EP0574343A2 - Procedure for the construction of polychrome pavements - Google Patents

Procedure for the construction of polychrome pavements Download PDFInfo

- Publication number

- EP0574343A2 EP0574343A2 EP93500048A EP93500048A EP0574343A2 EP 0574343 A2 EP0574343 A2 EP 0574343A2 EP 93500048 A EP93500048 A EP 93500048A EP 93500048 A EP93500048 A EP 93500048A EP 0574343 A2 EP0574343 A2 EP 0574343A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- pavements

- procedure

- tiles

- polychrome

- pavement

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B44—DECORATIVE ARTS

- B44C—PRODUCING DECORATIVE EFFECTS; MOSAICS; TARSIA WORK; PAPERHANGING

- B44C1/00—Processes, not specifically provided for elsewhere, for producing decorative surface effects

- B44C1/26—Inlaying with ornamental structures, e.g. niello work, tarsia work

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F21/00—Implements for finishing work on buildings

- E04F21/165—Implements for finishing work on buildings for finishing joints, e.g. implements for raking or filling joints, jointers

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04F—FINISHING WORK ON BUILDINGS, e.g. STAIRS, FLOORS

- E04F21/00—Implements for finishing work on buildings

- E04F21/165—Implements for finishing work on buildings for finishing joints, e.g. implements for raking or filling joints, jointers

- E04F21/1652—Implements for finishing work on buildings for finishing joints, e.g. implements for raking or filling joints, jointers for smoothing and shaping joint compound to a desired contour

Definitions

- This invention patent deals with a procedure conceived to lay out polychrome pavements of several kinds.

- the polychrome pavements that can be attained putting this patent into practice allow to start with prefabricated modular elements made of terrazzo, grit stone, clay, marble, etc. adequately fitted closely, or apart, including low relieves made by means of pressing, milling or moulding its upper surface on which it is flushed a formula with a high resistance and keying in matching or contrasting colours in contrast with the base, and with a lower equal or higher hardness.

- prefabricated modular elements made of terrazzo, grit stone, clay, marble, etc. adequately fitted closely, or apart, including low relieves made by means of pressing, milling or moulding its upper surface on which it is flushed a formula with a high resistance and keying in matching or contrasting colours in contrast with the base, and with a lower equal or higher hardness.

- a continuous polychrome surface will appear.

- the joints between the elements will be indistinguishable from the low relief pattern.

- the procedure which is the subject of this patent is based also on laying out levelled modular elements in the same fashion used for the traditional installation of terrazzo, grit stone or marble.

- a formula conceived to fill up the low relief is poured. It is composed of a synthetic resin and a crushed material, preferably hard or slip proof with a variable grain size distribution. After being poured out the necessary time for setting is allowed. It usually takes about 48 hours, proceeding afterwards with an overall polishing, similar to the procedure used for terrazzo.

- the procedure starts from prefabricated modular elements of the kind commonly used in the market. At present, those are normally used to build outdoor pavements, but applying this procedure they could also be used for indoor pavements.

- the use of the filling up product for setting will be limited to a light 2-3 mm layer, and the polishing phase will be very easy, taking into account that the levelling up of modular pieces shows a constant level which can be easily identified. This involves low fabrication costs and a remarkably fast preparation.

- Joints made of brass, PVC, aluminium, etc can be easily and safely made as they can be embedded between the modules, thus preventing them from deforming during the layout phase.

- the procedure object of this invention will allow the easy replacement of damaged pavement elements, broken or with cracks. After the overall embedding and polishing of the area, the shade differences of the pieces will be hard to distinguish if there is enough contrast between their colour and the settable filling up formula.

- This procedure can be also used to rehabilitate pavements already laid out by milling parts of the pavement, such as the joints between pieces which can be joined subsequently with a settable covering product, preferably slip proof.

- Figures 5 and 6 show the layout of relieves in adjoining pieces of a pavement and offsets for the pavement itself, respectively.

