308A (en) | Candy novelty | |

| US3568878A (en) | Container | |

| US3624788A (en) | Disposable liquid serving system | |

| US3533593A (en) | Mold for congealable foodstuffs and the like | |

| GB2029802A (en) | Display Containers | |

| JPH0141339Y2 (en) | ||

| EP0248814A1 (en) | Mould for use in making edible product | |

| KR20130000524U (en) | Hanging type container | |

| JPS6331669Y2 (en) | ||

| JPS6331667Y2 (en) | ||

| JPH0110336Y2 (en) | ||

| US184442A (en) | Improvement in jelly-jars | |

| JPS6016537Y2 (en) | Gellable food containers |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT CH DE FR GB IT NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT CH DE FR GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19810609 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19830107 |