EP2522714A1 - Aqueous concentrated laundry detergent compositions - Google Patents

Aqueous concentrated laundry detergent compositions Download PDFInfo

- Publication number

- EP2522714A1 EP2522714A1 EP11165990A EP11165990A EP2522714A1 EP 2522714 A1 EP2522714 A1 EP 2522714A1 EP 11165990 A EP11165990 A EP 11165990A EP 11165990 A EP11165990 A EP 11165990A EP 2522714 A1 EP2522714 A1 EP 2522714A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- composition according

- surfactant

- polyester

- acid

- hydroxamate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D1/00—Detergent compositions based essentially on surface-active compounds; Use of these compounds as a detergent

- C11D1/86—Mixtures of anionic, cationic, and non-ionic compounds

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D1/00—Detergent compositions based essentially on surface-active compounds; Use of these compounds as a detergent

- C11D1/38—Cationic compounds

- C11D1/52—Carboxylic amides, alkylolamides or imides or their condensation products with alkylene oxides

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D10/00—Compositions of detergents, not provided for by one single preceding group

- C11D10/04—Compositions of detergents, not provided for by one single preceding group based on mixtures of surface-active non-soap compounds and soap

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/0005—Other compounding ingredients characterised by their effect

- C11D3/0036—Soil deposition preventing compositions; Antiredeposition agents

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/16—Organic compounds

- C11D3/26—Organic compounds containing nitrogen

- C11D3/32—Amides; Substituted amides

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/16—Organic compounds

- C11D3/37—Polymers

- C11D3/3703—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- C11D3/3715—Polyesters or polycarbonates

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/16—Organic compounds

- C11D3/37—Polymers

- C11D3/3703—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- C11D3/3723—Polyamines or polyalkyleneimines

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D1/00—Detergent compositions based essentially on surface-active compounds; Use of these compounds as a detergent

- C11D1/02—Anionic compounds

- C11D1/12—Sulfonic acids or sulfuric acid esters; Salts thereof

- C11D1/29—Sulfates of polyoxyalkylene ethers

Definitions

- This invention relates to aqueous concentrated laundry detergent compositions and their use at low dosage for cleaning of soils from fabrics.

- wash surfactant that may be an anionic surfactant.

- Wash performance is boosted by inclusion of high levels of specific polymers and enzymes.

- a preferred enzyme is lipase, most preferably Lipex.

- Preferred polymers are a combination of ethoxylated polyethylene imine and a polyester soil release polymer.

- the surfactant system preferably includes SLES and most preferably also carbobeteine.

- a sequestrant is included in the exemplified compositions: Dequest 2066. This is Diethylenetriamine penta(methylene phosphonic acid). No use is made of soil specific sequestrants of the type disclosed in WO2010/069957 .

- WO2010/069957 discloses the use of specific hydroxamate (HA) in conjunction with a specific surfactant system to improve the cleaning performance of both powder and liquid compositions on certain stains, notably red clay.

- HA hydroxamate

- SRP Soil release polymer for polyester

- the benefit of SRP inclusion is said to be the known multiwash benefit of this type of polymer, when used with an efficient cleaning system.

- EPEI as used in WO2009/153184 .

- the examples all use high in-wash surfactant levels.

- compositions may also contain soil release polymers, for example sulphonated and unsulphonated PET/POET polymers, both end-capped and non-end-capped, and polyethylene glycol/polyvinyl alcohol graft copolymers for example Sokalan (Trade Mark) HP22.

- soil release polymers for example sulphonated and unsulphonated PET/POET polymers, both end-capped and non-end-capped, and polyethylene glycol/polyvinyl alcohol graft copolymers for example Sokalan (Trade Mark) HP22.

- soil release polymers are the sulphonated non-end-capped polyesters described and claimed in WO 95 32997A (Rhodia Chimie).

- WO2010/069957 also claims a composition comprising hydroxamate and a specific surfactant system in a specific ratio and further comprising at least 0.5 wt% of soil release polymer.

- compositions used at low in-wash surfactant levels as discussed in WO2009/153184 , particularly when the composition does not also comprise a lipase enzyme.

- wt% refers to the total weight percentage in the liquid as dry weight.

- an aqueous concentrated liquid laundry detergent comprising:

- Polyethylene imines comprise amino moieties where one, two or three hydrogens on a Nitrogen have been replaced.

- a substitution site means a residual hydrogen on the nitrogen.

- the Nitrogen is a terminal one having two hydrogens then it has two substitution sites and replacing each hydrogen with a 20EO group means that there are 20 alkoxy units on each substitution site on the Nitrogen and the average substitution is also 20.

- the polyester soil release polymer d) is a substantially linear polyester based polymer with a mid block of repeat units of terephthalate and (substituted) ethylene and one or more end blocks comprising repeat units of ethylene oxide.

- the amount of a) is greater than or equal to the amount of b), more preferably the amount of b) is at least 3 wt%.

- the composition comprises at least 0.4 wt% perfume, preferably at least 0.5 wt%.

- the perfume is selected from free oil perfume encapsulated perfume and mixtures thereof. Preferably it comprises mixtures of these types of perfume.

- the composition may further comprise 0 to 10 wt% of detersive surfactant other than that included in a) and b).

- detersive surfactant other than that included in a) and b).

- Preferred is soap and amphoteric surfactants, for example betaine.

- Amine oxide surfactant may also be included. Soap levels in the composition are preferably less than 3 wt%.

- compositions of the invention are concentrated compositions designed for dilution by a factor of at least 500 when forming a wash liquor, the amount of hydroxamate in the compositions is large as a percentage of the composition.

- the preferred ratio of hydroxamate to total detersive surfactant system (surfactant) for optimum particulate red clay soil removal lies in the range 1:4 to 1: 8000. More preferred is 1:7 to 1:40. An even more preferred range of ratios being 1:10 to 1:30 parts by weight.

- the amount of alkyl hydroxamate c) is preferably at least 0.1 wt%.

- the invention further comprises a method of washing polyester fabrics comprising the steps of combining 15 to 25 ml of the composition according to the invention with water to form a wash liquor having a non-soap surfactant concentration of less than 0.5 g/L and washing the polyester with the wash liquor.

- the invention further comprises the use of a composition according to the invention in a process to remove red clay from polyester.

- a concentrated laundry liquid with lower than expected levels of surfactant is used as described in WO2009/153184 .

- a low volume, less than 25 ml and preferably around 20 ml of the concentrated liquid is dosed to a wash load and diluted with water to form the wash liquor for use in the process.

- suitable compositions for use in the process according to the invention may comprise the ingredients described below at the levels detailed below.

- compositions for use in the method of the invention comprise detersive surfactant.

- the non-soap detersive surfactant makes up at least 10 wt% of the liquid composition, preferably it makes up from 12 to 60 wt%.

- the compositions for use according to the invention most preferably have total active detersive surfactant levels of at least 15 wt%.

- compositions are used in small doses that require them to be diluted in at least 500 times their own volume of water to form a main-wash liquor comprising at most 0.5 g/l surfactant.

- They may be concentrated compositions designed for front loading automatic washing machines, hand washing or top loading automatic washing machines. In hand washing less water may be used and in top loading automatic washing machines a higher amount of water would normally be used than for a front loading automatic machine.

- the dose of detergent liquid is adjusted accordingly to give similar wash liquor concentrations.

- compositions are aqueous.

- the amount of water is a least 5 wt%, preferably at least 25 wt%.

- Hydroxamic acids are a class of chemical compounds in which a hydroxylamine is inserted into a carboxylic acid.

- the general structure of a hydroxamic acid is the following: in which R 1 is an organic residue, for example alkyl or alkylene groups.

- the hydroxamic acid may be present as its corresponding alkali metal salt, or hydroxamate.

- the preferred salt is the potassium salt.

- hydroxamates may conveniently be formed from the corresponding hydroxamic acid by substitution of the acid hydrogen atom by a cation:

- L + is a monovalent cation for example the alkali metals (e.g. potassium, sodium), or ammonium or a substituted ammonium.

- hydroxamic acid or its corresponding hydroxamate has the structure: wherein R 1 is

- references to a number of carbon atoms include mixed chain length materials provided that some of the hydroxamate material falls within the ranges specified and the ratios and amounts are determined by excluding any material falling outside of the specified range.

- the preferred hydroxamates are those where R 2 is Hydrogen and R 1 is C 8 to C 14 alkyl, preferably normal alkyl, most preferably saturated.

- hydroxamate containing compositions according to the invention are particularly suitable for use on particulate stains for example soils and clays, especially red clay, and also grass.

- R 1 is an alkyl ether group CH 3 (CH 2 ) n (EO) m wherein n is from 2 to 20 and m is from 1 to 12 then the alkyl moiety terminates this side group.

- R 1 is chosen from the group consisting of C 4 , C 5 , C 6 , C 7 , C 8 , C 9 , C 10 , C 11 , C 12 and C 14 normal alkyl group, most preferably R 1 is at least a C 8 - 14 normal alkyl group.

- the C 8 material this is called octyl hydroxamic acid.

