EP0086418A2 - Procedure and tool for mounting elongated cylindrical elements in predrilled holes - Google Patents

Procedure and tool for mounting elongated cylindrical elements in predrilled holes Download PDFInfo

- Publication number

- EP0086418A2 EP0086418A2 EP83101100A EP83101100A EP0086418A2 EP 0086418 A2 EP0086418 A2 EP 0086418A2 EP 83101100 A EP83101100 A EP 83101100A EP 83101100 A EP83101100 A EP 83101100A EP 0086418 A2 EP0086418 A2 EP 0086418A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- hole

- sleeve

- tool

- striker

- procedure

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25B—TOOLS OR BENCH DEVICES NOT OTHERWISE PROVIDED FOR, FOR FASTENING, CONNECTING, DISENGAGING OR HOLDING

- B25B27/00—Hand tools, specially adapted for fitting together or separating parts or objects whether or not involving some deformation, not otherwise provided for

- B25B27/02—Hand tools, specially adapted for fitting together or separating parts or objects whether or not involving some deformation, not otherwise provided for for connecting objects by press fit or detaching same

- B25B27/04—Hand tools, specially adapted for fitting together or separating parts or objects whether or not involving some deformation, not otherwise provided for for connecting objects by press fit or detaching same inserting or withdrawing keys

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B25—HAND TOOLS; PORTABLE POWER-DRIVEN TOOLS; MANIPULATORS

- B25C—HAND-HELD NAILING OR STAPLING TOOLS; MANUALLY OPERATED PORTABLE STAPLING TOOLS

- B25C3/00—Portable devices for holding and guiding nails; Nail dispensers

- B25C3/006—Portable devices for holding and guiding nails; Nail dispensers only for holding and guiding

Definitions

- the present invention refers to a procedure for mounting elongated, principally cylindrical elements such as expander pins in predrilled holes, for example.

- Expander pins are resilient locking pins used for the demountable assembly of various machine elements or mechanical components, e.g. for mounting wheels and the like on shafts.

- the expanding capability is usually achieved by designing the expander pin as a slotted, springy sleeve of alloy steel which is made resilient by heat treatment.

- Expander pins are mounted in holes having a diameter less than that of the pin, with the result that the pin is compressed when driven into the hole. Since the pin endeavours to spring back to its normal expanding state it exerts sufficient pressure against the inner surface of the hole to prevent axial movement.

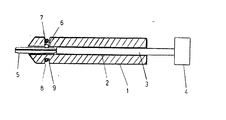

- FIG. 1 shows a longitudinal cross-section through a tool according to the invention.

- the tool consists of a sleeve 1 which is provided with an axial through hole 2.

- a striker 3 is so arranged in the hole 2 that it can move in an axial direction.

- the end of striker 3 outside the sleeve 1 is designed as an impact head 4.

- the cylindrical element which in the version shown consists of an expander pin 5 is arranged to be accommodated in the hole 2 at the opposite end of the sleeve 1 to the aforementioned impact head 4.

- a chiefly radial hole 6 is provided in the sleeve 1 close to the end accommodating expander pin 5.

- a loosely fitted locking pin 7 which rests against the expander pin.

- This locking pin is retained and pressed resiliently against the expander pin 5 by a rubber ring 8.

- the rubber ring 8 is fitted in an annular groove 9 in the surface of sleeve 1 adjacent to the radial hole 6. The resilience of rubber ring 8 is adapted so that expander pin 5 is retained by the friction, even when the tool is pointed downward, but not so that mounting of the pin is noticeably obstructed.

- a corresponding locking device can be utilized to retain the striker 3 in sleeve 1.

- a return spring (not shown) can be arranged between the striker and the sleeve to return the striker to the position of rest after each blow. Further, the aforementioned striker can be provided with a means of restricting its outward movement.

- the spring force applied to expander pin 5 from the side can naturally be arranged in many ways and the version described above is only an example.

- the tool can also be designed for easy connection to the pneumatic impact tool.

