EP2425791B1 - Dynamic and static bipolar electrical sealing and cutting device - Google Patents

Dynamic and static bipolar electrical sealing and cutting device Download PDFInfo

- Publication number

- EP2425791B1 EP2425791B1 EP11180182.5A EP11180182A EP2425791B1 EP 2425791 B1 EP2425791 B1 EP 2425791B1 EP 11180182 A EP11180182 A EP 11180182A EP 2425791 B1 EP2425791 B1 EP 2425791B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- jaw members

- tissue

- end effector

- disposed

- effector assembly

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000007789 sealing Methods 0.000 title claims description 100

- 230000003068 static effect Effects 0.000 title claims description 74

- 239000012636 effector Substances 0.000 claims description 53

- 230000004913 activation Effects 0.000 claims description 4

- 239000012212 insulator Substances 0.000 description 23

- 230000000694 effects Effects 0.000 description 14

- 238000002224 dissection Methods 0.000 description 9

- 230000007246 mechanism Effects 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 238000012800 visualization Methods 0.000 description 3

- 238000002679 ablation Methods 0.000 description 2

- 239000011248 coating agent Substances 0.000 description 2

- 238000000576 coating method Methods 0.000 description 2

- 238000012976 endoscopic surgical procedure Methods 0.000 description 2

- WABPQHHGFIMREM-AKLPVKDBSA-N lead-210 Chemical compound [210Pb] WABPQHHGFIMREM-AKLPVKDBSA-N 0.000 description 2

- 238000001356 surgical procedure Methods 0.000 description 2

- 230000002792 vascular Effects 0.000 description 2

- 102000008186 Collagen Human genes 0.000 description 1

- 108010035532 Collagen Proteins 0.000 description 1

- 102000016942 Elastin Human genes 0.000 description 1

- 108010014258 Elastin Proteins 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 230000000740 bleeding effect Effects 0.000 description 1

- 229920001436 collagen Polymers 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 229920002549 elastin Polymers 0.000 description 1

- 230000023597 hemostasis Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000002355 open surgical procedure Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B18/00—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body

- A61B18/04—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body by heating

- A61B18/12—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body by heating by passing a current through the tissue to be heated, e.g. high-frequency current

- A61B18/14—Probes or electrodes therefor

- A61B18/1442—Probes having pivoting end effectors, e.g. forceps

- A61B18/1445—Probes having pivoting end effectors, e.g. forceps at the distal end of a shaft, e.g. forceps or scissors at the end of a rigid rod

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B18/00—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body

- A61B18/04—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body by heating

- A61B18/08—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body by heating by means of electrically-heated probes

- A61B18/082—Probes or electrodes therefor

- A61B18/085—Forceps, scissors

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B18/00—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body

- A61B18/04—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body by heating

- A61B18/12—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body by heating by passing a current through the tissue to be heated, e.g. high-frequency current

- A61B18/1206—Generators therefor

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods, e.g. tourniquets

- A61B17/28—Surgical forceps

- A61B17/285—Surgical forceps combined with cutting implements

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B18/00—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body

- A61B2018/00053—Mechanical features of the instrument of device

- A61B2018/00059—Material properties

- A61B2018/00071—Electrical conductivity

- A61B2018/00083—Electrical conductivity low, i.e. electrically insulating

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B18/00—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body

- A61B2018/00315—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body for treatment of particular body parts

- A61B2018/00345—Vascular system

- A61B2018/00404—Blood vessels other than those in or around the heart

- A61B2018/00428—Severing

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B18/00—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body

- A61B2018/00571—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body for achieving a particular surgical effect

- A61B2018/00589—Coagulation

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B18/00—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body

- A61B2018/00571—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body for achieving a particular surgical effect

- A61B2018/00601—Cutting

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B18/00—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body

- A61B2018/00571—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body for achieving a particular surgical effect

- A61B2018/0063—Sealing

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B18/00—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body

- A61B2018/00636—Sensing and controlling the application of energy

- A61B2018/00696—Controlled or regulated parameters

- A61B2018/00702—Power or energy

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B18/00—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body

- A61B18/04—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body by heating

- A61B18/12—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body by heating by passing a current through the tissue to be heated, e.g. high-frequency current

- A61B18/1206—Generators therefor

- A61B2018/1246—Generators therefor characterised by the output polarity

- A61B2018/126—Generators therefor characterised by the output polarity bipolar

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B18/00—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body

- A61B18/04—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body by heating

- A61B18/12—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body by heating by passing a current through the tissue to be heated, e.g. high-frequency current

- A61B18/14—Probes or electrodes therefor

- A61B18/1442—Probes having pivoting end effectors, e.g. forceps

- A61B2018/1452—Probes having pivoting end effectors, e.g. forceps including means for cutting

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B18/00—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body

- A61B18/04—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body by heating

- A61B18/12—Surgical instruments, devices or methods for transferring non-mechanical forms of energy to or from the body by heating by passing a current through the tissue to be heated, e.g. high-frequency current

- A61B18/14—Probes or electrodes therefor

- A61B2018/1467—Probes or electrodes therefor using more than two electrodes on a single probe

Definitions

- the present disclosure relates to a surgical forceps, and more particularly, to an electrosurgical forceps capable of sealing, cutting, and dissecting tissue.

- Open or endoscopic electrosurgical forceps utilize both mechanical clamping action and electrical energy to effect hemostasis.

- the electrode of each opposing jaw member is charged to a different electric potential such that when the jaw members grasp tissue, electrical energy can be selectively transferred through the tissue.

- a surgeon can either cauterize, coagulate/desiccate and/or simply reduce or slow bleeding, by controlling the intensity, frequency and duration of the electrosurgical energy applied between the electrodes and through the tissue.

- Certain surgical procedures require more than simply cauterizing tissue and rely on the combination of clamping pressure, electrosurgical energy and gap distance to "seal" tissue, vessels and certain vascular bundles.

- "Vessel sealing” is defined as the process of liquefying the collagen, elastin and ground substances in the tissue so that the tissue reforms into a fused mass with significantly-reduced demarcation between the opposing tissue structures.

- this additional step may be both time consuming (particularly when sealing a significant number of vessels) and may contribute to imprecise separation of the tissue along the sealing line due to the misalignment or misplacement of the severing instrument along the center of the tissue seal.

- U.S. Patent No. 5,674,220 to Fox et al. discloses a transparent instrument which includes a longitudinally reciprocating knife which severs the tissue once sealed.

- the instrument includes a plurality of openings which enable direct visualization of the tissue during the treatment and severing processes. This direct visualization allows a user to visually and manually regulate the closure force and gap distance between jaw members to reduce and/or limit certain undesirable visual effects known to occur when treating vessels, thermal spread, charring, etc.

- U.S. Patent No. 5,702,390 to Austin et al. discloses an instrument which includes a triangularly-shaped electrode which is rotatable from a first position to treat tissue to a second position to cut tissue. Again, the user must rely on direct visualization and expertise to control the various effects of treating and cutting tissue.

- US-A-2002/0188294 discloses an endoscopic bipolar forceps for sealing and dividing tissue including an elongated shaft having opposing jaw members at a distal end thereof which are movable relative to one another from a first position wherein the jaw members are disposed in spaced relation relative to one another to a second position wherein the jaw members cooperate to grasp tissue therebetween.

- Each jaw member includes an electrically conductive sealing surface having a non-stick coating disposed thereon which is designed to reduce tissue adherence.

- a source of electrical energy is connected to each jaw member such that the jaw members are capable of conducting energy through tissue held therebetween to effect a seal.

- a longitudinally reciprocating knife is included which severs tissue proximate the seal.

- the vessel sealer and divider also includes a non-conductive stop member disposed on the electrically conductive surface of one of the jaw members which controls the distance between the jaw members when tissue is held therebetween.

