EP0809945B1 - Ladies underwear, especially brassière - Google Patents

Ladies underwear, especially brassière Download PDFInfo

- Publication number

- EP0809945B1 EP0809945B1 EP97108357A EP97108357A EP0809945B1 EP 0809945 B1 EP0809945 B1 EP 0809945B1 EP 97108357 A EP97108357 A EP 97108357A EP 97108357 A EP97108357 A EP 97108357A EP 0809945 B1 EP0809945 B1 EP 0809945B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- parts

- side parts

- brassiere according

- reinforcement

- brassiere

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41C—CORSETS; BRASSIERES

- A41C3/00—Brassieres

- A41C3/0014—Brassieres made from one piece with one or several layers

-

- A—HUMAN NECESSITIES

- A41—WEARING APPAREL

- A41D—OUTERWEAR; PROTECTIVE GARMENTS; ACCESSORIES

- A41D27/00—Details of garments or of their making

- A41D27/24—Hems; Seams

- A41D27/245—Hems; Seams made by welding or gluing

Definitions

- the invention relates to a piece of underwear for women elaborated top, especially a bra, from two side parts containing the bust cups, the in the front middle area between the bust cups connected together at the rear ends have a back closure and those with straps are provided.

- Bras are undergarments that are made with regard to on their determination to cover, support and shape the female breast in many different sizes and shapes must be manufactured and kept in stock.

- They due to this provision adapted spatial form exist they traditionally consist of a number of different parts, which make up a variety of their composition Work steps that are time-consuming and costly and a rational industrial way of working largely withdraw.

- Areas of a garment such as a panty girdle or a bra, known, on the basis of a textile material in the screen printing process in certain Pattern to apply a powdered glue, after that is melted in a drying oven (EP 0 255 101 B1).

- a powdered glue after that is melted in a drying oven (EP 0 255 101 B1).

- On the areas of the base coated with adhesive then becomes one of the areas of the glue application appropriate top layer applied by the application of Heat and pressure using the adhesive with the base is connected.

- Strength and shaping properties here by the shape and size of the adhesive application and choice of Adhesive material determined. The further assembly too this bra is made by sewing.

- the invention has for its object a design for a women's undergarment, especially one To create bras that are suitable for a modern industrial Manufacturing is suitable, especially any continuous and avoids sewing operations requiring a connecting medium.

- this object is achieved by a Women's undergarment, especially a bra solved with the features specified in claim 1.

- the invention Bras not only without any threads or the like Lanyards are made, but so are practically only selectively, i.e. by pressing, welding or the like, operations to connect the individual parts or required for assembly.

- the new bra By eliminating the most annoying and stretching behavior influencing or possibly also commissioning, by The new bra also has sewing seams improved wearing properties. Because of its flat End edges or material transitions is the Bra according to the invention ideal for wearing under tight-fitting clothes since he is on top of it worn clothing does not show. By reduced Variety of materials result in good care properties and also a simplified recyclability. Finally the method of manufacture also allows better reproduction the required fit and a comparably cheap Manufacturing cost structure.

- the invention is based on the example of a Bra shown as a women's undergarment.

- the invention is also applicable to other items of clothing applicable, which have a worked out top, such as e.g. Swimsuits or the like.

- Fig. 1 is a bra according to the invention of the Shown inside.

- the bra 1 consists of two side parts 2 and 3, which are mirror-symmetrical to one front central axis M are formed and arranged.

- the Side panels 2 and 3 each comprise by molding molded bust cups 4 and 5.

- the side parts 2 and 3 are in the area of the front central axis M in one area 6 connected to each other.

- At the rear ends of the Side panels 2 and 3 are the active and passive Parts of a back closure 7.

- carrier tapes 8 are fixed at 9 and in the rear Area at 10 in an adjustment element 11 formed loop 12 adjustably attached.

- the side parts 2 and 3 each consist of one of their entire surface covering layer 13 or 14 from one textile, to a certain extent stretchable material, at least partially contains thermoplastic fusible fibers.

- On these basic parts 13 and 14 are from the inside Reinforcement parts laminated, in their entirety with 15 and 16 are designated.

- These reinforcement parts 15, 16 also consist of a textile, preferably a less stretchy material, at least that too partially contains thermoplastic fusible fibers.

- the reinforcing parts 15, 16 from frame-like blanks that are approximately uniformly wide, band-like along the outer edges of the side parts 2 and 3 to reinforce and stabilize the Edges. These are lower, parallel to lower edge 17 extending parts 18, in the back area adjoining, running to the carrier tapes 8 Parts 19, parts 21 running along the upper edges 20 and finally above the bust cups 4, 5 Parts 22. Starting from the lower edge 17 of the bra 1 extend the parts 18 of the reinforcements 15, 16 to in into the area of the bust cups 4 and 5; they form there reinforcements 23 to support the chest or Shaping their contour.

- the invention is not limited to this.

- the bra can be used instead a back closure also have a front closure or completely without closure as a so-called “step-in bra” be trained. It can also be used without carrier tapes, so be strapless. After all, that is Invention also on swimsuits, both in one piece as well as bikini applicable.

- the bra according to the invention first made the two side parts 2 and 3, this then connected to each other in the front middle region 6 and finally the carrier tapes 8 and the closure parts 7 appropriate.

- the side parts 2 and 3 of the brassiere 1 is first on a base course or a rough cut of the reinforcement 15, 16 forming textile material applied a coating through which a connection with the base web 13 or 14 can be produced.

- This can either be a "hot melt” adhesive coating, or also a thin film that can be activated by applying heat.

- the application of heat and pressure Reinforcing parts 15, 16 containing rough cuts with the Rough cuts 13, 14 of the base web are connected. Only after the bust cups 4 and 5 are molded and the Punched outer contours. It makes sense to have two each corresponding side parts 2 and 3 in each other congruent location on top of each other.

- the Assembling the bra After these preparatory measures, the Assembling the bra. For this, the superimposed stamped and molded parts 2 and 3 opened, in the front middle area 6 of the Center axis M to form a triangular overlap 23 brought and in this area by a weld 24th firmly connected. This can be done by a single Pressing and welding process take place. This connection can also by designing a motif, e.g. "Bloom", optically be made attractive.

- the fixed connection 9 of the carrier tapes 8 with the front 2A shows the upper regions of the brassiere 1.

- the Carrier tapes 8 mostly made of elastic tape material exist, usually contain thermoplastic fusible fibers so that they, with the appropriate Areas of the side parts 2, 3 overlapped, can be connected to each other by welds 25.

- For adjustable attachment 10 of the carrier tapes 8 in rear area (Fig. 2B) is made of the material of the Side parts 2 or 3 with laminated reinforcement one Tab 26 formed, which is pulled through an eyelet 27 and then is repelled. By a weld 25, the Tab 26 welded to side part 2 or 3. Through the Eyelet 27 becomes the carrier tape 8 in a manner known per se pulled, which forms a loop 12.

- the back closure 7 consists of an active closure part 7a and passive closure part 7b.

- the active closure part 7a has a locking head 7c, the passive locking part 7b a recess 7d. Place both locking parts 7a and 7b each in an eyelet 7e.

- the ends run here too of the side parts 2 and 3 in tabs 28, each pulled through the eyelets 7e and backwards to be handled, then by welds 29 with the Material of the side parts 2 and 3 to be welded.

