EP0278419A2 - Waterproof sealing mat, essentially composed of a supporting layer, and intermediate layer of expandable clay, and a covering layer - Google Patents

Waterproof sealing mat, essentially composed of a supporting layer, and intermediate layer of expandable clay, and a covering layer Download PDFInfo

- Publication number

- EP0278419A2 EP0278419A2 EP88101679A EP88101679A EP0278419A2 EP 0278419 A2 EP0278419 A2 EP 0278419A2 EP 88101679 A EP88101679 A EP 88101679A EP 88101679 A EP88101679 A EP 88101679A EP 0278419 A2 EP0278419 A2 EP 0278419A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- layer

- bentonite

- sealing mat

- intermediate layer

- carrier

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B9/00—Layered products comprising a layer of a particular substance not covered by groups B32B11/00 - B32B29/00

- B32B9/04—Layered products comprising a layer of a particular substance not covered by groups B32B11/00 - B32B29/00 comprising such particular substance as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B9/047—Layered products comprising a layer of a particular substance not covered by groups B32B11/00 - B32B29/00 comprising such particular substance as the main or only constituent of a layer, which is next to another layer of the same or of a different material made of fibres or filaments

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02B—HYDRAULIC ENGINEERING

- E02B3/00—Engineering works in connection with control or use of streams, rivers, coasts, or other marine sites; Sealings or joints for engineering works in general

- E02B3/04—Structures or apparatus for, or methods of, protecting banks, coasts, or harbours

- E02B3/12—Revetment of banks, dams, watercourses, or the like, e.g. the sea-floor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/022—Non-woven fabric

-

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D31/00—Protective arrangements for foundations or foundation structures; Ground foundation measures for protecting the soil or the subsoil water, e.g. preventing or counteracting oil pollution

- E02D31/002—Ground foundation measures for protecting the soil or subsoil water, e.g. preventing or counteracting oil pollution

- E02D31/004—Sealing liners

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B38/00—Ancillary operations in connection with laminating processes

- B32B2038/0052—Other operations not otherwise provided for

- B32B2038/008—Sewing, stitching

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/02—Synthetic macromolecular fibres

- B32B2262/0253—Polyolefin fibres

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/726—Permeability to liquids, absorption

- B32B2307/7265—Non-permeable

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2315/00—Other materials containing non-metallic inorganic compounds not provided for in groups B32B2311/00 - B32B2313/04

- B32B2315/16—Clay

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2471/00—Floor coverings

- B32B2471/04—Mats

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24942—Structurally defined web or sheet [e.g., overall dimension, etc.] including components having same physical characteristic in differing degree

- Y10T428/2495—Thickness [relative or absolute]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/26—Web or sheet containing structurally defined element or component, the element or component having a specified physical dimension

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/30—Woven fabric [i.e., woven strand or strip material]

- Y10T442/3707—Woven fabric including a nonwoven fabric layer other than paper

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/50—FELT FABRIC

- Y10T442/57—Including particulate material other than fiber

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/60—Nonwoven fabric [i.e., nonwoven strand or fiber material]

- Y10T442/608—Including strand or fiber material which is of specific structural definition

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/60—Nonwoven fabric [i.e., nonwoven strand or fiber material]

- Y10T442/659—Including an additional nonwoven fabric

- Y10T442/666—Mechanically interengaged by needling or impingement of fluid [e.g., gas or liquid stream, etc.]

- Y10T442/667—Needled

Definitions

- the present invention relates to a water-impermeable sealing mat which is preferably suitable for water and landfill construction and which essentially consists of a carrier layer, an intermediate layer of swellable clay and a top layer, and a process for its production.

- Such sealing mats are known from European patent 0 059 625, in which a flexible carrier layer carries a bentonite intermediate layer, on which in turn a cover layer can be located. All three layers, i.e. the backing layer, which can be a nonwoven fabric, the bentonite intermediate layer and the cover layer, which can be an unspecified mat, are connected to one another by means of an adhesive.

- the backing layer which can be a nonwoven fabric

- the bentonite intermediate layer and the cover layer which can be an unspecified mat

- sealing mats lose flexibility due to the use of the adhesive that solidifies the individual layers, which has a particularly disadvantageous effect on deformations of the subsoil of earthworks.

- these prior art sealing mats have the disadvantage that the bentonite intermediate layer located therein can expand freely in all three dimensions when moistened, which often leads to cracks forming in the bentonite intermediate layer, which in turn makes the mats permeable to water.

- the object of the present invention is therefore to produce an absolutely watertight mat and to design the method in such a way that the use of an adhesive can be dispensed with.

- the carrier and / or the top layer a nonwoven fabric and the layer, which may not consist of a nonwoven fabric, consists of a woven or knitted fabric and (b) all three layers are needled together.

- Both the backing layer and the cover layer preferably consist of a nonwoven fabric.

- the backing layer consists of a nonwoven fabric and the top layer consists of a woven or knitted fabric or the top layer consists of a nonwoven fabric and the backing layer consists of a woven or knitted fabric.

- the procedure is such that first the intermediate layer of dry, swellable clay is applied to the carrier layer and then the cover layer is applied and then all three layers are needled in a needle chair.

- the nonwovens used according to the invention preferably consist of quality plastic fibers, in particular of polyethylene, polypropylene, polyester, polyacrylic and / or polyamide fibers.

- Nonwovens made of high density polyethylene (HDPE) are particularly preferred in the field of landfill technology.

- Such nonwovens are absolutely rot-proof (resistant to all substances found in water and soil) and thus verifiably guarantee an extremely long service life.

- Their extremely high tensile strength means that they are largely insensitive to mechanical stress. They are highly UV-stable and have a high specific weight (great advantage when underwater installation).

- the nonwovens used according to the invention are preferably mechanically consolidated Spunbonded nonwovens. They are constructed in such a way that the crimped fibers form a flat structure with innumerable labyrinthine passages.

- the floor structure is ideally reproduced.

- the structure of the nonwovens can be adjusted coarser or finer depending on the nature of the soil, so that an optimal adaptation to the type of soil is guaranteed.

- the mechanical strengthening guarantees a high coefficient of friction between the existing floor and the nonwoven and the cover.

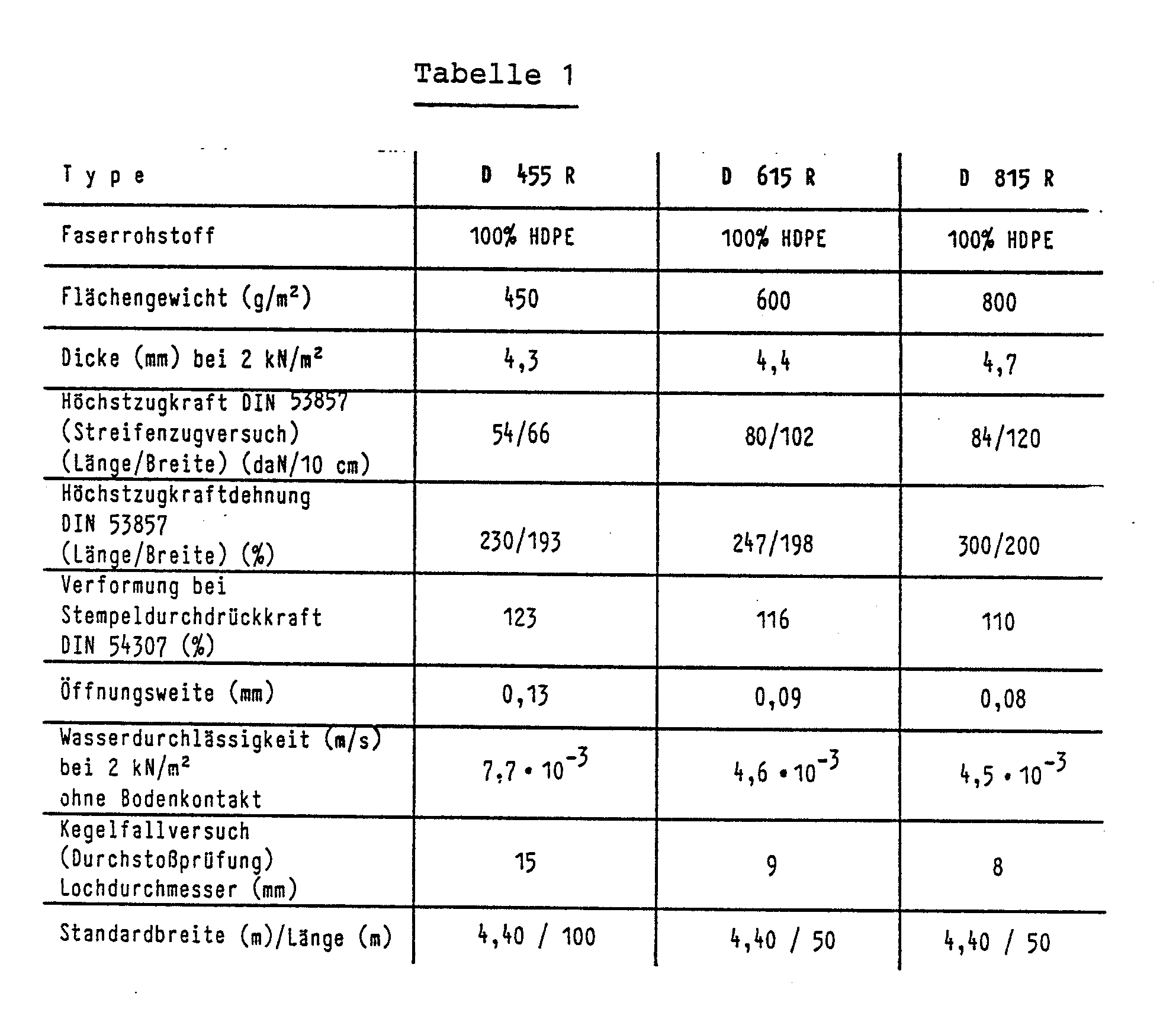

- Nonwovens used in accordance with the invention include, for example, those as can be seen from Tables 1 and 2 below.