- EP-A-1 920 725 discloses an endoscopic forceps including a housing having a shaft attached thereto, the shaft including a pair of jaw members disposed at a distal end thereof.

- the forceps also includes a drive assembly disposed in the housing which moves the jaw members relative to one another from a first position wherein the jaw members are disposed in spaced relation relative to one another to a second position wherein the jaw members are closer to one another for manipulating tissue.

- Each of the jaw members is adapted to connect to a source of electrical energy such that the jaw members are capable of conducting energy for treating tissue.

- the endoscopic forceps further includes a knife assembly operatively associated with the housing, the knife assembly being selectively actuatable to advance a knife through tissue disposed between the jaw members when the jaw members are disposed in the second position, the knife assembly including at least one safety mechanism to prevent damaging the knife upon selective actuation thereof.

- WO-A-2009/032623 discloses a surgical instrument including an ablation device.

- the ablation device includes an elongated flexible member having a proximal end and a distal end.

- the flexible member includes first and second lumens.

- a first needle electrode is configured to slideably move within the first lumen.

- a second needle electrode is located within the second lumen.

- the first and second needle electrodes are adapted to couple to an electrical waveform generator and to receive an electrical waveform sufficient to electrically ablate tissue located between the first and second needle electrodes.

- a clamp jaw portion may be located at the distal end of the elongated flexible member.

- the clamp jaw portion is operatively movable from an open position to a closed position.

- a cutting blade may be located in the clamp jaw portion.

- a blunt dissection portion may be formed on the clamp jaw portion.

- the clamp jaw portion is adapted to couple to an electrical waveform generator and to receive an electrical waveform.

- an end effector assembly for use with an electrosurgical instrument, e.g., a forceps.

- the end effector assembly includes first and second jaw members disposed in opposed relation relative to one another. One or both of the jaw members are moveable relative to the other from an open position to a closed position in which the jaw members cooperate to grasp tissue therebetween.

- Each jaw member includes an electrically conductive tissue sealing surface adapted to connect to a source of electrosurgical energy such that the sealing surfaces are capable of conducting electrosurgical energy through tissue disposed between the jaw members.

- a static bipolar electrosurgical cutting portion is disposed on one or both of the jaw members and includes one or more electrically conductive cutting elements and one or more insulating elements having a first configuration.

- the static cutting portion electrically cuts tissue disposed between the jaw members upon activation of the cutting element and an opposing sealing surface and/or an opposing cutting element.

- a dynamic electrosurgical cutting portion is disposed on one or bolh of the jaw members and includes one or more electrically conductive cutting elements and one or more insulating elements having a second configuration. The dynamic cutting portion is configured for electrically transecting tissue during movement relative to tissue grasped between the jaw members.

- the end effector assembly is configured to operate in a first, sealing mode wherein the sealing surfaces are activated to seal tissue.

- the end effector assembly may also be configured to operate in a second, cutting mode, wherein the static cutting portion and/or the dynamic cutting portion are activated to cut tissue.

- the static cutting portion is disposed at a proximal end of an opposed surface of one or both of the jaw members and the dynamic cutting portion is disposed at a distal end of the opposed surface of one or both of the jaw members.

- the dynamic cutting portion is disposed on a longitudinal side of one or both of the jaw members.

- the dynamic cutting portion is disposed on a distal tip of one or both of the jaw members.

- each of the sealing surfaces includes a pair of spaced apart sealing surface sections.

- One or more of the insulating element(s) of the static cutting portion is disposed between the pair of spaced apart sealing surface sections.

- the electrically conductive cutting element of the static cutting portion may be partially disposed within the insulating element disposed between the pair of spaced apart sealing surface sections.

- each of the jaw members are symmetrical with respect to each other.

- the opposed surfaces of each of the jaw members may be asymmetrical with respect to each other.

- the one or more electrically conductive cutting elements of the dynamic electrosurgical cutting portion is shorter in length than that of the static electrosurgical cutting portion.

- the static any dynamic cutting portions are spaced apart from one another, preferably with respect to a direction along the sealing surfaces, preferably longitudinally with respect to a longitudinal extent of the sealing surfaces.

- the static and dynamic cutting elements are electrically isolated from one another and include connections so that the dynamic and static cutting portions are independently electrically activatable.

- the sealing surfaces are provided along one plane when the jaw members are closed, the static cutting element extend along that phase and the dynamic cutting element extends along that plane or along a transverse plane to that plane.

- Fig. 1 depicts a bipolar forceps 10 for use in connection with endoscopic surgical procedures

- Fig. 2 depicts an open forceps 100 contemplated for use in connection with traditional open surgical procedures.

- an endoscopic instrument or an open instrument may be utilized with the end effector assembly described herein.

- the novel aspects with respect to the end effector assembly and its operating characteristics remain generally consistent with respect to both the open or endoscopic designs.

- Fig. 1 shows a bipolar forceps 10 for use with various endoscopic surgical procedures and generally includes a housing 20, a handle assembly 30, a rotating assembly 80, a switch assembly 70 and an end effector assembly 105 having opposing jaw members 110 and 120 that mutually cooperate to grasp, seal and divide tubular vessels and vascular tissue. More particularly, forceps 10 includes a shaft 12 that has a distal end 16 dimensioned to mechanically engage the end effector assembly 105 and a proximal end 14 that mechanically engages the housing 20.

- the shaft 12 may include one or more known mechanically engaging components that are designed to securely receive and engage the end effector assembly 105 such that the jaw members 110 and 120 are pivotable relative to one another to engage and grasp tissue therebetween.

- proximal end 14 of shaft 12 mechanically engages the rotating assembly 80 (the connection not shown in detail) to facilitate rotation of the end effector assembly 105.

- distal will refer to the end of the forceps 10 which is closer to the user, while the term “distal” will refer to the end which is further from the user.

- Handle assembly 30 includes a fixed handle 50 and a movable handle 40.

- Fixed handle 50 is integrally associated with housing 20 and handle 40 is movable relative to fixed handle 50 to actuate the opposing jaw members 110 and 120 of the end effector assembly 105 as explained in more detail below.

- Movable handle 40 and switch assembly 70 are of unitary construction and are operatively connected to the housing 20 and the fixed handle 50 during the assembly process.

- Housing 20 is constructed from two components halves 20a and 20b that are assembled about the proximal end of shaft 12 during assembly.

- Switch assembly 70 is configured to selectively provide electrical energy to the end effector assembly 105.

- end effector assembly 105 is attached to the distal end 16 of shaft 12 and includes the opposing jaw members 110 and 120.

- Movable handle 40 of handle assembly 30 imparts movement of the jaw members 110 and 120 from an open position wherein the jaw members 110 and 120 are disposed in spaced relation relative to one another, to a clamping or closed position wherein the jaw members 110 and 120 cooperate to grasp tissue therebetween.

- an open forceps 100 includes a pair of elongated shaft portions 111 a and 111b each having a proximal end 114a and 114b, respectively, and a distal end 116a and 116b, respectively.

- the forceps 100 includes jaw members 120 and 110 that attach to distal ends 116a and 116b of shafts 111a and 111b, respectively.

- the jaw members 110 and 120 are connected about pivot pin 119 which allows the jaw members 110 and 120 to pivot relative to one another from the first to second positions for treating tissue.

- the end effector assembly 105 is connected to opposing jaw members 110 and 120 and may include electrical connections through or around the pivot pin 119.

- Each shaft 111a and 111b includes a handle 117a and 117b disposed at the proximal end 114a and 114b thereof which each define a finger hole 118a and 118b, respectively, therethrough for receiving a finger of the user.

- Finger holes 118a and 118b facilitate movement of the shafts 111 a and 111 b relative to one another which, in turn, pivot the jaw members 110 and 120 from the open position wherein the jaw members 110 and 120 are disposed in spaced relation relative to one another to the clamping or closed position wherein the jaw members 110 and 120 cooperate to grasp tissue therebetween.