- the potassium salt is particularly useful.

- hydroxamic acids whilst less preferred, are suitable for use in the present invention.

- suitable compounds include, but are not limited to, the following compounds:

- Such hydroxamic acids are commercially available.

- the hydroxamate is thought to act by binding to metal ions that are present in the soil on the fabric. This binding action, which is, in effect, the known sequestrant property of the hydroxamate is not, in itself, of any use to remove the soil from the fabric.

- the key is the "tail" of the hydroxamate i.e. the group R 1 minus any branching that folds back onto the amate nitrogen via group R 2 .

- the tail is selected to have an affinity for the surfactant system.

- the soil removal ability of an already optimised surfactant system is further enhanced by the use of the hydroxamate as it, in effect, labels the difficult to remove particulate material (clay) as "soil” for removal by the surfactant system acting on the hydroxamate molecules now fixed to the particulates via their binding to the metal ions embedded in the clay type particulates.

- the non-soap detersive surfactants will adhere to the hydroxamate, leading overall to more surfactants interacting with the fabric, leading to better soil release.

- the hydroxamic acids act as a linker molecule facilitating the removal and suspension of the particulate soil from the fabric into a wash liquor and thus boosting the primary detergency.

- the hydroxamates have a higher affinity for transition metals, like iron, than for alkaline earth metals, for example calcium and magnesium, therefore the hydroxamic acid primarily acts to improve the removal of soil on fabric, especially particulate soils, and not additionally as a builder for calcium and magnesium.

- a preferred hydroxamate is the 80% solids coco hydroxamic acid available under the trade name RK853 from Axis House.

- the corresponding Potassium salt is available from Axis House under the trade name RK852.

- Axis house also supply the coco hydroxamic acid as a 50% solids material under the trade name RK858.

- the 50% coco hydroxamate potassium salt is available as RK857.

- Another preferred material is RK842, an Alkyl hydroxamic acid made from Palm Kernel Oil, from Axis House. The hydroxamates do not generate any residues.

- Surfactants assist in removing soil from the textile materials and also assist in maintaining removed soil in solution or suspension in the wash liquor.

- Anionic or blends of anionic and nonionic surfactants are a preferred feature of the present invention.

- the amount of anionic surfactant is preferably at least 5 wt%.

- anionic surfactants form the majority of the non-soap surfactant (a).

- Preferred alkyl sulphonates are alkylbenzene sulphonates, particularly linear alkylbenzene sulphonates (LAS) having an alkyl chain length of C 8 -C 15 .

- the counter ion for anionic surfactants is generally an alkali metal, typically sodium, although other counter-ions for example MEA, TEA or ammonium can be used. Suitable anionic surfactant materials are available in the marketplace as the 'Genapol'TM range from Clariant.

- Preferred linear alkyl benzene sulphonate surfactants are Detal LAS with an alkyl chain length of from 8 to 15, more preferably 12 to 14. LAS can be at least partially replaced by methyl ester sulphonate (MES), or, less preferably, partially replaced by up to 20 wt % Primary alcohol sulphate (PAS).

- MES methyl ester sulphonate

- PAS Primary alcohol sulphate

- composition further comprises an alkyl polyethoxylate sulphate anionic surfactant of the formula (IV): RO(C 2 H 4 O) x SO 3 - M + (Formula IV) where R is an alkyl chain having from 10 to 22 carbon atoms, saturated or unsaturated, M is a cation which makes the compound water-soluble, especially an alkali metal, ammonium or substituted ammonium cation, and x averages from 1 to 15.

- R is an alkyl chain having from 10 to 22 carbon atoms, saturated or unsaturated

- M is a cation which makes the compound water-soluble, especially an alkali metal, ammonium or substituted ammonium cation, and x averages from 1 to 15.

- R is an alkyl chain having from 12 to 16 carbon atoms

- M is Sodium and x averages from 1 to 3, preferably x is 3

- the anionic surfactant system comprises SLES, together with optional soap and mixtures thereof. Soap is not included in the calculation of amount of non-soap surfactant.

- a LAS/SLES surfactant blend has a superior foam profile to a LAS Nonionic surfactant blend and is therefore preferred for hand washing formulations requiring high levels of foam.

- SLES may be used at levels of up to 30%.

- the composition comprises at least 2 wt% SLES.

- alkyl sulphate surfactant may be used, especially the non-ethoxylated C 12-15 primary and secondary alkyl sulphates.

- PAS is preferably used in admixture with LAS and most preferably in admixture with LAS and SLES.

- a preferred SLES/AO/LAS/PAS liquid has a detersive surfactant system comprising 60 parts SLES, 20 parts amine oxide, 10 parts LAS and 10 parts PAS.

- Nonionic surfactants include primary and secondary alcohol ethoxylates, especially C 8 -C 20 aliphatic alcohol ethoxylated with an average of from 1 to 20 moles of ethylene oxide per mole of alcohol, and more especially the C 10 -C 15 primary and secondary aliphatic alcohols ethoxylated with an average of from 1 to 10 moles of ethylene oxide per mole of alcohol.

- Non-ethoxylated nonionic surfactants include alkyl polyglycosides, glycerol monoethers and polyhydroxy amides (glucamide). Mixtures of nonionic surfactant may be used.

- the composition contains from 0.2 wt% to 30 wt%, preferably 1 wt% to 20 wt%, more preferably 5 to 15 wt% of a non-ionic surfactant, for example alcohol ethoxylate, nonylphenol ethoxylate, alkylpolyglycoside, alkyldimethylamineoxide, ethoxylated fatty acid monoethanolamide, fatty acid monoethanolamide, polyhydroxy alkyl fatty acid amide, or N-acyl N-alkyl derivatives of glucosamine (“glucamides").

- a non-ionic surfactant for example alcohol ethoxylate, nonylphenol ethoxylate, alkylpolyglycoside, alkyldimethylamineoxide, ethoxylated fatty acid monoethanolamide, fatty acid monoethanolamide, polyhydroxy alkyl fatty acid amide, or N-acyl N-alkyl derivatives of glucosamine (“glucamides”).

- Nonionic surfactants that may be used include the primary and secondary alcohol ethoxylates, especially the C 8 -C 20 aliphatic alcohols ethoxylated with an average of from 1 to 35 moles of ethylene oxide per mole of alcohol, and more especially the C 10 -C 15 primary and secondary aliphatic alcohols ethoxylated with an average of from 1 to 10 moles of ethylene oxide per mole of alcohol.

- composition may comprise up to 10 wt% of an amine oxide (AO) of the formula (V): R 1 N(O)(CH 2 R 2 ) 2 (Formula V)

- R 1 is a long chain moiety and each CH 2 R 2 is a short chain moiety.

- R 2 is preferably selected from hydrogen, methyl and -CH 2 OH.

- R 1 is a primary or branched hydrocarbyl moiety which can be saturated or unsaturated, preferably, R 1 is a primary alkyl moiety.

- R 1 is a hydrocarbyl moiety having chain length of from about 8 to about 18.

- R 1 is C 8 -C 18 alkyl

- R 2 is H.

- These amine oxides are illustrated by C 12 - 14 alkyldimethyl amine oxide, hexadecyl dimethylamine oxide, octadecylamine oxide.

- a preferred amine oxide material is Lauryl dimethylamine oxide, also known as dodecyldimethylamine oxide or DDAO. Such an amine oxide material is commercially available from Huntsman under the trade name Empigen® OB.

- Amine oxides suitable for use herein are also available from Akzo Chemie and Ethyl Corp. See McCutcheon's compilation and Kirk-Othmer review article for alternate amine oxide manufacturers.

- R 2 is H

- R 2 may be CH 2 OH, for example: hexadecylbis(2-hydroxyethyl)amine oxide, tallowbis(2-hydroxyethyl)amine oxide, stearylbis(2-hydroxyethyl)amine oxide and oleylbis(2- hydroxyethyl)amine oxide.

- Preferred amine oxides have the formula (VI): O - - N + (Me) 2 R 1 (Formula VI) where R 1 is C 12-16 alkyl, preferably C 12-14 alkyl; Me is a methyl group.

- a preferred surfactant system for use in high suds (foam) applications comprises SLES and AO.

- Nonionic-free systems with up to 95 wt% of the surfactant system LAS can be made provided that some zwitterionic surfactant, for example sulphobetaine, is present.

- a preferred zwitterionic material is a betaine available from Huntsman under the name Empigen® BB. Betaines, improve particulate soil detergency in the compositions of the invention.

- Cationic surfactants are preferably substantially absent.

- compositions may comprise soap which can act as a builder and/or as an antifoam.

- the amount of non-soap anionic surfactant must exceed the amount of soap.

- the amount of soap must be less than or equal to 15 wt% of the total liquid composition, preferably it is less than 3 wt%.

- the fatty acid used preferably contains from about 16 to about 22 carbon atoms, preferably in a straight chain configuration.

- the anionic contribution from soap may be from 0 to 30 wt% of the total anionic. Use of more than 10 wt% soap is not preferred. Saturated fatty acids are preferred.

