US20040142041A1 - Triggerable delivery system for pharmaceutical and nutritional compounds and methods of utilizing same - Google Patents

Triggerable delivery system for pharmaceutical and nutritional compounds and methods of utilizing same Download PDFInfo

- Publication number

- US20040142041A1 US20040142041A1 US10/731,256 US73125603A US2004142041A1 US 20040142041 A1 US20040142041 A1 US 20040142041A1 US 73125603 A US73125603 A US 73125603A US 2004142041 A1 US2004142041 A1 US 2004142041A1

- Authority

- US

- United States

- Prior art keywords

- particles

- alumina

- particle

- functional

- compound

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

- 150000001875 compounds Chemical class 0.000 title claims abstract description 95

- 238000000034 method Methods 0.000 title claims description 41

- 235000016709 nutrition Nutrition 0.000 title claims description 18

- 239000002245 particle Substances 0.000 claims abstract description 173

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 claims abstract description 77

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims abstract description 51

- 239000003795 chemical substances by application Substances 0.000 claims description 32

- 239000000126 substance Substances 0.000 claims description 27

- 239000000758 substrate Substances 0.000 claims description 20

- 230000036541 health Effects 0.000 claims description 18

- 230000008859 change Effects 0.000 claims description 15

- 230000007613 environmental effect Effects 0.000 claims description 11

- 238000011282 treatment Methods 0.000 claims description 11

- 239000002253 acid Substances 0.000 claims description 9

- 238000012377 drug delivery Methods 0.000 claims description 9

- 210000000416 exudates and transudate Anatomy 0.000 claims description 8

- 239000007788 liquid Substances 0.000 claims description 7

- 125000000217 alkyl group Chemical group 0.000 claims description 6

- 125000003118 aryl group Chemical group 0.000 claims description 6

- 229910052739 hydrogen Inorganic materials 0.000 claims description 6

- 239000001257 hydrogen Substances 0.000 claims description 6

- 238000013271 transdermal drug delivery Methods 0.000 claims description 4

- 125000004435 hydrogen atom Chemical class [H]* 0.000 claims 4

- 239000003814 drug Substances 0.000 abstract description 16

- 239000008204 material by function Substances 0.000 abstract description 10

- 239000003205 fragrance Substances 0.000 abstract description 9

- 239000000203 mixture Substances 0.000 abstract description 8

- 239000004599 antimicrobial Substances 0.000 abstract description 5

- 239000002676 xenobiotic agent Substances 0.000 abstract description 5

- 239000003443 antiviral agent Substances 0.000 abstract description 4

- 239000000463 material Substances 0.000 description 50

- 239000002105 nanoparticle Substances 0.000 description 27

- 239000010410 layer Substances 0.000 description 22

- 239000000377 silicon dioxide Substances 0.000 description 20

- JYGXADMDTFJGBT-VWUMJDOOSA-N hydrocortisone Chemical compound O=C1CC[C@]2(C)[C@H]3[C@@H](O)C[C@](C)([C@@](CC4)(O)C(=O)CO)[C@@H]4[C@@H]3CCC2=C1 JYGXADMDTFJGBT-VWUMJDOOSA-N 0.000 description 18

- 229930101283 tetracycline Natural products 0.000 description 18

- 239000004098 Tetracycline Substances 0.000 description 17

- 229960002180 tetracycline Drugs 0.000 description 17

- 235000019364 tetracycline Nutrition 0.000 description 17

- 150000003522 tetracyclines Chemical class 0.000 description 17

- 229920000642 polymer Polymers 0.000 description 16

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 15

- CIWBSHSKHKDKBQ-JLAZNSOCSA-N Ascorbic acid Chemical compound OC[C@H](O)[C@H]1OC(=O)C(O)=C1O CIWBSHSKHKDKBQ-JLAZNSOCSA-N 0.000 description 14

- 239000000725 suspension Substances 0.000 description 12

- 239000000243 solution Substances 0.000 description 11

- 230000003115 biocidal effect Effects 0.000 description 10

- 239000008177 pharmaceutical agent Substances 0.000 description 10

- 239000004480 active ingredient Substances 0.000 description 9

- 229960000890 hydrocortisone Drugs 0.000 description 9

- SMQUZDBALVYZAC-UHFFFAOYSA-N salicylaldehyde Chemical compound OC1=CC=CC=C1C=O SMQUZDBALVYZAC-UHFFFAOYSA-N 0.000 description 9

- 238000010521 absorption reaction Methods 0.000 description 8

- 238000002371 ultraviolet--visible spectrum Methods 0.000 description 8

- 230000002378 acidificating effect Effects 0.000 description 7

- 239000003242 anti bacterial agent Substances 0.000 description 7

- -1 carboxy-hydroxy moiety Chemical group 0.000 description 7

- 239000011248 coating agent Substances 0.000 description 7

- 238000000576 coating method Methods 0.000 description 7

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 6

- 235000010323 ascorbic acid Nutrition 0.000 description 6

- 239000011668 ascorbic acid Substances 0.000 description 6

- 229960005070 ascorbic acid Drugs 0.000 description 6

- 230000008901 benefit Effects 0.000 description 6

- 238000003756 stirring Methods 0.000 description 6

- 230000037317 transdermal delivery Effects 0.000 description 6

- 239000012790 adhesive layer Substances 0.000 description 5

- 229940079593 drug Drugs 0.000 description 5

- 230000006870 function Effects 0.000 description 5

- 208000015181 infectious disease Diseases 0.000 description 5

- COLNVLDHVKWLRT-UHFFFAOYSA-N phenylalanine Natural products OC(=O)C(N)CC1=CC=CC=C1 COLNVLDHVKWLRT-UHFFFAOYSA-N 0.000 description 5

- 0 */N=C(C)/C=C(/C)O.C.C.C.C.C.C.C.C.C.C/C=C\C=O.C=C(O)/C=C(/C)O.C=C(O)C=C(C)C.CC(=O)C(C)N.CC(=O)CC(C)=O.CC(=O)CC(C)O.O=C/C=C\O.O=CCO Chemical compound */N=C(C)/C=C(/C)O.C.C.C.C.C.C.C.C.C.C/C=C\C=O.C=C(O)/C=C(/C)O.C=C(O)C=C(C)C.CC(=O)C(C)N.CC(=O)CC(C)=O.CC(=O)CC(C)O.O=C/C=C\O.O=CCO 0.000 description 4

- 206010017533 Fungal infection Diseases 0.000 description 4

- COLNVLDHVKWLRT-QMMMGPOBSA-N L-phenylalanine Chemical compound OC(=O)[C@@H](N)CC1=CC=CC=C1 COLNVLDHVKWLRT-QMMMGPOBSA-N 0.000 description 4

- 239000000499 gel Substances 0.000 description 4

- 230000008569 process Effects 0.000 description 4

- 230000005855 radiation Effects 0.000 description 4

- ORIHZIZPTZTNCU-YVMONPNESA-N salicylaldoxime Chemical compound O\N=C/C1=CC=CC=C1O ORIHZIZPTZTNCU-YVMONPNESA-N 0.000 description 4

- 230000001960 triggered effect Effects 0.000 description 4

- VEXZGXHMUGYJMC-UHFFFAOYSA-N Hydrochloric acid Chemical compound Cl VEXZGXHMUGYJMC-UHFFFAOYSA-N 0.000 description 3

- 239000007864 aqueous solution Substances 0.000 description 3

- NLYAJNPCOHFWQQ-UHFFFAOYSA-N kaolin Chemical compound O.O.O=[Al]O[Si](=O)O[Si](=O)O[Al]=O NLYAJNPCOHFWQQ-UHFFFAOYSA-N 0.000 description 3