- the intermediate layer made of swellable clay preferably consists of bentonites.

- Bentonites are clays with a noticeable to high content of smectite (montmorillonite), which determines the properties (high swellability, good water binding capacity, high plasticity).

- the Alkaline earth ions of the bentonites replaced by alkali ions, preferably sodium ions.

- sodium bentonite with its greatly increased plasticity, viscosity, thixotropy and water absorption is therefore preferred as the "highly swellable" active bentonite.

- the bentonites can be present in the intermediate layer as powder and / or granules.

- the granulate particles can have a grain size of greater than 2.5 mm. Of course, they can also be smaller.

- a reduction in the water permeability of the sealing mats according to the invention can be achieved by first applying a floury bentonite to the support layer during production and, if appropriate, shaking it in and then only applying the granular bentonite granules.

- a floury bentonite instead of shaking the floury bentonite into the carrier layer, one can also proceed by first impregnating the carrier layer with an aqueous bentonite suspension or rolling on an aqueous bentonite paste and only then, if necessary after prior drying, applying the granular bentonite granules.

- the top layer can also be treated in the same way as the carrier layer before it is applied. For some applications, you can even use the carrier or cover layer pretreated in this way alone as a sealing mat.

- the thickness of the bentonite intermediate layer is preferably 0.5 to 10.0 mm, depending on the application. However, it can also be smaller or larger, which also depends, for example, on whether or not the carrier and / or top layer, as stated above, has been pretreated with finely divided bentonites.

- the desired firm mechanical cohesion of the three layers of the sealing mat according to the invention is obtained with simultaneous switching off of the adhesive used according to the prior art.

- the needling on the inner surface facing the bentonite intermediate layer and the underlying zones of the nonwovens results in an intensive mixing of fibers and bentonite.

- the firm needling connection gives a swelling back pressure which, in conjunction with the intensive mixing of fibers and bentonite described above, guarantees that the sealing mats according to the invention are impermeable to water.

- the needling also ensures the flexibility of the sealing mats, whose flexibility comes close to the good deformability properties of the mechanically consolidated nonwovens.

- the waterproof sealing mats according to the invention are used in particular in water and landfill construction.

- the sealing mats After the large-area laying of the sealing mats produced in this way at the place of use, the sealing mats can be welded or sewn together at their edges with which they meet, which also ensures at the abutting edges that the bentonite intermediate layer 3 forms a swelling at the abutting edges connected continuous water-impermeable intermediate layer.

- a waterproof overlap is also achieved by inserting a bentoni track between the overlapping areas and then pressing these areas together.

- a nonwoven fabric 1004 R is used as the carrier layer 2 and a nonwoven fabric 201-3 with the following layers is used as the cover layer 4 specified values:

- the non-woven fabric 1004 R has been a tried and tested hydraulic engineering mat for years.

- the production width is usually 4.80 m. It is a composite of two nonwoven layers, namely a filter layer made of polyester (PES; approx. 70% of the total weight) and a coarse fiber layer made of polypropylene fibers (approx. 30% of the total weight). The fibers are mechanically consolidated by needling.

- This two-layer composite fleece serving as carrier layer 2 has a layer thickness of greater than 6.0 mm.

- the non-woven fabric 201-3 is a single-layer non-woven fabric made of 100% polyester fibers. As can be seen from the table above, the weight per unit area is approx. 225 g / m2 and the layer thickness is approx. 2.8 mm. The produc tion width is also usually 4.80 m.

- the bentonite intermediate layer 4 consists of an activated sodium bentonite, which is applied in an amount of approx. 2500 g / m2, which corresponds to a layer thickness of approx. 1 to 2 mm.

- a roll of nonwoven fabric 1004 R is rolled out over a winding block and fed to a needle chair 7 as carrier layer 2.

- a weighed amount of dry bentonite with a grain size of a few millimeters is applied to the carrier layer 2.

- a roll of nonwoven material 201-3 is fed to the bentonite intermediate layer 3 as a cover layer 4 via a further winding block.

- the needle chair 7 has one or more needle boards. Each needle board is equipped with thousands of needles. The needle boards are moved up and down very quickly (up to approx. 1000 strokes per minute).

- the needles equipped with notches pierce the nonwoven layers 2, 4 and the bentonite intermediate layer 3, the notches ensuring that the individual fibers are entwined with one another, so that a firm bond is created. Since the needling process is not vibration-free, part of the bentonite applied penetrates into the nonwoven layers, in particular into the pores of the coarse fiber layer of the carrier layer 2 facing the bentonite intermediate layer 3.

- the sealing mat obtained after leaving the needle chair 7 is wound again on a roll and for on transported to the place of installation, where, after laying and moistening, it fulfills the function of a waterproof sealing mat.

- the nonwovens specified in Table 1, which consist of high-density polyethylene fibers, are used for both the backing layer 2 and the top layer 4.

- Carrier layer 2 and cover layer 4 can be the same or different.

Abstract

Description

Die vorliegende Erfindung betrifft eine vorzugsweise für den Wasser- und Deponiebau geeignete wasserundurchlässige Dichtungsmatte, die im wesentlichen aus einer Trägerschicht, einer Zwischenschicht aus quellfähigem Ton und einer Deckschicht besteht, sowie ein Verfahren zu ihrer Herstellung.The present invention relates to a water-impermeable sealing mat which is preferably suitable for water and landfill construction and which essentially consists of a carrier layer, an intermediate layer of swellable clay and a top layer, and a process for its production.

Derartige Dichtungsmatten sind aus der europäischen Patentschrift 0 059 625 bekannt, bei der eine flexible Trägerschicht eine Bentonit-Zwischenschicht trägt, auf der sich wiederum eine Deckschicht befinden kann. Alle drei Schichten, d.h. die Trägerschicht, die ein Vliesstoff sein kann, die Bentonit-Zwischenschicht und die Abdeckschicht, die eine nicht näher definierte Matte sein kann, sind mittels eines Klebstoffes miteinander verbunden. Ein solches Produkt ist nicht nur in seiner Herstellung durch die Verwendung eines Klebstoffes nachteilig, sondern insbesondere dadurch, weil sowohl die Trägerschicht als auch die Deckschicht nur über die Bentonit-Zwischenschicht miteinander verbunden sind. Darüberhinaus verlieren derartige Dichtungsmatten durch die Verwendung des Klebstoffes, der die einzelnen Schichten verfestigt, an Flexibilität, was sich insbesondere bei Verformungen des Untergrundes von Erdbauwerken sehr nachteilig bemerkbar macht. Außerdem zeigen diese Dichtungsmatten des Standes der Technik den Nachteil, daß sich die in ihr befindliche Bentonit-Zwischenschicht beim Befeuchten in allen drei Dimensionen frei ausdehnen kann, wodurch es häufig zu Rissbildungen in der Bentonit-Zwischenschicht kommt, was wiederum die Matten wasserdurchlässig macht.Such sealing mats are known from European patent 0 059 625, in which a flexible carrier layer carries a bentonite intermediate layer, on which in turn a cover layer can be located. All three layers, i.e. the backing layer, which can be a nonwoven fabric, the bentonite intermediate layer and the cover layer, which can be an unspecified mat, are connected to one another by means of an adhesive. Such a product is disadvantageous not only in its manufacture due to the use of an adhesive, but in particular because both the carrier layer and the cover layer are connected to one another only via the bentonite intermediate layer. In addition, such sealing mats lose flexibility due to the use of the adhesive that solidifies the individual layers, which has a particularly disadvantageous effect on deformations of the subsoil of earthworks. In addition, these prior art sealing mats have the disadvantage that the bentonite intermediate layer located therein can expand freely in all three dimensions when moistened, which often leads to cracks forming in the bentonite intermediate layer, which in turn makes the mats permeable to water.

Aufgabe der vorliegenden Erfindung ist es daher, eine absolut wasserdichte Matte herzustellen, und dabei das Verfahren so zu gestalten, daß auf die Verwendung eines Klebstoffes verzichtet werden kann.The object of the present invention is therefore to produce an absolutely watertight mat and to design the method in such a way that the use of an adhesive can be dispensed with.

Gelöst wird diese Aufgabe gemäß der vorliegenden Erfindung dadurch, daß (a) die Träger- und/oder die Deckschicht aus einem Vliesstoff und die gegebenenfalls nicht aus einem Vliesstoff bestehende Schicht aus einem Gewebe oder Gewirke besteht und (b) alle drei Schichten miteinander vernadelt sind.This object is achieved according to the present invention in that (a) the carrier and / or the top layer a nonwoven fabric and the layer, which may not consist of a nonwoven fabric, consists of a woven or knitted fabric and (b) all three layers are needled together.