- a ratchet 130 is included for selectively locking the jaw members 110 and 120 relative to one another at various positions during pivoting.

- forceps 10 or 100 also includes an electrical cable 210 that connects the forceps 10, 100 to a source of electrosurgical energy, e.g., an electrosurgical generator (not shown). Cable 210 extends through the shaft(s) 12, 111 to transmit electrosurgical energy through various electrical feed paths to the end effector assembly 105.

- a source of electrosurgical energy e.g., an electrosurgical generator (not shown).

- Cable 210 extends through the shaft(s) 12, 111 to transmit electrosurgical energy through various electrical feed paths to the end effector assembly 105.

- each jaw member 110 and 120 of both the endoscopic forceps of Fig. 1 and the open forceps of Fig. 2 include similar component features which cooperate to permit rotation about pivot 19, 119, respectively, to effect the grasping and sealing of tissue.

- Each jaw member 110 and 120 includes an electrically conductive tissue sealing plate 112 and 122, respectively.

- Tissue sealing plates 112, 122 of jaw members 110, 120, respectively, define opposed electrically conductive tissue sealing surfaces that cooperate to seal tissue.

- each jaw member 110 and 120 also includes a static bipolar cutting portion 127 disposed thereon, although it is also envisioned that only one of the jaw members 110, 120 need include a static cutting portion 127.

- one (or both) jaw members e.g., jaw member 120

- static cutting portions 127 are disposed toward proximal ends 110b, 120b of jaw members 110 and 120, respectively, while dynamic cutting portion 137 is disposed toward a distal end 120a of jaw member 120.

- static and dynamic bipolar cutting portions 127, 137 may be positioned at different locations on either or both of jaw members 110 and 120, as will be described in more detail below.

- the combination of sealing plates 112, 122, static cutting portion(s) 127 and dynamic cutting portion(s) 137 allows for sealing, static cutting, and dynamic dissection of tissue with a single surgical device 10, 100.

- the various electrical connections of the end effector assembly 105 are configured to provide electrical continuity to the tissue sealing plates 112 and 122 and the cutting portions 127, 137 through the end effector assembly 105.

- cable lead 210 ( Fig. 1 ) may be configured to include four different leads (not shown) that carry different electrical potentials. The cable leads are fed through shaft 12 and connect to various electrical connectors (not shown) which ultimately connect to the electrically conductive sealing plates 112 and 122 and cutting portions 127, 137.

- the various electrical connections from cable lead 210 are dielectrically insulated from one another to allow selective and independent activation of either the tissue sealing plates 112 and 122 or the static and/or dynamic cutting portions 127, 137, respectively, as will be explained in more detail below.

- the end effector assembly 105 may include a single connector that includes an internal switch (not shown) to allow selective and independent activation of the tissue sealing plates 112, 122 and/or the cutting portions 127, 137.

- FIGs. 4A-4B several electrical configurations of the static cutting portion(s) 127 are shown which, in conjunction with the opposed sealing plates 112, 122, are designed to effectively seal and cut tissue disposed between opposing jaw members 110 and 120, respectively.

- the configuration of static cutting potion(s) 127 disposed between sealing plates 112, 122 shown in Figs. 4A and 4B are example configurations designed to effect both tissue sealing and static tissue cutting, that is, tissue cutting wherein the jaw members 110, 120 remain stationary relative to tissue to be cut. More particularly, during a sealing mode, sealing plates 112 and 122 are activated to supply electrosurgical energy through tissue to effect a tissue seal.

- static cutting portion(s) 127 are activated to apply electrosurgical energy through tissue to effect tissue division.

- Other configurations of static cutting portions 127 capable of effecting both tissue sealing and cutting may be provided, such as those disclosed in commonly-owned U.S. Patent No. 7,270,664 entitled “VESSEL SEALING INSTRUMENT WITH ELECTRICAL CUTTING MECHANISM”. Further, it is envisioned that similar, or different configurations of the static cutting portions 127 may be provided on each of the jaw members 110, 120.

- each of the static cutting portions 127 includes an insulator 129 and an electrically conductive cutting element 128 e.g., an electrically energizeable electrode.

- Insulators 129 are disposed between the electrically conductive sealing plates 112, 122 to divide each of the electrically conductive sealing plates 112, 122 into sections of electrically conductive sealing plates 112a, 112b and 122a, 122b on each jaw member 110 and 120, respectively.

- insulators 129 are disposed between sections 112a and 112b and sections 122a and 122b, of sealing plates 112 and 122, respectively.

- Each insulator 129 is generally centered between a respective tissue sealing plate 112a, 112b and 122a, 122b such that the two insulators 129 of the respective jaw members 110, 120 generally oppose one another. Further, each insulator 129 includes a pair of tabs 129a extending therefrom adjacent each of the sealing plate sections 112a, 112b, 122a, 122b and a recessed portion 129b defined between the tabs 129a and the electrodes 128.

- Fig. 4B The embodiment shown in Fig. 4B is substantially similar to the embodiment of Fig. 4A except that jaw member 110 includes an insulator 140 disposed between the sections 112a and 112b of sealing plate 112, rather than a static cutting portion 127 having both a cutting element 128 and an insulator 129.

- the electrically conductive cutting elements 128 of static cutting portions 127 are disposed substantially within or disposed on the insulators 129. With respect to Fig. 4A , the cutting elements 128 are electrically conductive; however, one or both of the cutting elements 128 may be made from an insulative material with a conductive coating disposed thereon or one (or both) of the cutting elements may be non-conductive (not shown).

- FIGs. 4C-4D several electrical configurations of the dynamic cutting portion(s) 137 are shown.

- the dynamic cutting portions 137 are shown disposed between electrically conductive sealing plate sections 112a, 112b and 122a, 122b of respective electrically conductive sealing plates 112, 122, similarly to the static cutting portions 127 shown in Figs. 4A-4B and described above.

- Figs. 4C-4D the dynamic cutting portions 137 are shown disposed between electrically conductive sealing plate sections 112a, 112b and 122a, 122b of respective electrically conductive sealing plates 112, 122, similarly to the static cutting portions 127 shown in Figs. 4A-4B and described above.

- Figs. 4C-4D several electrical configurations of the dynamic cutting portion(s) 137 are shown.

- the dynamic cutting portions 137 are shown disposed between electrically conductive sealing plate sections 112a, 112b and 122a, 122b of respective electrically conductive sealing plates 112, 122, similarly to the static cutting portions

- the static cutting portions 127 may be positioned between the sections 112a, 112b, 122a, 122b of sealing plates 112, 122 toward the proximal ends 110b and 120b of jaw members 110 and 120, respectively, while the dynamic cutting portions 137 are positioned between the sealing plates 112, 122 toward the distal ends 110a and 120a of the jaw members 110 and 120, respectively.

- This configuration may also be reversed, e.g., where the static cutting portions 127 are disposed toward the distal ends 110a and 120a and where the dynamic cutting portions 137 are disposed toward the proximal ends 110b and 120b of the jaw members 110 and 120, respectively.

- the dynamic cutting portions 137 may be disposed in various other positions on either or both jaw members 110, 120.

- the dynamic cutting portions 137 include an electrically conductive cutting element 138, e.g., an electrically energizeable electrode, positioned within and extending from an insulator 139 disposed between the electrically conductive sealing plates 112, 122, much like the configuration of the static cutting portions 127 discussed above ( Fig. 4A-4B ).

- the embodiment shown in Fig. 4D is similar to the embodiment of Fig. 4A except that jaw member 120 includes an insulator 140 disposed between the sections 122a and 122b of sealing plate 122 and does not include a cutting element 138 therein.