- 230000007246 mechanism Effects 0.000 description 3

- 238000001179 sorption measurement Methods 0.000 description 3

- 210000002784 stomach Anatomy 0.000 description 3

- 229940124597 therapeutic agent Drugs 0.000 description 3

- NWXMGUDVXFXRIG-WESIUVDSSA-N (4s,4as,5as,6s,12ar)-4-(dimethylamino)-1,6,10,11,12a-pentahydroxy-6-methyl-3,12-dioxo-4,4a,5,5a-tetrahydrotetracene-2-carboxamide Chemical class C1=CC=C2[C@](O)(C)[C@H]3C[C@H]4[C@H](N(C)C)C(=O)C(C(N)=O)=C(O)[C@@]4(O)C(=O)C3=C(O)C2=C1O NWXMGUDVXFXRIG-WESIUVDSSA-N 0.000 description 2

- STQGQHZAVUOBTE-UHFFFAOYSA-N 7-Cyan-hept-2t-en-4,6-diinsaeure Natural products C1=2C(O)=C3C(=O)C=4C(OC)=CC=CC=4C(=O)C3=C(O)C=2CC(O)(C(C)=O)CC1OC1CC(N)C(O)C(C)O1 STQGQHZAVUOBTE-UHFFFAOYSA-N 0.000 description 2

- FXNFHKRTJBSTCS-UHFFFAOYSA-N Baicalein Natural products C=1C(=O)C=2C(O)=C(O)C(O)=CC=2OC=1C1=CC=CC=C1 FXNFHKRTJBSTCS-UHFFFAOYSA-N 0.000 description 2

- 230000002745 absorbent Effects 0.000 description 2

- 239000002250 absorbent Substances 0.000 description 2

- 150000001299 aldehydes Chemical class 0.000 description 2

- 235000010357 aspartame Nutrition 0.000 description 2

- UDFLTIRFTXWNJO-UHFFFAOYSA-N baicalein Chemical compound O1C2=CC(=O)C(O)=C(O)C2=C(O)C=C1C1=CC=CC=C1 UDFLTIRFTXWNJO-UHFFFAOYSA-N 0.000 description 2

- 229940015301 baicalein Drugs 0.000 description 2

- 239000011230 binding agent Substances 0.000 description 2

- 238000010276 construction Methods 0.000 description 2

- 239000011162 core material Substances 0.000 description 2

- 239000012530 fluid Substances 0.000 description 2

- 229940088597 hormone Drugs 0.000 description 2

- 239000005556 hormone Substances 0.000 description 2

- 150000002431 hydrogen Chemical class 0.000 description 2

- 238000005259 measurement Methods 0.000 description 2

- 239000002417 nutraceutical Substances 0.000 description 2

- 239000010453 quartz Substances 0.000 description 2

- 210000000813 small intestine Anatomy 0.000 description 2

- 239000012258 stirred mixture Substances 0.000 description 2

- 229920001059 synthetic polymer Polymers 0.000 description 2

- 230000000699 topical effect Effects 0.000 description 2

- 210000001215 vagina Anatomy 0.000 description 2

- 238000000733 zeta-potential measurement Methods 0.000 description 2

- WLEKZZMZTPAGDD-ZSESPEEFSA-N (2s,3s,4s,5r,6s)-6-(5,6-dihydroxy-4-oxo-2-phenylchromen-7-yl)oxy-3,4,5-trihydroxyoxane-2-carboxylic acid;hydrate Chemical compound O.O1[C@H](C(O)=O)[C@@H](O)[C@H](O)[C@@H](O)[C@@H]1OC(C(=C1O)O)=CC2=C1C(=O)C=C(C=1C=CC=CC=1)O2 WLEKZZMZTPAGDD-ZSESPEEFSA-N 0.000 description 1

- 108010011485 Aspartame Proteins 0.000 description 1

- BVKZGUZCCUSVTD-UHFFFAOYSA-M Bicarbonate Chemical class OC([O-])=O BVKZGUZCCUSVTD-UHFFFAOYSA-M 0.000 description 1

- LHZYYYOMMZFCQW-UHFFFAOYSA-N CC1=CC2C=C3CC4OCOC5=C4/C(=C(/O)C4=C5C(=O)C5=C(C4)C(C(=O)O)CCC5O)C3=C(O)C2C(=O)N1N.NC(=O)C1=C(O)C=CC=C1.O=C(O)C1=C(OC(=O)C2=C(O)C=CC=C2)C=CC=C1.[H]N(C(=O)C1=C(O)C=CC=C1)C1=CC=CC=C1.[H]N(C(C)=O)C(=O)C1=C(O)C=CC=C1 Chemical compound CC1=CC2C=C3CC4OCOC5=C4/C(=C(/O)C4=C5C(=O)C5=C(C4)C(C(=O)O)CCC5O)C3=C(O)C2C(=O)N1N.NC(=O)C1=C(O)C=CC=C1.O=C(O)C1=C(OC(=O)C2=C(O)C=CC=C2)C=CC=C1.[H]N(C(=O)C1=C(O)C=CC=C1)C1=CC=CC=C1.[H]N(C(C)=O)C(=O)C1=C(O)C=CC=C1 LHZYYYOMMZFCQW-UHFFFAOYSA-N 0.000 description 1

- KNBSPPYPEJKVFU-XDJYKUFASA-N CN(C)C1C(O)=C(C(N)=O)C(=O)[C@@]2(O)C(O)=C3C(=O)C4=C(O)C=CC=C4[C@@](C)(O)C3CC12.[H][C@@]12CCC3=CC(=O)CC[C@]3(C)[C@@]1([H])[C@@H](O)C[C@@]1(C)[C@@]2([H])CC[C@]1(O)C(=O)CO Chemical compound CN(C)C1C(O)=C(C(N)=O)C(=O)[C@@]2(O)C(O)=C3C(=O)C4=C(O)C=CC=C4[C@@](C)(O)C3CC12.[H][C@@]12CCC3=CC(=O)CC[C@]3(C)[C@@]1([H])[C@@H](O)C[C@@]1(C)[C@@]2([H])CC[C@]1(O)C(=O)CO KNBSPPYPEJKVFU-XDJYKUFASA-N 0.000 description 1

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical group [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- ZZZCUOFIHGPKAK-UHFFFAOYSA-N D-erythro-ascorbic acid Natural products OCC1OC(=O)C(O)=C1O ZZZCUOFIHGPKAK-UHFFFAOYSA-N 0.000 description 1

- 208000034423 Delivery Diseases 0.000 description 1

- 208000028018 Lymphocytic leukaemia Diseases 0.000 description 1

- 241001465754 Metazoa Species 0.000 description 1

- 206010028980 Neoplasm Diseases 0.000 description 1

- GPDJGLOROGNHJD-UHFFFAOYSA-N O=C1CC(C2=CC=CC=C2)OC2=C1C(O)=C(O)C(O)=C2 Chemical compound O=C1CC(C2=CC=CC=C2)OC2=C1C(O)=C(O)C(O)=C2 GPDJGLOROGNHJD-UHFFFAOYSA-N 0.000 description 1

- UVNUGBQJLDGZKE-UHFFFAOYSA-N O=C1CC(C2=CC=CC=C2)OC2=C1C(O)=C(O)C(OC1OC(C(=O)O)C(O)C(O)C1O)=C2 Chemical compound O=C1CC(C2=CC=CC=C2)OC2=C1C(O)=C(O)C(OC1OC(C(=O)O)C(O)C(O)C1O)=C2 UVNUGBQJLDGZKE-UHFFFAOYSA-N 0.000 description 1

- CUOKHACJLGPRHD-UHFFFAOYSA-N O=C1OC(CO)C(O)C1O Chemical compound O=C1OC(CO)C(O)C1O CUOKHACJLGPRHD-UHFFFAOYSA-N 0.000 description 1