- the pin 5 When using the tool described above for mounting an expander pin 5 in a predrilled hole, the pin 5 is first fitted in the hole 2 in the sleeve 1. Locking pin 7 is pressed against expander pin 5 by means of rubber ring 8. The sleeve 1 is then applied to the predrilled hole and expander pin 5 is located in its mouth. Impact head 4 is subjected to repeated blows with the effect that the striker 3 strikes expander pin 5 and drives it into the hole.

Abstract

In a procedure for mounting elongated cylindrical elements in predrilled holes the element (5) is first fitted with resilient retention in one end of an axial through hole (2) in a sleeve (1). Accommodated at the other end of the hole (2) is a striker (3). The sleeve (1) with the cylindrical element (5) is applied to the mouth of the predrilled hole and the striker (3) is then subjected to blows so that it strikes the element (5) and drives it into the hole.

A tool for implementing the procedure embraces a sleeve (1) with an axial through hole (2). One end of the hole (2) is arranged to accommodate an elongated striker (3) and the other end to accommodate the cylindrical element (5) which is retained in the sleeve (1) by spring pressure.

Description

- The present invention refers to a procedure for mounting elongated, principally cylindrical elements such as expander pins in predrilled holes, for example.

- Expander pins are resilient locking pins used for the demountable assembly of various machine elements or mechanical components, e.g. for mounting wheels and the like on shafts. The expanding capability is usually achieved by designing the expander pin as a slotted, springy sleeve of alloy steel which is made resilient by heat treatment. Expander pins are mounted in holes having a diameter less than that of the pin, with the result that the pin is compressed when driven into the hole. Since the pin endeavours to spring back to its normal expanding state it exerts sufficient pressure against the inner surface of the hole to prevent axial movement.

- Mounting of expander pins in holes is usually carried out manually by holding the pin at the mouth of the hole and driving it into the hole with a hammer or other impact tool. This form of mounting is time-consuming and troublesome, particularly in confined spaces.

- With the present invention a procedure and a tool has been achieved which has the effect of substantially facilitating this mounting work. For this purpose the invention has the characteristics specified in the following patent claims.

- The invention will be described in greater detail in the following with reference to the version shown in the drawing. The figure in the drawing shows a longitudinal cross-section through a tool according to the invention.

- The tool consists of a

sleeve 1 which is provided with an axial throughhole 2. Astriker 3 is so arranged in thehole 2 that it can move in an axial direction. The end ofstriker 3 outside thesleeve 1 is designed as an impact head 4. The cylindrical element which in the version shown consists of anexpander pin 5 is arranged to be accommodated in thehole 2 at the opposite end of thesleeve 1 to the aforementioned impact head 4. - For retaining the expander pin 5 a chiefly

radial hole 6 is provided in thesleeve 1 close to the end accommodatingexpander pin 5. Positioned in the aforementioned hole is a loosely fitted locking pin 7 which rests against the expander pin. This locking pin is retained and pressed resiliently against theexpander pin 5 by arubber ring 8. Therubber ring 8 is fitted in anannular groove 9 in the surface ofsleeve 1 adjacent to theradial hole 6. The resilience ofrubber ring 8 is adapted so thatexpander pin 5 is retained by the friction, even when the tool is pointed downward, but not so that mounting of the pin is noticeably obstructed. - A corresponding locking device can be utilized to retain the

striker 3 insleeve 1. A return spring (not shown) can be arranged between the striker and the sleeve to return the striker to the position of rest after each blow. Further, the aforementioned striker can be provided with a means of restricting its outward movement. - The spring force applied to expander

pin 5 from the side can naturally be arranged in many ways and the version described above is only an example. - The tool can also be designed for easy connection to the pneumatic impact tool.

- When using the tool described above for mounting an

expander pin 5 in a predrilled hole, thepin 5 is first fitted in thehole 2 in thesleeve 1. Locking pin 7 is pressed against expanderpin 5 by means ofrubber ring 8. Thesleeve 1 is then applied to the predrilled hole and expanderpin 5 is located in its mouth. Impact head 4 is subjected to repeated blows with the effect that thestriker 3 strikes expanderpin 5 and drives it into the hole.