- Figures 7 and 8 are schematic views of two milling heads of a cylindrical milling cutter.

- Figures 9 and 10 are equivalent views depicting a disc-shaped milling cutter.

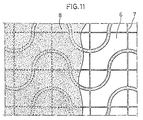

- Figure 11 shows schematically a plain view of the pavement with a polished and an unpolished surface.

- Figures 12 and 13 show two schematic views of a pavement being polished.

- Figures 14 and 15 show two views of a completely polished pavement.

- Figures 16 and 17 show two views of a detail of a tile offset of a pavement laid out according to this patent.

- the procedure explained in this patent can be applied to pavements made with a series of tiles -1-, figure 1, for instance, square-shaped which are regularly distributed, separated by interstices -2-.

- the pavements can be made using individual tiles of several shapes such as triangular tiles -3-, figure 2, rectangular tiles -4, figure 3 or polygonal tiles -5- shown in figure 4.

- the filling up product composed by a hardenable resin containing a slip proof product can be poured out, applying thicknesses of 2 to 3 cm in average, shown in figures 11 to 17.

- Figure 11 shows the layout of a series of tiles -6-, in the required pattern, with interstices -7- between them. It also shows the covering poured out on the tiles -8- which will cover its surface with a 2-3 mm layer and which, in addition, will fill up both the low relief creases -9- and the interstices -7-.

- the single surface obtained pouring the material -8- can be polished in such a fashion that, with this polishing operation effected by heads, schematically shown in number -10-, the cover will be cut -8- up to the level of the tile -6- obtaining a free covering surface corresponding to the upper side of the tile and filling the joints -9- and interstices -7-.

- a tile pavement -11- already installed can be rehabilitated milling the joints thus creating new joints -12- with the relevant mill cutter -13-.

- some fancy patterns can be obtained such as those shown by slots -14- and -15- of adjoining tiles -16- and -17-, figure 5, using a milling head -18-.

- the interstices between tiles can be filled with any material, which will be clearly visible once polished.

Abstract

The procedure can be applied to pavements composed of tiles (6) laid out at the same level, with spaces (7) in between and low relieves (9) in their upper surface. The whole pavement will be covered subsequently with a fine layer of a settable mass (8) which fill up the joints (7) and bass relieves (9) and it will be polished completely until reaching the surface of the tiles which will have their original appearance, whereas the joints (7) and low relieves (9) will adopt the polychrome finishing of the filling. It allows to obtain decorated slip-proof pavements and to rehabilitate pavements.

Description

- This invention patent deals with a procedure conceived to lay out polychrome pavements of several kinds.

- The polychrome pavements that can be attained putting this patent into practice, including those of the continuous type, allow to start with prefabricated modular elements made of terrazzo, grit stone, clay, marble, etc. adequately fitted closely, or apart, including low relieves made by means of pressing, milling or moulding its upper surface on which it is flushed a formula with a high resistance and keying in matching or contrasting colours in contrast with the base, and with a lower equal or higher hardness. Thus, after an overall polishing of the combined pavement a continuous polychrome surface will appear. In the above surface, the joints between the elements will be indistinguishable from the low relief pattern.

- As it can be understood, the procedure dealt with in this patent is substantially different from the procedures applied to build continuous pavements known up to now. For the latter, the procedure followed is to pour and level out a huge mortar mass that contains marble aggregates with thicknesses ranging from 10 mm up to 50-60 mm, which require a highly technical know-how, both to lay it out and to polish it afterwards. In addition, nowadays there are more and more cracks on continuous pavement. Those adopt peculiar shapes which contrast sharply with the desired uniformity of the pavement.

- On the contrary, the procedure which is the subject of this patent is based also on laying out levelled modular elements in the same fashion used for the traditional installation of terrazzo, grit stone or marble. Subsequently, a formula conceived to fill up the low relief is poured. It is composed of a synthetic resin and a crushed material, preferably hard or slip proof with a variable grain size distribution. After being poured out the necessary time for setting is allowed. It usually takes about 48 hours, proceeding afterwards with an overall polishing, similar to the procedure used for terrazzo.