- 239000004698 Polyethylene Substances 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 206010070834 Sensitisation Diseases 0.000 description 1

- 241000187747 Streptomyces Species 0.000 description 1

- 206010046914 Vaginal infection Diseases 0.000 description 1

- 229930003268 Vitamin C Natural products 0.000 description 1

- 238000002835 absorbance Methods 0.000 description 1

- 238000000862 absorption spectrum Methods 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 210000004404 adrenal cortex Anatomy 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 230000000172 allergic effect Effects 0.000 description 1

- 150000001408 amides Chemical group 0.000 description 1

- 150000001413 amino acids Chemical class 0.000 description 1

- 125000003277 amino group Chemical group 0.000 description 1

- 230000003110 anti-inflammatory effect Effects 0.000 description 1

- 230000000118 anti-neoplastic effect Effects 0.000 description 1

- 230000001028 anti-proliverative effect Effects 0.000 description 1

- 229940088710 antibiotic agent Drugs 0.000 description 1

- 239000007900 aqueous suspension Substances 0.000 description 1

- IAOZJIPTCAWIRG-QWRGUYRKSA-N aspartame Chemical compound OC(=O)C[C@H](N)C(=O)N[C@H](C(=O)OC)CC1=CC=CC=C1 IAOZJIPTCAWIRG-QWRGUYRKSA-N 0.000 description 1

- 239000000605 aspartame Substances 0.000 description 1

- 229960003438 aspartame Drugs 0.000 description 1

- 208000010668 atopic eczema Diseases 0.000 description 1

- 239000013060 biological fluid Substances 0.000 description 1

- 210000001124 body fluid Anatomy 0.000 description 1

- 239000010839 body fluid Substances 0.000 description 1

- 239000006172 buffering agent Substances 0.000 description 1

- 235000019846 buffering salt Nutrition 0.000 description 1

- 201000011510 cancer Diseases 0.000 description 1

- 239000002775 capsule Substances 0.000 description 1

- 150000004649 carbonic acid derivatives Chemical class 0.000 description 1

- 239000008139 complexing agent Substances 0.000 description 1

- 238000003851 corona treatment Methods 0.000 description 1

- 239000013078 crystal Substances 0.000 description 1

- STQGQHZAVUOBTE-VGBVRHCVSA-N daunorubicin Chemical compound O([C@H]1C[C@@](O)(CC=2C(O)=C3C(=O)C=4C=CC=C(C=4C(=O)C3=C(O)C=21)OC)C(C)=O)[C@H]1C[C@H](N)[C@H](O)[C@H](C)O1 STQGQHZAVUOBTE-VGBVRHCVSA-N 0.000 description 1

- 229960000975 daunorubicin Drugs 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000002708 enhancing effect Effects 0.000 description 1

- 230000037406 food intake Effects 0.000 description 1

- 235000003599 food sweetener Nutrition 0.000 description 1

- 238000009472 formulation Methods 0.000 description 1

- 239000003862 glucocorticoid Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 229910001385 heavy metal Inorganic materials 0.000 description 1

- 239000000416 hydrocolloid Substances 0.000 description 1

- 239000000017 hydrogel Substances 0.000 description 1

- 230000003116 impacting effect Effects 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 239000004615 ingredient Substances 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 229910052809 inorganic oxide Inorganic materials 0.000 description 1

- 210000000936 intestine Anatomy 0.000 description 1

- 239000003446 ligand Substances 0.000 description 1

- 208000003747 lymphoid leukemia Diseases 0.000 description 1

- 238000002483 medication Methods 0.000 description 1

- 239000004750 melt-blown nonwoven Substances 0.000 description 1

- 230000037353 metabolic pathway Effects 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000000813 microbial effect Effects 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- SYSQUGFVNFXIIT-UHFFFAOYSA-N n-[4-(1,3-benzoxazol-2-yl)phenyl]-4-nitrobenzenesulfonamide Chemical class C1=CC([N+](=O)[O-])=CC=C1S(=O)(=O)NC1=CC=C(C=2OC3=CC=CC=C3N=2)C=C1 SYSQUGFVNFXIIT-UHFFFAOYSA-N 0.000 description 1

- 235000021436 nutraceutical agent Nutrition 0.000 description 1

- 235000015097 nutrients Nutrition 0.000 description 1

- 239000002304 perfume Substances 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 239000002861 polymer material Substances 0.000 description 1

- 229920000307 polymer substrate Polymers 0.000 description 1

- 229920000098 polyolefin Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 231100000683 possible toxicity Toxicity 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 238000002203 pretreatment Methods 0.000 description 1

- 150000003141 primary amines Chemical class 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 150000003335 secondary amines Chemical class 0.000 description 1

- 230000008313 sensitization Effects 0.000 description 1

- 239000003352 sequestering agent Substances 0.000 description 1

- 239000011343 solid material Substances 0.000 description 1

- 239000002344 surface layer Substances 0.000 description 1

- 238000006557 surface reaction Methods 0.000 description 1

- 239000003765 sweetening agent Substances 0.000 description 1

- 208000024891 symptom Diseases 0.000 description 1

- 150000003512 tertiary amines Chemical class 0.000 description 1

- 229920001169 thermoplastic Polymers 0.000 description 1

- 238000004448 titration Methods 0.000 description 1

- 238000000870 ultraviolet spectroscopy Methods 0.000 description 1

- 230000009677 vaginal delivery Effects 0.000 description 1

- 229930003231 vitamin Natural products 0.000 description 1

- 235000013343 vitamin Nutrition 0.000 description 1

- 239000011782 vitamin Substances 0.000 description 1

- 229940088594 vitamin Drugs 0.000 description 1

- 235000019154 vitamin C Nutrition 0.000 description 1

- 239000011718 vitamin C Substances 0.000 description 1

- 239000002351 wastewater Substances 0.000 description 1

- 238000009736 wetting Methods 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23L—FOODS, FOODSTUFFS, OR NON-ALCOHOLIC BEVERAGES, NOT COVERED BY SUBCLASSES A21D OR A23B-A23J; THEIR PREPARATION OR TREATMENT, e.g. COOKING, MODIFICATION OF NUTRITIVE QUALITIES, PHYSICAL TREATMENT; PRESERVATION OF FOODS OR FOODSTUFFS, IN GENERAL

- A23L27/00—Spices; Flavouring agents or condiments; Artificial sweetening agents; Table salts; Dietetic salt substitutes; Preparation or treatment thereof

- A23L27/30—Artificial sweetening agents

- A23L27/31—Artificial sweetening agents containing amino acids, nucleotides, peptides or derivatives

- A23L27/32—Artificial sweetening agents containing amino acids, nucleotides, peptides or derivatives containing dipeptides or derivatives

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23L—FOODS, FOODSTUFFS, OR NON-ALCOHOLIC BEVERAGES, NOT COVERED BY SUBCLASSES A21D OR A23B-A23J; THEIR PREPARATION OR TREATMENT, e.g. COOKING, MODIFICATION OF NUTRITIVE QUALITIES, PHYSICAL TREATMENT; PRESERVATION OF FOODS OR FOODSTUFFS, IN GENERAL

- A23L27/00—Spices; Flavouring agents or condiments; Artificial sweetening agents; Table salts; Dietetic salt substitutes; Preparation or treatment thereof

- A23L27/70—Fixation, conservation, or encapsulation of flavouring agents

- A23L27/77—Use of inorganic solid carriers, e.g. silica

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23P—SHAPING OR WORKING OF FOODSTUFFS, NOT FULLY COVERED BY A SINGLE OTHER SUBCLASS