- thermoplastic fusible fibers can be applied using ultrasound or Heat, if necessary with the simultaneous application of Pressure to be welded. It succeeds after Overlay the from the rough cuts 13, 14 and Reinforcement parts 15, 16 existing side parts 2, 3 in mutually congruent location this in the area of the later ends 32, 33 forming the front central region 6 Welding with application of pressure under complete Cut to connect so that after Opening parts 2, 3 the two lying one on top of the other welded ends 32, 33 into an elongated Get in position and so blunt with each other are welded. In this way, one succeeds practically invisible, at least not bulky straightforward Connection of the two front inner ends of the side parts 2, 3.

- Fig. 5 is shown schematically how the two Side parts 2, 3 from the base material 13, 14 and Reinforcement parts 15, 16 are placed on top of each other so that whose front inner ends 32, 33 cover each other.

- an ultrasonic welding device 34 that only through a sonotrode 34a and a lower abutment 34b is indicated.

- the lower abutment 34b has in its upper part facing the material triangular Cross section to not only a weld but also to enable a separation of the material parts.

- the two front central edges 32, 33 are thus the Side parts 2, 3 connected to each other.

Abstract

Description

Die Erfindung betrifft ein Damenunterbekleidungsstück mit ausgearbeitetem Oberteil, insbesondere einen Büstenhalter, aus zwei die Büstenkörbchen enthaltenden Seitenteilen, die im vorderen mittleren Bereich zwischen den Büstenkörbchen miteinander verbunden sind, die an den rückwärtigen Enden einen Rückenverschluß aufweisen und die mit Trägerbändern versehen sind.The invention relates to a piece of underwear for women elaborated top, especially a bra, from two side parts containing the bust cups, the in the front middle area between the bust cups connected together at the rear ends have a back closure and those with straps are provided.

Büstenhalter sind Unterbekleidungsstücke, die im Hinblick auf ihre Bestimmung zur Bedeckung, Stützung und Formung der weiblichen Brust in vielen verschiedenen Größen und Formen hergestellt und vorrätig gehalten werden müssen. Durch ihre, dieser Bestimmung angepaßte räumliche Form bedingt, bestehen sie herkömmlich aus einer Mehrzahl unterschiedlicher Teile, die zu ihrer Zusammensetzung einer Vielzahl von Arbeitsschritten bedürfen, die zeit- und lohnaufwendig sind und sich einer rationellen industriellen Arbeitsweise weitgehend entziehen. Abgesehen davon, daß ein Büstenhalter aus einer Anzahl verschiedener Teile, meist aus textilem Material, besteht, wie Seitenteile, Büstenkörbchen, Trägerbänder, Besatz- oder Einfaßbänder, Rückenverschluß usw., ist es nach herkömmlicher Weise erforderlich, diese Teile durch Nähen miteinander zu verbinden. Das erfordert nicht nur einen sich an den Verbindungsstellen entlangziehenden Nähvorgang, sondern auch den Einsatz eines Verbindungsmediums, z.B. eines Nähfadens.Bras are undergarments that are made with regard to on their determination to cover, support and shape the female breast in many different sizes and shapes must be manufactured and kept in stock. Through her, due to this provision adapted spatial form exist they traditionally consist of a number of different parts, which make up a variety of their composition Work steps that are time-consuming and costly and a rational industrial way of working largely withdraw. Aside from being a bra from a number of different parts, mostly from textile Material, like side parts, bust cups, Carrier tapes, trimming or edging tapes, back closure etc., it is conventionally required to do this Connect parts together by sewing. That requires not just one yourself at the junctions along the sewing process, but also the use of a Connecting medium, e.g. a sewing thread.

Es hat im Stand der Technik nicht an Versuchen gefehlt, einerseits diesen aufwendigen Herstellungsvorgang zu vereinfachen, andererseits aber auch eine Paßform zu finden, die möglichst mehrere Größen und Formen umfaßt, und schließlich diese beiden Bedingungen miteinander zu verbinden.There has been no shortage of attempts in the prior art on the one hand this complex manufacturing process simplify, but also find a fit, which comprises as many sizes and shapes as possible, and finally these two conditions together connect.

So ist ein unter der Bezeichnung "Einer für Alle" vertriebener Büstenhalter bekannt, der aus zwei jeweils einteiligen, die Büstenkörbchen umfassenden Seitenteilen aus textilem, dehnbarem Material besteht. Diese Teile sind jeweils an den Rändern durch Streifen aus elastischem Material verstärkt, welche durch Punktverschweißung mit den Seitenteilen verbunden sind. Auf diese Weise wurden auch Trägerbänder erzeugt, wobei zumindest diese Verstärkungsstreifen von den Seitenteilen ausgehend entlang der Trägerbänder durchlaufen. Wenngleich durch diese Art von Randverstärkungen auf das Verbindungsmedium für den Nähvorgang verzichtet werden konnte, bleibt doch noch der Zeitaufwand, der erforderlich ist, um die Ränder des Büstenhalters zum Erzeugen der Schweißverbindungen abzufahren. Außerdem konnte weder zur Verbindung der Seitenteile, noch zur Anbringung der Verschlußteile oder der Träger auf Nähte verzichtet werden.So one is called "One for All" sold bra known from two each one-piece, the bust cups from side parts textile, stretchy material. These parts are each at the edges by strips of elastic Reinforced material, which is welded to the Side parts are connected. That way too Carrier tapes generated, at least this Reinforcement strips starting from the side panels of the carrier tapes. Although through this type of Edge reinforcements on the connection medium for the Sewing process could be dispensed with, but still remains Time required to cover the edges of the Brassieres for creating welded joints to leave. Furthermore, neither could connect the Side parts, still for attaching the closure parts or the Seams should be avoided.

Vor allem um den Tragekomfort solcher Büstenhalter zu steigern, in die zur Erhöhung der Formungskraft Verstärkungsteile, wie z.B. Stäbchen, Bügel oder dergleichen eingearbeitet sind, ist es auch bekannt geworden, Zuschnitteile in Form der zu verstärkenden Bereiche aus einem entsprechend festeren Material mit einem verschweißbaren Polyestermaterial zu kaschieren und diese Teile dann mit einem zweiten durchgehenden Werkstück aus dehnfähigem Material zusammenzubringen und durch Erwärmen zu einem dreilagigen Werkstück zu verbinden (US 5 154 659). Nach dem Abkühlen werden dann aus dem elastischen Grundmaterial im Brustbereich durch Molden die Büstenkörbchen herausgearbeitet. Auch bei diesem Büstenhalter werden die Seitenteile in der vorderen Mittelachse durch einen Nähvorgang mit Faden miteinander verbunden und die Rückenverschlußteile und Trägerbänder angenäht.Especially for the comfort of such bras increase, in order to increase the shaping power Reinforcement parts such as Chopsticks, hangers or the like are incorporated, it has also become known Cut parts in the form of the areas to be reinforced a correspondingly firmer material with a laminate weldable polyester material and this Then hand out with a second continuous workpiece elastic material to bring together and by heating to connect a three-layer workpiece (US 5 154 659). After cooling, the elastic is then removed Base material in the chest area by Molden die Bust cup worked out. This one too Bra will be the side panels in the front Center axis by sewing with thread together connected and the back fastener parts and carrier tapes sewn on.