Vorzugsweise besteht sowohl die Trägerschicht als auch die Deckschicht aus einem Vliesstoff. Es kann aber auch ein solcher Aufbau gewünscht sein, bei dem die Trägerschicht aus einem Vliesstoff und die Deckschicht aus einem Gewebe oder Gewirke oder die Deckschicht aus einem Vliesstoff und die Trägerschicht aus einem Gewebe oder Gewirke besteht.Both the backing layer and the cover layer preferably consist of a nonwoven fabric. However, such a construction may also be desired in which the backing layer consists of a nonwoven fabric and the top layer consists of a woven or knitted fabric or the top layer consists of a nonwoven fabric and the backing layer consists of a woven or knitted fabric.

Bei dem erfindungsgemäß beanspruchten, vorzugsweise kontinuierlich arbeitenden Verfahren geht man so vor, daß man auf die Trägerschicht zunächst die Zwischenschicht aus trockenem, quellfähigen Ton und dann darauf die Deckschicht aufbringt und anschließend alle drei Schichten in einem Nadelstuhl vernadelt.In the process according to the invention, which is preferably operated continuously, the procedure is such that first the intermediate layer of dry, swellable clay is applied to the carrier layer and then the cover layer is applied and then all three layers are needled in a needle chair.

Die erfindungsgemäß verwendeten Vliesstoffe bestehen vorzugsweise aus Qualitäts-Kunststoff-Fasern, insbesondere aus Polyethylen-, Polypropylen-, Polyester-, Polyacryl- und/oder Polyamidfasern. Besonders bevorzugt im Einsatzgebiet der Deponietechnik sind Vliesstoffe aus Polyethylen hoher Dichte (HDPE).The nonwovens used according to the invention preferably consist of quality plastic fibers, in particular of polyethylene, polypropylene, polyester, polyacrylic and / or polyamide fibers. Nonwovens made of high density polyethylene (HDPE) are particularly preferred in the field of landfill technology.

Derartige Vliesstoffe sind absolut verrottungsfest (resistent gegen alle im Gewässer und im Boden vorkommenden Substanzen) und gewährleisten somit nachweislich eine extrem hohe Lebensdauer. Ihre überaus hohe Reißfestigkeit bewirkt eine weitgehende Unempfindlichkeit gegen mechanische Beanspruchungen. Sie sind hochgradig UV-stabil und haben ein hohes spezifisches Gewicht (großer Vorteil beim Unterwassereinbau).Such nonwovens are absolutely rot-proof (resistant to all substances found in water and soil) and thus verifiably guarantee an extremely long service life. Their extremely high tensile strength means that they are largely insensitive to mechanical stress. They are highly UV-stable and have a high specific weight (great advantage when underwater installation).

Im Aufbau handelt es sich bei den erfindungsgemäß eingesetzten Vliesstoffen vorzugsweise um mechanisch verfestigte Spinnfaservliese. Sie sind so aufgebaut, daß die gekräuselt zusammengefügten Fasern ein Flächengebilde mit unzähligen labyrinthartigen Gängen bilden. Hierbei wird die Bodenstruktur ideal nachgebildet. Das Gefüge der Vliesstoffe läßt sich je nach der Bodenbeschaffenheit gröber oder feiner einstellen, so daß eine optimale Anpassung an die anstehende Bodenart gewährleistet ist. Die mechanische Verfestigung garantiert einen hohen Reibungswert zwischen dem anstehenden Boden und dem Vliesstoff sowie der Abdeckung. Anstelle der durch Vernadelung mechanisch verfestigten Vliesstoffe kann man auch solche Vliesstoffe einsetzen, die mittels der Nähwirktechnik oder durch Verwirbelung mechanisch verfestigt wurden oder chemisch verfestigt wurden.In terms of structure, the nonwovens used according to the invention are preferably mechanically consolidated Spunbonded nonwovens. They are constructed in such a way that the crimped fibers form a flat structure with innumerable labyrinthine passages. The floor structure is ideally reproduced. The structure of the nonwovens can be adjusted coarser or finer depending on the nature of the soil, so that an optimal adaptation to the type of soil is guaranteed. The mechanical strengthening guarantees a high coefficient of friction between the existing floor and the nonwoven and the cover. Instead of the nonwovens mechanically consolidated by needling, it is also possible to use those nonwovens which have been mechanically consolidated or chemically consolidated by means of sewing technology or by swirling.

Zu erfindungsgemäß eingesetzten Vliesstoffen gehören beispielsweise solche, wie sie aus den nachfolgenden Tabellen 1 und 2 ersichtlich sind.

Die Zwischenschicht aus quellfähigem Ton besteht vorzugsweise aus Bentoniten. Bentonite sind Tone mit merklichem bis hohem Gehalt an Smectit (Montmorillonit), der die Eigenschaften (hohe Quellbarkeit, gutes Wasserbindevermögen, hohe Plastizität) maßgebend bestimmt. Um aus einem in Wasser wenig quellfähigen Erdalkali-Bentonit einen hochquellfähigen Aktivbentonit zu erhalten, werden die Erdalkaliionen der Bentonite durch Alkaliionen, vorzugsweise Natriumionen, ersetzt. Als "hochquellfähiger" Aktivbentonit wird daher Natrium-Bentonit mit seiner stark erhöhten Plastizität, Viskosität, Thixotropie und Wasseraufnahme, gemäß der vorliegenden Erfindung, bevorzugt.The intermediate layer made of swellable clay preferably consists of bentonites. Bentonites are clays with a noticeable to high content of smectite (montmorillonite), which determines the properties (high swellability, good water binding capacity, high plasticity). In order to obtain a highly swellable active bentonite from an alkaline earth bentonite with little swellable in water, the Alkaline earth ions of the bentonites replaced by alkali ions, preferably sodium ions. According to the present invention, sodium bentonite with its greatly increased plasticity, viscosity, thixotropy and water absorption is therefore preferred as the "highly swellable" active bentonite.

Die Bentonite können in der Zwischenschicht als Pulver und/oder Granulat vorliegen. Beim Einsatz von Granulat können die Granulatteilchen eine Korngröße von größer als 2,5 mm haben. Sie können selbstverständlich aber auch kleiner sein.The bentonites can be present in the intermediate layer as powder and / or granules. When using granulate, the granulate particles can have a grain size of greater than 2.5 mm. Of course, they can also be smaller.

Außerdem läßt sich eine Verminderung der Wasserdurchlässigkeit der erfindungsgemäßen Dichtungsmatten dadurch erreichen, daß man bei der Herstellung zunächst auf die Trägerschicht einen mehligen Bentonit aufbringt und gegebenenfalls einrüttelt und dann erst das körnige Bentonitgranulat aufbringt. Anstelle des Einrüttelns des mehligen Bentonits in die Trägerschicht kann man auch so verfahren, daß man die Trägerschicht zunächst mit einer wässrigen Bentonit-Suspension imprägniert oder eine wässrige Bentonitpaste aufwalzt und dann erst, gegebenenfalls nach vorheriger Trocknung, das körnige Bentonitgranulat aufbringt. Gewünschtenfalls kann man die Deckschicht vor ihrer Aufbringung ebenfalls in der vorstehenden Weise wie die Trägerschicht behandeln. Für manche Anwendungszwecke kann man sogar die auf diese Weise vorbehandelte Träger- oder Deckschicht allein als Dichtungsmatte einsetzen.In addition, a reduction in the water permeability of the sealing mats according to the invention can be achieved by first applying a floury bentonite to the support layer during production and, if appropriate, shaking it in and then only applying the granular bentonite granules. Instead of shaking the floury bentonite into the carrier layer, one can also proceed by first impregnating the carrier layer with an aqueous bentonite suspension or rolling on an aqueous bentonite paste and only then, if necessary after prior drying, applying the granular bentonite granules. If desired, the top layer can also be treated in the same way as the carrier layer before it is applied. For some applications, you can even use the carrier or cover layer pretreated in this way alone as a sealing mat.

Die Dicke der Bentonit-Zwischenschicht beträgt je nach Anwendungszweck vorzugsweise 0,5 bis 10,0 mm. Sie kann aber auch kleiner oder größer sein, was sich z.B. auch danach richtet, ob die Träger- und/oder Deckschicht, wie vorstehend angegeben, mit feinstteiligen Bentoniten vorbehandelt wurde oder nicht.The thickness of the bentonite intermediate layer is preferably 0.5 to 10.0 mm, depending on the application. However, it can also be smaller or larger, which also depends, for example, on whether or not the carrier and / or top layer, as stated above, has been pretreated with finely divided bentonites.