- Therefore, in basic terms the procedure starts from prefabricated modular elements of the kind commonly used in the market. At present, those are normally used to build outdoor pavements, but applying this procedure they could also be used for indoor pavements. The use of the filling up product for setting will be limited to a light 2-3 mm layer, and the polishing phase will be very easy, taking into account that the levelling up of modular pieces shows a constant level which can be easily identified. This involves low fabrication costs and a remarkably fast preparation.

- Joints made of brass, PVC, aluminium, etc can be easily and safely made as they can be embedded between the modules, thus preventing them from deforming during the layout phase.

- As it can be understood, the use of this procedure will allow the obtention of a combined pavement made of grit stone and clay or terrazzo, impossible up to now. With this materials continuous pavements can be built with functional features in a measure equivalent to the continuous terrazzo pavements used up to now. In addition, the procedure object of this patent offers a greater range of economic and decorative possibilities as the grit stone or clay manufacturer can finish the manufacturing cycle after pressing and single-firing the so-called "biscuit" thus saving work, eliminating the enamelling and double-firing processes; saving time, raw materials and energy. The subsequent pouring of the fill up formula to be set in the works itself will replace the enamelling phase and will solve the obstacle of the lay out joints which posed a hygienic and aesthetic inconvenient for the continuous pavements used up to now.

- Besides, the procedure dealt with by this patent can be usefully applied to the restoration of existing pavements, as the low relieves will be replaced by filling products which will attain the polychrome features sought and it will also retain its slip proof features. After being polished, the pavement will resemble a one piece mosaic

- The combination of two or more colours during the fabrication process of a terrazzo, clay or grit stone tile, will allow to obtain a highly decorative product, that can be used in all kinds of surfacing, highly enhancing the range of possibilities of prefabricated materials known at present.

- Likewise, the procedure object of this invention will allow the easy replacement of damaged pavement elements, broken or with cracks. After the overall embedding and polishing of the area, the shade differences of the pieces will be hard to distinguish if there is enough contrast between their colour and the settable filling up formula.

- This procedure can be also used to rehabilitate pavements already laid out by milling parts of the pavement, such as the joints between pieces which can be joined subsequently with a settable covering product, preferably slip proof.

- Some drawings explaining the procedure shown in this patent are enclosed by way of example to enhance the understanding of the process.

- Each of the figures 1, 2, 3 and 4 are views of several tile shapes laid out on a pavement conceived for the procedure object of this patent.

- Figures 5 and 6 show the layout of relieves in adjoining pieces of a pavement and offsets for the pavement itself, respectively.

- Figures 7 and 8 are schematic views of two milling heads of a cylindrical milling cutter.

- Figures 9 and 10 are equivalent views depicting a disc-shaped milling cutter.

- Figure 11 shows schematically a plain view of the pavement with a polished and an unpolished surface.

- Figures 12 and 13 show two schematic views of a pavement being polished.

- Figures 14 and 15 show two views of a completely polished pavement.

- Figures 16 and 17 show two views of a detail of a tile offset of a pavement laid out according to this patent.

- The procedure explained in this patent can be applied to pavements made with a series of tiles -1-, figure 1, for instance, square-shaped which are regularly distributed, separated by interstices -2-. The pavements can be made using individual tiles of several shapes such as triangular tiles -3-, figure 2, rectangular tiles -4, figure 3 or polygonal tiles -5- shown in figure 4.