In ähnlicher Weise ist es zur Verstärkung ausgewählter Bereiche eines Kleidungsstücks, wie z.B. einer Miederhose oder eines Büstenhalters, bekannt, auf eine Grundlage eines textilen Materials im Siebdruckverfahren in bestimmten Mustern einen pulverförmigen Kleber aufzutragen, der danach in einem Trockenofen aufgeschmolzen wird (EP 0 255 101 B1). Auf die so mit Kleber beschichteten Bereiche der Grundlage wird dann eine den Bereichen des Kleberauftrags entsprechende Decklage aufgebracht, die durch Anwendung von Wärme und Druck mittels des Klebers mit der Grundlage verbunden wird. Festigkeit und Formungseigenschaften werden hier durch Form und Größe des Kleberauftrags sowie Wahl des Klebermaterials bestimmt. Die weitere Konfektionierung auch dieses Büstenhalters erfolgt durch Nähen.Similarly, it is selected for amplification Areas of a garment, such as a panty girdle or a bra, known, on the basis of a textile material in the screen printing process in certain Pattern to apply a powdered glue, after that is melted in a drying oven (EP 0 255 101 B1). On the areas of the base coated with adhesive then becomes one of the areas of the glue application appropriate top layer applied by the application of Heat and pressure using the adhesive with the base is connected. Strength and shaping properties here by the shape and size of the adhesive application and choice of Adhesive material determined. The further assembly too this bra is made by sewing.

Der Erfindung liegt die Aufgabe zugrunde, eine Gestaltung für ein Damenunterbekleidungsstück, insbesondere einen Büstenhalter zu schaffen, die für eine moderne industrielle Fertigung geeignet ist, die vor allem jegliche fortlaufende und ein Verbindungsmedium benötigende Nähvorgänge vermeidet.The invention has for its object a design for a women's undergarment, especially one To create bras that are suitable for a modern industrial Manufacturing is suitable, especially any continuous and avoids sewing operations requiring a connecting medium.

Gemäß der Erfindung wird diese Aufgabe durch ein Damenunterbekleidungsstück, insbesondere einen Büstenhalter mit den im Anspruch 1 angegebenen Merkmalen gelöst.According to the invention, this object is achieved by a Women's undergarment, especially a bra solved with the features specified in claim 1.

Vorteilhafte Weiterbildungen ergeben sich aus den Unteransprüchen.Advantageous further developments result from the Subclaims.

Gegenüber den herkömmlichen Verbindungstechniken, insbesondere durch Nähen, kann der erfindungsgemäße Büstenhalter nicht nur ohne jegliche Fäden oder ähnliche Verbindungsmittel hergestellt werden, sondern es sind auch praktisch nur punktuell, also durch Pressen, Schweißen oder dergleichen, erfolgende Arbeitsgänge zur Verbindung der einzelnen Teile bzw. zur Konfektionierung erforderlich.Compared to the conventional connection techniques, in particular by sewing, the invention Bras not only without any threads or the like Lanyards are made, but so are practically only selectively, i.e. by pressing, welding or the like, operations to connect the individual parts or required for assembly.

Durch den Wegfall von meist störenden und das Dehnverhalten beeinflussenden oder eventuell auch auftragenden, durch Nähen erzeugten Nähten hat der neue Büstenhalter auch verbesserte Trageeigenschaften. Wegen seiner flachen Abschlußkanten bzw. Materialübergänge ist der erfindungsgemäße Büstenhalter ideal zum Tragen unter enganliegender Kleidung, da er sich auf der darüber getragenen Kleidung nicht abzeichnet. Durch verringerte Materialvielfalt ergeben sich gute Pflegeeigenschaften und auch eine vereinfachte Recyclingfähigkeit. Schließlich erlaubt die Herstellungsart auch eine bessere Reproduktion der erforderlichen Paßform und eine vergleichbar günstige Kostenstruktur in der Fertigung.By eliminating the most annoying and stretching behavior influencing or possibly also commissioning, by The new bra also has sewing seams improved wearing properties. Because of its flat End edges or material transitions is the Bra according to the invention ideal for wearing under tight-fitting clothes since he is on top of it worn clothing does not show. By reduced Variety of materials result in good care properties and also a simplified recyclability. Finally the method of manufacture also allows better reproduction the required fit and a comparably cheap Manufacturing cost structure.

Die Erfindung wird nachstehend anhand eines in der Zeichnung dargestellten Ausführungsbeispiels näher erläutert. Es zeigt

- Fig. 1

- eine Innenansicht eines erfindungsgemäßen Büstenhalters, die

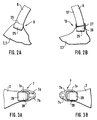

- Fig. 2A/B

- Detaildarstellungen der Befestigung der Trägerbänder,

- Fig. 3A/B

- Detaildarstellungen der Befestigung der Teile eines Rückenverschlusses,

- Fig. 4A/B

- Detaildarstellungen des vorderen mittleren Bereichs einer anderen Ausführungsform des Büstenhalters mit einer stumpfen Schweißnaht und die

- Fig. 5 bis 7

- im schematischen Vertikalschnitt aufeinanderfolgende Stationen der Herstellung einer solchen Schweißnaht.

- Fig. 1

- an interior view of a bra according to the invention, the

- 2A / B

- Detailed representations of the fastening of the carrier tapes,

- 3A / B

- Detailed representations of the fastening of the parts of a back fastener,

- Fig. 4A / B

- Detailed representations of the front middle region of another embodiment of the bra with a butt weld and the

- 5 to 7

- in the schematic vertical section successive stations of the production of such a weld.

In der Zeichnung ist die Erfindung am Beispiel eines Büstenhalters als Damenunterbekleidungsstück dargestellt. Die Erfindung ist aber auch auf andere Bekleidungsstücke anwendbar, die ein ausgearbeitetes Oberteil aufweisen, wie z.B. Badeanzüge oder dergleichen.In the drawing, the invention is based on the example of a Bra shown as a women's undergarment. However, the invention is also applicable to other items of clothing applicable, which have a worked out top, such as e.g. Swimsuits or the like.

In Fig. 1 ist ein erfindungsgemäßer Büstenhalter von der

Innenseite her dargestellt. Der Büstenhalter 1 besteht aus

zwei Seitenteilen 2 und 3, die spiegelsymmetrisch zu einer

vorderen Mittelachse M ausgebildet und angeordnet sind. Die

Seitenteile 2 und 3 umfassen jeweils durch Molden

ausgeformte Büstenkörbchen 4 und 5. Die Seitenteile 2 und 3

sind im Bereich der vorderen Mittelachse M in einem Bereich

6 miteinander verbunden. An den rückwärtigen Enden der

Seitenteile 2 und 3 befinden sich die aktiven und passiven

Teile eines Rückenverschlusses 7. Im vorderen oberen Bereich

der Seitenteile 2 und 3, oberhalb der Büstenkörbchen 4 und

5, sind Trägerbänder 8 bei 9 fest und im rückwärtigen

Bereich bei 10 in einer durch ein Verstellelement 11

gebildeten Schlaufe 12 verstellbar befestigt.In Fig. 1 is a bra according to the invention of the