- Insulators 139 of dynamic cutting portions 137 are different from insulators 129 of static cutting portions 127 ( Figs. 4A-4B ) in that the surfaces of insulators 139 are generally flat and do not include tabs or recesses. It has been found that this configuration of dynamic cutting portions 137, namely, the configuration of insulators 139, helps facilitate dissection, or dynamic tissue cutting, i.e., cutting of tissue while the jaw members 110 and/or 120 are moved relative to tissue.

- the configuration of static cutting portions 127 ( Figs. 4A-4B ), on the other hand, has been found to help facilitate static electrosurgical cutting.

- the static cutting portions may define a variety of configurations, e.g., the configurations disclosed in commonly-owned U.S. Patent No. 7,270,664 or the configurations of Figs. 4A-4B , which facilitate static electrosurgical cutting.

- the dynamic cutting portions may define a variety of configurations, including those disclosed in U.S. Patent No. 7,270,664 or the configurations shown in Figs. 4C-4D , which facilitate dynamic electrosurgical dissection.

- the static and dynamic cutting portions may be configured differently, each configuration being adapted for a particular application, e.g., static or dynamic bipolar electrosurgical cutting.

- dynamic cutting portions 137 are shown disposed at various positions on jaw member 120. Although dynamic cutting portions 137 are shown disposed on jaw member 120, it is envisioned that dynamic cutting portions 137 may be similarly disposed on jaw member 110 in cooperation with or in place of the dynamic cutting portions 137 of jaw member 120. Further, the positioning of dynamic cutting potions 137 shown in Figs. 5A-9 are examples and other positions are contemplated.

- Fig. 5A shows jaw member 120 including an electrically conductive sealing plate 122 including sealing plate sections 122a and 122b having static cutting portion 127 disposed therebetween.

- static cutting portion 127 includes an electrically energizeable electrode, or cutting element 128, and a pair of insulators 129 configured for static electrosurgical cutting.

- dynamic cutting portion 137 is shown including a dynamic cutting element 138 and a pair of insulators 139 configured for dynamic electrosurgical cutting. Sealing plate sections 122a and 122b may extend toward the distal end of jaw member 120 to surround the dynamic cutting portion 137, or, as shown in Fig.

- a pair of electrically conductive elements 141 may be positioned surrounding the insulators 139 to act as return electrode.

- jaw member 110 includes sealing plates 112a, 122b and static cutting portion 127 disposed therebetween.

- Jaw member 110 also includes an insulator 140 opposing dynamic cutting portion 137 of jaw member 120; however, jaw member 110 may include a dynamic cutting portion 137 in place of, or in addition to, dynamic cutting portion 137 disposed on jaw member 120.

- Figs. 6-9 illustrate various different positionings of the dynamic cutting portion.

- a dynamic cutting portion 237 is disposed on a longitudinal side 123 of jaw member 120.

- Dynamic cutting portion 237 may be disposed on either longitudinal side 123 of jaw member 120 and/or jaw member 110 and may be positioned toward a distal end 120a of the jaw member 120, or toward the proximal end 110b, 120b of either (or both) of the jaw members 110, 120, as desired.

- a dynamic cutting portion 337 is disposed on a distal tip 121 of jaw member 120.

- Dynamic cutting portion 337 may be aligned vertically, as shown in Fig. 7 , or may be aligned horizontally on jaw member 110 and/or jaw member 120.

- Each dynamic cutting portion 237 and 337 shown in Figs. 6 and 7 , respectively, includes a cutting element 238, 338, which may be an electrically energizeable electrode 238, 338.

- Dynamic cutting portion 237, 337 also include insulators (not explicitly shown) which may be defined as the portion 125, 126 of insulated outer housing 124 of jaw member 120 surrounding the cutting element 238, 338.

- insulators not explicitly shown

- a pair of electrically conductive elements, or return electrodes 241, 341 are provided surrounding the cutting element 238, 338, with the insulators, e.g., the portions 125, 126 of insulated outer housing 124, therebetween.

- dynamic cutting portions 137, 237, 337 are configured for bipolar electrosurgical cutting, e.g., each cutting portion 137, 237, 337 includes an electrically energizeable cutting element 138, 238, 338 and a pair of return electrodes, e.g., sealing plates 112, 122 or electrically conductive elements 141, 241, 341, thus obviating the need for a remote return pad, as is required for monopolar cutting.

- Fig. 8 shows another configuration wherein a dynamic cutting portion 437 is disposed adjacent pivot 19 of jaw members 110, 120. More particularly, dynamic cutting portion 437 is positioned between jaw members 110, 120 at proximal ends 110b, 120b, respectively, thereof such that, upon distal advancement of the forceps with jaw members 110, 120 in the open position, tissue disposed between jaw members 110, 120 may be electrically transected, or cut via dynamic cutting portion 437. Dynamic cutting portion 437 may be configured similarly to any of the dynamic cutting portions described above.

- Fig. 9 shows yet another configuration wherein a dynamic cutting portion 537 is disposed on an outer, top surface of jaw member 110, although dynamic cutting portion 537 may alternatively be disposed on an outer, bottom surface of jaw member 120.

- Dynamic cutting portion 537 is configured for bipolar electrosurgical cutting, obviating the need for a remote return pad, as is required for monopolar cutting.

- forceps 10 will now be described in detail. More specifically, the tissue sealing, static tissue cutting and dynamic tissue cutting modes, or phases of forceps 10 will be described with reference to Figs. 5A-9 . As shown in the drawings, the various polarities of the components are shown corresponding to the "cutting" phases, and thus do not represent the relative polarities of the components during the sealing phase.

- forceps 10 is initially positioned such that jaw members 110 and 120 of end effector assembly 105 are disposed in the open position with tissue to be sealed therebetween.

- the jaw members 110, 120 are then moved to the closed position, clamping, or grasping tissue between electrically conductive sealing plates 112 and 122 of jaw members 110 and 120, respectively.

- the cutting elements 128 (and 138) are configured to extend from their respective insulators 129, respectively, beyond the sealing plates 112a, 112b and 122a and 122b such that the cutting elements 128 (and 138) act as stop members (i.e., create a gap distance "G" between opposing sealing surfaces of sealing plates 112 and 122) which promote accurate, consistent and effective tissue sealing.

- the opposing sealing plates 112a, 122a and 112b, 122b are activated, i.e., electrosurgical energy from a generator is supplied to sealing plates 112, 122 to seal the tissue disposed therebetween.

- sealing plate 112 is energized to a first potential "+” and sealing plate 122 is energized to a second potential "-".

- the cutting element 128 is not energized. Since the insulator 129 does not conduct energy as well as the conductive sealing plates 112, 122, the first potential is not effectively or. efficiently transferred to the cutting element 128 and the tissue is not necessarily heated or damaged during the sealing phase.

- energy is transferred from sealing plate sections 112a and 112b and through tissue to the return electrode, or return sealing plate sections 122a and 122b.

- the static cutting element 128 of the static cutting portion 127 (and the dynamic cutting element 138 of dynamic cutting portion 137) mainly acts as a stop member for creating and maintaining a gap between the opposing sealing plates 112 and 122.

- the static cutting element(s) 128 may be independently activated, e.g., energized with electrosurgical energy, by the user or automatically activated by a generator (not shown) or other energy source to effect tissue cutting.

- a generator not shown

- the electrical potential to sealing plates 112, 122 is turned off, static cutting element 128 of jaw member 110 is energized with a first electrical potential "+” and static cutting element 128 of jaw member 120 is energized with a second electrical potential "-" (see Fig. 4A ).

- the static cutting element 128 of jaw members 120 may be energized with a first electrical potential "+” and opposing sealing plates 112 and 122 may be energized with a second electrical potential "-" (see Fig.

- tissue may be initially sealed and thereafter cut using the static electrosurgical cutting portion 127 without re-grasping the tissue.