- the composition comprises an ethoxylated polyethyleneimine polymer (EPEI) for cleaning.

- EPEI ethoxylated polyethyleneimine polymer

- the EPEI is nonionic. That means it does not have any quaternary nitrogens, or nitrogen oxides or any ionic species other than possible pH effected protonation of nitrogens.

- Polyethylene imines are materials composed of ethylene imine units -CH2CH2NH- and, where branched, the hydrogen on the nitrogen is replaced by another chain of ethylene imine units.

- These polyethyleneimines can be prepared, for example, by polymerizing ethyleneimine in the presence of a catalyst for example carbon dioxide, sodium bisulphite, sulphuric acid, hydrogen peroxide, hydrochloric acid, acetic acid, and the like.

- a catalyst for example carbon dioxide, sodium bisulphite, sulphuric acid, hydrogen peroxide, hydrochloric acid, acetic acid, and the like. Specific methods for preparing these polyamine backbones are disclosed in U.S. Pat. No. 2,182,306, Ulrich et al., issued Dec. 5, 1939 ; U.S. Pat. No.

- the EPEI comprises a polyethyleneimine backbone wherein the modification of the polyethyleneimine backbone is intended to leave the polymer without quaternisation.

- Such nonionic EPEI may be represented as PEI(X)YEO where X represents the molecular weight of the unmodified PEI and Y represents the average moles of ethoxylation per nitrogen atom in the polyethyleneimine backbone. This is the same as the average per substitution site if the number of nitrogens with no hydrogen is balanced by the number with two hydrogens in the unethoxylated PEI.

- the ethoxylation number Y may range from 7 to 40 ethoxy moieties per modification, preferably it is in the range of 16 to 26, most preferably 18 to 22.

- X is selected to be from about 300 to about 10000 weight average molecular weight and is preferably about 600.

- the ethoxylated polyethyleneimine polymer (EPEI) is present in the composition at a level of between 2 and 20 wt%, preferably at a level of less than 9.5 wt%, more preferably from 3 to 9 wt% and with a ratio of non-soap surfactant to EPEI of from 2:1 to 7:1, preferably from 3:1 to 6:1, even about 5:1.

- composition further comprises at least 0.5 wt% of a polymeric soil release agent for oily soil removal from polyester.

- Soil release polymers improve the main wash performance of the compositions when used in the low in wash surfactant process of the present invention.

- One preferred class of polymer is the fabric-substantive polymers comprising at least one of (i) saccharide or (ii) dicarboxylic acid and polyol monomer units.

- these polymers have soil release properties and, while they can have a primary detergency effect, they generally assist in subsequent cleaning.

- these polymers are present at a level of at least 2% wt, more preferably at least 3 wt% of the composition.

- the soil release polymer will preferably comprise up to 10 wt%, of the detergent composition, more preferably up to 9 wt%, preferably they are used at greater than 2 wt% and more preferably greater than 3 wt% in the composition.

- the soil release polymers for polyester will comprise polymers of aromatic dicarboxylic acids and alkylene glycols (including polymers containing polyalkylene glycols).

- the polymeric soil release agents useful herein include those soil release agents having:

- the polyoxyethylene segments of (a)(i) will have a degree of polymerization of from about 200, although higher levels can be used, preferably from 3 to about 150, more preferably from 6 to about 100.

- Soil release agents characterized by poly(vinyl ester) hydrophobic segments include graft copolymers of poly(vinyl ester), e.g., C 1 -C 6 vinyl esters, preferably poly(vinyl acetate) grafted onto polyalkylene oxide backbones, for example polyethylene oxide backbones.

- poly(vinyl ester) e.g., C 1 -C 6 vinyl esters

- poly(vinyl acetate) grafted onto polyalkylene oxide backbones for example polyethylene oxide backbones.

- Commercially available soil release agents of this kind include the SOKALAN type of material, e.g., SOKALAN HP22, available from BASF (West Germany).

- One type of preferred soil release agent is a copolymer having random blocks of ethylene terephthalate and polyethylene oxide (PEO) terephthalate.

- the molecular weight of this polymeric soil release agent is in the range of from about 25,000 to about 55,000. See U.S. Pat. No. 3,959,230 to Hays, issued May 25, 1976 and U.S. Pat. No. 3,893,929 to Basadur issued Jul. 8, 1975 .

- Another preferred polymeric soil release agent is a polyester with repeat units of ethylene terephthalate units contains 10 to 15 wt% of ethylene terephthalate units together with 90 to 80 wt% weight of polyoxyethylene terephthalate units, derived from a polyoxyethylene glycol of average molecular weight 300 to 5000.

- this polymer include ZELCON 5126 (from DuPont) and MILEASE T (from ICI). See also U.S. Pat. No. 4,702,857, issued Oct. 27, 1987 to Gosselink .

- the invention provides a combinations of relatively high levels of EPEI, especially >2.5 wt% on the composition, with the polyester soil release polymer(s).

- EPEI and soil release polymers of the above types enables increased performance at lower surfactant levels compared to 1.0g/L or higher non soap surfactant wash liquors without either EPEI or SRP. This effect is particularly visible on a range of stains on polyester, most particularly red clay.

- SRP performance is enhanced significantly by repeated pre-treatment. There is some evidence of a build-up effect of EPEI performance.

- the most preferred soil release polymers are the water soluble/miscible or dispersible polyesters for example those supplied under the Texcare brand by Clariant, especially Texcare® SRN 170, and heavily branched polyesters for example those available from Sasol and described in US 7119056 . Combinations of soil release polymers may be used.

- compositions may further comprise one or more further polymers selected from the group comprising dye transfer inhibition polymers, anti redeposition polymers and cotton soil release polymers based on modified cellulosic materials.

- At least one or more enzymes may be present in the compositions for cleaning boost.

- proteases include those of animal, vegetable or microbial origin. Microbial origin is preferred. Chemically modified or protein engineered mutants are included.

- the protease may be a serine protease or a metallo protease, preferably an alkaline microbial protease or a trypsin-like protease.

- Preferred commercially available protease enzymes include AlcalaseTM, SavinaseTM, PrimaseTM, DuralaseTM, DyrazymTM, EsperaseTM, EverlaseTM, PolarzymeTM, and KannaseTM, (Novozymes A/S), MaxataseTM, MaxacalTM, MaxapemTM, ProperaseTM, PurafectTM, Purafect OxPTM, FN2TM , and FN3TM (Genencor International Inc.).

- Suitable amylases include those of bacterial or fungal origin. Chemically modified or protein engineered mutants are included. Amylases include, for example, alpha-amylases obtained from Bacillus, e.g. a special strain of B . licheniformis, described in more detail in GB 1,296,839 , or the Bacillus sp. strains disclosed in WO 95/026397 or WO 00/060060 .

- amylases are DuramylTM, TermamylTM Termamyl UltraTM, NatalaseTM, StainzymeTM, FungamylTM and BANTM (Novozymes A/S), RapidaseTM and PurastarTM (from Genencor International Inc.).

- Pectate lyases also called polygalacturonate lyases

- pectate lyases include pectate lyases that have been cloned from different bacterial genera for example Erwinia, Pseudomonas, Klebsiella and Xanthomonas, as well as from Bacillus subtilis ( Nasser et al. (1993) FEBS Letts. 335:319-326 ) and Bacillus sp. YA-14 ( Kim et al. (1994) Biosci. Biotech. Biochem. 58:947-949 ).

- the pectate lyase comprises the pectate lyase disclosed in Heffron et al., (1995) Mol. Plant-Microbe Interact. 8: 331-334 and Henrissat et al., (1995) Plant Physiol. 107: 963-976 .

- pectate lyases are disclosed in WO 99/27083 and WO 99/27084 .

- pectate lyases derived from Bacillus licheniformis

- US patent no. 6,284,524 Specifically contemplated pectate lyase variants are disclosed in WO 02/006442 , especially the variants disclosed in the Examples in WO 02/006442 .

- Examples of commercially available alkaline pectate lyases include BIOPREPTM and SCOURZYMETM L from Novozymes A/S, Denmark.

- Suitable examples of mannanases include mannanases of bacterial and fungal origin.

- the mannanase is derived from a strain of the filamentous fungus genus Aspergillus, preferably Aspergillus niger or Aspergillus aculeatus ( WO 94/25576 ).

- WO 93/24622 discloses a mannanase isolated from Trichoderma reseei. Mannanases have also been isolated from several bacteria, including Bacillus organisms. For example, Talbot et al., Appl. Environ. Microbiol., Vol.56, No. 11, pp.

- JP-A-03047076 discloses a beta-mannanase derived from Bacillus sp.

- JP-A-63056289 describes the production of an alkaline, thermostable beta-mannanase.

- JP-A-63036775 relates to the Bacillus microorganism FERM P-8856 which produces beta-mannanase and beta-mannosidase.

- JP-A-08051975 discloses alkaline beta-mannanases from alkalophilic Bacillus sp. AM-001.

- a purified mannanase from Bacillus amyloliquefaciens is disclosed in WO 97/11164 .