- A23P10/00—Shaping or working of foodstuffs characterised by the products

- A23P10/30—Encapsulation of particles, e.g. foodstuff additives

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23P—SHAPING OR WORKING OF FOODSTUFFS, NOT FULLY COVERED BY A SINGLE OTHER SUBCLASS

- A23P20/00—Coating of foodstuffs; Coatings therefor; Making laminated, multi-layered, stuffed or hollow foodstuffs

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/185—Acids; Anhydrides, halides or salts thereof, e.g. sulfur acids, imidic, hydrazonic or hydroximic acids

- A61K31/19—Carboxylic acids, e.g. valproic acid

- A61K31/195—Carboxylic acids, e.g. valproic acid having an amino group

- A61K31/197—Carboxylic acids, e.g. valproic acid having an amino group the amino and the carboxyl groups being attached to the same acyclic carbon chain, e.g. gamma-aminobutyric acid [GABA], beta-alanine, epsilon-aminocaproic acid, pantothenic acid

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/33—Heterocyclic compounds

- A61K31/335—Heterocyclic compounds having oxygen as the only ring hetero atom, e.g. fungichromin

- A61K31/365—Lactones

- A61K31/375—Ascorbic acid, i.e. vitamin C; Salts thereof

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/56—Compounds containing cyclopenta[a]hydrophenanthrene ring systems; Derivatives thereof, e.g. steroids

- A61K31/57—Compounds containing cyclopenta[a]hydrophenanthrene ring systems; Derivatives thereof, e.g. steroids substituted in position 17 beta by a chain of two carbon atoms, e.g. pregnane or progesterone

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/65—Tetracyclines

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K47/00—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient

- A61K47/50—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates

- A61K47/69—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the conjugate being characterised by physical or galenical forms, e.g. emulsion, particle, inclusion complex, stent or kit

- A61K47/6921—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the conjugate being characterised by physical or galenical forms, e.g. emulsion, particle, inclusion complex, stent or kit the form being a particulate, a powder, an adsorbate, a bead or a sphere

- A61K47/6923—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the conjugate being characterised by physical or galenical forms, e.g. emulsion, particle, inclusion complex, stent or kit the form being a particulate, a powder, an adsorbate, a bead or a sphere the form being an inorganic particle, e.g. ceramic particles, silica particles, ferrite or synsorb

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23V—INDEXING SCHEME RELATING TO FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES AND LACTIC OR PROPIONIC ACID BACTERIA USED IN FOODSTUFFS OR FOOD PREPARATION

- A23V2002/00—Food compositions, function of food ingredients or processes for food or foodstuffs

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23V—INDEXING SCHEME RELATING TO FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES AND LACTIC OR PROPIONIC ACID BACTERIA USED IN FOODSTUFFS OR FOOD PREPARATION

- A23V2200/00—Function of food ingredients

- A23V2200/20—Ingredients acting on or related to the structure

- A23V2200/25—Nanoparticles, nanostructures

Definitions

- a delivery system generally refers to a system that aids or otherwise facilitates the delivery of a functional material to a desired location.

- the functional material can be any material that acts upon a substrate or otherwise provides a benefit once delivered to the desired location.

- Examples of functional materials that may benefit from the use of a delivery system include pharmaceuticals that are intended to be ingested, transferred transdermally, or subcutaneously injected into a human or animal patient's body, vitamins and nutrients (nutritional materials), and various other and numerous additives that can similarly be introduced into the body of a patient.

- the present invention is generally directed to a delivery system for various functional materials.

- the functional materials can be, for instance, health-related compounds/materials such as pharmaceuticals, anti-microbial agents, anti-viral agents, antibiotics, xenobiotics, nutriceutical agents (nutritional materials), signal agents, combinations of such, and the like.

- the functional materials are adsorbed onto alumina that is contained in or on a particle, and desirably a nanoparticle. Nanoparticles are particularly desirable for the large surface area they offer and the potential exposure of the functional agent to body tissue.

- the resulting carrier particles can then be used as is or can be combined with a vehicle, such as a liquid vehicle, to deliver the functional material to a desired location within or on a patient's body.

- a vehicle such as a liquid vehicle

- the particles making up the delivery system of the present invention can be incorporated into a liquid vehicle and either ingested, applied subcutaneously, or applied topically to the skin of a patient using any conventional application means.

- the pharmaceutical may then be selectively released from the carrier particle (such as an alumina, silica, or alumina coated silica particle) so as to release the pharmaceutical at a targeted/desirable body location, or at a desirable moment.

- such selective release can be accomplished by exposure of the particle to a change in environmental condition, such as a pH change.

- a change in environmental condition such as a pH change.

- such selective release may be accomplished by exposure to an alkaline environment.

- such selective release may be accomplished by exposure to an acidic environment.

- such selective release may be the result of exposure of the carrier particle to particular chemical stimuli.

- a method for applying a health related compound utilizes a health-related compound coated particle, and selectively releasing the compound upon exposure of the particle to either a change in environmental condition, or upon exposure to a chemical stimulus.

- the present invention is directed to a particle containing alumina. At least a portion of the alumina contained by the particle is present on a surface of the particle. A functional compound is bonded to the alumina on the surface of the particle. The functional compound prior to bonding with the alumina contains a moiety comprising one or more of:

- each of the above moieties can include further R groups attached to the carbon chain shown above.

- any such R group can appear in association with the above moieties as long as the R group does not interfere with the bonding of the moiety to an alumina particle.

- the above moieties have been found to form a bond with alumina in constructing the compositions of the present invention.

- the functional compounds can then in one embodiment, be selectively released in either a basic or acidic environmental condition.

- the functional compounds can be released in the basic/alkaline environment of a vagina experiencing a yeast infection.

- the functional compounds can be released in the basic environment of the small intestine so as to treat an infection, after passing through the acidic environment of the stomach.

- a functional compound may be released as a result of environmental stimuli as an alert or in conjunction with the completion of the delivery of a pharmaceutical material so as to provide indication of such delivery or the success of such treatment.

- Such indicator or signal may be in the form of a dye or fragrance.

- such signal may be the result of a functional material contained on a first type of particle, and such coated particle may be included with additional particles of a different variety, that contain health related compounds.

- the functional material may be released in response to a particular chemical stimuli, which is intentionally applied to the site of the carrier particles.

- a method of utilizing a triggerably releasable delivery system in the treatment of a patient's body includes the steps of providing at least one type of particle selected from alumina particles, alumina covered particles, and silica particles; adsorbing at least one functional compound to the surface of the particle or particles to form at least a partially coated particle or particles; exposing the at least partially coated particle or particles to a patient's body such as by ingestion, injection, transdermal transfer or transmucosal transfer; and exposing the particle or particles to an environmental or chemical condition whereby the health related compound is released from the surface of the particle to the patient's body.

- FIG. 1 illustrates an exploded perspective view of a transdermal drug delivery device in accordance with the invention.

- FIG. 2 illustrates a cross-sectional view of the transdermal delivery device of FIG. 1.

- the present invention is directed to a triggerable delivery system for functional compounds and methods of using the same.

- Functional compounds can be any pharmaceutical and/or nutritionally suitable substance that can provide a benefit to a location on or within a patient's body once delivered.

- patient refers to both human and non-human patients.

- functional materials are health related compounds such as pharmaceutical or nutritional materials.

- the delivery system is generally directed to the construction of a particle containing alumina and use of such particle to selectively deliver functional compounds contained on the particle upon the occurrence/exposure of a triggering mechanism.

- the particle acts as a carrier for a functional compound.

- the alumina contained within the particle provides a bonding site on the surface of the particle for a functional compound.

- the functional compound (the pharmaceutical, nutritional material, or other health related material cited herein) becomes adsorbed onto the surface of the alumina.

- the resulting particle can then be used to deliver the functional compound to a particular location within, or on a body.