- the dynamic cutting element 138, 238, 338 is activated to a first electrical potential "+” and the opposing sealing plates 112 and 122 ( Fig. 4D ) or electrically conductive elements 141, 241, 341 ( Figs. 5A-7 ) are activated to a second electrical potential "-".

- dynamic cutting element 138 of jaw member 110 may be activated to the first electrical potential "+” while dynamic cutting element 138 of jaw member 120 is activated to the second electrical potential "-".

- the activated dynamic cutting portions 137, 237, 337 create a concentrated electrical path between the potentials "+” any "-" to cut the tissue as the end effector assembly 105 is advanced through tissue.

- Jaw members 110 and 120 are opened slightly during translation of end effector assembly 105 in the embodiment of Figs. 5A-5B to effect dynamic bipolar cutting of tissue.

- end effector assembly 105 is translated laterally, in the direction of dynamic cutting portions 237, 537, respectively, to effect tissue dissection.

- the end effector assembly 105 is translated distally to effect electrosurgical tissue dissection via dynamic cutting portion 337, 437, in the embodiments of Fig. 7 and 8 , respectively.

- any combination of electrical potentials as described herein or in U.S. Patent No. 7,270,664 may be utilized with the various jaw members 110, 120 and/or cutting portions 127, 137 to effectively seal tissue during an electrical sealing phase and cut tissue during static and/or dynamic electrical cutting phases.

- sealing plates 112 and 122 of jaw members 110 and 120, static and dynamic cutting elements 128, 138, 238, 338 of static and dynamic cutting portions 127, 137, 237, 337, respectively, and/or electrically conductive element 141, 241, 341, may be energized with any combination of first and second electrical potential(s) (or other electrical potentials) to effectively seal and/or cut tissue.

- the forceps 10, 100 is configured to operate in three modes or phases: (1) electrosurgical tissue sealing, (2) static bipolar electrosurgical cutting, and (3) dynamic bipolar electrosurgical cutting.

- the sealing plates 112, 122, the static cutting portions 127 and the dynamic cutting portions 137 are configured to seal, statically cut, and dynamically cut tissue, respectively.

- all three functions may be carried out with a single device, e.g. endoscopic forceps 10 or open forceps 100. It is envisioned that various manually operated and/or automatic switching mechanisms may be employed to alternate between the sealing and cutting modes.

- forceps 10 may be configured as a handheld, battery-powered device.

- the battery (not shown) may be disposed within fixed handle 50 and may be configured to provide electrosurgical energy to the end effector assembly 105.

Description

- The present disclosure relates to a surgical forceps, and more particularly, to an electrosurgical forceps capable of sealing, cutting, and dissecting tissue.

- Open or endoscopic electrosurgical forceps utilize both mechanical clamping action and electrical energy to effect hemostasis. The electrode of each opposing jaw member is charged to a different electric potential such that when the jaw members grasp tissue, electrical energy can be selectively transferred through the tissue. A surgeon can either cauterize, coagulate/desiccate and/or simply reduce or slow bleeding, by controlling the intensity, frequency and duration of the electrosurgical energy applied between the electrodes and through the tissue.

- Certain surgical procedures require more than simply cauterizing tissue and rely on the combination of clamping pressure, electrosurgical energy and gap distance to "seal" tissue, vessels and certain vascular bundles. "Vessel sealing" is defined as the process of liquefying the collagen, elastin and ground substances in the tissue so that the tissue reforms into a fused mass with significantly-reduced demarcation between the opposing tissue structures.

- Typically, once a vessel is sealed, the surgeon has to remove the sealing instrument from the operative site, substitute a new instrument, and accurately sever the vessel along the newly formed tissue seal. As can be appreciated, this additional step may be both time consuming (particularly when sealing a significant number of vessels) and may contribute to imprecise separation of the tissue along the sealing line due to the misalignment or misplacement of the severing instrument along the center of the tissue seal.

- Several attempts have been made to design an instrument which incorporates a knife or blade member which effectively severs the tissue after forming a tissue seal. For example,

U.S. Patent No. 5,674,220 to Fox et al. discloses a transparent instrument which includes a longitudinally reciprocating knife which severs the tissue once sealed. The instrument includes a plurality of openings which enable direct visualization of the tissue during the treatment and severing processes. This direct visualization allows a user to visually and manually regulate the closure force and gap distance between jaw members to reduce and/or limit certain undesirable visual effects known to occur when treating vessels, thermal spread, charring, etc. As can be appreciated, the overall success of creating an effective tissue seal with this instrument is greatly reliant upon the user's expertise, vision, dexterity, and experience in judging the appropriate closure force, gap distance and length of reciprocation of the knife to uniformly, consistently and effectively seal the vessel and separate the tissue at the seal along an ideal cutting plane -

U.S. Patent No. 5,702,390 to Austin et al. discloses an instrument which includes a triangularly-shaped electrode which is rotatable from a first position to treat tissue to a second position to cut tissue. Again, the user must rely on direct visualization and expertise to control the various effects of treating and cutting tissue. -

US-A-2002/0188294 discloses an endoscopic bipolar forceps for sealing and dividing tissue including an elongated shaft having opposing jaw members at a distal end thereof which are movable relative to one another from a first position wherein the jaw members are disposed in spaced relation relative to one another to a second position wherein the jaw members cooperate to grasp tissue therebetween. Each jaw member includes an electrically conductive sealing surface having a non-stick coating disposed thereon which is designed to reduce tissue adherence. A source of electrical energy is connected to each jaw member such that the jaw members are capable of conducting energy through tissue held therebetween to effect a seal. A longitudinally reciprocating knife is included which severs tissue proximate the seal. The vessel sealer and divider also includes a non-conductive stop member disposed on the electrically conductive surface of one of the jaw members which controls the distance between the jaw members when tissue is held therebetween. -

EP-A-1 920 725 discloses an endoscopic forceps including a housing having a shaft attached thereto, the shaft including a pair of jaw members disposed at a distal end thereof. The forceps also includes a drive assembly disposed in the housing which moves the jaw members relative to one another from a first position wherein the jaw members are disposed in spaced relation relative to one another to a second position wherein the jaw members are closer to one another for manipulating tissue. Each of the jaw members is adapted to connect to a source of electrical energy such that the jaw members are capable of conducting energy for treating tissue. The endoscopic forceps further includes a knife assembly operatively associated with the housing, the knife assembly being selectively actuatable to advance a knife through tissue disposed between the jaw members when the jaw members are disposed in the second position, the knife assembly including at least one safety mechanism to prevent damaging the knife upon selective actuation thereof. -

WO-A-2009/032623 discloses a surgical instrument including an ablation device. The ablation device includes an elongated flexible member having a proximal end and a distal end. The flexible member includes first and second lumens. A first needle electrode is configured to slideably move within the first lumen. A second needle electrode is located within the second lumen. The first and second needle electrodes are adapted to couple to an electrical waveform generator and to receive an electrical waveform sufficient to electrically ablate tissue located between the first and second needle electrodes. A clamp jaw portion may be located at the distal end of the elongated flexible member. The clamp jaw portion is operatively movable from an open position to a closed position. A cutting blade may be located in the clamp jaw portion. A blunt dissection portion may be formed on the clamp jaw portion. The clamp jaw portion is adapted to couple to an electrical waveform generator and to receive an electrical waveform. - The invention is set out in the claims.