Shown inside. The bra 1 consists of

two

Die Seitenteile 2 und 3 bestehen jeweils aus einer ihre

gesamte Fläche überdeckenden Lage 13 bzw. 14 aus einem

textilen, in gewissem Maß dehnbaren Material, das zumindest

teilweise thermoplastisch verschmelzbare Fasern enthält. Auf

diese Grundteile 13 und 14 sind von der Innenseite her

Verstärkungsteile aufkaschiert, die in ihrer Gesamtheit mit

15 und 16 bezeichnet sind. Diese Verstärkungsteile 15, 16

bestehen ebenfalls aus einem textilen, vorzugsweise einem

weniger dehnbaren Material, das ebenfalls zumindest

teilweise thermoplastisch verschmelzbare Fasern enthält.The

Wie die Fig. 1 zeigt, bestehen die Verstärkungsteile 15, 16

aus rahmenartigen Zuschnitten, die etwa gleichmäßig breit,

bandartig entlang der Außenränder der Seitenteile 2 bzw. 3

verlaufen, um hier eine Verstärkung und Stabilisierung der

Kanten zu bewirken. Es sind dies untere, parallel zum

unteren Rand 17 verlaufende Teile 18, sich im Rückenbereich

daran anschließende, zu den Trägerbändern 8 verlaufende

Teile 19, entlang der oberen Ränder 20 verlaufende Teile 21

und schließlich oberhalb der Büstenkörbchen 4, 5 verlaufende

Teile 22. Ausgehend vom unteren Rand 17 des Büstenhalters 1

erstrecken sich die Teile 18 der Verstärkungen 15, 16 bis in

den Bereich der Büstenkörbchen 4 und 5 hinein; sie bilden

dort Verstärkungen 23 zur Stützung der Brust bzw. zur

Formung ihrer Kontur.1 shows, the reinforcing

Wenn auch das erfindungsgemäße Unterbekleidungsstück hier am Beispiel eines Büstenhalters mit Rückenverschluß und Trägerbändern dargestellt ist, so ist die Erfindung doch nicht hierauf beschränkt. Der Büstenhalter kann anstelle eines Rückenverschlusses auch einen Vorderverschluß besitzen bzw. ganz ohne Verschluß als sogenannter "step-in Bra" ausgebildet sein. Ebenso kann er auch ohne Trägerbänder, also trägerlos ausgebildet sein. Schließlich ist die Erfindung auch auf Badeanzüge, und zwar sowohl einteilige als auch Bikini anwendbar.If the undergarment according to the invention here on Example of a bra with back closure and Carrier tapes is shown, so the invention is not limited to this. The bra can be used instead a back closure also have a front closure or completely without closure as a so-called "step-in bra" be trained. It can also be used without carrier tapes, so be strapless. After all, that is Invention also on swimsuits, both in one piece as well as bikini applicable.

Zur Herstellung des erfindungsgemäßen Büstenhalters werden

zunächst die beiden Seitenteile 2 und 3 hergestellt, diese

sodann im vorderen mittleren Bereich 6 miteinander verbunden

und schließlich die Trägerbänder 8 und die Verschlußteile 7

angebracht.To manufacture the bra according to the invention

first made the two

Zur Herstellung der Seitenteile 2 und 3 des Büstenhalters 1

wird zunächst auf eine Grundbahn oder einen Grobzuschnitt

des die Verstärkungen 15, 16 bildenden textilen Materials

eine Beschichtung aufgebracht, durch die eine Verbindung mit

der Grundbahn 13 bzw. 14 hergestellt werden kann. Dies kann

entweder eine "hot melt"-Kleberbeschichtung sein, oder auch

eine dünne, durch Anwendung von Wärme aktivierbare Folie.

Danach werden aus diesem Grobzuschnitt die Innenkonturen der

Verstärkungsteile 15, 16 ausgestanzt und die verbleibenden

rahmenartigen Teile - noch ohne Außenkontur - auf den

Grobzuschnitt für die Zuschnitteile 13 und 14 aufgelegt.

Durch Anwendung von Wärme und Druck werden die die

Verstärkungsteile 15, 16 enthaltenden Grobzuschnitte mit den

Grobzuschnitten 13, 14 der Grundbahn verbunden. Erst danach

werden die Büstenkörbchen 4 und 5 gemoldet und die

Außenkonturen gestanzt. Dabei ist es sinnvoll, jeweils zwei

einander entsprechende Seitenteile 2 und 3 in zueinander

kongruenter Lage übereinanderzulegen.For the production of the

Nach diesen vorbereitenden Maßnahmen beginnt die

Konfektionierung des Büstenhalters. Hierzu werden die

übereinanderliegend gestanzten und gemoldeten Teile 2 und 3

aufgeschlagen, im vorderen mittleren Bereich 6 der

Mittelachse M zu einer dreieckförmigen Überlappung 23

gebracht und in diesem Bereich durch eine Schweißnaht 24

fest miteinander verbunden. Dies kann durch einen einzigen

Preß- und Schweißvorgang erfolgen. Diese Verbindung kann

auch durch eine Motivgestaltung, z.B. "Blüte", optisch

attraktiv gestaltet werden.After these preparatory measures, the

Assembling the bra. For this, the

superimposed stamped and molded

Sodann werden die Teile des Rückenverschlusses 7 und die

Trägerbänder 8 angebracht. Dies kann anhand der Fig. 2 und 3

erläutert werden, die jeweils Ausschnitte in größerem

Maßstab zeigen.Then the parts of the

Die feste Verbindung 9 der Trägerbänder 8 mit den vorderen

oberen Bereichen des Büstenhalters 1 zeigt Fig. 2A. Die

Trägerbänder 8, die meist aus elastischem Bandmaterial

bestehen, enthalten in aller Regel thermoplastisch

verschmelzbare Fasern, so daß sie, mit den entsprechenden

Bereichen der Seitenteile 2, 3 in Überlappung gebracht,

durch Schweißnähte 25 miteinander verbunden werden können.

Zur verstellbaren Befestigung 10 der Trägerbänder 8 im

rückwärtigen Bereich (Fig. 2B) wird aus dem Material der

Seitenteile 2 bzw. 3 mit aufkaschierter Verstärkung eine

Lasche 26 gebildet, die durch eine Öse 27 gezogen und dann

zurückgeschlagen wird. Durch eine Schweißnaht 25 wird die

Lasche 26 mit dem Seitenteil 2 bzw. 3 verschweißt. Durch die

Öse 27 wird in an sich bekannter Weise das Trägerband 8

gezogen, das eine Schlaufe 12 bildet.The fixed

In ähnlicher Weise wird mit den Teilen des

Rückenverschlusses 7 verfahren (Fig. 3). Der Rückenverschluß

7 besteht aus einem aktiven Verschlußteil 7a und einem

passiven Verschlußteil 7b. Das aktive Verschlußteil 7a

besitzt einen Verschlußkopf 7c, das passive Verschlußteil 7b

eine Ausnehmung 7d. Beide Verschlußteile 7a und 7b setzen

sich jeweils in eine Öse 7e fort. Auch hier laufen die Enden

der Seitenteile 2 bzw. 3 in Laschen 28 aus, die jeweils

durch die Ösen 7e hindurchgezogen und nach rückwärts

umgeschlagen werden, um dann durch Schweißnähte 29 mit dem

Material der Seitenteile 2 bzw. 3 verschweißt zu werden.Similarly, with the parts of the

Move back fastener 7 (Fig. 3). The

Hieraus folgt, daß es zur Konfektionierung des erfindungsgemäßen Büstenhalters keiner entlang einer Strecke verlaufender und ein Verbindungsmedium benötigender Nähvorgänge bedarf; die Herstellung beschränkt sich vielmehr auf einfache Stanz-, Preß- und Schweißvorgänge, also auf Vorgänge, die auf einfache Weise automatengerecht durch Maschinen ausgeführt werden können.It follows from this that it is for the assembly of the Brassieres according to the invention none along a route running and requiring a connection medium Sewing operations required; the production is rather limited on simple punching, pressing and welding processes, i.e. on Processes that can be carried out easily in a way that is suitable for automatic machines Machines can be run.