- the particles can be used as is, for instance, or can be combined with a liquid, gel or other vehicle which may facilitate delivery of the particles depending upon the particular application. Such liquid and gel vehicles are known to those skilled in the art.

- the particles and/or vehicle can also be used in conjunction with a drug delivery apparatus, such as a modified bandage or modified tampon. Such a bandage or tampon would be modified to include either the particles themselves or a vehicle containing the particles.

- a functional equivalent to one of the above moieties refers to functional materials that include similar reactive groups as shown above, but which are not positioned on a molecule exactly as shown above and yet will still bond with alumina in a similar manner.

- the above moieties may form a relatively strong bond to an alumina surface. Without wishing to be bound by theory, it is believed that the above moieties form a bidentate ligand bonding system with alumina surfaces. For instance, it is believed that alumina forms a covalent bond and a coordinate bond with the above moieties. Further, it is believed that a surface reaction occurs causing the functional compound to remain on the surface of the particle (unless triggerably released) and form a coating thereon.

- the functional material can cover the entire resulting particle or can be located at particular locations on the particle. Further, it should be understood that the particles of the present invention can contain more than one functional compound so as to deliver multiple treatments to address either a patient's multiple symptoms or a patient's multiple conditions.

- particles made according to the present invention can have a zeta potential of greater than 20 mV, particularly greater than 30 mV, and, in some embodiments, greater than 40 mV.

- the particles are well suited for being affixed to substrates that carry a negative surface charge through coulombic attraction.

- the bond of the particle in some applications can be relatively permanent and substantive. Consequently, the delivery system of the present invention can be used to affix functional compounds to various substrates without the use of chemical binders or other attachment structures.

- the alumina particle reacted with the functional compound can contain various other ingredients.

- the particle can contain any material that does not adversely interfere with the ability of the functional material to bond to alumina.

- at least a portion of the alumina contained by the particle should be present on the surface of the particle so that the alumina is available for adsorbing the functional compound.

- any suitable pharmaceutical and/or nutritional functional compound containing one of the above moieties, a tautomer thereof, or a functional equivalent thereof may be used in accordance with the present invention.

- functional compounds include pharmaceuticals, and xenobiotics. Xenobiotics is a general term used to describe any chemical interacting with an organism that does not occur in the normal metabolic pathways of that organism.

- Other functional compounds can include therapeutic agents, nutriceutical (nutritional )agents, anti-viral agents, anti-microbial agents, and the like.

- the terms “functional compound or functional agent” shall be taken to include “health -related compounds” which shall encompass pharmaceuticals, nutritional compounds, xenobiotics, anti-microbial agents, anti-viral agents, therapeutic agents and signal agents.

- a method used to prepare alumina nanoparticles having functional compounds bonded to the surface included the following steps.

- the functional compound was dissolved in water with stirring. To this stirred solution was slowly added the alumina nanoparticles and the resulting mixture stirred for about 5 to 10 minutes to allow the functional compound to bond to the surface of the nanoparticle.

- the UV-VIS spectrum of the water solution was obtained by taking an aliquot of the stirred mixture and placing it in a quartz cell. The UV-VIS spectra were obtained using a UV-VIS spectrophotometer Model UV- 1601 (Shimadzu Corporation) with water as a reference. Zeta Potential and particle size measurements were determined using a ZetaPals Instrument (Brookhaven Instrument Company, Holtsville, N.Y.).

- a method used to release the bonded functional compound utilizing a pH trigger included the following steps.

- the alumina nanoparticle having the functional agent bonded to the surface was placed in an aqueous solution (suspension) with stirring.

- dilute sodium hydroxide (0.1N) dropwise was slowly added to this stirred suspension.

- An aliquot of this suspension was taken and the UV-VIS spectrum measured.

- the bonded functional agent's Lambda max peak can be observed to decrease with the free functional agent's Lambda max peak observed to appear and increase.

- SNOWTEX-AK was initially used in a 50 ml portion of 20% wt/wt suspension.

- the physical parameters of the SNOWTEX-AK nanoparticles are as follows: SNOWTEX-AK-size :62 nm and Zeta Potential of +36 mV.

- additional pharmaceutical agents were evaluated for their propensity to bind strongly to alumina particles. They included the following agents described in Table 1, and which demonstrated the noted shift.

- Still additional pharmaceutical agents which may be used in conjunction with this invention include the following materials.

- the pharmaceutical agent was released as observed by a second red shift of the UV-VIS Lambda Maxima.

- the alkaline agent dilute sodium hydroxide (0.1 N)

- 0.1 N dilute sodium hydroxide

- the tetracycline was released from the alumina surface when the suspension of modified nanoparticles was altered to pH ⁇ fraction (9/10) ⁇ or greater.

- the noted shifts correspond to the absorption maximum of the free pharmaceutical agents.

- a method used to release the bonded functional agent from the silica surface using a pH trigger included the following steps.

- the silica nanoparticle having the functional agent bonded to the surface was placed in aqueous solution (suspension) with stirring.

- dilute hydrochloric acid (0.1N) dropwise was slowly added to this stirred suspension.

- An aliquot of this suspension was taken and the UV-VIS spectrum measured.

- the bonded functional agent's Lambda max peak can be observed to decrease with the free functional agent's Lambda max peak observed to appear and increase.

- the red shift is characteristic of the binding of the aryl aldehyde functionality to the silica surface.

- dilute acid hydrochloric acid

- the aldehyde was released and the fragrance returned.

- the UV-VIS absorption also underwent a blue shift to return to that of the starting aldehyde.

- Such chemistry may be used in conjunction with a pharmaceutical to be released upon the change of an environmental condition to indicate/signal that the pharmaceutical material has been delivered.

- signal agent may be adsorbed onto a silica particle.

- a pharmaceutical compound may be separately adsorbed onto an alumina particle.

- the particles may be combined and jointly used within a delivery vehicle or as part of a modified drug delivery device. The functional agents then would be triggered upon the occurrence of separate chemical events.

- nanoparticle delivery systems may be employed to carry the pharmaceutical agent through the stomach (having an acidic environment) and then release the agents into the small intestine (having a basic/alkaline environment).

- nanoparticle delivery systems may be used as part of a treatment on a tampon for vaginal infections.

- a medicated tampon may include a bound antibiotic (“bound” meaning the functional compound adsorbed to the surface of nanoparticles which are themselves attached through charge attraction to a tampon substrate).

- such nanoparticle delivery systems may be used as an application to a topical bandage. Upon a change in condition or application of a pH changing chemistry, functional materials contained on carrier nanoparticles on the bandage can be selectively released into or onto a wound site.

- the particle acts as a delivery vehicle for delivering the functional compound to a desired location.

- the functional compounds may be easier to handle, may be more stable, or may have other improved properties depending upon the application.

- the resulting particle structure can be incorporated into various other mediums.

- the particle structure can be incorporated into liquid vehicles, can be formed into capsules, can be combined with gels, pastes, other solid materials, and the like, depending on the end-use application.

- the particles of the present invention include a surface layer that contains one or more functional compounds.

- the coating on the particle can be continuous or discontinuous.

- the particle itself is believed to be amorphous.

- compositions made according to the present invention have been found to be well suited to being applied to substrates made from synthetic polymers, such as thermoplastic polymers.

- substrates can include, for instance, woven and non-woven materials made from a polyolefin polymer such as polypropylene or polyethylene, polyester, and the like.

- polyolefin polymer such as polypropylene or polyethylene, polyester, and the like.

- various problems have been experienced in trying to affix materials to these types of materials. These materials can be particularly effective as drug delivery substrates for delivery through the skin of a patient.

- the particles of the present invention can be affixed to these materials (as a result of differences in Zeta potential) without the use of chemical binders or complex chemical constructions.