- WO 91/18974 describes a hemicellulase for example a glucanase, xylanase or mannanase active.

- mannanases derived from Bacillus agaradhaerens, Bacillus licheniformis, Bacillus halodurans, Bacillus clausii, Bacillus sp., and Humicola insolens disclosed in WO 99/64619 .

- Bacillus sp. mannanases concerned in the Examples in WO 99/64619 .

- mannanases examples include MannawayTM available from Novozymes A/S Denmark.

- Suitable cellulases include those of bacterial or fungal origin. Chemically modified or protein engineered mutants are included. Suitable cellulases include cellulases from the genera Bacillus, Pseudomonas, Humicola, Fusarium, Thielavia, Acremonium, e.g. the fungal cellulases produced from Humicola insolens, Thielavia terrestris, Myceliophthora thermophila, and Fusarium oxysporum disclosed in US 4,435,307 , US 5,648,263 , US 5,691,178 , US 5,776,757 , WO 89/09259 , WO 96/029397 , and WO 98/012307 .

- cellulases include CelluzymeTM, CarezymeTM, EndolaseTM, RenozymeTM (Novozymes A/S), ClazinaseTM and Puradax HATM (Genencor International Inc.), and KAC-500(B)TM (Kao Corporation).

- Suitable peroxidases/oxidases include those of plant, bacterial or fungal origin. Chemically modified or protein engineered mutants are included. Examples of useful peroxidases include peroxidases from Coprinus, e.g. from C . cinereus, and variants thereof as those described in WO 93/24618 , WO 95/10602 , and WO 98/15257 . Commercially available peroxidases include GuardzymeTM and NovozymTM 51004 (Novozymes A/S).

- the composition may comprise from about 5 to about 20000 LU/g of a lipase.

- Preferred lipase enzymes include those of bacterial or fungal origin. Chemically modified or protein engineered mutants are included.

- useful lipases include lipases from Humicola, more preferably ones which comprise a polypeptide having an amino acid sequence which has at least 90% sequence identity with the wild-type lipase derived from Humicola lanuginose, most preferably strain DSM 4109.

- the amount in the composition is higher than typically found in liquid detergents. This can be seen by the ratio of non-soap surfactant to lipase enzyme, in particular.

- a particularly preferred lipase enzyme is available under the trademark Lipoclean TM from Novozymes.

- Suitable lipases include those of bacterial or fungal origin. Chemically modified or protein engineered mutants are included. Examples of useful lipases include lipases from Humicola (synonym Thermomyces ), e.g. from H. lanuginosa ( T. lanuginosus ) as described in EP 258 068 and EP 305 216 or from H. insolens as described in WO 96/13580 , a Pseudomonas lipase, e.g. from P. alcaligenes or P . pseudoalcaligenes ( EP 218 272 ), P. cepacia ( EP 331 376 ), P. stutzeri ( GB 1,372,034 ), P.

- lipase variants for example those described in WO 92/05249 , WO 94/01541 , EP 407 225 , EP 260 105 , WO 95/35381 , WO 96/00292 , WO 95/30744 , WO 94/25578 , WO 95/14783 , WO 95/22615 , WO 97/04079 and WO 97/07202 .

- LipolaseTM and Lipolase UltraTM LipexTM and LipocleanTM (Novozymes A/S).

- lipase In addition to or as an alternative to lipase one or more other enzymes may be present. However lipase is particularly preferred.

- the presence of relatively high levels of calcium in the poorly built or unbuilt compositions of the invention has a beneficial effect on the turnover of certain enzymes, particularly lipase enzymes and preferably lipases from Humicola.

- the preferred lipases include first wash lipases which comprise a polypeptide having an amino acid sequence which has at least 90% sequence identity with the wild-type lipase derived from Humicola lanuginosa strain DSM 4109 and compared to said wild-type lipase, comprises a substitution of an electrically neutral or negatively charged amino acid within 15 A of E1 or Q249 with a positively charged amino acid; and may further comprise:

- phospholipase classified as EC 3.1.1.4 and/or EC 3.1.1.32.

- phospholipase is an enzyme which has activity towards phospholipids.

- Phospholipids for example lecithin or phosphatidylcholine, consist of glycerol esterified with two fatty acids in an outer (sn-1) and the middle (sn-2) positions and esterified with phosphoric acid in the third position; the phosphoric acid, in turn, may be esterified to an amino-alcohol.

- Phospholipases are enzymes which participate in the hydrolysis of phospholipids.

- phospholipases A 1 and A 2 which hydrolyze one fatty acyl group (in the sn-1 and sn-2 position, respectively) to form lysophospholipid

- lysophospholipase or phospholipase B

- Phospholipase C and phospholipase D release diacyl glycerol or phosphatidic acid respectively.

- the method of the invention may be carried out in the presence of cutinase. classified in EC 3.1.1.74.

- the cutinase used according to the invention may be of any origin.

- Preferably cutinases are of microbial origin, in particular of bacterial, of fungal or of yeast origin.

- Enzymes and any perfume/fragrance or pro-fragrance present may show some interaction and should be chosen such that this interaction is not negative. Some negative interactions may be avoided by encapsulation of one or other of enzyme and pro-fragrance and/or other segregation within the product.

- Any enzyme present in the composition may be stabilized using conventional stabilizing agents, e.g., a polyol for example propylene glycol or glycerol, a sugar or sugar alcohol, lactic acid, boric acid, or a boric acid derivative, e.g., an aromatic borate ester, or a phenyl boronic acid derivative for example 4-formylphenyl boronic acid, and the composition may be formulated as described in e.g. WO 92/19709 and WO 92/19708 .

- stabilizing agents e.g., a polyol for example propylene glycol or glycerol, a sugar or sugar alcohol, lactic acid, boric acid, or a boric acid derivative, e.g., an aromatic borate ester, or a phenyl boronic acid derivative for example 4-formylphenyl boronic acid

- compositions of the invention may contain one or more other ingredients.

- Such ingredients include viscosity modifiers, foam boosting agents, preservatives (e.g. bactericides), pH buffering agents, polyelectrolytes, anti-shrinking agents, anti-wrinkle agents, anti-oxidants, sunscreens, anti-corrosion agents, drape imparting agents, anti-static agents and ironing aids.

- the compositions may further comprise, colorants, pearlisers and/or opacifiers, and shading dye.

- fluorescer in the compositions.

- these fluorescent agents are supplied and used in the form of their alkali metal salts, for example, the sodium salts.

- the total amount of the fluorescent agent or agents used in the composition is generally from 0.005 to 2 wt %, more preferably 0.01 to 0.5 wt %.

- Preferred classes of fluorescer are: Di-styryl biphenyl compounds, e.g. Tinopal (Trade Mark) CBS-X, Di-amine stilbene di-sulphonic acid compounds, e.g. Tinopal DMS pure Xtra and Blankophor (Trade Mark) HRH, and Pyrazoline compounds, e.g. Blankophor SN.

- Di-styryl biphenyl compounds e.g. Tinopal (Trade Mark) CBS-X

- Di-amine stilbene di-sulphonic acid compounds e.g. Tinopal DMS pure Xtra and Blankophor (Trade Mark) HRH

- Pyrazoline compounds e.g. Blankophor SN.

- Preferred fluorescers are: sodium 2 (4-styryl-3-sulfophenyl)-2H-napthol[1,2-d]triazole, disodium 4,4'-bis ⁇ [(4-anilino-6-(N methyl-N-2 hydroxyethyl) amino 1,3,5-triazin-2-yl)]amino ⁇ stilbene-2-2' disulfonate, disodium 4,4'-bis ⁇ [(4-anilino-6-morpholino-1,3,5-triazin-2-yl)]amino ⁇ stilbene-2-2' disulfonate, and disodium 4,4'-bis(2-sulfoslyryl)biphenyl.

- Detergent compositions according to the invention may comprise a weight efficient bleach system.

- Such bleach systems typically do not utilise the conventional peracid or bleach activator with perborate/percarbonate "oxygen" bleach systems, but rely instead on a bleach catalyst used at a low level as the main bleach component.

- the present invention may be used in a formulation that is used to bleach via air, or an air bleach catalyst system.

- Suitable complexes and organic molecule (ligand) precursors for forming complexes are available to the skilled worker, for example, from: WO 98/39098 ; WO 98/39406 , WO 97/48787 , WO 00/29537 ; WO 00/52124 , and WO00/60045 .

- An example of a preferred catalyst is a transition metal complex of MeN 4 Py ligand (N,N-bis(pyridin-2-yl-methyl)-1-,1-bis(pyridin-2-yl)-1-aminoethane).

- Suitable bispidon catalyst materials and their action are described in WO02/48301 .

- the bleach catalyst is typically incorporated at a level of about 0.0001 to about 10 wt%, preferably about 0.001 to about 5 wt%.

- Photobleaches may also be employed.

- a "photobleach” is any chemical species that forms a reactive bleaching species on exposure to sunlight, and preferably is not permanently consumed in the reaction.

- Preferred photo-bleaches include singlet oxygen photo-bleaches and radical photo-bleaches.