Während die Seitenteile 2, 3 des erfindungsgemäßen

Büstenhalters 1 in dem in Fig. 1 dargestellten

Ausführungsbeispiel im vorderen mittleren Bereich 6 durch

Überlappung 23 gestoßen und durch eine dem dreieckförmigen

Umriß des Überlappungsstoßes entsprechende, ebenfalls

dreieckförmige Schweißnaht 24 verbunden sind, besteht auch

die Möglichkeit, die Seitenteile 2, 3 im vorderen mittleren

Bereich 6 zwischen den Büstenkörbchen 4, 5 kantengleich

stumpf in einer Schweißnaht 30 miteinander zu verbinden.

Diese Möglichkeit ist in Fig. 4A im Detail in Vorderansicht

und in Fig. 4B in entsprechendem Ausschnitt in einer Ansicht

von der Innenseite her dargestellt. Wie eine solche stumpfe

Schweißnaht auf einfache Weise hergestellt werden kann, ist

schematisch in einigen aufeinanderfolgenden Phasen in den

Fig. 5 bis 7 dargestellt.While the

Diese einfache Verbindungsmöglichkeit beruht darauf, daß

erfindungsgemäß sowohl für die Grobzuschnitte 13, 14 der

Seitenteile, als auch für die Verstärkungsteile 15, 16

textile Materialien verwendet werden, die zumindest

teilweise thermoplastisch verschmelzbare Fasern enthalten.

Derartige Fasern können durch Anwendung von Ultraschall oder

Wärme, gegebenenfalls unter gleichzeitiger Anwendung von

Druck, verschweißt werden. Dabei gelingt es, nach

Übereinanderlegen der aus den Grobzuschnitten 13, 14 und den

Verstärkungsteilen 15, 16 bestehenden Seitenteile 2, 3 in

zueinander kongruenter Lage diese im Bereich der später den

vorderen mittleren Bereich 6 bildenden Enden 32, 33 durch

Schweißung mit Druckanwendung unter vollständiger

Durchtrennung so miteinander zu verbinden, daß nach

Aufschlagen der Teile 2, 3 die beiden aufeinanderliegend

miteinander verschweißten Enden 32, 33 in eine gestreckte

Lage geraten und so kantengleich stumpf miteinander

verschweißt sind. Auf diese Weise gelingt eine praktisch

unsichtbare, jedenfalls nicht auftragende geradlinige

Verbindung der beiden vorderen inneren Enden der Seitenteile

2, 3.This simple connection option is based on the fact that

according to the invention both for the

Um diese Schweißnaht 30 zu sichern und zugleich diesen sehr

stark beanspruchten vorderen mittleren Bereich 6 des

Büstenhalters 1 zu verstärken, ist es sinnvoll, in diesem

Bereich vorzugsweise an der Innenseite des Büstenhalters ein

Verstärkungsteil 31 aufzukaschieren, das sinnvollerweise aus

dem gleichen Material besteht wie die Seitenteile 2, 3

selbst und in gleicher Weise wie deren verschiedene Lagen

mit diesen Materiallagen verbunden werden kann (Fig. 4A/B).To secure this

Wie eine solche stumpfe Schweißnaht 30 vorteilhaft erzeugt

werden kann, zeigen die Fig. 5 bis 7.How such a

In Fig. 5 ist schematisch dargestellt, wie die beiden

Seitenteile 2, 3 aus dem Grundmaterial 13, 14 und den

Verstärkungsteilen 15, 16 so aufeinandergelegt werden, daß

deren vordere innere Enden 32, 33 einander decken. Der

doppellagige Bereich wird sodann in den Wirkungsbereich

eines Ultraschallschweißgerätes 34 gebracht, das lediglich

durch eine Sonotrode 34a und ein unteres Widerlager 34b

angedeutet ist. Das untere Widerlager 34b hat in seinem

oberen, dem Material zugewandten Teil dreieckförmigen

Querschnitt, um nicht nur eine Verschweißung, sondern auch

eine Trennung der Materialteile zu ermöglichen.In Fig. 5 is shown schematically how the two

Durch Herabführen der Sonotrode 34a in Richtung des Pfeils

35 wird dem zwischen der Sonotrode 34a und dem Widerlager

34b befindlichen Material Energie zugeführt. Dies führt zu

einer Wärmeentwicklung und somit zu einem Verschweißen der

Kunsttoffäden in den beiden Materiallagen. Die die beiden

übereinanderliegenden Enden 32, 33 der Seitenteile 2, 3

verbindende Schweißnaht 30 ist in Fig. 6, welche die

Situation nach Schweißung und Trennung zeigt, angedeutet. By lowering the sonotrode 34a in the direction of the

Damit sind die beiden vorderen mittleren Ränder 32, 33 der

Seitenteile 2, 3 miteinander verbunden.The two front

Nach dem Aufschlagen der beiden Seitenteile 2 und 3 geraten

die zuvor noch aufeinanderliegenden Enden 32, 33 in eine

gestreckte Lage (Fig. 7), in der die Seitenteile 2, 3 mit

ihren Enden 32, 33 kantengleich stumpf miteinander gestoßen

sind.After opening both

Claims (12)

- Ladies' undergarment, in particular a brassiere, consisting of two side parts (2, 3) which comprise the cups (4, 5), are joined together in the front central area (6) between the cups (4, 5), have a back fastener (7) at the back ends and are provided with shoulder straps (8), characterised by the following featuresa) the side parts (2, 3) each consist of a blank (13, 14) which covers their entire surface and consists of a textile material which comprises at least in part thermoplastically fusible fibres,b) reinforcement parts (15, 16) are bonded to the blank parts (13, 14), at least along their outer edges, which parts (15, 16) also consist of a textile material which comprises at least in part thermoplastically fusible fibres,c) the side parts (2, 3) are joined together in the front central area (6) by a weld (24, 30) produced by thermal means,d) the parts (7a, 7b) of the back fastener (7) as well as the shoulder straps (8) are indirectly or directly joined to the side parts (2, 3) by welds (25, 29) produced by thermal means.

- Brassiere according to claim 1, characterised in that the blank parts (13, 14) of the side parts (2, 3) and/or the reinforcement parts (15, 16) consist of an elastic material.

- Brassiere according to claim 1 or 2, characterised in that the reinforcement parts (15, 16) extend approximately like a tape with a substantially uniform width along the edges of the side parts (2, 3).

- Brassiere according to claim 3, characterised in that, starting from the bottom edge (17) of the brassiere (1), the reinforcement parts (15, 16) extend into the area of the cups (4, 5).

- Brassiere according to one of claims 1 to 4, characterised in that the outer contour and the arrangement of the reinforcement parts (15, 16) are adapted to the respective fit requirements.

- Brassiere according to one of claims 3 to 5, characterised in that the tape-like areas (18, 19, 21, 22) of the reinforcement parts (15, 16) are undulating.