Claims (10)

1. A procedure for mounting elongated, principally cylindrical elements such as expander pins (5) in predrilled holes, for example, characterized in that the element (5) before mounting is fitted and resiliently retained in one end of an axial through hole (2) in a sleeve (1) the other end of which is occupied by a striker (3) and said sleeve (1) then being applied to an object with the element (5) against a predrilled hole, following which the striker (3) is subjected to impacts so that it strikes the element (5) and drives it into the aforementioned predrilled hole.

2. A procedure as in Claim I, characterized in that the sleeve (1) is fitted to a pneumatic impact tool for achieving blows on the striker (3).

3. A tool for mounting elongated, principally cylindrical elements such as expander pins (5) as in the procedure in Claim 1, characterized by a sleeve (1) provided with an axial through hole (2) one end of which is arranged to accommodate a striker (3) and the other end to accommodate and resiliently retain the aforementioned cylindrical element (5).

4. A tool as in Claim 3, characterized in that the sleeve (1) close to the end accommodating the element (5) is designed with a mainly radial hole (6) which extends inward to the through hole (2) in the sleeve (1) in which hole a resilient device (7) is arranged to press against the element (5) with a force so adapted that the element (5) is retained even when the sleeve (1) is in a vertical position but so that movement of the element is not noticeably prevented in connection with mounting.

5. A tool as in Claim 4, characterized by an annular groove (9) in the surface of the sleeve (1) close to the radial hole (6) in which groove (9) a resilient ring (8) is arranged to press a loosely fitted locking pin (7) present in the hole (6) against the element (5) for the purpose of retaining it.

6. A tool as in Claim 5, characterized in that the resilient ring (6) is of rubber.

7. A tool as in any of Claims 3-6, characterized in that the striker (3) is provided with a means of restricting its outward movement.

8. A tool as in Claim 7, characterized in that the striker (3) is designed with an impact head (4) situated outside the hole (2) which serves as a stop to interrupt the movement of the striker (3) into the sleeve (1).

9. A tool as in any of Claims 3-8, characterized in that a return spring is arranged to counteract the movement of the striker (3) into the sleeve (1).

10. A tool as in any of Claims 3-9, characterized in that it is designed to be connected to a pneumatic impact tool.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SE8200827 | 1982-02-11 | ||

| SE8200827A SE8200827L (en) | 1982-02-11 | 1982-02-11 | PROCEDURE AND TOOLS FOR FITTING LONG-TERM CYLINDRICAL ELEMENTS IN PREVENTED HALLS |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0086418A2 true EP0086418A2 (en) | 1983-08-24 |

| EP0086418A3 EP0086418A3 (en) | 1984-09-12 |

Family

ID=20345982

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP83101100A Withdrawn EP0086418A3 (en) | 1982-02-11 | 1983-02-07 | Procedure and tool for mounting elongated cylindrical elements in predrilled holes |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0086418A3 (en) |

| SE (1) | SE8200827L (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1506844A1 (en) * | 2003-08-12 | 2005-02-16 | The Goodyear Tire & Rubber Company | Tire sensor insertion tool and method |

| CN103978460A (en) * | 2014-05-23 | 2014-08-13 | 安徽江淮汽车股份有限公司 | Retractor assembling and disassembling tool |

| CN106985121A (en) * | 2017-04-30 | 2017-07-28 | 桂林电子科技大学 | A kind of crushing type nail servicing unit that can repeatedly utilize and its method of work |

| CN110270964A (en) * | 2019-06-24 | 2019-09-24 | 中国五冶集团有限公司 | It is a kind of for assist tap nail nail barrel |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2839754A (en) * | 1957-03-22 | 1958-06-24 | Elmer F Pfaff | Fastener driving tool |

| US2973520A (en) * | 1959-06-16 | 1961-03-07 | Star Prec Devices Inc | Small diameter stud adapter |

| US3036482A (en) * | 1960-09-02 | 1962-05-29 | Kenworthy Kenneth | Axial-impact type hand tool |

| US3788537A (en) * | 1972-07-31 | 1974-01-29 | Mechanical Applic Inc | Hand-loaded pin chuck |

| FR2291001A2 (en) * | 1974-11-18 | 1976-06-11 | Chatard Henri | Piston cylinder unit for securing nails during rotary drive - has elastic sleeve nose locating nail gripping ball bearing |

| US3979978A (en) * | 1974-05-15 | 1976-09-14 | Smolik Robert A | Nail setting tool |