Durch die Vernadelung der drei Schichten im Nadelstuhl erhält man den gewünschten festen mechanischen Zusammenhalt der drei Schichten der erfindungsgemäßen Dichtungsmatte unter gleichzeitiger Ausschaltung des gemäß dem Stande der Technik eingesetzten Klebstoffes. Gleichzeitig ergeben sich dadurch weitere wesentliche Vorteile. Selbst wenn Träger- und/oder Deckschicht nicht, wie vorstehend beschrieben, vorbehandelt wurden, erhält man durch die Vernadelung an den der Bentonit-Zwischenschicht zugewandten Innenoberfläche und den darunter liegenden Zonen der Vliesstoffe eine intensive Vermischung von Fasern und Bentonit. Außerdem erhält man durch die feste Vernadelungsverbindung beim Aufquellen des Bentonits durch Befeuchten einen Quellgegendruck, der in Verbindung mit der vorstehend geschilderten intensiven Vermischung von Fasern und Bentonit eine Wasserundurchlässigkeit der erfindungsgemäßen Dichtungsmatten garantiert. Durch die Vernadelung wird ferner die Flexibilität der Dichtungsmatten gewährleistet, die in ihrer Flexibilität den guten Verformbarkeitseigenschaften der mechanisch verfestigten Vliesstoffe nahekommt.By needling the three layers in the needle chair, the desired firm mechanical cohesion of the three layers of the sealing mat according to the invention is obtained with simultaneous switching off of the adhesive used according to the prior art. At the same time, there are other significant advantages. Even if the backing and / or top layer have not been pretreated as described above, the needling on the inner surface facing the bentonite intermediate layer and the underlying zones of the nonwovens results in an intensive mixing of fibers and bentonite. In addition, when the bentonite is swollen by moistening, the firm needling connection gives a swelling back pressure which, in conjunction with the intensive mixing of fibers and bentonite described above, guarantees that the sealing mats according to the invention are impermeable to water. The needling also ensures the flexibility of the sealing mats, whose flexibility comes close to the good deformability properties of the mechanically consolidated nonwovens.

Die erfindungsgemäßen wasserundurchlässigen Dichtungsmatten finden insbesondere im Wasser- und Deponiebau Anwendung.The waterproof sealing mats according to the invention are used in particular in water and landfill construction.

Die vorliegende Erfindung wird weiterhin anhand der Fig. 1 und 2 und der nachfolgenden Beispiele erläutert, ohne sie jedoch darauf zu beschränken.

- Fig. 1 zeigt im Querschnitt einen Teil der erfindungsgemäßen Dichtungsmatte 1;

- Fig. 2 zeigt in schematischer Darstellung im Längsschnitt die kontinuierliche Herstellung der erfindungsgemäßen wasserundurchlässigen Dichtungsmatte 1. Von einem

Vorratssilo 6 wird der Bentonit als Bentonit-Zwischenschicht 3 auf die von einer nicht dargestellten Vorratsrolle abgewickelte Trägerschicht 2 (Vliesstoff) aufgebracht. Im Anschluß daran wird die ebenfalls von einer nicht dargestellten Vorratsrolle abgewickelte Deckschicht 4 (auch Vliesstoff) auf die Bentonit-Zwischenschicht 3 aufgebracht. Das so erhaltene aus drei Schichten bestehende Flächengebilde wird durch einen Nadelstuhl 7 geführt, in dem alle drei Schichten in üblicher Weise vernadelt werden. Je nach Schichtdicke der Bentonit-Zwischenschicht 3 wird das vernadelte Flächengebilde, das die wasserundurchlässige Dichtungsmatte 1 darstellt, auf Rolle gewickelt oder jeweils in der gewünschten Länge abgeschnitten.

- Fig. 1 shows in cross section a part of the sealing mat 1 according to the invention;

- 2 shows a schematic representation in longitudinal section of the continuous production of the waterproof sealing mat 1 according to the invention. The bentonite is applied as a bentonite intermediate layer 3 from a

storage silo 6 to the carrier layer 2 (nonwoven fabric) unwound from a supply roll (not shown). Subsequently, the cover layer 4 (also nonwoven), which is also unwound from a supply roll (not shown), is applied to the bentonite intermediate layer 3. The three-layer fabric thus obtained is passed through a needle chair 7 in which all three layers are needled in the usual way. Depending on the layer thickness of the bentonite intermediate layer 3, the needled fabric, which is the waterproof sealing mat 1, is wound on a roll or cut to the desired length.

Nach der großflächigen Verlegung der so hergestellten Dichtungsmatten am Einsatzort können die Dichtungsmatten an ihren Rändern, mit denen sie aneinanderstoßen, miteinander verschweißt oder zusammengenäht werden, wodurch auch an den Stoßkanten gewährleistet ist, daß sich die Bentonit-Zwischenschicht 3 beim Aufquellen an den Stoßkanten zu einer zusammenhängenden wasserundurchlässigen Zwischenschicht verbindet. Eine wasserdichte Überlappung erreicht man auch dadurch, daß man zwischen den sich überlappenden Bereichen eine Bentonitraupe einbringt und dann diese Bereiche zusammenpreßt.After the large-area laying of the sealing mats produced in this way at the place of use, the sealing mats can be welded or sewn together at their edges with which they meet, which also ensures at the abutting edges that the bentonite intermediate layer 3 forms a swelling at the abutting edges connected continuous water-impermeable intermediate layer. A waterproof overlap is also achieved by inserting a bentoni track between the overlapping areas and then pressing these areas together.

Zur Herstellung einer Dichtungsmatte für Wasserbau verwendet man als Trägerschicht 2 einen Vliesstoff 1004 R und als Deckschicht 4 einen Vliesstoff 201-3 mit den nachfol gend angegebenen Kennwerten:

Der Vliesstoff 1004 R ist eine seit Jahren eingesetzte und bewährte Wasserbaumatte. Die Produktionsbreite beträgt in der Regel 4,80 m. Er stellt einen Verbundstoff aus zwei Vliesstoffschichten dar, und zwar aus einer Filterschicht aus Polyester (PES; ca. 70 % Anteil am Gesamtgewicht) und einer Grobfaserschicht aus Polypropylenfasern (ca. 30 % Anteil am Gesamtgewicht). Die Fasern sind durch Vernadeln rein mechanisch verfestigt. Dieser als Trägerschicht 2 dienende Zweischicht-Verbundvlies hat eine Schichtdicke von größer als 6,0 mm.The non-woven fabric 1004 R has been a tried and tested hydraulic engineering mat for years. The production width is usually 4.80 m. It is a composite of two nonwoven layers, namely a filter layer made of polyester (PES; approx. 70% of the total weight) and a coarse fiber layer made of polypropylene fibers (approx. 30% of the total weight). The fibers are mechanically consolidated by needling. This two-layer composite fleece serving as carrier layer 2 has a layer thickness of greater than 6.0 mm.

Der Vliesstoff 201-3 ist ein einschichtiger Vliesstoff aus 100 % Polyesterfasern. Wie aus der vorstehenden Tabelle ersichtlich, beträgt das Flächengewicht ca. 225 g/m² und die Schichtdicke ca. 2,8 mm. Die Produk tionsbreite beträgt in der Regel ebenfalls 4,80 m.The non-woven fabric 201-3 is a single-layer non-woven fabric made of 100% polyester fibers. As can be seen from the table above, the weight per unit area is approx. 225 g / m² and the layer thickness is approx. 2.8 mm. The produc tion width is also usually 4.80 m.

Die Bentonit-Zwischenschicht 4 besteht aus einem aktivierten Natrium-Bentonit, das in einer Menge von ca. 2500 g/m² aufgebracht wird, was einer Schichtdicke von ca. 1 bis 2 mm entspricht.The bentonite intermediate layer 4 consists of an activated sodium bentonite, which is applied in an amount of approx. 2500 g / m², which corresponds to a layer thickness of approx. 1 to 2 mm.

Bei der Herstellung geht man wie folgt vor:The process is as follows:

Eine Rolle Vliesstoff 1004 R wird über einen Wickelblock abgerollt und als Trägerschicht 2 einem Nadelstuhl 7 zugeführt. Während des Abrollvorganges wird eine abgewogene Menge trockenen Bentonits mit einer Korngröße von wenigen Millimetern auf die Trägerschicht 2 aufgebracht. Gleichzeitig wird eine Rolle Vliesstoff 201-3 über einen weiteren Wickelblock als Deckschicht 4 der Bentonit-Zwischenschicht 3 zugeführt. Diese drei Schichten durchlaufen dann den Nadelstuhl 7 und werden dort mechanisch fest miteinander verbunden.A roll of nonwoven fabric 1004 R is rolled out over a winding block and fed to a needle chair 7 as carrier layer 2. During the rolling process, a weighed amount of dry bentonite with a grain size of a few millimeters is applied to the carrier layer 2. At the same time, a roll of nonwoven material 201-3 is fed to the bentonite intermediate layer 3 as a cover layer 4 via a further winding block. These three layers then pass through the needle chair 7 and are mechanically firmly connected to one another there.

Der Nadelstuhl 7 weist ein oder mehrere Nadelbretter auf. Jedes Nadelbrett ist mit tausenden von Nadeln ausgerüstet. Die Nadelbretter werden sehr schnell auf und ab geführt (bis ca. 1000 Hübe je Minute). Die mit Einkerbungen ausgestatteten Nadeln durchstechen die Vliesstoffschichten 2, 4 und die Bentonit-Zwischenschicht 3, wobei die Einkerbungen dafür sorgen, daß die einzelnen Fasern miteinander verschlungen werden, so daß ein fester Verbund entsteht. Da der Vernadelungsvorgang nicht vibrationsfrei ist, dringt ein Teil des aufgebrachten Bentonits in die Faservliesschichten, insbesondere in die Poren die der Bentonit-Zwischenschicht 3 zugewandten Grobfaserschicht der Trägerschicht 2 ein.The needle chair 7 has one or more needle boards. Each needle board is equipped with thousands of needles. The needle boards are moved up and down very quickly (up to approx. 1000 strokes per minute). The needles equipped with notches pierce the nonwoven layers 2, 4 and the bentonite intermediate layer 3, the notches ensuring that the individual fibers are entwined with one another, so that a firm bond is created. Since the needling process is not vibration-free, part of the bentonite applied penetrates into the nonwoven layers, in particular into the pores of the coarse fiber layer of the carrier layer 2 facing the bentonite intermediate layer 3.