- Brassiere according to one of claims 1 to 6, characterised in that the side parts (2, 3) overlap in the front central area (6) between the cups (4, 5) and are joined together in the area of the overlap (23) by a weld (24).

- Brassiere according to one of claims 1 to 6, characterised in that the facing ends (32, 33) of the side parts (2, 3) are butt-welded together edge-to-edge in a weld (30) in the front central area (6) between the cups (4, 5).

- Brassiere according to claim 8, characterised in that the weld (30) is preferably backed with a bonded reinforcement part (31) on the inside of the brassiere (1).

- Brassiere according to one of claims 1 to 9, characterised in that the side parts (2, 3) form at the back ends narrow tongues which are passed through eyelets (7e) of the back fastener parts (7a, 7b) and closed by forming a loop (28).

- Brassiere according to one of claims 1 to 10, characterised in that the shoulder straps (8) are joined directly to the side parts at the front shoulder strap fixtures (9).

- Brassiere according to one of claims 1 to 11, characterised in that the shoulder straps (8) are attached to the back shoulder strap fixtures (10) such that they can be adjusted by means of a respective loop (12) at an eyelet (27), which eyelets are in turn joined to the side parts (2, 3) by means of a tongue (26) which is pulled through and formed into a loop.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SI9730016T SI0809945T1 (en) | 1996-05-31 | 1997-05-23 | Ladies underwear, especially brassiÞre |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE29609672U | 1996-05-31 | ||

| DE29609672U DE29609672U1 (en) | 1996-05-31 | 1996-05-31 | Bra |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0809945A2 EP0809945A2 (en) | 1997-12-03 |

| EP0809945A3 EP0809945A3 (en) | 1998-09-23 |

| EP0809945B1 true EP0809945B1 (en) | 1999-09-01 |

Family

ID=8024621

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP97108357A Expired - Lifetime EP0809945B1 (en) | 1996-05-31 | 1997-05-23 | Ladies underwear, especially brassière |

Country Status (23)

| Country | Link |

|---|---|

| US (1) | US5820443A (en) |

| EP (1) | EP0809945B1 (en) |

| JP (1) | JP3057027B2 (en) |

| CN (1) | CN1106164C (en) |

| AT (1) | ATE183895T1 (en) |

| BR (1) | BR9703413A (en) |

| CZ (1) | CZ284559B6 (en) |

| DE (2) | DE29609672U1 (en) |

| DK (1) | DK0809945T3 (en) |

| EE (1) | EE9700120A (en) |

| ES (1) | ES2138414T3 (en) |

| GR (1) | GR3031946T3 (en) |

| HK (1) | HK1008970A1 (en) |

| HR (1) | HRP970300B1 (en) |

| HU (1) | HU216817B (en) |

| IS (1) | IS4489A (en) |

| NO (1) | NO309355B1 (en) |

| PL (1) | PL183760B1 (en) |

| RU (1) | RU2127535C1 (en) |

| SI (1) | SI0809945T1 (en) |

| SK (1) | SK68497A3 (en) |

| UA (1) | UA42031C2 (en) |

| YU (1) | YU22297A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1275313A2 (en) | 2001-07-11 | 2003-01-15 | MAYSER GmbH & Co. | Manufacturing method of under garments ot sport garments and garment thereby obtained |

| WO2010081446A2 (en) | 2009-01-17 | 2010-07-22 | Mayser Gmbh & Co. Kg | Flocking film, method for the production thereof, and use thereof |

Families Citing this family (53)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1033084B1 (en) * | 1999-02-26 | 2003-04-23 | Triumph International Aktiengesellschaft | Ladies' undergarment |

| DE29920469U1 (en) * | 1999-06-06 | 2000-10-19 | Triumph International Ag | Underwear, in particular women's underwear |

| DE29909775U1 (en) * | 1999-06-06 | 2000-10-12 | Triumph International Ag | Brassieres with stiffening straps |

| IT1311535B1 (en) * | 1999-08-02 | 2002-03-13 | Benetton Spa | STRUCTURE OF A CLOTHING, IN PARTICULAR A BRA. |

| DE19944700C1 (en) * | 1999-09-18 | 2001-05-10 | Hans Bauer | Process for the production of undergarments by means of an adhesive connection |

| IT1317820B1 (en) * | 2000-02-09 | 2003-07-15 | Erreci Spa | PERFECTED BRA. |

| FR2806267B1 (en) * | 2000-05-29 | 2002-08-09 | Georges Lucien Altounian | METHOD FOR FINISHING AN EDGE OF A GARMENT PIECE OR A GARMENT |

| FR2809932B1 (en) | 2000-06-09 | 2002-09-27 | Playtex Apparel Inc | LINGERIE ARTICLE MADE FROM A CYLINDRICAL KNITTING COMPRISING HOLDING CHARACTERISTICS |

| KR20030068122A (en) * | 2000-07-20 | 2003-08-19 | 사라 리 브랜디드 어패럴 이탈리아 에스.피.에이. | Stiffened Brassiere |

| US6296728B1 (en) * | 2000-08-07 | 2001-10-02 | Shirley Mao | Brassiere and manufacturing process thereof |

| AU2001273507A1 (en) * | 2000-10-05 | 2002-04-15 | Alba-Waldensian, Inc. | Garments assembled without sewing |

| IT1320082B1 (en) * | 2000-11-10 | 2003-11-18 | Fashion Lab S R L | PROCEDURE FOR THE CREATION OF BRA, AS WELL AS BRA 'OBTAINED. |

| US6517651B2 (en) | 2000-12-21 | 2003-02-11 | Tefron Ltd. | Apparatus and method for joining fabrics without sewing |

| TW526714U (en) * | 2001-01-19 | 2003-04-01 | Strong Castle Ind Co Ltd | Seamless bra |

| US6837771B2 (en) * | 2001-02-06 | 2005-01-04 | Playtex Apparel, Inc. | Undergarments made from multi-layered fabric laminate material |

| US7690965B2 (en) * | 2001-02-06 | 2010-04-06 | Hbi Branded Apparel Enterprises, Llc | Methods of making cotton blend glue brassieres |

| FR2823075B1 (en) * | 2001-04-05 | 2003-08-15 | Desseilles Textiles Sa | PROCESS FOR PRODUCING A TEXTILE ARTICLE, PARTICULARLY FOR A BRA |

| ITBO20010423A1 (en) * | 2001-07-03 | 2003-01-03 | Liberti Spa | METHOD TO CREATE AN UNDERWEAR OR SWIMSUIT |

| EP1275312A1 (en) * | 2001-07-11 | 2003-01-15 | Hui-Na Mao | Brassiere and manufacturing process thereof |

| DE10151643C1 (en) * | 2001-10-11 | 2003-07-10 | Naturana Doelker Gmbh & Co Kg | bra |

| JP3939965B2 (en) * | 2001-11-19 | 2007-07-04 | グンゼ株式会社 | Bra fasteners, method for producing the same, and bras using the same |

| ES2197824B1 (en) * | 2002-06-21 | 2005-05-01 | Manufacturas Teleno, S.L. | Textile products bonding technique includes thermal adhesive application for hot pressing of overlapped and reinforced textiles |