-

1982

- 1982-02-11 SE SE8200827A patent/SE8200827L/en unknown

-

1983

- 1983-02-07 EP EP83101100A patent/EP0086418A3/en not_active Withdrawn

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2839754A (en) * | 1957-03-22 | 1958-06-24 | Elmer F Pfaff | Fastener driving tool |

| US2973520A (en) * | 1959-06-16 | 1961-03-07 | Star Prec Devices Inc | Small diameter stud adapter |

| US3036482A (en) * | 1960-09-02 | 1962-05-29 | Kenworthy Kenneth | Axial-impact type hand tool |

| US3788537A (en) * | 1972-07-31 | 1974-01-29 | Mechanical Applic Inc | Hand-loaded pin chuck |

| US3979978A (en) * | 1974-05-15 | 1976-09-14 | Smolik Robert A | Nail setting tool |

| FR2291001A2 (en) * | 1974-11-18 | 1976-06-11 | Chatard Henri | Piston cylinder unit for securing nails during rotary drive - has elastic sleeve nose locating nail gripping ball bearing |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1506844A1 (en) * | 2003-08-12 | 2005-02-16 | The Goodyear Tire & Rubber Company | Tire sensor insertion tool and method |

| US7021164B2 (en) | 2003-08-12 | 2006-04-04 | The Goodyear Tire & Rubber Company | Tire sensor insertion tool and method |

| CN103978460A (en) * | 2014-05-23 | 2014-08-13 | 安徽江淮汽车股份有限公司 | Retractor assembling and disassembling tool |

| CN106985121A (en) * | 2017-04-30 | 2017-07-28 | 桂林电子科技大学 | A kind of crushing type nail servicing unit that can repeatedly utilize and its method of work |

| CN106985121B (en) * | 2017-04-30 | 2023-03-10 | 桂林电子科技大学 | Crushing type nail auxiliary device capable of being used repeatedly and working method thereof |

| CN110270964A (en) * | 2019-06-24 | 2019-09-24 | 中国五冶集团有限公司 | It is a kind of for assist tap nail nail barrel |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0086418A3 (en) | 1984-09-12 |

| SE8200827L (en) | 1983-08-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2851295A (en) | Socket adaptor | |

| CA1256717A (en) | Tool holder for drilling and chiselling tools | |

| US8028762B2 (en) | Shock absorber for a reciprocating tool assembly | |

| US4395051A (en) | Quick-change holder | |

| US5390749A (en) | Apparatus for positioning a split retaining ring in a down-hole percussive drill | |

| US4582144A (en) | Percussive tools | |

| EP0395335A1 (en) | Bit for drilling an undercut hole | |

| US2576786A (en) | Centralizing drill | |

| US4202557A (en) | Drilling device | |

| US3633640A (en) | Tool having retractable and removable centering sleeve | |

| US3209445A (en) | Combination tool for driving out an old bushing and driving in a new one | |

| EP0086418A2 (en) | Procedure and tool for mounting elongated cylindrical elements in predrilled holes | |

| US5100256A (en) | Retaining pin module | |

| US3152391A (en) | Tool for wheel weights | |

| US4073046A (en) | Shock absorber installation tool | |

| EP4126456A1 (en) | Socket holding device for power tool | |

| JPS6393578A (en) | Hammer drill | |

| US2701359A (en) | Hand tool | |

| US20050092503A1 (en) | Shockproof spindle | |

| WO2021094213A1 (en) | Striking mechanism assembly | |

| US20070125564A1 (en) | Percussion power tool | |

| SU1253767A1 (en) | Arrangement for securing working tool in impact-action machine | |

| US4174848A (en) | Latching mechanism for reciprocating impact tools | |

| US1613399A (en) | Chisel retainer for riveting hammers | |

| EP0684095A1 (en) | Punching tool |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): CH DE FR GB IT LI |

|

| 17P | Request for examination filed |

Effective date: 19840221 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): CH DE FR GB IT LI |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Withdrawal date: 19850402 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: PUOLAKAINEN, NIKOLAI |