Die nach Verlassen des Nadelstuhls 7 erhaltene Dichtungsmatte wird wieder auf eine Rolle gewickelt und zum Ein satzort transportiert, wo sie nach Verlegung und Befeuchtung die Funktion als wasserundurchlässige Dichtungsmatte erfüllt.The sealing mat obtained after leaving the needle chair 7 is wound again on a roll and for on transported to the place of installation, where, after laying and moistening, it fulfills the function of a waterproof sealing mat.

Zur Herstellung einer wasserundurchlässigen Dichtungsmatte für den Deponiebau verwendet man sowohl für die Trägerschicht 2 als auch für die Deckschicht 4 die in Tabelle 1 angegebenen Vliesstoffe, die aus Polyethylenfasern hoher Dichte bestehen. Trägerschicht 2 und Deckschicht 4 können dabei gleich oder unterschiedlich sein.For the production of a water-impermeable sealing mat for landfill construction, the nonwovens specified in Table 1, which consist of high-density polyethylene fibers, are used for both the backing layer 2 and the top layer 4. Carrier layer 2 and cover layer 4 can be the same or different.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT88101679T ATE75275T1 (en) | 1987-02-13 | 1988-02-05 | WATERPROOF SEALING MAT, CONSISTING ESSENTIALLY OF A BASE LAYER, AN INTERMEDIATE LAYER OF SWELLING CLAY AND A TOP LAYER. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3704503A DE3704503C3 (en) | 1987-02-13 | 1987-02-13 | Waterproof sealing mat |

| DE3704503 | 1987-02-13 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0278419A2 true EP0278419A2 (en) | 1988-08-17 |

| EP0278419A3 EP0278419A3 (en) | 1989-03-29 |

| EP0278419B1 EP0278419B1 (en) | 1992-04-22 |

Family

ID=6320897

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88101679A Expired - Lifetime EP0278419B1 (en) | 1987-02-13 | 1988-02-05 | Waterproof sealing mat, essentially composed of a supporting layer, and intermediate layer of expandable clay, and a covering layer |

Country Status (15)

| Country | Link |

|---|---|

| US (1) | US5041330A (en) |

| EP (1) | EP0278419B1 (en) |

| AT (1) | ATE75275T1 (en) |

| AU (1) | AU604839B2 (en) |

| CA (1) | CA1310569C (en) |

| DE (2) | DE3704503C3 (en) |

| DK (1) | DK164957C (en) |

| ES (1) | ES2031166T3 (en) |

| FI (1) | FI88064C (en) |

| GB (1) | GB2202185B (en) |

| GR (1) | GR3005195T3 (en) |

| HK (1) | HK45393A (en) |

| IE (1) | IE60781B1 (en) |

| NO (1) | NO168660C (en) |

| SG (1) | SG113592G (en) |

Cited By (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0381342A2 (en) * | 1989-02-01 | 1990-08-08 | Clem Environmental Corporation | Clay mixture having contamination resistance |

| EP0437723A2 (en) * | 1990-01-16 | 1991-07-24 | Hüls Troisdorf Aktiengesellschaft | Composite seal |

| EP0449182A2 (en) * | 1990-03-28 | 1991-10-02 | SERVIZI ECOLOGICI S.p.A. | Composite self-sealing membrane, particularly for the waterproofing of construction elements, pits, tanks and the like, and process for the manufacture thereof |

| EP0490529A1 (en) * | 1990-12-11 | 1992-06-17 | James Clem Corporation | Clay liner for steep slopes |

| EP0491453A1 (en) * | 1990-12-17 | 1992-06-24 | Amcol International Corporation | Waterproofing material |

| EP0491454A1 (en) * | 1990-12-17 | 1992-06-24 | Amcol International Corporation | A method of manufacturing a multilayer article |

| WO1992010617A1 (en) * | 1990-12-06 | 1992-06-25 | Akzo Nv | Use of a protective mat for sealing webs |

| EP0522481A1 (en) * | 1991-07-11 | 1993-01-13 | SERVIZI ECOLOGICI S.p.A. | Sealing liner, Particularly for eliminating infiltrations |

| DE4133097A1 (en) * | 1991-10-05 | 1993-04-08 | Friedrich Geb | Filter bed mat - has layers of textile material and sand held in position by needle punching |

| EP0536475A1 (en) * | 1991-10-08 | 1993-04-14 | Paul Schreck | Waterimpervious liner to be used in civil engineering for the protection of soil from liquids |

| FR2699855A1 (en) * | 1992-12-31 | 1994-07-01 | Guiraud Patrick | Composite flexible sheet for dispensing water, absorbing oil or chemical liq. |

| AT398284B (en) * | 1991-05-10 | 1994-11-25 | Hofinger Rudolf G | METHOD FOR PRODUCING A SEALING MAT, AND SEALING MAT PRODUCED BY THIS PROCESS |

| US5389166A (en) * | 1990-12-17 | 1995-02-14 | American Colloid Company | Water barrier formed from a clay-fiber mat |

| EP0667417A1 (en) * | 1994-02-08 | 1995-08-16 | Rudolf G. Hofinger | Method for sealing an impervious barrier in soil |

| EP0684343A1 (en) * | 1994-05-27 | 1995-11-29 | Süd-Chemie Ag | Process for the production of impervious walls |

| EP0736633A1 (en) * | 1995-04-04 | 1996-10-09 | Claymax Corporation | Geosynthetic clay liner and method of manufacture thereof |

| WO1997006222A1 (en) * | 1995-08-03 | 1997-02-20 | Thomas Eichenauer | Mats with integrated rubber mulch |

| NL1014348C2 (en) | 2000-02-10 | 2001-08-13 | Louis Hubertus Maria Kreukels | Mat used for floor coverings comprises two carrier layers of and an intermediate pre-wetted layer of a swellable clay composition containing at least 50 wt.% extrudable calcium bentonite |

| US6537676B1 (en) | 1992-08-26 | 2003-03-25 | Rawell Group Holdings Limited | Waterproofing material and method of fabrication therefor |

| WO2004016425A3 (en) * | 2002-08-15 | 2004-04-29 | Paul Vogt | Sealing mat comprising a superabsorbent layer, method for the production thereof, use thereof, superabsorber, and hot melt adhesive |

| WO2008146074A1 (en) * | 2007-06-01 | 2008-12-04 | Laviosa Chimica Mineraria S.P.A. | Apparatus for making bentonitic needled geocomposite products |

| ITTV20080104A1 (en) * | 2008-08-05 | 2010-02-06 | Volteco S P A | WATERPROOF MEMBRANE, PARTICULARLY FOR THE INSULATION OF CONSTRUCTIONS SUBJECT TO HYDROSTATIC PRESSURE. |

| EP2199447A1 (en) * | 2008-12-19 | 2010-06-23 | Michael C. Dehn | Superabsorbent polymer felt and method for its manufacture |

| EP2439342A1 (en) | 2010-10-06 | 2012-04-11 | Naue GmbH & Co. KG | Reinforcement mesh |

| WO2016146709A1 (en) | 2015-03-17 | 2016-09-22 | Volteco S.P.A. | Self-repairing and self-sealing waterproof membrane, for insulating built structures subjected to hydrostatic pressure |

| US9516914B2 (en) | 2006-09-06 | 2016-12-13 | IQTEX Patentverwaltunq UG | Self-closing ventilation insert and method for producing it |

Families Citing this family (70)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USRE37295E1 (en) | 1987-02-13 | 2001-07-24 | Naue-Fasertechnik Gmbh & Co. Kg | Water and/or oil-impermeable sealing mat consisting substantially of a substrate layer, a layer of swellable clay and a cover layer |

| US5180255A (en) * | 1990-02-15 | 1993-01-19 | American Colloid Company | Moisture-impervious panel capable of delayed hydration |

| GB2243804A (en) * | 1990-03-06 | 1991-11-13 | Naue Fasertechnik | A water and/or oil-impermeable sealing mat |

| US5259698A (en) * | 1990-06-19 | 1993-11-09 | Maurice Garzon | Method for hiding from sight and protecting a dumping site |

| US5173344A (en) * | 1990-10-01 | 1992-12-22 | American Colloid Company | Article and method for sealing seams between water barrier articles |

| DE4033506C2 (en) * | 1990-10-21 | 1994-04-07 | Naue Fasertechnik | Method and device for laying underwater geotextiles in water |

| DE4119989C2 (en) * | 1991-06-18 | 1994-02-03 | Naue Fasertechnik | Radiation protection mat for the shielding of radioactive radiation |

| DE4122992A1 (en) * | 1991-07-11 | 1993-01-28 | Naue Fasertechnik | IMPROVED COMPOSITION IN THE OVERLAP AREA OF NEEDLED BENTONITE SEALING MATS |

| DE4122993A1 (en) * | 1991-07-11 | 1993-01-14 | Naue Fasertechnik | Sealing matting interlayer fibre bond strength enhancement - by needle bonding projecting thermoplastic fibres and tufts resin adhered at outer surfaces for swelling clay layer water and/or oil impermeability |