| ITCO20020013U1 (en) * | 2002-08-08 | 2004-02-09 | Airily Srl | SUPPORT THAT REPLACES THE FERRETTO IN THE BRA |

| EP1571936B1 (en) * | 2002-12-05 | 2008-06-11 | DBA Lux 1 Sàrl | A brassiere |

| US20070004315A1 (en) * | 2003-01-21 | 2007-01-04 | Theone Luk | Brassiere |

| US7179150B2 (en) * | 2003-01-21 | 2007-02-20 | Regina Miracle International Limited | Brassiere |

| US6805610B2 (en) * | 2003-01-21 | 2004-10-19 | Regina Miracle International Limited | Brassiere |

| FR2850536B1 (en) | 2003-02-03 | 2005-03-25 | Lee Sara Corp | TEXTILE ARTICLE OF LINGERIE MOLD, ESPECIALLY BRASS, WITH SILICONE SUPPORT REGION |

| EP1601258A2 (en) * | 2003-02-19 | 2005-12-07 | Sara Lee Corporation | Fusion undergarment |

| US7214120B2 (en) * | 2003-02-19 | 2007-05-08 | Hbi Branded Apparel Enterprises, Llc | Brassiere having a spacer fabric and a method of making same |

| US6837772B1 (en) * | 2003-07-18 | 2005-01-04 | Regina Miracle International Limited | Breast cup construction |

| US7131888B2 (en) * | 2004-08-31 | 2006-11-07 | Chi-Shang Enterprise Ltd. | Bra cups without sewing seams |

| US20060281389A1 (en) * | 2004-11-12 | 2006-12-14 | Zhen Qiang Liu | Brassiere |

| US7192332B2 (en) * | 2004-11-12 | 2007-03-20 | Regina Miracle International Limited | Brassiere |

| US7854022B2 (en) | 2005-01-10 | 2010-12-21 | Hbi Branded Apparel Enterprises, Llc | Garments having seamless edge bands and processes for making same |

| JP2006200084A (en) * | 2005-01-21 | 2006-08-03 | Utax:Kk | Garment having back part such as brassiere |

| US7128635B1 (en) * | 2005-11-04 | 2006-10-31 | Regina Miracle International Ltd. | Molded seamless brassiere incorporating fasteners |

| US20070251636A1 (en) * | 2006-05-01 | 2007-11-01 | Anthony Herbert | Bonding elastic to fabric of a garment |

| WO2007143928A1 (en) * | 2006-06-08 | 2007-12-21 | Clover Group International Limited | Method for joining fabric panels and manufacturing brassieres |

| US7927441B2 (en) * | 2006-06-08 | 2011-04-19 | Clover Group International Limited | Method for joining fabric panels and manufacturing brassieres |

| US20080096465A1 (en) * | 2006-10-18 | 2008-04-24 | Zhen Qiang Liu | Brassiere |

| US7758401B2 (en) * | 2006-12-06 | 2010-07-20 | Hbi Branded Apparel Enterprises, Llc | Upper support garment having an improved back |

| RU2368511C1 (en) * | 2008-03-26 | 2009-09-27 | Игорь Олегович Макаревич | Method of producing decorative product |

| US8251772B2 (en) * | 2010-05-10 | 2012-08-28 | Mei Hui Lin | Method for forming a brassiere cup |

| US10441003B2 (en) * | 2011-03-02 | 2019-10-15 | Clover Mystique Co. Limited | X-shaped brassiere support and brassiere incorporating such support |

| CN104248048B (en) * | 2013-06-28 | 2017-04-26 | 维珍妮国际(集团)有限公司 | Method for attaching fixed part liner of bra to flanks and bra and assembly |

| US9351524B2 (en) * | 2014-01-28 | 2016-05-31 | Tracy Buescher | Brassiere accessory |

| US9427030B2 (en) | 2014-01-28 | 2016-08-30 | Tracy Buescher | Brassiere accessory |

| KR200481709Y1 (en) | 2014-10-02 | 2016-11-03 | 신칠호 | Cabinet fixing device |

| CN110996698A (en) * | 2017-07-31 | 2020-04-10 | 旭化成株式会社 | Underwear and bra |

| US10231492B1 (en) * | 2017-11-27 | 2019-03-19 | Gelmart Industries, Inc. | Supportive light weight bra |

| US10721974B2 (en) * | 2017-11-27 | 2020-07-28 | Gelmart Industries, Inc. | Light weight supportive bra |

| WO2019202652A1 (en) * | 2018-04-17 | 2019-10-24 | 株式会社ユタックス | Garment having cup portions and method of manufacturing same |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2659085A (en) * | 1951-08-09 | 1953-11-17 | Hilda M Ericson | Brassiere |

| US2721323A (en) * | 1952-08-09 | 1955-10-25 | Int Latex Corp | Preformed deposited brassiere |

| US2797415A (en) * | 1952-08-09 | 1957-07-02 | Int Latex Corp | Preformed latex brassiere |

| US2772418A (en) * | 1954-01-11 | 1956-12-04 | Int Latex Corp | Rubber latex brasseiere |

| US2824563A (en) * | 1955-11-17 | 1958-02-25 | Iver F Hill | Plastic brassiere |

| US3225768A (en) * | 1961-07-17 | 1965-12-28 | Jantzen Inc | Fabric laminated brassiere |

| IT699907A (en) * | 1962-06-12 | |||

| FR2562768B3 (en) * | 1984-04-11 | 1986-06-27 | Dim Sa | BRA |

| US4701964A (en) * | 1986-07-29 | 1987-10-27 | International Playtex, Inc. | Garment having additional support to selected portions |

| DE8705929U1 (en) * | 1987-04-24 | 1987-08-20 | Naturana Doelker Gmbh & Co Kg, 7413 Gomaringen, De | |

| US5154659A (en) * | 1990-12-14 | 1992-10-13 | Gerald Gluckin | Method of making molded brassiere cup and side panel |

| US5447462A (en) * | 1993-04-13 | 1995-09-05 | Playtex Apparel, Inc. | Fabric laminate and garments incorporating same |

-

1996

- 1996-05-31 DE DE29609672U patent/DE29609672U1/en not_active Expired - Lifetime

-

1997

- 1997-05-23 ES ES97108357T patent/ES2138414T3/en not_active Expired - Lifetime

- 1997-05-23 AT AT97108357T patent/ATE183895T1/en active

- 1997-05-23 DK DK97108357T patent/DK0809945T3/en active

- 1997-05-23 DE DE59700380T patent/DE59700380D1/en not_active Expired - Fee Related

- 1997-05-23 SI SI9730016T patent/SI0809945T1/en unknown

- 1997-05-23 EP EP97108357A patent/EP0809945B1/en not_active Expired - Lifetime

- 1997-05-26 IS IS4489A patent/IS4489A/en unknown

- 1997-05-27 JP JP9136861A patent/JP3057027B2/en not_active Expired - Fee Related

- 1997-05-28 PL PL97320245A patent/PL183760B1/en not_active IP Right Cessation

- 1997-05-28 YU YU22297A patent/YU22297A/en unknown

- 1997-05-28 NO NO972431A patent/NO309355B1/en not_active IP Right Cessation

- 1997-05-29 CZ CZ971669A patent/CZ284559B6/en not_active IP Right Cessation

- 1997-05-29 US US08/865,000 patent/US5820443A/en not_active Expired - Fee Related