- Suitable singlet oxygen photo-bleaches may be selected from, water soluble phthalocyanine compounds, particularly metallated phthalocyanine compounds where the metal is Zn or Al-Z1 where Z1 is a halide, sulphate, nitrate, carboxylate, alkanolate or hydroxyl ion.

- the phthalocyanin has 1-4 SO 3 X groups covalently bonded to it where X is an alkali metal or ammonium ion. Such compounds are described in WO2005/014769 (Ciba).

- compositions preferably comprise from 0.001 to 5 wt % perfume. Given that the composition of the present invention is designed to be used at very low levels of product dosage, it is advantageous to ensure that perfume is employed efficiently.

- a particularly preferred way of ensuring that perfume is employed efficiently is to use an encapsulated perfume.

- Use of a perfume that is encapsulated reduces the amount of perfume vapour that is produced by the composition before it is diluted. This is important when the perfume concentration is increased to allow the amount of perfume per wash to be kept at a reasonably high level.

- the perfume is not only encapsulated but also that the perfume encapsulate is provided with a deposition aid to increase the efficiency of perfume deposition and retention on fabrics.

- the deposition aid is preferably attached to the encapsulate by means of a covalent bond, entanglement or strong adsorption, preferably by a covalent bond or entanglement.

- Shading dye can be used to improve the performance of the compositions used in the method of the present invention.

- the deposition of shading dye onto fabric is improved when they are used in compositions of the invention and according to the process of the invention.

- Preferred dyes are violet or blue. It is believed that the deposition on fabrics of a low level of a dye of these shades, masks yellowing of fabrics.

- a further advantage of shading dyes is that they can be used to mask any yellow tint in the composition itself.

- Direct dyes are the class of water soluble dyes which have an affinity for fibres and are taken up directly. Direct violet and direct blue dyes are preferred. Preferably bis-azo or tris-azo dyes are used.

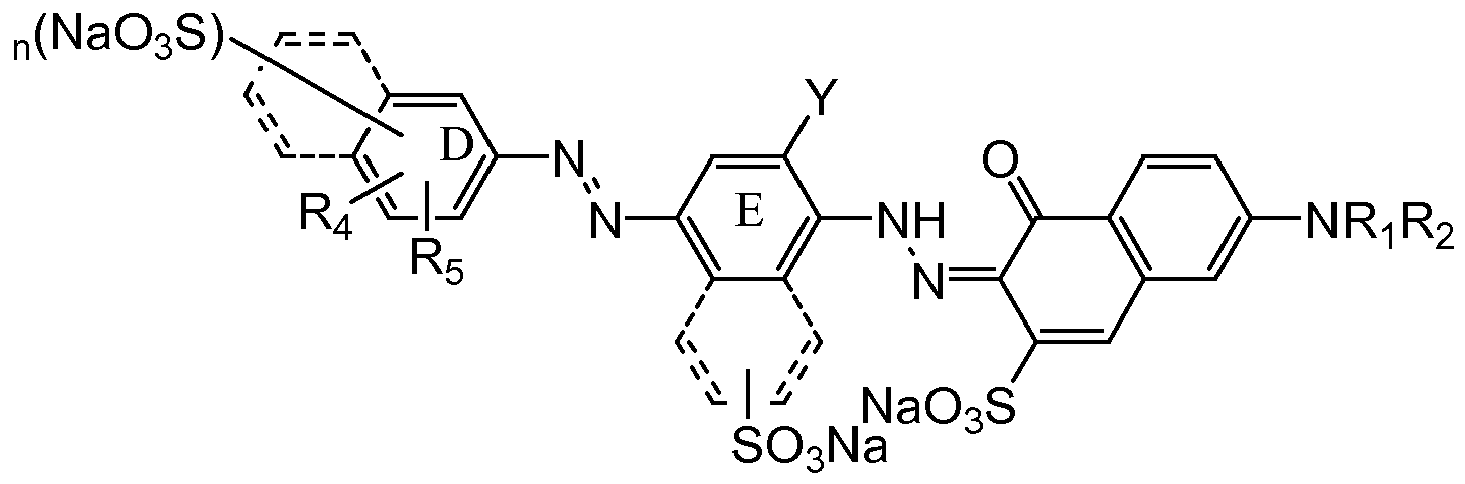

- the direct dye is a direct violet of the following structures: or wherein:

- Preferred dyes are direct violet 7, direct violet 9, direct violet 11, direct violet 26, direct violet 31, direct violet 35, direct violet 40, direct violet 41, direct violet 51, and direct violet 99.

- Bis-azo copper containing dyes for example direct violet 66 may be used.

- the benzidene based dyes are less preferred.

- the direct dye may be covalently linked to the photo-bleach, for example as described in WO2006/024612 .

- the direct dye is present at 0.000001 to 1 wt% more preferably 0.00001 wt% to 0.0010 wt% of the composition.

- Cotton substantive acid dyes give benefits to cotton containing garments.

- Preferred dyes and mixes of dyes are blue or violet.

- Preferred acid dyes are:

- Preferred azine dyes are: acid blue 98, acid violet 50, and acid blue 59, more preferably acid violet 50 and acid blue 98.

- Other preferred non-azine acid dyes are acid violet 17, acid black 1 and acid blue 29.

- the acid dye is present at 0.0005 wt% to 0.01 wt% of the formulation.

- the composition may comprise one or more hydrophobic dyes selected from benzodifuranes, methine, triphenylmethanes, napthalimides, pyrazole, napthoquinone, anthraquinone and mono-azo or di-azo dye chromophores.

- Hydrophobic dyes are dyes which do not contain any charged water solubilising group. Hydrophobic dyes may be selected from the groups of disperse and solvent dyes. Blue and violet anthraquinone and mono-azo dye are preferred.

- Preferred dyes include solvent violet 13, disperse violet 27 disperse violet 26, disperse violet 28, disperse violet 63 and disperse violet 77.

- the hydrophobic dye is present at 0.0001 wt% to 0.005 wt% of the formulation.

- Basic dyes are organic dyes which carry a net positive charge. They deposit onto cotton. They are of particular utility for used in composition that contain predominantly cationic surfactants. Dyes may be selected from the basic violet and basic blue dyes listed in the Colour Index International. Preferred examples include triarylmethane basic dyes, methane basic dye, anthraquinone basic dyes, basic blue 16, basic blue 65, basic blue 66, basic blue 67, basic blue 71, basic blue 159, basic violet 19, basic violet 35, basic violet 38, basic violet 48; basic blue 3, basic blue 75, basic blue 95, basic blue 122, basic blue 124, basic blue 141.

- Reactive dyes are dyes which contain an organic group capable of reacting with cellulose and linking the dye to cellulose with a covalent bond. They deposit onto cotton.

- the reactive group is hydrolysed or reactive group of the dyes has been reacted with an organic species for example a polymer, so as to the link the dye to this species.

- Dyes may be selected from the reactive violet and reactive blue dyes listed in the Colour Index International.

- Preferred examples include reactive blue 19, reactive blue 163, reactive blue 182 and reactive blue, reactive blue 96.

- Dye conjugates are formed by binding direct, acid or basic dyes to polymers or particles via physical forces. Dependent on the choice of polymer or particle they deposit on cotton or synthetics. A description is given in WO2006/055787 .

- Particularly preferred dyes are: direct violet 7, direct violet 9, direct violet 11, direct violet 26, direct violet 31, direct violet 35, direct violet 40, direct violet 41, direct violet 51, direct violet 99, acid blue 98, acid violet 50, acid blue 59, acid violet 17, acid black 1, acid blue 29, solvent violet 13, disperse violet 27 disperse violet 26, disperse violet 28, disperse violet 63, disperse violet 77 and mixtures thereof.

- Shading dye can be used in the absence of fluorescer, but it is especially preferred to use a shading dye in combination with a fluorescer, for example in order to reduce yellowing due to chemical changes in adsorbed fluorescer.

- Sequestrants may be present in the compositions. However, because the hydroxamate technology is affected by competing sequestrants, for maximum performance of the hydroxamate any phosphonate or similar sequestrants that may complex with iron are preferably absent or used at a low level of up to 1 wt%, preferably less than 0.5 wt%.

- the detergent compositions may also optionally contain relatively low levels of organic detergent builder material. Examples include the alkali metal, citrates, succinates, malonates, carboxymethyl succinates, carboxylates, polycarboxylates and polyacetyl carboxylates.

- Specific examples include sodium, potassium and lithium salts of oxydisuccinic acid, mellitic acid, benzene polycarboxylic acids, and citric acid.

- Other examples are DEQUEST TM , organic phosphonate type sequestering agents sold by Monsanto and alkanehydroxy phosphonates.

- suitable organic builders include the higher molecular weight polymers and copolymers known to have builder properties.

- such materials include appropriate polyacrylic acid, polymaleic acid, and polyacrylic/polymaleic acid copolymers and their salts, for example those sold by BASF under the name SOKALAN TM .

- the organic builder materials may comprise from about 0.5 wt% to 20 wt%, preferably from 1 wt% to 10 wt%, of the composition.