- In accordance with the present disclosure, an end effector assembly for use with an electrosurgical instrument, e.g., a forceps, is provided. The end effector assembly includes first and second jaw members disposed in opposed relation relative to one another. One or both of the jaw members are moveable relative to the other from an open position to a closed position in which the jaw members cooperate to grasp tissue therebetween. Each jaw member includes an electrically conductive tissue sealing surface adapted to connect to a source of electrosurgical energy such that the sealing surfaces are capable of conducting electrosurgical energy through tissue disposed between the jaw members. A static bipolar electrosurgical cutting portion is disposed on one or both of the jaw members and includes one or more electrically conductive cutting elements and one or more insulating elements having a first configuration. The static cutting portion electrically cuts tissue disposed between the jaw members upon activation of the cutting element and an opposing sealing surface and/or an opposing cutting element. A dynamic electrosurgical cutting portion is disposed on one or bolh of the jaw members and includes one or more electrically conductive cutting elements and one or more insulating elements having a second configuration. The dynamic cutting portion is configured for electrically transecting tissue during movement relative to tissue grasped between the jaw members.

- In one embodiment, the end effector assembly is configured to operate in a first, sealing mode wherein the sealing surfaces are activated to seal tissue. The end effector assembly may also be configured to operate in a second, cutting mode, wherein the static cutting portion and/or the dynamic cutting portion are activated to cut tissue.

- In another embodiment, the static cutting portion is disposed at a proximal end of an opposed surface of one or both of the jaw members and the dynamic cutting portion is disposed at a distal end of the opposed surface of one or both of the jaw members.

- In yet another embodiment, the dynamic cutting portion is disposed on a longitudinal side of one or both of the jaw members.

- In still another embodiment, the dynamic cutting portion is disposed on a distal tip of one or both of the jaw members.

- In still yet another embodiment, each of the sealing surfaces includes a pair of spaced apart sealing surface sections. One or more of the insulating element(s) of the static cutting portion is disposed between the pair of spaced apart sealing surface sections. The electrically conductive cutting element of the static cutting portion may be partially disposed within the insulating element disposed between the pair of spaced apart sealing surface sections.

- In yet another embodiment, the opposed surfaces of each of the jaw members are symmetrical with respect to each other. Alternatively, the opposed surfaces of each of the jaw members may be asymmetrical with respect to each other.

- In an embodiment, the one or more electrically conductive cutting elements of the dynamic electrosurgical cutting portion is shorter in length than that of the static electrosurgical cutting portion. In an embodiment, the static any dynamic cutting portions are spaced apart from one another, preferably with respect to a direction along the sealing surfaces, preferably longitudinally with respect to a longitudinal extent of the sealing surfaces. In an embodiment, the static and dynamic cutting elements are electrically isolated from one another and include connections so that the dynamic and static cutting portions are independently electrically activatable. In an embodiment, the sealing surfaces are provided along one plane when the jaw members are closed, the static cutting element extend along that phase and the dynamic cutting element extends along that plane or along a transverse plane to that plane.

- Various embodiments of the subject instrument are described herein with reference to the drawings wherein:

-

Fig. 1 is a right, perspective view of an endoscopic bipolar forceps including a housing, a shaft and an end effector assembly; -

Fig. 2 is a left, perspective view of an open bipolar forceps showing a pair of first and second shafts having an end effector assembly disposed at a distal end thereof; -

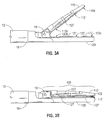

Fig. 3A is an enlarged, side view of the end effector assembly ofFig. 1 with a pair of jaw members in the open position; -

Fig. 3B is an enlarged, side view of the end effector assembly ofFig. 1 with the pair of jaw members in the closed position; -

Fig. 4A is a schematic of one configuration of tissue sealing surfaces and static cutting portions that may be used with the end effector assembly ofFig. 1 ; -

Fig. 4B is a schematic of another configuration of the tissue sealing surfaces and the static cutting portion that may be used with the end effector assembly ofFig. 1 ; -

Fig. 4C is a schematic of one configuration of the tissue sealing surfaces and dynamic cutting portions that may be used with the end effector assembly ofFig. 1 ; -

Fig. 4D is a schematic of another configuration of the tissue sealing surfaces and the dynamic cutting portion that may be used with the end effector assembly ofFig. 1 ; -

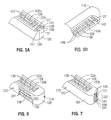

Fig. 5A is a front, perspective view of a bottom jaw member that may be used with the end effector assembly ofFig. 1 showing the tissue sealing surfaces and static and dynamic cutting portions according to another embodiment of the present disclosure; -

Fig. 5B is a rear, perspective view of a top jaw member that may be used with the end effector assembly ofFig. 1 showing the sealing surfaces and static cutting portion in accordance with yet another embodiment of the present disclosure; -

Fig. 6 is a front, perspective view of yet another embodiment showing the static and dynamic cutting portions of a bottom jaw member that may be used with the end effector assembly ofFig. 1 ; -

Fig. 7 is a front, perspective view of still yet another embodiment showing the static and dynamic cutting portions of a bottom jaw member that may be used with the end effector assembly ofFig. 1 -

Fig. 8 is an enlarged, side view of yet another embodiment showing the dynamic cutting portion disposed adjacent a pivot of the jaw members of the end effector assembly ofFig. 1 ; and -

Fig. 9 is a top view of still another embodiment showing the dynamic cutting portion of a top jaw member that may be used with the end effector assembly ofFig. 1 . - Referring now to

Figs. 1 and2 ,Fig. 1 depicts abipolar forceps 10 for use in connection with endoscopic surgical procedures andFig. 2 depicts anopen forceps 100 contemplated for use in connection with traditional open surgical procedures. For the purposes herein, either an endoscopic instrument or an open instrument may be utilized with the end effector assembly described herein. Obviously, different electrical and mechanical connections and considerations apply to each particular type of instrument, however, the novel aspects with respect to the end effector assembly and its operating characteristics remain generally consistent with respect to both the open or endoscopic designs. -

Fig. 1 shows abipolar forceps 10 for use with various endoscopic surgical procedures and generally includes ahousing 20, ahandle assembly 30, a rotatingassembly 80, aswitch assembly 70 and anend effector assembly 105 having opposingjaw members forceps 10 includes ashaft 12 that has adistal end 16 dimensioned to mechanically engage theend effector assembly 105 and aproximal end 14 that mechanically engages thehousing 20. Theshaft 12 may include one or more known mechanically engaging components that are designed to securely receive and engage theend effector assembly 105 such that thejaw members - The

proximal end 14 ofshaft 12 mechanically engages the rotating assembly 80 (the connection not shown in detail) to facilitate rotation of theend effector assembly 105. In the drawings and in the descriptions which follow, the term "proximal", as is traditional, will refer to the end of theforceps 10 which is closer to the user, while the term "distal" will refer to the end which is further from the user. - Handle

assembly 30 includes a fixedhandle 50 and amovable handle 40. Fixedhandle 50 is integrally associated withhousing 20 and handle 40 is movable relative to fixedhandle 50 to actuate the opposingjaw members end effector assembly 105 as explained in more detail below.Movable handle 40 and switchassembly 70 are of unitary construction and are operatively connected to thehousing 20 and the fixedhandle 50 during the assembly process.Housing 20 is constructed from twocomponents halves shaft 12 during assembly.Switch assembly 70 is configured to selectively provide electrical energy to theend effector assembly 105. - As mentioned above,

end effector assembly 105 is attached to thedistal end 16 ofshaft 12 and includes the opposingjaw members Movable handle 40 ofhandle assembly 30 imparts movement of thejaw members jaw members jaw members - Referring now to

Fig. 2 , anopen forceps 100 includes a pair ofelongated shaft portions proximal end distal end forceps 100 includesjaw members distal ends shafts jaw members pivot pin 119 which allows thejaw members end effector assembly 105 is connected to opposingjaw members pivot pin 119. - Each

shaft handle proximal end finger hole Finger holes shafts jaw members jaw members jaw members ratchet 130 is included for selectively locking thejaw members - As shown in

Figs. 1 and2 ,forceps electrical cable 210 that connects theforceps Cable 210 extends through the shaft(s) 12, 111 to transmit electrosurgical energy through various electrical feed paths to theend effector assembly 105. - Referring now to the schematic illustrations of