- substrates made from synthetic polymers can undergo a pretreatment process for increasing the negative surface charge.

- pretreatment processes include subjecting the substrate to a corona treatment or to an electret treatment.

- An electret treatment for instance, is disclosed in U.S. Pat. No. 5,964,926 to Cohen, which is incorporated herein by reference in its entirety.

- Such pretreatments have been found not only to increase the negative surface charge of polymeric materials, but also assist in wetting out the polymer and enhancing surface adhesion between the polymer and the particles of the present invention.

- FIG. 1 depicts an exploded perspective view of a transdermal drug delivery device in accordance with the invention.

- FIG. 2 depicts a cross-sectional view of the transdermal delivery device of FIG. 1.

- the transdermal delivery device 70 is designed to deliver a functional agent/compound, either drugs, medicaments, or other treatments, across the skin of a patient's body.

- the delivery device includes an adhesive layer 72 , for affixing the device (patch) to the skin of the patient.

- the adhesive layer may include a removable protective liner, to protect the adhesive layer during nonuse and also to reduce the likelihood of loss of active ingredient.

- the medicaments may be targeted to narrower areas of skin, depending upon the ability of each polymer component to allow the passage of the functional compound.

- the polymer layer is essentially the skin contacting layer, through which the active ingredient passes after the device is applied to the skin of a consumer.

- the device further includes a backing layer 76 , which includes a raised portion 78 , for housing the functional compound/active ingredient.

- the active ingredient is allowed to pass through the polymer layer 74 / 80 but desirably does not pass through the backing layer 76 .

- the polymer material of the present invention may be utilized as the material for forming a polymer layer in the patch, in order to provide the ability to pass functional compounds to the skin of a user.

- Such polymer layer may be for example a film (such as a selectively permeable or apertured film) or nonwoven sheet (such as a spunbond or meltblown, or a combination of such).

- Such polymer layer may also be in the form of a hydrogel-type material.

- such drug enclosure 82 may in fact be comprised of an absorbent sheet material, such as a nonwoven, that is designed to either retain exudates from a wound site, or to both retain exudates, and also to release moisture or select medicaments that are stored within the absorbent sheet material, upon a change in condition, such as appearance of moisture, body exudates or a change in pH.

- a nonwoven web may be, for instance either a spunbond or meltblown nonwoven web, or a combination of such.

- the depicted wound dressing/transdermal delivery device can function as either a hydrogel or hydrocolloid.

- the bound pharmaceutical or nutritional chemistry could be used with or without triggerable release.

- some of the bound chemistry in a multiple chemistry particle system could triggerably releasable, while other bound chemistry could be intentionally retained on the carrier particles.

- the bound chemistry could perform its advantageous function while still being attached to the carrier particles, for ease of removal or to lower the potential toxicity of the functional agent/compound.

- An example of such usage would be using a bound salicylaldoxime to remove heavy metals from the body or waste water without the loss of or exposure to the free complexing agent.

- tetracycline could function as an antibiotic while still being bound on a particle. This could allow the antibiotic to function in the stomach and intestines without crossing over into the bloodstream of a patient (because of the size of the particle). This control of the antibiotic release could assist with lowering the risk of sensitization of patients who are allergic to such medications.

Abstract

A triggerable delivery system for various functional compounds is disclosed. The delivery system incorporates a carrier composition containing alumina particles, silica particles or alumina coated particles. Various functional materials containing particular moieties may be adsorbed onto the particles and used as desired. The functional compounds can be, for instance, pharmaceuticals, xenobiotics, anti-microbial agents, anti-viral agents, fragrances, and the like.

Description

- This application is a Continuation in Part and claims priority to U.S. patent application Ser. No. 10/325,474 filed on Dec. 20, 2002 in the names of Jason Lye and Gavin MacDonald (and referenced by attorney docket number 18, 113). U.S. patent application Ser. No. 10/325,474 is incorporated by reference herein it its entirety.

- This invention relates to delivery systems for pharmaceutical materials. More specifically, this invention relates to delivery systems and methods of delivering various pharmaceutical materials into or onto a patient's body.

- A delivery system generally refers to a system that aids or otherwise facilitates the delivery of a functional material to a desired location. The functional material can be any material that acts upon a substrate or otherwise provides a benefit once delivered to the desired location. Examples of functional materials that may benefit from the use of a delivery system include pharmaceuticals that are intended to be ingested, transferred transdermally, or subcutaneously injected into a human or animal patient's body, vitamins and nutrients (nutritional materials), and various other and numerous additives that can similarly be introduced into the body of a patient.

- Even in view of recent advances in the art of delivery systems, further improvements in delivery systems for pharmaceutical and nutritional functional materials are still needed. For example, a need currently exists for a delivery system that can bind to various functional materials that does not incorporate relatively expensive chemical formulations or that does not require any complex process steps for incorporating a functional material into the delivery system. With respect to pharmaceutical and nutritional materials, a need also exists in the art for a delivery system for such materials that is capable of affixing the pharmaceutical or other health-related compounds to the delivery system, but will readily release such pharmaceutical materials or other health-related compounds upon the occurrence of a selected event or trigger. A need also exists for a method for selectively triggering the release of a pharmaceutical material or other health-related compound where and when it is needed. It is to such needs that the current invention is directed.

- The present invention is generally directed to a delivery system for various functional materials. The functional materials can be, for instance, health-related compounds/materials such as pharmaceuticals, anti-microbial agents, anti-viral agents, antibiotics, xenobiotics, nutriceutical agents (nutritional materials), signal agents, combinations of such, and the like. In accordance with one embodiment of the present invention, the functional materials are adsorbed onto alumina that is contained in or on a particle, and desirably a nanoparticle. Nanoparticles are particularly desirable for the large surface area they offer and the potential exposure of the functional agent to body tissue. The resulting carrier particles can then be used as is or can be combined with a vehicle, such as a liquid vehicle, to deliver the functional material to a desired location within or on a patient's body. For example, when the functional material is a pharmaceutical, the particles making up the delivery system of the present invention, can be incorporated into a liquid vehicle and either ingested, applied subcutaneously, or applied topically to the skin of a patient using any conventional application means. The pharmaceutical may then be selectively released from the carrier particle (such as an alumina, silica, or alumina coated silica particle) so as to release the pharmaceutical at a targeted/desirable body location, or at a desirable moment. In one embodiment, such selective release can be accomplished by exposure of the particle to a change in environmental condition, such as a pH change. For example, such selective release may be accomplished by exposure to an alkaline environment. Alternatively, such selective release may be accomplished by exposure to an acidic environment. Still further, such selective release may be the result of exposure of the carrier particle to particular chemical stimuli. In an alternative embodiment of the invention, a method for applying a health related compound utilizes a health-related compound coated particle, and selectively releasing the compound upon exposure of the particle to either a change in environmental condition, or upon exposure to a chemical stimulus.

- Thus, in one embodiment, the present invention is directed to a particle containing alumina. At least a portion of the alumina contained by the particle is present on a surface of the particle. A functional compound is bonded to the alumina on the surface of the particle. The functional compound prior to bonding with the alumina contains a moiety comprising one or more of:

- a tautomer thereof, or a functional equivalent thereof and wherein R and R′ comprise independently hydrogen, an alkyl group, or an aryl group.

- The above moieties can be present as is on a functional compound. Alternatively, however, each of the above moieties can include further R groups attached to the carbon chain shown above. In general, any such R group can appear in association with the above moieties as long as the R group does not interfere with the bonding of the moiety to an alumina particle. The above moieties have been found to form a bond with alumina in constructing the compositions of the present invention.