| DE4203861A1 (en) * | 1992-02-11 | 1993-08-12 | Naue Fasertechnik | WATER AND / OR OIL-RESISTANT SEALING MAT made of SOAKABLE CLAY |

| ATE127188T1 (en) * | 1992-04-02 | 1995-09-15 | Naue Fasertechnik | METHOD FOR PRODUCING A WATER AND/OR OIL-PERMEABLE SEALING MAT CONTAINING SWELLABLE CLAY. |

| SG50604A1 (en) * | 1992-08-26 | 1998-07-20 | Rawell Group Holdings Ltd | Water proofing liner |

| DE4317537A1 (en) * | 1993-05-26 | 1994-12-01 | Siemens Ag | Arrangement for sealing and monitoring a body, in particular a landfill site |

| DE4310317A1 (en) * | 1993-03-30 | 1994-10-06 | Siemens Ag | Arrangement for sealing and monitoring a body, in particular a landfill site |

| DE9412555U1 (en) * | 1993-06-18 | 1994-11-03 | Huels Troisdorf | Protective layer for landfill - and other seals |

| US5401552A (en) * | 1994-01-28 | 1995-03-28 | Slt Environmental, Inc. | Geocomposite liner |

| DE4418646A1 (en) * | 1994-05-27 | 1995-11-30 | Sued Chemie Ag | Swellable smectite sealing layer |

| US5589257A (en) * | 1995-05-08 | 1996-12-31 | Claymax Corporation | Low permeability geosynthetic clay liner and method of manufacture thereof |

| DE29516797U1 (en) * | 1995-10-24 | 1995-12-14 | Envirotec Handelsgesellschaft | Material for coating surfaces and cover layers with this material |

| US5788413A (en) * | 1996-03-28 | 1998-08-04 | I-Corp International, Inc. | Geocomposite membrane |

| US6009946A (en) * | 1997-11-14 | 2000-01-04 | Exploration Products Company, Llc | Device for sealing charges in shot holes and a method for using the same |

| DE19813611A1 (en) | 1998-03-27 | 1999-09-30 | Huesker Synthetic Gmbh & Co | Sealing mat |

| DE19816705A1 (en) * | 1998-04-15 | 1999-10-21 | Nabento Vliesstoff Gmbh | Sealing mat |

| DE19858180A1 (en) | 1998-12-17 | 2000-06-21 | Nabento Vliesstoff Gmbh | Sealing mat and method for manufacturing a sealing mat |

| US6284681B1 (en) * | 1999-03-05 | 2001-09-04 | Westinghouse Savannah River Company | Reactive composite compositions and mat barriers |

| DE19956783A1 (en) * | 1999-11-25 | 2001-05-31 | Huesker Synthetic Gmbh & Co | Shroud for use in coffin or other burials has an intermediate layer containing a microbiocidal powder or granulate to prevent escape of viruses or other microorganisms |

| DE10023906C2 (en) * | 2000-03-16 | 2003-06-05 | Marinus Zwiersen | Assembled flat sealant made of moist clay or the like and method for flat underwater sealing of an already existing waterway and device for carrying out this method |

| DE10020859A1 (en) * | 2000-04-28 | 2001-10-31 | Nabento Vliesstoff Gmbh | Drainage mat and method and device for its production |

| US6846532B1 (en) | 2001-02-15 | 2005-01-25 | Sonoco Development, Inc. | Laminate packaging material |

| US20020151241A1 (en) * | 2001-04-11 | 2002-10-17 | Sheahan Thomas Clair | Reactive geocomposite for remediating contaminated sediments |

| DE10156288A1 (en) * | 2001-11-19 | 2003-06-05 | Friedrich Geb | Sealing mat joining involves burning back mat edges so bentonite mat contents swell out and make contact along preferably overlapped mat edges. |

| GB2389560B (en) * | 2002-06-12 | 2005-04-13 | Rawell Group Holdings Ltd | Waterproofing material |

| US6857818B2 (en) * | 2002-08-02 | 2005-02-22 | Harry Bussey, Jr. | Drainage element for walls and septic tank systems |

| US20060009100A1 (en) * | 2004-07-08 | 2006-01-12 | Mcgroarty Bryan | Waterproofing membrane |

| DE102004039368A1 (en) | 2004-08-12 | 2006-03-02 | Naue Gmbh & Co.Kg | Method of applying plastic sealing sheets to the surfaces of hydraulic engineering concrete structures |

| CA2560602C (en) * | 2005-10-26 | 2007-07-31 | Albarrie Canada Limited | Textile barrier for containment of liquid hydrocarbons |

| US8287982B2 (en) * | 2006-06-12 | 2012-10-16 | Concrete Canvas Limited | Impregnated fabric |

| US20090317583A1 (en) * | 2006-08-01 | 2009-12-24 | Bnp Brinkmann Nadelfilz Produkte Gmbh & Co. Kg | Textile Sealing Membrane |

| US10016954B2 (en) | 2007-11-19 | 2018-07-10 | Amcol International Corporation | Self healing salt water barrier |

| US10012079B2 (en) | 2007-11-19 | 2018-07-03 | Amcol International Corporation | Self healing salt water barrier |

| BG110093A (en) * | 2008-03-26 | 2009-10-30 | Карен АРУТЮНЯН | Waterproofing bentonite membrane |

| NL1036062C (en) * | 2008-10-13 | 2010-04-14 | Bonno Koers | DEVICE FOR CLEANING GASES, SUCH AS SPECIAL AIR, OR LIQUIDS, SUCH AS SPECIAL WATER. |

| EP2213777A1 (en) | 2009-01-29 | 2010-08-04 | Concrete Canvas Limited | Impregnated cloth |

| US8318616B2 (en) | 2009-08-19 | 2012-11-27 | Amcol International Corporation | Salt water swellable compositions and articles |

| GB0920284D0 (en) * | 2009-11-19 | 2010-01-06 | Environmental Defence Systems Ltd | Method of manufacture of a barrage unit |

| ES2585334T3 (en) | 2011-03-31 | 2016-10-05 | Amcol International Corporation | Self-healing barrier against salt water |

| US10167635B2 (en) | 2011-11-01 | 2019-01-01 | Cortex Composites, Inc. | Nonwoven cementitious composite for In-Situ hydration |

| US10221569B2 (en) | 2011-11-01 | 2019-03-05 | Cortex Composites, Inc. | Cementitious composite constituent relationships |

| US9187902B2 (en) | 2011-11-01 | 2015-11-17 | Cortex Composites, Llc | Nonwoven cementitious composite for in-situ hydration |

| RU2523499C2 (en) * | 2012-07-05 | 2014-07-20 | Федеральное государственное бюджетное образовательное учреждение высшего профессионального образования "Новочеркасская государственная мелиоративная академия" (ФГБОУ ВПО НГМА) | Method for creating impervious coating with bentomates on subsiding soils |

| CN105492095B (en) | 2013-08-26 | 2017-08-15 | 红叶资源公司 | Gas transport compound barrier |

| US9529391B2 (en) | 2013-09-27 | 2016-12-27 | Apple Inc. | Button retention, assembly, and water sealing |

| WO2015047359A1 (en) | 2013-09-29 | 2015-04-02 | Bodhi Technology Ventures Llc | Waterproof port for electronic devices |

| US9980026B2 (en) | 2013-09-30 | 2018-05-22 | Apple Inc. | Method for clearing water from acoustic port and membrane |

| US11045847B2 (en) | 2013-10-29 | 2021-06-29 | Watershed Geosynthetics Llc | Geocomposite covering |

| US9573165B2 (en) * | 2014-08-22 | 2017-02-21 | Apple Inc. | Hydrophobic mesh cover |

| US9716934B2 (en) | 2015-04-24 | 2017-07-25 | Apple Inc. | Liquid ingress-redirecting acoustic device reservoir |

| US9627797B2 (en) | 2015-07-21 | 2017-04-18 | Apple Inc. | Ejection assembly with plug feature |

| US9780554B2 (en) | 2015-07-31 | 2017-10-03 | Apple Inc. | Moisture sensors |

| US10149396B2 (en) | 2015-09-30 | 2018-12-04 | Apple Inc. | Circuit assembly for an electronic device |

| AU2016349494A1 (en) | 2015-11-05 | 2018-05-17 | Cortex Composites, Inc. | Cementitious composite mat |

| US10784062B2 (en) | 2016-09-08 | 2020-09-22 | Apple Inc. | Ingress prevention for keyboards |

| US10595107B2 (en) | 2016-09-20 | 2020-03-17 | Apple Inc. | Speaker module architecture |

| RS60116B1 (en) * | 2017-04-28 | 2020-05-29 | Gda Spolka Z Ograniczona Odpowiedzialnoscia | Multilayer synthetic-mineral protective-levelling and/or sealing lining |

| US10165694B1 (en) | 2017-09-11 | 2018-12-25 | Apple Inc. | Concealed barometric vent for an electronic device |

| SG11202002793VA (en) | 2017-10-31 | 2020-04-29 | Univ Nanyang Tech | Bioslurry-induced water barrier and process of forming thereof |

| US11614716B2 (en) | 2019-09-23 | 2023-03-28 | Apple Inc. | Pressure-sensing system for a wearable electronic device |