- 1997-05-29 HR HR970300A patent/HRP970300B1/en not_active IP Right Cessation

- 1997-05-29 HU HU9700969A patent/HU216817B/en not_active IP Right Cessation

- 1997-05-30 UA UA97052544A patent/UA42031C2/en unknown

- 1997-05-30 SK SK684-97A patent/SK68497A3/en unknown

- 1997-05-30 RU RU97109095A patent/RU2127535C1/en active

- 1997-05-30 EE EE9700120A patent/EE9700120A/en unknown

- 1997-05-31 CN CN97113560A patent/CN1106164C/en not_active Expired - Fee Related

- 1997-06-02 BR BR9703413A patent/BR9703413A/en not_active IP Right Cessation

-

1998

- 1998-08-10 HK HK98109796A patent/HK1008970A1/en not_active IP Right Cessation

-

1999

- 1999-11-25 GR GR990403039T patent/GR3031946T3/en unknown

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1275313A2 (en) | 2001-07-11 | 2003-01-15 | MAYSER GmbH & Co. | Manufacturing method of under garments ot sport garments and garment thereby obtained |

| DE10133644A1 (en) * | 2001-07-11 | 2003-04-03 | Mayser Gmbh & Co Kg | Process for the manufacture of an undergarment or sportswear item and item of clothing produced thereafter |

| DE10133644C2 (en) * | 2001-07-11 | 2003-07-10 | Mayser Gmbh & Co Kg | Process for the manufacture of an undergarment or sportswear item and item of clothing produced thereafter |

| WO2010081446A2 (en) | 2009-01-17 | 2010-07-22 | Mayser Gmbh & Co. Kg | Flocking film, method for the production thereof, and use thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| CN1106164C (en) | 2003-04-23 |

| NO972431L (en) | 1997-12-01 |

| HRP970300A2 (en) | 1998-04-30 |

| PL320245A1 (en) | 1997-12-08 |

| SK68497A3 (en) | 1997-12-10 |

| JP3057027B2 (en) | 2000-06-26 |

| EP0809945A3 (en) | 1998-09-23 |

| PL183760B1 (en) | 2002-07-31 |

| HK1008970A1 (en) | 1999-05-21 |

| ES2138414T3 (en) | 2000-01-01 |

| HRP970300B1 (en) | 2000-10-31 |

| EE9700120A (en) | 1998-02-16 |

| BR9703413A (en) | 1998-09-15 |

| DE29609672U1 (en) | 1997-10-02 |

| HUP9700969A3 (en) | 1998-10-28 |

| JPH1088405A (en) | 1998-04-07 |

| CZ284559B6 (en) | 1999-01-13 |

| EP0809945A2 (en) | 1997-12-03 |

| GR3031946T3 (en) | 2000-03-31 |

| CZ166997A3 (en) | 1997-12-17 |

| IS4489A (en) | 1997-12-01 |

| DK0809945T3 (en) | 2000-03-27 |

| CN1174686A (en) | 1998-03-04 |

| SI0809945T1 (en) | 1999-12-31 |

| RU2127535C1 (en) | 1999-03-20 |

| US5820443A (en) | 1998-10-13 |

| UA42031C2 (en) | 2001-10-15 |

| YU22297A (en) | 1999-11-22 |

| NO309355B1 (en) | 2001-01-22 |

| NO972431D0 (en) | 1997-05-28 |

| HU9700969D0 (en) | 1997-07-28 |

| DE59700380D1 (en) | 1999-10-07 |

| HUP9700969A2 (en) | 1997-11-28 |

| ATE183895T1 (en) | 1999-09-15 |

| HU216817B (en) | 1999-09-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0809945B1 (en) | Ladies underwear, especially brassière | |

| DE60316803T2 (en) | BUST HOLDER WITH SHAPED CARRIER | |

| EP1211956B2 (en) | Method for producing undergarment by using glued joints | |

| US8176572B2 (en) | Method of forming a laminated fabric panty | |

| EP1275313B1 (en) | Manufacturing method of under garments ot sport garments and garment thereby obtained | |

| EP1033084B1 (en) | Ladies' undergarment | |

| DE60033194T2 (en) | STICKED BRA | |

| DE202007006693U1 (en) | bra | |

| WO2014174332A1 (en) | Closure | |

| DE202007006694U1 (en) | bra | |

| DE202007006705U1 (en) | bra | |

| EP1060678A2 (en) | Brassiere with shaping inserts | |

| DE202007006700U1 (en) | bra | |

| DE202007006706U1 (en) | Brassiere with information carrier | |

| DE202007006704U1 (en) | bra | |

| DE202009011419U1 (en) | Fabric cut for a garment, in particular underwear item | |

| DE60119390T2 (en) | METHOD FOR THE PRODUCTION OF LUSHES, PANTS AND THE LIKE | |

| EP0604812B1 (en) | Brassière having a support wire | |

| DE2939573A1 (en) | METHOD FOR PRODUCING A POCKET / OR POCKET HATCHES ON CLOTHING PIECES, AND A POCKET AND / OR POCKET HAT MADE BY THE METHOD | |

| EP1302118B1 (en) | Brassiere | |

| EP1101416B1 (en) | Brassiere | |

| EP0749701B1 (en) | Tubular textile band, in particular to use as a waistband | |

| EP2241205A2 (en) | Item of clothing with small cup | |

| DE4442344C1 (en) | Brassiere wiring | |

| WO2016115580A1 (en) | Connecting element for clothing parts which are to be connected to one another |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: LT PAYMENT 970612;LV PAYMENT 970612;SI PAYMENT 970612 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: LT PAYMENT 970612;LV PAYMENT 970612;SI PAYMENT 970612 |

|

| 17P | Request for examination filed |

Effective date: 19980827 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| 17Q | First examination report despatched |

Effective date: 19990126 |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: LT PAYMENT 19970612;LV PAYMENT 19970612;SI PAYMENT 19970612 |

|

| REF | Corresponds to: |

Ref document number: 183895 Country of ref document: AT Date of ref document: 19990915 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59700380 Country of ref document: DE Date of ref document: 19991007 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: PATENTANWAELTE SCHAAD, BALASS, MENZL & PARTNER AG |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| ITF | It: translation for a ep patent filed |

Owner name: JACOBACCI & PERANI S.P.A. |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19991202 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2138414 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 19991130 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| LTIE | Lt: invalidation of european patent or patent extension | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20000523 Year of fee payment: 4 Ref country code: MC Payment date: 20000523 Year of fee payment: 4 Ref country code: LU Payment date: 20000523 Year of fee payment: 4 Ref country code: FI Payment date: 20000523 Year of fee payment: 4 Ref country code: BE Payment date: 20000523 Year of fee payment: 4 Ref country code: AT Payment date: 20000523 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20000524 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20000525 Year of fee payment: 4 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20000529 Year of fee payment: 4 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010523 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010523 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010523 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010523 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010523 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010524 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010531 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010622 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010622 |

|

| BERE | Be: lapsed |

Owner name: TRIUMPH INTERNATIONAL A.G. Effective date: 20010531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011130 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20011201 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20011201 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20011130 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20080523 Year of fee payment: 12 Ref country code: DE Payment date: 20080426 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20080524 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20080522 Year of fee payment: 12 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20080527 Year of fee payment: 12 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20090523 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20100129 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090602 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20080519 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090523 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091202 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20091201 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20090525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090525 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090523 |