- Once the pavement composed by several tiles of terrazzo, grit stone, clay, marble or combinations of those is laid out, the filling up product composed by a hardenable resin containing a slip proof product, preferably with a fine grain size, can be poured out, applying thicknesses of 2 to 3 cm in average, shown in figures 11 to 17. Figure 11 shows the layout of a series of tiles -6-, in the required pattern, with interstices -7- between them. It also shows the covering poured out on the tiles -8- which will cover its surface with a 2-3 mm layer and which, in addition, will fill up both the low relief creases -9- and the interstices -7-. Once the material is already set, a process which takes 48 hours approximately, the single surface obtained pouring the material -8- can be polished in such a fashion that, with this polishing operation effected by heads, schematically shown in number -10-, the cover will be cut -8- up to the level of the tile -6- obtaining a free covering surface corresponding to the upper side of the tile and filling the joints -9- and interstices -7-. This has been depicted schematically in figure 15 and in the relevant section of figure 14. Obviously, depending on the low relief shapes, the patterns obtained can have a greater size and they can cover the whole pavement.

- If so desired -figure 6- a tile pavement -11- already installed can be rehabilitated milling the joints thus creating new joints -12- with the relevant mill cutter -13-. In some cases, some fancy patterns can be obtained such as those shown by slots -14- and -15- of adjoining tiles -16- and -17-, figure 5, using a milling head -18-. The interstices between tiles can be filled with any material, which will be clearly visible once polished.

- As it can be observed in the description of this invention which has been offered, it will allow to create pavements with the same features of a continuous pavement using tiles of several kinds and qualities, thus achieving a new and original polychrome effect for indoor and outdoor pavements.

- Everything that does not affect, alter, change or modify the essence of the procedure described above will be variable for the purposes of this invention.

Claims (5)

- Procedure for the construction of polychrome pavements whose main feature is that the above are composed of tiles laid out at the same level, with spaces between them and with low relieves on the upper surface. The whole pavement is covered with a fine layer of a settable mass which fill up the joints and the low relieves, subsequently polishing the whole pavement up to the level of the tiles which will have their original aspect whereas the joints and low relieves will show the polychrome finishing of the filling.

- Procedure for the construction of polychrome pavements, according to claim 1, whose main feature is that the filling of joints and low relieves is composed of a slip-proof granular mass.

- Procedure for the construction of polychrome pavements, according to claim 1, whose main feature is that the pavement is obtained using combined tiles made of terrazzo, grit stone, clay and other materials.

- Procedure for the construction of polychrome pavements, according to claim 1, whose main feature is that the pavement is constituted by grit stone or clay tiles finished after pressing and single-firing the biscuit, the final covering being effected by means of a settable mass. The latter is polished without revealing the surface of the tiles which are covered by the settable mass replacing the enamel layer of the tiles.

- Procedure for the construction of polychrome pavements, according to claim 1, whose main feature is that the milling of joints and other areas of a pavement already laid out is effected to attain an offset which will be filled up subsequently with a settable filling mass thus enabling the restoration of pavements already installed.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| ES9200828 | 1992-04-20 | ||

| ES9200828 | 1992-04-20 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0574343A2 true EP0574343A2 (en) | 1993-12-15 |

| EP0574343A3 EP0574343A3 (en) | 1994-04-13 |

Family

ID=8276770

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93500048A Withdrawn EP0574343A2 (en) | 1992-04-20 | 1993-04-20 | Procedure for the construction of polychrome pavements |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP0574343A2 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0931893A2 (en) * | 1998-01-19 | 1999-07-28 | André Waldenburger | Process for making floors of stone and floors of stony materials |

| CN105332501A (en) * | 2015-11-27 | 2016-02-17 | 中国一冶集团有限公司 | Intelligent cart for spreading sand powdery matter and construction method |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2274907A (en) * | 1941-05-31 | 1942-03-03 | Joseph A Madala | Process of making mosaic |

| DE841345C (en) * | 1952-04-30 | Remscheid Karl Pauel | Process for the production of multicolored coverings from liquid masses, in particular for floors | |

| US3772051A (en) * | 1971-07-29 | 1973-11-13 | Ici Ltd | Decorative flooring surfaces |

| FR2511949A1 (en) * | 1981-08-31 | 1983-03-04 | Fabre Gerald | Method of making lacquered inlaid pattern - involves engraving plate before coating with lacquer and polishing |

| DE4103978C1 (en) * | 1991-02-09 | 1992-02-13 | Paul 4420 Coesfeld De Hunkemoeller |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| BE895130A (en) * | 1982-11-25 | 1983-03-16 | Moeschal Jacques | Permanent coloured pattern for decorating concrete surfaces - where surface is provided with pattern of grooves, which are filled with mixt. of synthetic resin and pigments |