- The functional compounds can then in one embodiment, be selectively released in either a basic or acidic environmental condition. For instance, in one specific embodiment of the invention, the functional compounds can be released in the basic/alkaline environment of a vagina experiencing a yeast infection. In a second embodiment, the functional compounds can be released in the basic environment of the small intestine so as to treat an infection, after passing through the acidic environment of the stomach. In still a further alternative embodiment, a functional compound may be released as a result of environmental stimuli as an alert or in conjunction with the completion of the delivery of a pharmaceutical material so as to provide indication of such delivery or the success of such treatment. Such indicator or signal may be in the form of a dye or fragrance.

- In still a further alternative embodiment, such signal may be the result of a functional material contained on a first type of particle, and such coated particle may be included with additional particles of a different variety, that contain health related compounds. In still a further alternative embodiment, the functional material may be released in response to a particular chemical stimuli, which is intentionally applied to the site of the carrier particles. In still a further alternative embodiment, a method of utilizing a triggerably releasable delivery system in the treatment of a patient's body includes the steps of providing at least one type of particle selected from alumina particles, alumina covered particles, and silica particles; adsorbing at least one functional compound to the surface of the particle or particles to form at least a partially coated particle or particles; exposing the at least partially coated particle or particles to a patient's body such as by ingestion, injection, transdermal transfer or transmucosal transfer; and exposing the particle or particles to an environmental or chemical condition whereby the health related compound is released from the surface of the particle to the patient's body.

- Other features and aspects of the present invention are discussed in greater detail below.

- FIG. 1 illustrates an exploded perspective view of a transdermal drug delivery device in accordance with the invention.

- FIG. 2 illustrates a cross-sectional view of the transdermal delivery device of FIG. 1.

- In general, the present invention is directed to a triggerable delivery system for functional compounds and methods of using the same. Functional compounds can be any pharmaceutical and/or nutritionally suitable substance that can provide a benefit to a location on or within a patient's body once delivered. For the purposes of this application, it should be understood that the term “patient” refers to both human and non-human patients. Desirably, such functional materials are health related compounds such as pharmaceutical or nutritional materials.

- In accordance with one embodiment of the present invention, the delivery system is generally directed to the construction of a particle containing alumina and use of such particle to selectively deliver functional compounds contained on the particle upon the occurrence/exposure of a triggering mechanism. The particle acts as a carrier for a functional compound.

- Specifically, the alumina contained within the particle provides a bonding site on the surface of the particle for a functional compound. The functional compound (the pharmaceutical, nutritional material, or other health related material cited herein) becomes adsorbed onto the surface of the alumina. Once the functional compound is bonded to the alumina, the resulting particle can then be used to deliver the functional compound to a particular location within, or on a body. The particles can be used as is, for instance, or can be combined with a liquid, gel or other vehicle which may facilitate delivery of the particles depending upon the particular application. Such liquid and gel vehicles are known to those skilled in the art. The particles and/or vehicle can also be used in conjunction with a drug delivery apparatus, such as a modified bandage or modified tampon. Such a bandage or tampon would be modified to include either the particles themselves or a vehicle containing the particles.

-

- a tautomer thereof, or a functional equivalent thereof and wherein R and R′ comprise independently hydrogen, an alkyl group, or an aryl group. As used herein, a functional equivalent to one of the above moieties refers to functional materials that include similar reactive groups as shown above, but which are not positioned on a molecule exactly as shown above and yet will still bond with alumina in a similar manner.

- Referring to the moieties shown above, moiety (1) may be considered a carboxy-hydroxy moiety. Moiety (2) may be considered a hyrdoxy-hydroxy moiety, while moiety (3) may be considered a carboxy-carboxy moiety. Moieties (4) and (5), on the other hand, can be considered vinylalogous amide moieties. In moieties (4) and (5) above, the amine groups can be primary amines, secondary amines, or tertiary amines. Moieties (6) and (7) may be considered hydroxyl carbonyl moieties. Moiety (8) may be considered a carboxy amine. Moieties such as (8) may be found in amino acids. Moiety (9) may be considered a hydroxy imine. In general, any suitable functional compound containing one of the above moieties or a functional equivalent thereof may be used in accordance with the present invention. Further, it should be understood that various additional R groups may be included with the above moieties as long as the R groups do not interfere with the bond that is formed with alumina.

- The above moieties may form a relatively strong bond to an alumina surface. Without wishing to be bound by theory, it is believed that the above moieties form a bidentate ligand bonding system with alumina surfaces. For instance, it is believed that alumina forms a covalent bond and a coordinate bond with the above moieties. Further, it is believed that a surface reaction occurs causing the functional compound to remain on the surface of the particle (unless triggerably released) and form a coating thereon. The functional material can cover the entire resulting particle or can be located at particular locations on the particle. Further, it should be understood that the particles of the present invention can contain more than one functional compound so as to deliver multiple treatments to address either a patient's multiple symptoms or a patient's multiple conditions.

- Of particular advantage, in many embodiments, it has also been discovered that a functional compound can be bonded to alumina without significantly impacting the positive surface charge of alumina, which can be measured as zeta potential. The term “zeta potential” is used herein to mean without limitation, a potential gradient that arises across an interface. This term especially refers to the potential gradient that arises across the interface between the Stern layer in contact with the particle of the present invention and the diffuse layer surrounding the particle. Zeta potential measurements can be taken using, for instance, a Zetapals instrument which is available from the Brookhaven Instrument Corporation of Holtsville, N.Y. For example, zeta potential measurements can be conducted by adding one to three drops of a sample into a cuvet containing 1 mM KCl solution, and using the instrument's default functions preset for aqueous solutions.

- Thus, once alumina is bonded to the functional material, the resulting molecule continues to maintain a relatively strong positive charge. For instance, particles made according to the present invention can have a zeta potential of greater than 20 mV, particularly greater than 30 mV, and, in some embodiments, greater than 40 mV. By remaining positively charged, the particles are well suited for being affixed to substrates that carry a negative surface charge through coulombic attraction. Depending upon the difference in charge between the particle of the present invention and the surface of a substrate, the bond of the particle in some applications can be relatively permanent and substantive. Consequently, the delivery system of the present invention can be used to affix functional compounds to various substrates without the use of chemical binders or other attachment structures. As an example, the carrier particle (delivery system) can include along its surface a pharmaceutical functional compound, and yet the particle may still retain sufficient positive charge, to allow it to be attached to a negatively charged bandage or other topically contacting substrate layer. Then upon the occurrence of a specific chemical or environmental stimuli, the functional material contained on the particle can be selectively released to the body of a patient, but the carrier particles will remain affixed to the bandage or other charged surface.

- Various different particles and compositions can be used in the present invention. For instance, alumina or silica particles may be used, depending upon the functional compound and the trigger for releasing it. Silica particles are available under the designation SNOWTEX-C through from Nissan Chemical America (Houston, Tex.). Various different particles and compositions that contain alumina can be used in the present invention. For example, in one embodiment, the functional material is combined with an alumina sol. Many different types of alumina sols are commercially available with varying particle size. Of particular advantage, alumina sols can be prepared that carry a relatively strong positive surface charge or zeta potential. In this embodiment, the particle that is reacted with the functional compound contains primarily and in some embodiments exclusively alumina. Examples of alumina particle materials, include Aluminasol-100, and Aluminasol-200, available from Nissan Chemical America (Houston, Tex.).

- In other embodiments, however, the alumina particle reacted with the functional compound can contain various other ingredients. In general, the particle can contain any material that does not adversely interfere with the ability of the functional material to bond to alumina. In this regard, at least a portion of the alumina contained by the particle should be present on the surface of the particle so that the alumina is available for adsorbing the functional compound.