- the preferred builder level is less than 10 wt% and preferably less than 5 wt% of the composition.

- a preferred sequestrant is HEDP (1-Hydroxyethylidene -1,1,-diphosphonic acid), for example sold as Dequest® 2010.

- Dequest® 2066 Diethylenetriamine penta(methylene phosphonic acid or Heptasodium DTPMP).

- compositions preferably comprise one or more hydrotropes; although the minimum amount consistent with the need for concentration should be used.

- Suitable hydrotropes include MPG (monopropylene glycol). This and/or other conventionally employed hydrotropes may be used in the composition at levels of from 2 to 25 wt%.

- a hydrotrope is a solvent that is neither water nor conventional surfactant that aids the solubilisation of the surfactants and other components in the aqueous liquid to render it isotropic.

- MPG monopropylene glycol

- suitable hydrotropes there may be mentioned as preferred: glycerol, sodium cumene sulphonate, ethanol, other glycols, e.g. di propylene glycol, diethers and urea.

- buffers are monoethanolamine (MEA), and triethanolamine (TEA). If present, they are preferably used in the composition at levels of from 5 to 15 wt%.

- compositions may have their rheology modified by use of a material or materials that form a structuring network within the composition.

- Suitable structurants include hydrogenated castor oil, microfibrous cellulose and natural based structurants for example citrus pulp fibre. Citrus pulp fibre is particularly preferred especially if lipase enzyme is included in the composition.

- compositions may, and preferably do, comprise visual cues of solid material that is not dissolved in the composition. Preferably they are used in combination with an external structurant to ensure that they remain in suspension.

- visual cues are lamellar cues formed from polymer film and possibly comprising functional ingredients that may not be as stable if exposed to the alkaline liquid. Enzymes and bleach catalysts are examples of such ingredients. Also perfume, particularly microencapsulated perfume.

- the liquids may be packaged as unit doses. To allow greater flexibility in dosing the liquids may alternatively be supplied in multiuse plastics packs with a top or bottom closure. A dosing system may be supplied with the pack either as a part of the cap or as an integrated system.

- liquids according to the invention may be formulated to allow them to be dosed to a typical front loading automatic washing machine at a dosage level of 20 ml.

- the low in wash surfactant level being compensated by the presence of enzymes, soil release polymer and EPEI together with further optional high efficacy cleaning ingredients, for example enzymes.

- the invention is also suitable for the more conventional dosage levels of about 35 ml. To obtain suitable concentrated liquids of this greater dose volume it is necessary is to add further water and preferably additional perfume to the 20ml composition before it is packaged.

- SRI 100 - ⁇ E * aw

- a SRI of 100 means complete stain removal.

- composition is designed to dose to European front loading washing machines at a standard dose of 20ml which is approximately 20% of the normal dose of a dilute liquid and less than the current "concentrated" 3X formulations that are dosed from 30-40 ml per wash.

- Base 5X Composition D was used at 1.41 g/L. When additional ingredients were added to the composition the water balance was reduced to keep the dose of surfactant to the wash constant.

- the undiluted compositions have a pH of about 6.5.

- the other (in-wash) levels were:

Abstract

An aqueous concentrated liquid laundry detergent comprising:

a) 8 to 40 wt% anionic non-soap surfactant;

b) 0 to 30 wt% nonionic surfactant;

c) 0.05 to 10 wt% alkyl hydroxamate;

d) 2 to 10 wt% polyester soil release polymer; and

e) 2 to 20 wt% nonionic alkoxylated polyethylene imine with an average

of between 7 and 40 alkoxy units per substitution site on a Nitrogen.

a) 8 to 40 wt% anionic non-soap surfactant;

b) 0 to 30 wt% nonionic surfactant;

c) 0.05 to 10 wt% alkyl hydroxamate;

d) 2 to 10 wt% polyester soil release polymer; and

e) 2 to 20 wt% nonionic alkoxylated polyethylene imine with an average

of between 7 and 40 alkoxy units per substitution site on a Nitrogen.

Description

- This invention relates to aqueous concentrated laundry detergent compositions and their use at low dosage for cleaning of soils from fabrics.

- In

WO2009/153184 there is described a method of laundering fabrics that uses very low levels of in wash surfactant (that may be an anionic surfactant). Wash performance is boosted by inclusion of high levels of specific polymers and enzymes. A preferred enzyme is lipase, most preferably Lipex. Preferred polymers are a combination of ethoxylated polyethylene imine and a polyester soil release polymer. The surfactant system preferably includes SLES and most preferably also carbobeteine. A sequestrant is included in the exemplified compositions: Dequest 2066. This is Diethylenetriamine penta(methylene phosphonic acid). No use is made of soil specific sequestrants of the type disclosed inWO2010/069957 . -

WO2010/069957 discloses the use of specific hydroxamate (HA) in conjunction with a specific surfactant system to improve the cleaning performance of both powder and liquid compositions on certain stains, notably red clay. Various formulation possibilities are discussed. Soil release polymer for polyester (SRP) is mentioned and claimed but is not exemplified. The benefit of SRP inclusion is said to be the known multiwash benefit of this type of polymer, when used with an efficient cleaning system. No mention is made of EPEI as used inWO2009/153184 . The examples all use high in-wash surfactant levels.WO2010/069957 discloses that the compositions may also contain soil release polymers, for example sulphonated and unsulphonated PET/POET polymers, both end-capped and non-end-capped, and polyethylene glycol/polyvinyl alcohol graft copolymers for example Sokalan (Trade Mark) HP22. Especially preferred soil release polymers are the sulphonated non-end-capped polyesters described and claimed inWO 95 32997A WO2010/069957 also claims a composition comprising hydroxamate and a specific surfactant system in a specific ratio and further comprising at least 0.5 wt% of soil release polymer. - It is desirable to further improve the performance of compositions used at low in-wash surfactant levels as discussed in

WO2009/153184 , particularly when the composition does not also comprise a lipase enzyme. - Unless otherwise stated wt% refers to the total weight percentage in the liquid as dry weight.

- According to the present invention there is provided an aqueous concentrated liquid laundry detergent comprising:

- a) 8 to 40 wt% anionic non-soap surfactant;

- b) 0 to 30 wt% nonionic surfactant;

- c) 0.05 to 10 wt% alkyl hydroxamate;

- d) 2 to 10 wt% polyester soil release polymer; and

- e) 2 to 20 wt% nonionic alkoxylated polyethylene imine with an average

- Polyethylene imines comprise amino moieties where one, two or three hydrogens on a Nitrogen have been replaced. In this specification a substitution site means a residual hydrogen on the nitrogen. For example if the Nitrogen is a terminal one having two hydrogens then it has two substitution sites and replacing each hydrogen with a 20EO group means that there are 20 alkoxy units on each substitution site on the Nitrogen and the average substitution is also 20.

- Preferably the polyester soil release polymer d) is a substantially linear polyester based polymer with a mid block of repeat units of terephthalate and (substituted) ethylene and one or more end blocks comprising repeat units of ethylene oxide.

- Preferably the amount of a) is greater than or equal to the amount of b), more preferably the amount of b) is at least 3 wt%.

- Desirably the composition comprises at least 0.4 wt% perfume, preferably at least 0.5 wt%. When present, the perfume is selected from free oil perfume encapsulated perfume and mixtures thereof. Preferably it comprises mixtures of these types of perfume.

- The composition may further comprise 0 to 10 wt% of detersive surfactant other than that included in a) and b). Preferred is soap and amphoteric surfactants, for example betaine. Amine oxide surfactant may also be included. Soap levels in the composition are preferably less than 3 wt%.

- Because the compositions of the invention are concentrated compositions designed for dilution by a factor of at least 500 when forming a wash liquor, the amount of hydroxamate in the compositions is large as a percentage of the composition.

- The preferred ratio of hydroxamate to total detersive surfactant system (surfactant) for optimum particulate red clay soil removal lies in the range 1:4 to 1: 8000. More preferred is 1:7 to 1:40. An even more preferred range of ratios being 1:10 to 1:30 parts by weight. The amount of alkyl hydroxamate c) is preferably at least 0.1 wt%.

- The invention further comprises a method of washing polyester fabrics comprising the steps of combining 15 to 25 ml of the composition according to the invention with water to form a wash liquor having a non-soap surfactant concentration of less than 0.5 g/L and washing the polyester with the wash liquor.

- The invention further comprises the use of a composition according to the invention in a process to remove red clay from polyester.

- To form the wash liquor for use in the method according to the invention a concentrated laundry liquid with lower than expected levels of surfactant is used as described in

WO2009/153184 . Thus, in one embodiment a low volume, less than 25 ml and preferably around 20 ml of the concentrated liquid is dosed to a wash load and diluted with water to form the wash liquor for use in the process. Although the exact dilution will vary from load to load and from one washing machine to another it is expected suitable compositions for use in the process according to the invention may comprise the ingredients described below at the levels detailed below. - The compositions for use in the method of the invention comprise detersive surfactant. The non-soap detersive surfactant makes up at least 10 wt% of the liquid composition, preferably it makes up from 12 to 60 wt%. The compositions for use according to the invention most preferably have total active detersive surfactant levels of at least 15 wt%.