Figs. 3A-3B , thejaw members Fig. 1 and the open forceps ofFig. 2 include similar component features which cooperate to permit rotation aboutpivot jaw member tissue sealing plate Tissue sealing plates jaw members Figs. 3A-3B , eachjaw member bipolar cutting portion 127 disposed thereon, although it is also envisioned that only one of thejaw members static cutting portion 127. Further, one (or both) jaw members, e.g.,jaw member 120, includes a dynamicbipolar cutting portion 137. As shown inFigs. 3A-3B ,static cutting portions 127 are disposed toward proximal ends 110b, 120b ofjaw members dynamic cutting portion 137 is disposed toward adistal end 120a ofjaw member 120. However, static and dynamicbipolar cutting portions jaw members plates surgical device - The various electrical connections of the

end effector assembly 105 are configured to provide electrical continuity to thetissue sealing plates portions end effector assembly 105. For example, cable lead 210 (Fig. 1 ) may be configured to include four different leads (not shown) that carry different electrical potentials. The cable leads are fed throughshaft 12 and connect to various electrical connectors (not shown) which ultimately connect to the electricallyconductive sealing plates portions cable lead 210 are dielectrically insulated from one another to allow selective and independent activation of either thetissue sealing plates dynamic cutting portions end effector assembly 105 may include a single connector that includes an internal switch (not shown) to allow selective and independent activation of thetissue sealing plates portions - As best seen in

Figs. 4A-4B , several electrical configurations of the static cutting portion(s) 127 are shown which, in conjunction with the opposed sealingplates jaw members plates Figs. 4A and 4B are example configurations designed to effect both tissue sealing and static tissue cutting, that is, tissue cutting wherein thejaw members plates static cutting portions 127 capable of effecting both tissue sealing and cutting may be provided, such as those disclosed in commonly-ownedU.S. Patent No. 7,270,664 entitled "VESSEL SEALING INSTRUMENT WITH ELECTRICAL CUTTING MECHANISM". Further, it is envisioned that similar, or different configurations of thestatic cutting portions 127 may be provided on each of thejaw members - With reference to the embodiment of

Fig. 4A , each of thestatic cutting portions 127 includes aninsulator 129 and an electricallyconductive cutting element 128 e.g., an electrically energizeable electrode.Insulators 129 are disposed between the electricallyconductive sealing plates conductive sealing plates conductive sealing plates jaw member insulators 129 are disposed betweensections sections plates insulator 129 is generally centered between a respectivetissue sealing plate insulators 129 of therespective jaw members insulator 129 includes a pair oftabs 129a extending therefrom adjacent each of the sealingplate sections portion 129b defined between thetabs 129a and theelectrodes 128. - The embodiment shown in

Fig. 4B is substantially similar to the embodiment ofFig. 4A except thatjaw member 110 includes aninsulator 140 disposed between thesections plate 112, rather than astatic cutting portion 127 having both acutting element 128 and aninsulator 129. - The electrically

conductive cutting elements 128 ofstatic cutting portions 127 are disposed substantially within or disposed on theinsulators 129. With respect toFig. 4A , the cuttingelements 128 are electrically conductive; however, one or both of the cuttingelements 128 may be made from an insulative material with a conductive coating disposed thereon or one (or both) of the cutting elements may be non-conductive (not shown). - With reference now to

Figs. 4C-4D , several electrical configurations of the dynamic cutting portion(s) 137 are shown. InFigs. 4C-4D , thedynamic cutting portions 137 are shown disposed between electrically conductivesealing plate sections conductive sealing plates static cutting portions 127 shown inFigs. 4A-4B and described above. In these embodiments, as shown inFigs. 3A-3B , thestatic cutting portions 127 may be positioned between thesections plates jaw members dynamic cutting portions 137 are positioned between the sealingplates jaw members static cutting portions 127 are disposed toward the distal ends 110a and 120a and where thedynamic cutting portions 137 are disposed toward the proximal ends 110b and 120b of thejaw members dynamic cutting portions 137 may be disposed in various other positions on either or bothjaw members - As shown in

Fig. 4C , thedynamic cutting portions 137 include an electricallyconductive cutting element 138, e.g., an electrically energizeable electrode, positioned within and extending from aninsulator 139 disposed between the electricallyconductive sealing plates static cutting portions 127 discussed above (Fig. 4A-4B ). The embodiment shown inFig. 4D is similar to the embodiment ofFig. 4A except thatjaw member 120 includes aninsulator 140 disposed between thesections plate 122 and does not include acutting element 138 therein. -

Insulators 139 of dynamic cutting portions 137 (Figs. 4C-4D ) are different frominsulators 129 of static cutting portions 127 (Figs. 4A-4B ) in that the surfaces ofinsulators 139 are generally flat and do not include tabs or recesses. It has been found that this configuration ofdynamic cutting portions 137, namely, the configuration ofinsulators 139, helps facilitate dissection, or dynamic tissue cutting, i.e., cutting of tissue while thejaw members 110 and/or 120 are moved relative to tissue. The configuration of static cutting portions 127 (Figs. 4A-4B ), on the other hand, has been found to help facilitate static electrosurgical cutting. - Put more generally, it has been found that some electrical configurations, e.g., the configuration of static cutting portions 127 (

Figs. 4A-4B ), are more advantageous for static electrosurgical cutting, while other electrical configurations, e.g., the configuration of dynamic cutting portions 137 (Figs. 4C-4D ), are more advantageous for dynamic electrosurgical tissue dissection. Thus, the static cutting portions may define a variety of configurations, e.g., the configurations disclosed in commonly-ownedU.S. Patent No. 7,270,664 or the configurations ofFigs. 4A-4B , which facilitate static electrosurgical cutting. The dynamic cutting portions may define a variety of configurations, including those disclosed inU.S. Patent No. 7,270,664 or the configurations shown inFigs. 4C-4D , which facilitate dynamic electrosurgical dissection. As mentioned above, the static and dynamic cutting portions may be configured differently, each configuration being adapted for a particular application, e.g., static or dynamic bipolar electrosurgical cutting. - With reference now to

Figs. 5A-9 ,dynamic cutting portions 137 are shown disposed at various positions onjaw member 120. Althoughdynamic cutting portions 137 are shown disposed onjaw member 120, it is envisioned thatdynamic cutting portions 137 may be similarly disposed onjaw member 110 in cooperation with or in place of thedynamic cutting portions 137 ofjaw member 120. Further, the positioning of dynamic cuttingpotions 137 shown inFigs. 5A-9 are examples and other positions are contemplated. -

Fig. 5A showsjaw member 120 including an electricallyconductive sealing plate 122 including sealingplate sections static cutting portion 127 disposed therebetween. As mentioned above,static cutting portion 127 includes an electrically energizeable electrode, or cuttingelement 128, and a pair ofinsulators 129 configured for static electrosurgical cutting. Toward a distal end ofjaw member 120,dynamic cutting portion 137 is shown including adynamic cutting element 138 and a pair ofinsulators 139 configured for dynamic electrosurgical cutting. Sealingplate sections jaw member 120 to surround thedynamic cutting portion 137, or, as shown inFig. 5A , a pair of electricallyconductive elements 141 may be positioned surrounding theinsulators 139 to act as return electrode. As shown inFig. 5B ,jaw member 110 includes sealingplates static cutting portion 127 disposed therebetween.Jaw member 110 also includes aninsulator 140 opposingdynamic cutting portion 137 ofjaw member 120; however,jaw member 110 may include adynamic cutting portion 137 in place of, or in addition to,dynamic cutting portion 137 disposed onjaw member 120. -