-

1993

- 1993-04-20 EP EP93500048A patent/EP0574343A2/en not_active Withdrawn

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE841345C (en) * | 1952-04-30 | Remscheid Karl Pauel | Process for the production of multicolored coverings from liquid masses, in particular for floors | |

| US2274907A (en) * | 1941-05-31 | 1942-03-03 | Joseph A Madala | Process of making mosaic |

| US3772051A (en) * | 1971-07-29 | 1973-11-13 | Ici Ltd | Decorative flooring surfaces |

| FR2511949A1 (en) * | 1981-08-31 | 1983-03-04 | Fabre Gerald | Method of making lacquered inlaid pattern - involves engraving plate before coating with lacquer and polishing |

| DE4103978C1 (en) * | 1991-02-09 | 1992-02-13 | Paul 4420 Coesfeld De Hunkemoeller |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0931893A2 (en) * | 1998-01-19 | 1999-07-28 | André Waldenburger | Process for making floors of stone and floors of stony materials |

| EP0931893A3 (en) * | 1998-01-19 | 2000-02-02 | André Waldenburger | Process for making floors of stone and floors of stony materials |

| CN105332501A (en) * | 2015-11-27 | 2016-02-17 | 中国一冶集团有限公司 | Intelligent cart for spreading sand powdery matter and construction method |

| CN105332501B (en) * | 2015-11-27 | 2018-04-10 | 中国一冶集团有限公司 | A kind of intelligent carriage and construction method for spreading sand powder material |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0574343A3 (en) | 1994-04-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8793964B2 (en) | Concrete mosaic and method of forming the same | |

| US5927034A (en) | Flexible cement textured building tile and tile manufacturing process | |

| US20070187873A1 (en) | Cement-based, mesh reinforced concrete tiles with integral color and design | |

| CA2370783C (en) | Method of making terrazzo floors with design elements | |

| EP0574343A2 (en) | Procedure for the construction of polychrome pavements | |

| US1949517A (en) | Antislipping tread and method of making the same | |

| EP2060362A2 (en) | Process and plant for working a stone tile and tile thus obtained | |

| WO2001036762A1 (en) | Terrazzo flooring system | |

| JP2834197B2 (en) | Decorative construction method | |

| KR19980064941A (en) | Soil floor packing method | |

| RU2164866C1 (en) | Method for manufacture of decorative tile or panel and decorative tile or panel | |

| GB2331540A (en) | Pavement construction | |

| CN206016165U (en) | Large area is seamless overall ground | |

| JPH07206461A (en) | Production of water-permeable glass block used in sidewalk | |

| US313221A (en) | Composite tiling | |

| EP4242183A1 (en) | Process for making a decorative flooring tile and decorative flooring tile obtained by this process | |

| WO1993017881A1 (en) | Process for tarsia-working of marble, granite, etc. | |

| CN2402716Y (en) | Greenstone pebble paving brick | |

| JPH1119918A (en) | Manufacture of concrete member having surface hard to stain and property for lasting good appearance | |

| EP3546675A1 (en) | Method for the realization and laying of a coating structure | |

| KR880002224B1 (en) | Method for preparing artificial stone | |

| KR0143811B1 (en) | Method of producing terazo-testiles | |

| WO2001019624A1 (en) | Reflective products | |

| SULLIVAN | Versatility in Design | |

| JP2805677B2 (en) | Base decoration method using inlaid molded product and design panel obtained by the method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB IT PT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB IT PT |

|

| 17P | Request for examination filed |

Effective date: 19941011 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19951101 |