- In the method the compositions are used in small doses that require them to be diluted in at least 500 times their own volume of water to form a main-wash liquor comprising at most 0.5 g/l surfactant. They may be concentrated compositions designed for front loading automatic washing machines, hand washing or top loading automatic washing machines. In hand washing less water may be used and in top loading automatic washing machines a higher amount of water would normally be used than for a front loading automatic machine. The dose of detergent liquid is adjusted accordingly to give similar wash liquor concentrations.

- The compositions are aqueous. The amount of water is a least 5 wt%, preferably at least 25 wt%.

- Whenever either the term 'hydroxamic acid' or `hydroxamate' is used, this encompasses both hydroxamic acid and the corresponding hydroxamate (salt of hydroxamic acid), unless indicated otherwise.

- Hydroxamic acids are a class of chemical compounds in which a hydroxylamine is inserted into a carboxylic acid. The general structure of a hydroxamic acid is the following:

-

- L+ is a monovalent cation for example the alkali metals (e.g. potassium, sodium), or ammonium or a substituted ammonium.

-

- a straight or branched C4-C20 alkyl, or

- a straight or branched substituted C4-C20 alkyl, or

- a straight or branched C4-C20 alkenyl, or

- a straight or branched substituted C4-C20 alkenyl, or

- an alkyl ether group CH3 (CH2)n (EO)m wherein n is from 2 to 20 and m is from 1 to 12, or

- a substituted alkyl ether group CH3 (CH2)n (EO)m wherein n is from 2 to 20 and m is from 1 to 12, and

- the types of substitution include one or more of NH2, OH, S , -O-, COOH, and

- and R2 is selected from hydrogen and a moiety that forms part of a cyclic structure with a branched R1 group.

- References to a number of carbon atoms include mixed chain length materials provided that some of the hydroxamate material falls within the ranges specified and the ratios and amounts are determined by excluding any material falling outside of the specified range.

- The preferred hydroxamates are those where R2 is Hydrogen and R1 is C8 to C14 alkyl, preferably normal alkyl, most preferably saturated.

- The hydroxamate containing compositions according to the invention are particularly suitable for use on particulate stains for example soils and clays, especially red clay, and also grass.

- The general structure of a hydroxamic acid in the context of the present invention has been indicated in formula 3, and R1, is as defined above. When R1 is an alkyl ether group CH3 (CH2)n (EO)m wherein n is from 2 to 20 and m is from 1 to 12 then the alkyl moiety terminates this side group. Preferably, R1 is chosen from the group consisting of C4, C5, C6, C7, C8, C9, C10, C11, C12 and C14 normal alkyl group, most preferably R1 is at least a C8-14 normal alkyl group. When the C8 material is used this is called octyl hydroxamic acid. The potassium salt is particularly useful.

-

- Such hydroxamic acids are commercially available.

- The hydroxamate is thought to act by binding to metal ions that are present in the soil on the fabric. This binding action, which is, in effect, the known sequestrant property of the hydroxamate is not, in itself, of any use to remove the soil from the fabric. The key is the "tail" of the hydroxamate i.e. the group R1 minus any branching that folds back onto the amate nitrogen via group R2. The tail is selected to have an affinity for the surfactant system. This means that the soil removal ability of an already optimised surfactant system is further enhanced by the use of the hydroxamate as it, in effect, labels the difficult to remove particulate material (clay) as "soil" for removal by the surfactant system acting on the hydroxamate molecules now fixed to the particulates via their binding to the metal ions embedded in the clay type particulates. The non-soap detersive surfactants will adhere to the hydroxamate, leading overall to more surfactants interacting with the fabric, leading to better soil release. Therewith the hydroxamic acids act as a linker molecule facilitating the removal and suspension of the particulate soil from the fabric into a wash liquor and thus boosting the primary detergency.

- The hydroxamates have a higher affinity for transition metals, like iron, than for alkaline earth metals, for example calcium and magnesium, therefore the hydroxamic acid primarily acts to improve the removal of soil on fabric, especially particulate soils, and not additionally as a builder for calcium and magnesium.

- A preferred hydroxamate is the 80% solids coco hydroxamic acid available under the trade name RK853 from Axis House. The corresponding Potassium salt is available from Axis House under the trade name RK852. Axis house also supply the coco hydroxamic acid as a 50% solids material under the trade name RK858. The 50% coco hydroxamate potassium salt is available as RK857. Another preferred material is RK842, an Alkyl hydroxamic acid made from Palm Kernel Oil, from Axis House. The hydroxamates do not generate any residues.

- Surfactants assist in removing soil from the textile materials and also assist in maintaining removed soil in solution or suspension in the wash liquor. Anionic or blends of anionic and nonionic surfactants are a preferred feature of the present invention. The amount of anionic surfactant is preferably at least 5 wt%. Preferably, anionic surfactants form the majority of the non-soap surfactant (a).

- Preferred alkyl sulphonates are alkylbenzene sulphonates, particularly linear alkylbenzene sulphonates (LAS) having an alkyl chain length of C8-C15. The counter ion for anionic surfactants is generally an alkali metal, typically sodium, although other counter-ions for example MEA, TEA or ammonium can be used. Suitable anionic surfactant materials are available in the marketplace as the 'Genapol'™ range from Clariant. Preferred linear alkyl benzene sulphonate surfactants are Detal LAS with an alkyl chain length of from 8 to 15, more preferably 12 to 14. LAS can be at least partially replaced by methyl ester sulphonate (MES), or, less preferably, partially replaced by up to 20 wt % Primary alcohol sulphate (PAS).

- It is desirable that the composition further comprises an alkyl polyethoxylate sulphate anionic surfactant of the formula (IV):

RO(C2H4O)xSO3 -M+ (Formula IV)

where R is an alkyl chain having from 10 to 22 carbon atoms, saturated or unsaturated, M is a cation which makes the compound water-soluble, especially an alkali metal, ammonium or substituted ammonium cation, and x averages from 1 to 15. - Preferably R is an alkyl chain having from 12 to 16 carbon atoms, M is Sodium and x averages from 1 to 3, preferably x is 3; This is the anionic surfactant sodium lauryl ether sulphate (SLES). It is the sodium salt of lauryl ether sulphonic acid in which the predominantly C12 lauryl alkyl group has been ethoxylated with an average of 3 moles of ethylene oxide per mole. Preferably, the anionic surfactant system comprises SLES, together with optional soap and mixtures thereof. Soap is not included in the calculation of amount of non-soap surfactant. A LAS/SLES surfactant blend has a superior foam profile to a LAS Nonionic surfactant blend and is therefore preferred for hand washing formulations requiring high levels of foam. SLES may be used at levels of up to 30%. Preferably the composition comprises at least 2 wt% SLES.

- Although less preferred, some alkyl sulphate surfactant (PAS) may be used, especially the non-ethoxylated C12-15 primary and secondary alkyl sulphates. A particularly preferred material, commercially available from Cognis, is Sulphopon 1214G.

- PAS is preferably used in admixture with LAS and most preferably in admixture with LAS and SLES. A preferred SLES/AO/LAS/PAS liquid has a detersive surfactant system comprising 60 parts SLES, 20 parts amine oxide, 10 parts LAS and 10 parts PAS.

- Nonionic surfactants include primary and secondary alcohol ethoxylates, especially C8-C20 aliphatic alcohol ethoxylated with an average of from 1 to 20 moles of ethylene oxide per mole of alcohol, and more especially the C10-C15 primary and secondary aliphatic alcohols ethoxylated with an average of from 1 to 10 moles of ethylene oxide per mole of alcohol. Non-ethoxylated nonionic surfactants include alkyl polyglycosides, glycerol monoethers and polyhydroxy amides (glucamide). Mixtures of nonionic surfactant may be used. When included therein the composition contains from 0.2 wt% to 30 wt%, preferably 1 wt% to 20 wt%, more preferably 5 to 15 wt% of a non-ionic surfactant, for example alcohol ethoxylate, nonylphenol ethoxylate, alkylpolyglycoside, alkyldimethylamineoxide, ethoxylated fatty acid monoethanolamide, fatty acid monoethanolamide, polyhydroxy alkyl fatty acid amide, or N-acyl N-alkyl derivatives of glucosamine ("glucamides").

- Nonionic surfactants that may be used include the primary and secondary alcohol ethoxylates, especially the C8-C20 aliphatic alcohols ethoxylated with an average of from 1 to 35 moles of ethylene oxide per mole of alcohol, and more especially the C10-C15 primary and secondary aliphatic alcohols ethoxylated with an average of from 1 to 10 moles of ethylene oxide per mole of alcohol.

- The composition may comprise up to 10 wt% of an amine oxide (AO) of the formula (V):

R1 N(O)(CH2 R2)2 (Formula V)

- In which R1 is a long chain moiety and each CH2R2 is a short chain moiety. R2 is preferably selected from hydrogen, methyl and -CH2OH. In general R1 is a primary or branched hydrocarbyl moiety which can be saturated or unsaturated, preferably, R1 is a primary alkyl moiety. R1 is a hydrocarbyl moiety having chain length of from about 8 to about 18.