Figs. 6-9 illustrate various different positionings of the dynamic cutting portion. As shown inFig. 6 , adynamic cutting portion 237 is disposed on alongitudinal side 123 ofjaw member 120. Dynamic cuttingportion 237 may be disposed on eitherlongitudinal side 123 ofjaw member 120 and/orjaw member 110 and may be positioned toward adistal end 120a of thejaw member 120, or toward theproximal end jaw members Fig. 7 , adynamic cutting portion 337 is disposed on adistal tip 121 ofjaw member 120. Dynamic cuttingportion 337 may be aligned vertically, as shown inFig. 7 , or may be aligned horizontally onjaw member 110 and/orjaw member 120. - Each

dynamic cutting portion Figs. 6 and 7 , respectively, includes acutting element energizeable electrode portion portion outer housing 124 ofjaw member 120 surrounding the cuttingelement electrodes element portions outer housing 124, therebetween. It should be noted thatdynamic cutting portions portion energizeable cutting element plates conductive elements -

Fig. 8 shows another configuration wherein adynamic cutting portion 437 is disposedadjacent pivot 19 ofjaw members dynamic cutting portion 437 is positioned betweenjaw members proximal ends jaw members jaw members dynamic cutting portion 437. Dynamic cuttingportion 437 may be configured similarly to any of the dynamic cutting portions described above. -

Fig. 9 shows yet another configuration wherein adynamic cutting portion 537 is disposed on an outer, top surface ofjaw member 110, althoughdynamic cutting portion 537 may alternatively be disposed on an outer, bottom surface ofjaw member 120. Dynamic cuttingportion 537 is configured for bipolar electrosurgical cutting, obviating the need for a remote return pad, as is required for monopolar cutting. - The operation of

forceps 10 will now be described in detail. More specifically, the tissue sealing, static tissue cutting and dynamic tissue cutting modes, or phases offorceps 10 will be described with reference toFigs. 5A-9 . As shown in the drawings, the various polarities of the components are shown corresponding to the "cutting" phases, and thus do not represent the relative polarities of the components during the sealing phase. - To effect tissue sealing,

forceps 10 is initially positioned such thatjaw members end effector assembly 105 are disposed in the open position with tissue to be sealed therebetween. Thejaw members conductive sealing plates jaw members respective insulators 129, respectively, beyond the sealingplates plates 112 and 122) which promote accurate, consistent and effective tissue sealing. - During sealing, the opposing

sealing plates plates - More specifically, during sealing, sealing

plate 112 is energized to a first potential "+" and sealingplate 122 is energized to a second potential "-". The cuttingelement 128 is not energized. Since theinsulator 129 does not conduct energy as well as theconductive sealing plates cutting element 128 and the tissue is not necessarily heated or damaged during the sealing phase. During the sealing phase, energy is transferred from sealingplate sections plate sections static cutting element 128 of the static cutting portion 127 (and thedynamic cutting element 138 of dynamic cutting portion 137) mainly acts as a stop member for creating and maintaining a gap between the opposing sealingplates - Once sealing is complete, the static cutting element(s) 128 may be independently activated, e.g., energized with electrosurgical energy, by the user or automatically activated by a generator (not shown) or other energy source to effect tissue cutting. During the static cutting mode, or phase, the electrical potential to sealing

plates static cutting element 128 ofjaw member 110 is energized with a first electrical potential "+" andstatic cutting element 128 ofjaw member 120 is energized with a second electrical potential "-" (seeFig. 4A ). Alternatively, thestatic cutting element 128 ofjaw members 120 may be energized with a first electrical potential "+" and opposing sealingplates Fig. 4B ). In either embodiment, a concentrated electrical path is created between the potentials "+" and "-" through the tissue to cut the tissue between the previously formed tissue seal. Hence, tissue may be initially sealed and thereafter cut using the staticelectrosurgical cutting portion 127 without re-grasping the tissue. - However, it may be desirable, depending on the surgical procedure to be performed, to effect dynamic tissue dissection, or cutting, either before, after, or in place of tissue sealing and/or static cutting. To effect dynamic electrosurgical dissection, the

dynamic cutting element plates 112 and 122 (Fig. 4D ) or electricallyconductive elements Figs. 5A-7 ) are activated to a second electrical potential "-". Alternatively, as shown inFig. 4C ,dynamic cutting element 138 ofjaw member 110 may be activated to the first electrical potential "+" whiledynamic cutting element 138 ofjaw member 120 is activated to the second electrical potential "-". As with thestatic cutting portions 127, the activateddynamic cutting portions end effector assembly 105 is advanced through tissue.Jaw members end effector assembly 105 in the embodiment ofFigs. 5A-5B to effect dynamic bipolar cutting of tissue. In the embodiments ofFigs. 6 and9 ,end effector assembly 105 is translated laterally, in the direction ofdynamic cutting portions end effector assembly 105 is translated distally to effect electrosurgical tissue dissection viadynamic cutting portion Fig. 7 and8 , respectively. - Any combination of electrical potentials as described herein or in

U.S. Patent No. 7,270,664 may be utilized with thevarious jaw members portions plates jaw members dynamic cutting elements dynamic cutting portions conductive element - As can be appreciated from the description above, the

forceps plates static cutting portions 127 and thedynamic cutting portions 137 are configured to seal, statically cut, and dynamically cut tissue, respectively. Thus, all three functions may be carried out with a single device, e.g. endoscopic forceps 10 oropen forceps 100. It is envisioned that various manually operated and/or automatic switching mechanisms may be employed to alternate between the sealing and cutting modes. - Additionally, and particularly with reference to

Fig. 1 ,forceps 10 may be configured as a handheld, battery-powered device. The battery (not shown) may be disposed within fixedhandle 50 and may be configured to provide electrosurgical energy to theend effector assembly 105.

Claims (11)

- An end effector assembly (105) for use with an electrosurgical instrument (10), the end effector assembly comprising:first and second jaw members (110, 120) disposed in opposed relation relative to one another, at least one of the jaw members moveable relative to the other from a first, open position to a second, closed position wherein jaw members cooperate to grasp tissue therebetween;each jaw member including an electrically conductive tissue sealing surface (112, 122) adapted to connect to a source of electrosurgical energy such that the sealing surfaces are capable of conducting electrosurgical energy through tissue disposed between the jaw members;characterized in that the end effector assembly further comprises:a static electrosurgical cutting portion (127) disposed on at least one of the jaw members, the static cutting portion including at least one electrically conductive cutting element (128) and at least one insulating element (129) having a first configuration, the static cutting portion configured to electrically cut tissue disposed between the jaw members upon activation of the cutting element and at least one of an opposing sealing surface and an opposing cutting element; anda dynamic electrosurgical cutting portion (137) disposed on at least one of the jaw members, the dynamic cutting portion including at least one electrically conductive cutting element (138) and at least one insulating element (139) having a second configuration, the dynamic cutting portion capable of electrically transecting tissue during movement relative to tissue grasped between the jaw members.

- The end effector assembly according to Claim 1, wherein the end effector assembly is configured to operate in a first, sealing mode wherein the sealing surfaces are activated to seal tissue.

- The end effector assembly according to Claim 1 or 2, wherein the end effector assembly is configured to operate in a second, cutting mode wherein at least one of the static cutting portion and the dynamic cutting portion is activated to cut tissue.

- The end effector assembly according to Claim 1, 2 or 3, wherein the static cutting portion is disposed at a proximal end of an opposed surface of at least one of the jaw members and wherein the dynamic cutting portion is disposed at a distal end of the opposed surface of at least one of the jaw members.

- The end effector assembly according to Claim 1, 2 or 3, wherein the dynamic cutting portion is disposed on a longitudinal side of at least one of the jaw members.

- The end effector assembly according to Claim 1, 2 or 3, wherein the dynamic cutting portion is disposed on a distal tip of at least one of the jaw members.

- The end effector assembly according to any one of the preceding claims, wherein each of the sealing surfaces includes a pair of spaced apart sealing surface sections and wherein one of the at least one insulating elements of the static cutting portion is disposed between the pair of spaced apart sealing surface sections.