| US11860585B2 (en) | 2020-06-17 | 2024-01-02 | Apple Inc. | Wearable electronic device with a compressible air-permeable seal |

| RU2770559C1 (en) * | 2021-01-28 | 2022-04-18 | Юрий Петрович Удалов | Composite waterproofing block and method for manufacture thereof |

| DE202022103585U1 (en) | 2022-06-28 | 2023-09-29 | Naue Gmbh & Co. Kg | Biodegradable soil sealing membrane |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2195237A5 (en) * | 1972-08-01 | 1974-03-01 | Bayer Ag | |

| US4048373A (en) * | 1974-05-23 | 1977-09-13 | American Colloid Company | Water barrier panel |

| US4344722A (en) * | 1981-01-13 | 1982-08-17 | Bemalux Inc. | Waterproofing barrier |

| US4565468A (en) * | 1983-10-24 | 1986-01-21 | Crawford Leslie A | Moisture impervient barrier and method for making same |

| DE3435983A1 (en) * | 1984-10-01 | 1986-04-17 | Ed. Züblin AG, 7000 Stuttgart | Arrangement for the base seal of storage basins and landfill sites |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3186896A (en) * | 1962-05-09 | 1965-06-01 | American Colloid Co | Moisture impervious panel |

| US3630762A (en) * | 1969-12-29 | 1971-12-28 | Mineral Products Corp | Waterproofing barrier |

| DE2327618A1 (en) * | 1973-05-16 | 1974-12-05 | Naue Kg E A H | LARGE-AREA MULTI-LAYER DRAIN ELEMENT |

| NL7812241A (en) * | 1977-12-24 | 1979-06-26 | Breveteam Sa | FLAT, FLEXIBLE LAYERED BODY FOR TREATING GASES OR LIQUIDS AS WELL AS A PROCEDURE FOR MANUFACTURING SUCH A BODY. |

| US4209568A (en) * | 1978-09-18 | 1980-06-24 | American Colloid Company | Bentonite-gelled oil waterproofing composition |

| US4250172A (en) * | 1979-02-09 | 1981-02-10 | Hausheer Hans P | Needled fiber mat containing granular agent |

| US4501788A (en) * | 1981-02-27 | 1985-02-26 | Clem Environmental Corp. | Waterproofing soil |

| CA1187748A (en) * | 1981-02-27 | 1985-05-28 | Clem Environmental Corp. | Waterproofing soil |

| US4656062A (en) * | 1984-04-27 | 1987-04-07 | American Colloid Company | Self-healing bentonite sheet material composite article |

| DE3700645A1 (en) * | 1987-01-12 | 1988-07-21 | Niederberg Chemie | SEALING FOR NEW DEPOSITIES |

-

1987

- 1987-02-13 DE DE3704503A patent/DE3704503C3/en not_active Expired - Fee Related

-

1988

- 1988-02-04 IE IE31188A patent/IE60781B1/en not_active IP Right Cessation

- 1988-02-05 AT AT88101679T patent/ATE75275T1/en not_active IP Right Cessation

- 1988-02-05 ES ES198888101679T patent/ES2031166T3/en not_active Expired - Lifetime

- 1988-02-05 DE DE8888101679T patent/DE3870273D1/en not_active Expired - Lifetime

- 1988-02-05 EP EP88101679A patent/EP0278419B1/en not_active Expired - Lifetime

- 1988-02-12 DK DK075088A patent/DK164957C/en not_active IP Right Cessation

- 1988-02-12 CA CA000558806A patent/CA1310569C/en not_active Expired - Lifetime

- 1988-02-12 GB GB8803277A patent/GB2202185B/en not_active Expired - Lifetime

- 1988-02-12 AU AU11668/88A patent/AU604839B2/en not_active Expired

- 1988-02-12 FI FI880668A patent/FI88064C/en active IP Right Grant

- 1988-02-12 NO NO880640A patent/NO168660C/en not_active IP Right Cessation

-

1989

- 1989-09-27 US US07/412,803 patent/US5041330A/en not_active Ceased

-

1992

- 1992-07-16 GR GR920401192T patent/GR3005195T3/el unknown

- 1992-11-02 SG SG1135/92A patent/SG113592G/en unknown

-

1993

- 1993-05-13 HK HK453/93A patent/HK45393A/en not_active IP Right Cessation

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2195237A5 (en) * | 1972-08-01 | 1974-03-01 | Bayer Ag | |

| US4048373A (en) * | 1974-05-23 | 1977-09-13 | American Colloid Company | Water barrier panel |

| US4344722A (en) * | 1981-01-13 | 1982-08-17 | Bemalux Inc. | Waterproofing barrier |

| US4565468A (en) * | 1983-10-24 | 1986-01-21 | Crawford Leslie A | Moisture impervient barrier and method for making same |

| DE3435983A1 (en) * | 1984-10-01 | 1986-04-17 | Ed. Züblin AG, 7000 Stuttgart | Arrangement for the base seal of storage basins and landfill sites |

Cited By (41)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0381342A3 (en) * | 1989-02-01 | 1991-07-31 | Clem Environmental Corporation | Clay mixture having contamination resistance |

| EP0381342A2 (en) * | 1989-02-01 | 1990-08-08 | Clem Environmental Corporation | Clay mixture having contamination resistance |

| EP0437723A3 (en) * | 1990-01-16 | 1992-08-05 | Huels Troisdorf Aktiengesellschaft | Composite seal |

| EP0437723A2 (en) * | 1990-01-16 | 1991-07-24 | Hüls Troisdorf Aktiengesellschaft | Composite seal |

| EP0449182A2 (en) * | 1990-03-28 | 1991-10-02 | SERVIZI ECOLOGICI S.p.A. | Composite self-sealing membrane, particularly for the waterproofing of construction elements, pits, tanks and the like, and process for the manufacture thereof |

| EP0449182A3 (en) * | 1990-03-28 | 1992-04-15 | Servizi Ecologici S.P.A. | Composite self-sealing membrane, particularly for the waterproofing of construction elements, pits, tanks and the like, and process for the manufacture thereof |

| WO1992010617A1 (en) * | 1990-12-06 | 1992-06-25 | Akzo Nv | Use of a protective mat for sealing webs |

| EP0490529A1 (en) * | 1990-12-11 | 1992-06-17 | James Clem Corporation | Clay liner for steep slopes |

| US5654064A (en) * | 1990-12-11 | 1997-08-05 | Claymax Corporation | Clay liner for steep slopes |

| US5346565A (en) * | 1990-12-17 | 1994-09-13 | American Colloid Company | Water barrier of water-swellable clay sandwiched between interconnected layers of flexible fabric needled together using a lubricant |

| US5237945A (en) * | 1990-12-17 | 1993-08-24 | American Colloid Company | Water barrier formed from a clay-fiber mat |

| EP0491454A1 (en) * | 1990-12-17 | 1992-06-24 | Amcol International Corporation | A method of manufacturing a multilayer article |

| US5346566A (en) * | 1990-12-17 | 1994-09-13 | American Colloid Company | Water barrier of water-swellable clay or other abrasive material sandwiched between interconnected layers of flexible fabric sewn or needled together using a lubricant and/or a liquid adhesive |

| US5389166A (en) * | 1990-12-17 | 1995-02-14 | American Colloid Company | Water barrier formed from a clay-fiber mat |

| EP0491453A1 (en) * | 1990-12-17 | 1992-06-24 | Amcol International Corporation | Waterproofing material |

| AT398284B (en) * | 1991-05-10 | 1994-11-25 | Hofinger Rudolf G | METHOD FOR PRODUCING A SEALING MAT, AND SEALING MAT PRODUCED BY THIS PROCESS |

| EP0522481A1 (en) * | 1991-07-11 | 1993-01-13 | SERVIZI ECOLOGICI S.p.A. | Sealing liner, Particularly for eliminating infiltrations |

| DE4133097A1 (en) * | 1991-10-05 | 1993-04-08 | Friedrich Geb | Filter bed mat - has layers of textile material and sand held in position by needle punching |

| EP0536475A1 (en) * | 1991-10-08 | 1993-04-14 | Paul Schreck | Waterimpervious liner to be used in civil engineering for the protection of soil from liquids |

| US6537676B1 (en) | 1992-08-26 | 2003-03-25 | Rawell Group Holdings Limited | Waterproofing material and method of fabrication therefor |

| FR2699855A1 (en) * | 1992-12-31 | 1994-07-01 | Guiraud Patrick | Composite flexible sheet for dispensing water, absorbing oil or chemical liq. |

| EP0667417A1 (en) * | 1994-02-08 | 1995-08-16 | Rudolf G. Hofinger | Method for sealing an impervious barrier in soil |

| EP0684343A1 (en) * | 1994-05-27 | 1995-11-29 | Süd-Chemie Ag | Process for the production of impervious walls |

| US5584609A (en) * | 1995-04-04 | 1996-12-17 | Claymax Corporation | Geosynthetic clay liner and method of manufacture |

| US5900085A (en) * | 1995-04-04 | 1999-05-04 | Claymax Corporation | Method of manufacturing a geosynthetic clay liner |

| EP0736633A1 (en) * | 1995-04-04 | 1996-10-09 | Claymax Corporation | Geosynthetic clay liner and method of manufacture thereof |

| WO1997006222A1 (en) * | 1995-08-03 | 1997-02-20 | Thomas Eichenauer | Mats with integrated rubber mulch |