- In preferred amine oxides R1 is C8-C18 alkyl, and R2 is H. These amine oxides are illustrated by C12-14 alkyldimethyl amine oxide, hexadecyl dimethylamine oxide, octadecylamine oxide.

- A preferred amine oxide material is Lauryl dimethylamine oxide, also known as dodecyldimethylamine oxide or DDAO. Such an amine oxide material is commercially available from Huntsman under the trade name Empigen® OB.

- Amine oxides suitable for use herein are also available from Akzo Chemie and Ethyl Corp. See McCutcheon's compilation and Kirk-Othmer review article for alternate amine oxide manufacturers.

- Whereas in certain of the preferred embodiments R2 is H, it is possible for R2 to be a moiety larger than H. Specifically, R2 may be CH2OH, for example: hexadecylbis(2-hydroxyethyl)amine oxide, tallowbis(2-hydroxyethyl)amine oxide, stearylbis(2-hydroxyethyl)amine oxide and oleylbis(2- hydroxyethyl)amine oxide.

- Preferred amine oxides have the formula (VI):

O- - N+(Me)2R1 (Formula VI)

where R1 is C12-16 alkyl, preferably C12-14 alkyl; Me is a methyl group. A preferred surfactant system for use in high suds (foam) applications comprises SLES and AO. - Nonionic-free systems with up to 95 wt% of the surfactant system LAS can be made provided that some zwitterionic surfactant, for example sulphobetaine, is present. A preferred zwitterionic material is a betaine available from Huntsman under the name Empigen® BB. Betaines, improve particulate soil detergency in the compositions of the invention.

- Cationic surfactants are preferably substantially absent.

- The compositions may comprise soap which can act as a builder and/or as an antifoam. The amount of non-soap anionic surfactant must exceed the amount of soap. The amount of soap must be less than or equal to 15 wt% of the total liquid composition, preferably it is less than 3 wt%. The fatty acid used preferably contains from about 16 to about 22 carbon atoms, preferably in a straight chain configuration. The anionic contribution from soap may be from 0 to 30 wt% of the total anionic. Use of more than 10 wt% soap is not preferred. Saturated fatty acids are preferred.

- The composition comprises an ethoxylated polyethyleneimine polymer (EPEI) for cleaning. Preferably the EPEI is nonionic. That means it does not have any quaternary nitrogens, or nitrogen oxides or any ionic species other than possible pH effected protonation of nitrogens.

- Polyethylene imines (PEIs, especially modified PEIs) are materials composed of ethylene imine units -CH2CH2NH- and, where branched, the hydrogen on the nitrogen is replaced by another chain of ethylene imine units. These polyethyleneimines can be prepared, for example, by polymerizing ethyleneimine in the presence of a catalyst for example carbon dioxide, sodium bisulphite, sulphuric acid, hydrogen peroxide, hydrochloric acid, acetic acid, and the like. Specific methods for preparing these polyamine backbones are disclosed in

U.S. Pat. No. 2,182,306, Ulrich et al., issued Dec. 5, 1939 ;U.S. Pat. No. 3,033,746, Mayle et al., issued May 8, 1962 ;U.S. Pat. No. 2,208,095, Esselmann et al., issued Jul. 16, 1940 ;U.S. Pat. No. 2,806,839, Crowther, issued Sep. 17, 1957 ; andU.S. Pat. No. 2,553,696, Wilson, issued May 21, 1951 . - Preferably, the EPEI comprises a polyethyleneimine backbone wherein the modification of the polyethyleneimine backbone is intended to leave the polymer without quaternisation. Such nonionic EPEI may be represented as PEI(X)YEO where X represents the molecular weight of the unmodified PEI and Y represents the average moles of ethoxylation per nitrogen atom in the polyethyleneimine backbone. This is the same as the average per substitution site if the number of nitrogens with no hydrogen is balanced by the number with two hydrogens in the unethoxylated PEI. The ethoxylation number Y may range from 7 to 40 ethoxy moieties per modification, preferably it is in the range of 16 to 26, most preferably 18 to 22. X is selected to be from about 300 to about 10000 weight average molecular weight and is preferably about 600.

- The ethoxylated polyethyleneimine polymer (EPEI) is present in the composition at a level of between 2 and 20 wt%, preferably at a level of less than 9.5 wt%, more preferably from 3 to 9 wt% and with a ratio of non-soap surfactant to EPEI of from 2:1 to 7:1, preferably from 3:1 to 6:1, even about 5:1.

- The composition further comprises at least 0.5 wt% of a polymeric soil release agent for oily soil removal from polyester.

- Soil release polymers improve the main wash performance of the compositions when used in the low in wash surfactant process of the present invention.

- One preferred class of polymer is the fabric-substantive polymers comprising at least one of (i) saccharide or (ii) dicarboxylic acid and polyol monomer units. Typically these polymers have soil release properties and, while they can have a primary detergency effect, they generally assist in subsequent cleaning. Preferably these polymers are present at a level of at least 2% wt, more preferably at least 3 wt% of the composition.

- The soil release polymer will preferably comprise up to 10 wt%, of the detergent composition, more preferably up to 9 wt%, preferably they are used at greater than 2 wt% and more preferably greater than 3 wt% in the composition. Generally the soil release polymers for polyester will comprise polymers of aromatic dicarboxylic acids and alkylene glycols (including polymers containing polyalkylene glycols).

- The polymeric soil release agents useful herein include those soil release agents having:

- (a) one or more nonionic hydrophilic components consisting essentially of:

- (i) polyoxyethylene segments with a degree of polymerization of at least 2, or

- (ii) oxypropylene or polyoxypropylene segments with a degree of polymerization of from 2 to 10, wherein said hydrophilic segment does not encompass any oxypropylene unit unless it is bonded to adjacent moieties at each end by ether linkages, or

- (iii) a mixture of oxyalkylene units comprising oxyethylene and from 1 to about 30 oxypropylene units wherein said mixture contains a sufficient amount of oxyethylene units such that the hydrophilic component has hydrophilicity great enough to increase the hydrophilicity of conventional polyester synthetic fibre surfaces upon deposit of the soil release agent on such surface, said hydrophilic segments preferably comprising at least about 25% oxyethylene units and more preferably, especially for such components having about 20 to 30 oxypropylene units, at least about 50% oxyethylene units; or

- (b) one or more hydrophobic components comprising:

- (i) C3 oxyalkylene terephthalate segments, wherein, if said hydrophobic components also comprise oxyethylene terephthalate, the ratio of oxyethylene terephthalate: C3 oxyalkylene terephthalate units is about 2:1 or lower,

- (ii) C4 -C6 alkylene or oxy C4 -C6 alkylene segments, or mixtures therein,

- (iii) poly (vinyl ester) segments, preferably poly(vinyl acetate), having a degree of polymerization of at least 2, or

- (iv) C1 -C4 alkyl ether or C4 hydroxyalkyl ether substituents, or mixtures therein, wherein said substituents are present in the form of C1 -C4 alkyl ether or C4 hydroxyalkyl ether cellulose derivatives, or mixtures therein, and such cellulose derivatives are amphiphilic, whereby they have a sufficient level of C1 -C4 alkyl ether and/or C4 hydroxyalkyl ether units to deposit upon conventional polyester synthetic fibre surfaces and retain a sufficient level of hydroxyls, once adhered to such conventional synthetic fibre surface, to increase fibre surface hydrophilicity, or a combination of (a) and (b).

- Typically, the polyoxyethylene segments of (a)(i) will have a degree of polymerization of from about 200, although higher levels can be used, preferably from 3 to about 150, more preferably from 6 to about 100.

- Soil release agents characterized by poly(vinyl ester) hydrophobic segments include graft copolymers of poly(vinyl ester), e.g., C1 -C6 vinyl esters, preferably poly(vinyl acetate) grafted onto polyalkylene oxide backbones, for example polyethylene oxide backbones. See

European Patent Application 0 219 048, published Apr. 22, 1987 by Kud, et al. Commercially available soil release agents of this kind include the SOKALAN type of material, e.g., SOKALAN HP22, available from BASF (West Germany). - One type of preferred soil release agent is a copolymer having random blocks of ethylene terephthalate and polyethylene oxide (PEO) terephthalate. The molecular weight of this polymeric soil release agent is in the range of from about 25,000 to about 55,000. See

U.S. Pat. No. 3,959,230 to Hays, issued May 25, 1976 andU.S. Pat. No. 3,893,929 to Basadur issued Jul. 8, 1975 . - Another preferred polymeric soil release agent is a polyester with repeat units of ethylene terephthalate units contains 10 to 15 wt% of ethylene terephthalate units together with 90 to 80 wt% weight of polyoxyethylene terephthalate units, derived from a polyoxyethylene glycol of average molecular weight 300 to 5000. Examples of this polymer include ZELCON 5126 (from DuPont) and MILEASE T (from ICI). See also