| NL1014348C2 (en) | 2000-02-10 | 2001-08-13 | Louis Hubertus Maria Kreukels | Mat used for floor coverings comprises two carrier layers of and an intermediate pre-wetted layer of a swellable clay composition containing at least 50 wt.% extrudable calcium bentonite |

| WO2004016425A3 (en) * | 2002-08-15 | 2004-04-29 | Paul Vogt | Sealing mat comprising a superabsorbent layer, method for the production thereof, use thereof, superabsorber, and hot melt adhesive |

| US9516914B2 (en) | 2006-09-06 | 2016-12-13 | IQTEX Patentverwaltunq UG | Self-closing ventilation insert and method for producing it |

| WO2008146074A1 (en) * | 2007-06-01 | 2008-12-04 | Laviosa Chimica Mineraria S.P.A. | Apparatus for making bentonitic needled geocomposite products |

| EP2151317A1 (en) | 2008-08-05 | 2010-02-10 | Volteco S.p.A. | Waterproof membrane, particularly for insulating buildings subjected to hydrostatic pressure |

| ITTV20080104A1 (en) * | 2008-08-05 | 2010-02-06 | Volteco S P A | WATERPROOF MEMBRANE, PARTICULARLY FOR THE INSULATION OF CONSTRUCTIONS SUBJECT TO HYDROSTATIC PRESSURE. |

| EP2199447A1 (en) * | 2008-12-19 | 2010-06-23 | Michael C. Dehn | Superabsorbent polymer felt and method for its manufacture |

| WO2010069592A1 (en) * | 2008-12-19 | 2010-06-24 | Michael Christian Dehn | Super absorber polymer felt and method for the production thereof |

| US8844158B2 (en) | 2008-12-19 | 2014-09-30 | Iqtex Patentverwaltung Ug | Super absorber polymer felt and method for the production thereof |

| RU2543602C2 (en) * | 2008-12-19 | 2015-03-10 | Икветекс Патентфервальтунг Уг (Хафтунгсбешрэнкт) | Felt from superabsorbing polymer and method of manufacturing thereof |

| RU2543602C9 (en) * | 2008-12-19 | 2015-07-20 | Икветекс Патентфервальтунг Уг (Хафтунгсбешрэнкт) | Felt from superabsorbing polymer and method of manufacturing thereof |

| EP2439342A1 (en) | 2010-10-06 | 2012-04-11 | Naue GmbH & Co. KG | Reinforcement mesh |

| WO2016146709A1 (en) | 2015-03-17 | 2016-09-22 | Volteco S.P.A. | Self-repairing and self-sealing waterproof membrane, for insulating built structures subjected to hydrostatic pressure |

| US11007755B2 (en) | 2015-03-17 | 2021-05-18 | Volteco S.P.A. | Self-repairing and self-sealing waterproof membrane, for insulating built structures subjected to hydrostatic pressure |

Also Published As

| Publication number | Publication date |

|---|---|

| US5041330A (en) | 1991-08-20 |

| FI880668A0 (en) | 1988-02-12 |

| DK164957B (en) | 1992-09-21 |

| ATE75275T1 (en) | 1992-05-15 |

| NO168660B (en) | 1991-12-09 |

| DE3704503C3 (en) | 1998-02-26 |

| FI88064C (en) | 1993-03-25 |

| AU604839B2 (en) | 1991-01-03 |

| AU1166888A (en) | 1988-08-18 |

| DK75088D0 (en) | 1988-02-12 |

| IE880311L (en) | 1988-08-13 |

| GR3005195T3 (en) | 1993-05-24 |

| DK164957C (en) | 1993-02-15 |

| EP0278419B1 (en) | 1992-04-22 |

| DE3704503A1 (en) | 1988-08-25 |

| NO880640D0 (en) | 1988-02-12 |

| GB2202185A (en) | 1988-09-21 |

| NO880640L (en) | 1988-08-15 |

| IE60781B1 (en) | 1994-08-10 |

| SG113592G (en) | 1993-06-11 |

| FI880668A (en) | 1988-08-14 |

| FI88064B (en) | 1992-12-15 |

| CA1310569C (en) | 1992-11-24 |

| DE3870273D1 (en) | 1992-05-27 |

| GB8803277D0 (en) | 1988-03-09 |

| DE3704503C2 (en) | 1990-03-08 |

| EP0278419A3 (en) | 1989-03-29 |

| GB2202185B (en) | 1990-10-17 |

| DK75088A (en) | 1988-08-14 |

| NO168660C (en) | 1992-03-18 |

| ES2031166T3 (en) | 1992-12-01 |

| HK45393A (en) | 1993-05-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3704503C3 (en) | Waterproof sealing mat | |

| EP0445788B1 (en) | Waterproof- and oilproof sealing mat to be used as water- and oil barrier | |

| EP0563453B1 (en) | Method for making a water- and/or oil-impervious liner containing expansive clay | |

| EP0522546B1 (en) | Improved bonding of the overlapping areas of needle punched bentonite sealing liners | |

| EP0447649B1 (en) | Arrangement for covering sloping surfaces of bulk material | |

| DE3905607A1 (en) | LAYER BUILDING FOR THE PRODUCTION OF SOUND INSULATIONS, SOUND INSULATIONS AND METHOD FOR THE PRODUCTION OF THE LAYER BUILDING OR OF SOUND INSULATION | |

| EP0071213A2 (en) | Laminated article for construction purposes, and its application | |

| EP0555800B1 (en) | Water and/or oil impervious membrane with swellable clay | |

| DE4119989C2 (en) | Radiation protection mat for the shielding of radioactive radiation | |

| WO2004016425A2 (en) | Sealing mat comprising a superabsorbent layer, method for the production thereof, use thereof, superabsorber, and hot melt adhesive | |

| EP1455612A2 (en) | Flexible fluid-tight web | |

| EP1838523A1 (en) | Multilayer fabric | |

| EP1141490B1 (en) | Sealing mat and method for producing same | |

| DE3922028C2 (en) | ||

| DE19649628A1 (en) | Mineral seal construction, manufacturing processes and geosynthetic sealing strip | |

| DE19950057A1 (en) | Two or three layer laminates of synthetic non-woven fabric and woven glass fabric or scrim, for use in bituminized roofing webs and sealing membranes, in which the layers are bonded by needling and consolidated with a binder | |

| DE60310403T2 (en) | METHOD FOR PRODUCING A WATERPROOFING MATERIAL | |

| EP2052103B1 (en) | Method for producing a base non-woven fibre as support for a coating | |

| AT410228B (en) | Optimising pore saturation of artificial yarn structures with gravity filling | |

| EP0731220A1 (en) | Ground mat | |

| DE4133097A1 (en) | Filter bed mat - has layers of textile material and sand held in position by needle punching | |

| DE2123158A1 (en) | Composite foam and fibre laminate mfr - from waste foam particles esp polyurethane useful for upholstery etc |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19890919 |

|

| 17Q | First examination report despatched |

Effective date: 19901016 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB GR IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 75275 Country of ref document: AT Date of ref document: 19920515 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3870273 Country of ref document: DE Date of ref document: 19920527 |

|

| ITF | It: translation for a ep patent filed |

Owner name: BARZANO' E ZANARDO MILANO S.P.A. |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: CLEM ENVIRONMENTAL CORPORATION Effective date: 19920924 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2031166 Country of ref document: ES Kind code of ref document: T3 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: CLEM ENVIRONMENTAL CORPORATION |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: FG4A Free format text: 3005195 |

|

| 26 | Opposition filed |

Opponent name: HUESKER SYNTHETIC GMBH & CO. Effective date: 19930113 Opponent name: CLEM ENVIRONMENTAL CORPORATION Effective date: 19920924 |

|

| 26 | Opposition filed |

Opponent name: HOECHST AKTIENGESELLSCHAFT ZENTRALE PATENTABTEILUN Effective date: 19930115 Opponent name: HUESKER SYNTHETIC GMBH & CO. Effective date: 19930113 Opponent name: CLEM ENVIRONMENTAL CORPORATION Effective date: 19920924 |

|

| 26 | Opposition filed |

Opponent name: HUESKER SYNTHETIC GMBH & CO. Effective date: 19930113 Opponent name: HOECHST AKTIENGESELLSCHAFT ZENTRALE PATENTABTEILUN Effective date: 19930115 Opponent name: FABROMONT AG Effective date: 19930122 Opponent name: CLEM ENVIRONMENTAL CORPORATION Effective date: 19920924 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: HUESKER SYNTHETIC GMBH & CO. |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: FABROMONT AG. Opponent name: HOECHST AG. |

|

| EPTA | Lu: last paid annual fee | ||

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: CLEM ENVIRONMENTAL CORPORATION * 930113 HUESKER SY Effective date: 19920924 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 88101679.4 |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| PLBN | Opposition rejected |

Free format text: ORIGINAL CODE: 0009273 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: OPPOSITION REJECTED |

|

| 27O | Opposition rejected |

Effective date: 19960207 |

|

| NLR2 | Nl: decision of opposition | ||

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20070124 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20070126 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20070131 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20070208 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20070209 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20070212 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20070215 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20070216 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20070307 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20070524 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 |

|

| BE20 | Be: patent expired |

Owner name: *NAUE-FASERTECHNIK G.M.B.H. & CO. K.G. Effective date: 20080205 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|