- In one particular embodiment of the present invention, the particle can contain a core material coated with alumina. The alumina can form a continuous coating over the particle or a discontinuous coating. The core material can be, for instance, an inorganic oxide, such as silica. For example, in one embodiment, sols can be used that contain silica nanoparticles that have an alumina surface coating. Such sols are currently commercially available, for instance, from Nissan Chemical America of Houston, Tex. The silica is coated with alumina to provide stability to the sols over certain pH ranges. In fact, alumina coated silica sols may have greater stability in some applications of the present invention in comparison to alumina sols. A specific example of alumina particle materials with silica cores, include Snowtex-AK, available from Nissan Chemical America, Houston, Tex.) and Ludox Cl from Grace Davison, Columbia, Md.

- As described above, any suitable pharmaceutical and/or nutritional functional compound containing one of the above moieties, a tautomer thereof, or a functional equivalent thereof may be used in accordance with the present invention. Examples of functional compounds include pharmaceuticals, and xenobiotics. Xenobiotics is a general term used to describe any chemical interacting with an organism that does not occur in the normal metabolic pathways of that organism. Other functional compounds can include therapeutic agents, nutriceutical (nutritional )agents, anti-viral agents, anti-microbial agents, and the like. For the purposes of this application, the terms “functional compound or functional agent” shall be taken to include “health -related compounds” which shall encompass pharmaceuticals, nutritional compounds, xenobiotics, anti-microbial agents, anti-viral agents, therapeutic agents and signal agents.

- One example of a therapeutic agent that may be used in the present invention is hydrocortisone. Hydrocortisone is a natural anti-inflammatory hormone of the glucocorticoid family of hormones produced by the adrenal cortex. Examples of nutritional compounds include ascorbic acid and aspartame. In one particular embodiment, the functional compound may be a pharmaceutical/anti-microbial agent such as an antibiotic. An example of such an antibiotic may include tetracycline. Tetracycline is an antibiotic substance produced by Streptomyces spp. Hydrocortisone and tetracycline structural formulas are provided below:

-

- As can be seen by the above structural formula, tetracycline is an antibacterial agent that contains a carbonyl-hydroxy functionality, capable of bonding with alumina in accordance with the present invention. Tetracycline is a series of isomers of cyclomycin.

- In still a further alternative embodiment, a signal agent, such as a fragrance, may be used by itself or in conjunction with a health related compound on a variety of particle types to both treat a condition, and also to provide an indication to the patient of the effectiveness of such treatment or the occurrence of a particular event. As an example, a fragrance may be adsorbed to one type of particle and an antibiotic may be adsorbed to a second type of particle. The particles can be delivered to an infected site simultaneously. If the infected site is alkaline, it will prompt the release of the antibiotic. Upon removal of the infection, and the return to a more normal acidic environment, the fragrance may be released, thereby providing an indication of the effective treatment of the infection. In a further example, the signal can be used to generate an indication of a particular event, such as the release of body fluids or exudates as in a bandage or personal care product, such as a feminine care product or child care diaper product.

- A method used to prepare alumina nanoparticles having functional compounds bonded to the surface included the following steps.

- The functional compound was dissolved in water with stirring. To this stirred solution was slowly added the alumina nanoparticles and the resulting mixture stirred for about 5 to 10 minutes to allow the functional compound to bond to the surface of the nanoparticle. The UV-VIS spectrum of the water solution was obtained by taking an aliquot of the stirred mixture and placing it in a quartz cell. The UV-VIS spectra were obtained using a UV-VIS spectrophotometer Model UV- 1601 (Shimadzu Corporation) with water as a reference. Zeta Potential and particle size measurements were determined using a ZetaPals Instrument (Brookhaven Instrument Company, Holtsville, N.Y.).

- A method used to release the bonded functional compound utilizing a pH trigger included the following steps. The alumina nanoparticle having the functional agent bonded to the surface was placed in an aqueous solution (suspension) with stirring. To this stirred suspension was slowly added dilute sodium hydroxide (0.1N) dropwise and the pH was subsequently measured. An aliquot of this suspension was taken and the UV-VIS spectrum measured. In this manner, the bonded functional agent's Lambda max peak can be observed to decrease with the free functional agent's Lambda max peak observed to appear and increase.

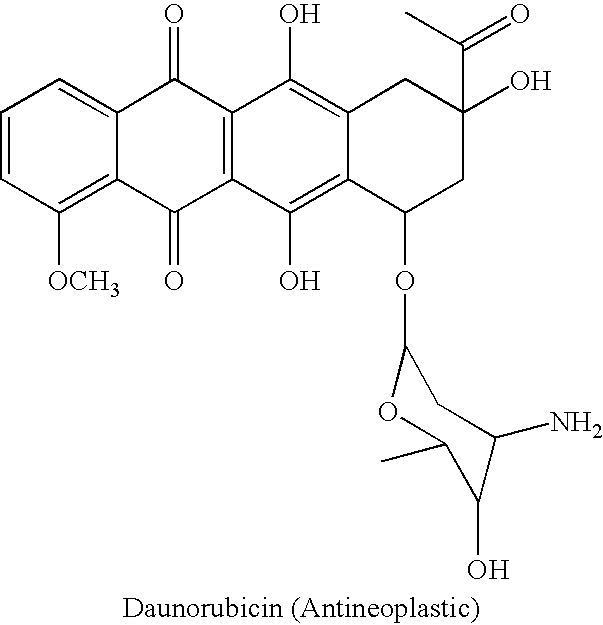

- In a first example of the adsorption of pharmaceutical materials onto the surface of a carrier nanoparticle, the UV-visible absorbance spectrum of Tetracycline was initially measured using a UV-visible spectrophotometer (Perkin-Elmer UV-Visible spectrophotometer.) Tetracycline was found to absorb at 357 nm in water. In particular, 10 mg tetracycline was in 50 ml water. When 5.0 ml SNOWTEX AK suspension 20% wt/wt (a sol containing silica particles that had an alumina surface coating, as obtained from Nissan Chemical America of Houston, Tex.) was added, with stirring, to the tetracycline solution. An aliquot was removed and the UV-VIS spectrum of the solution recorded. A bathochromic shift occurred to give an absorbance of 365 nm, suggesting that the tetracycline had adsorbed onto the alumina surface of SNOWTEX-AK particles. SNOWTEX-AK was initially used in a 50 ml portion of 20% wt/wt suspension. The physical parameters of the SNOWTEX-AK nanoparticles are as follows: SNOWTEX-AK-size :62 nm and Zeta Potential of +36 mV.In further Examples, additional pharmaceutical agents were evaluated for their propensity to bind strongly to alumina particles. They included the following agents described in Table 1, and which demonstrated the noted shift. These agents are considered antineoplastic for use as drugs that kill or stop the spread of cancer cells. Baicalein has been studied for its antiproliferation effect of human T-lymphoid leukemia cells.

TABLE 1 UV-VIS ABSORPTION (nm) SAMPLE FREE AGENT SN-AK/AGENT Baicalin Hydrate 278 and 322 295 and 388 Baicalein 320 348 Daunorubicin 472 480 -

- In a similar manner to the previous systems, examples of nutraceutical agents with the desired functional moieties were evaluated for their propensity to bind to alumina particles. Examples of such compounds were ascorbic acid (Vitamin C) and phenylalanine (sweetener found in Equal®). The structural equations for these materials and their ability to bind to such particles was demonstrated as can be seen in Table 2 which follows:

TABLE 2 SAMPLE UV-VIS ABSORPTION (nm) Ascorbic Acid in water 266 Ascorbic Acid/SN-AK 260 Phenylalanine in water 230 Phenylalanine/SN-AK 224* - It should be noted here that a shift in the absorption maximum was observed on addition of SNOWTEX-AK to the ascorbic acid solution, however a blue shift was observed (hypsochromic). This shift was due to binding, as no shift was observed when dilute acid was added to a separate solution of ascorbic acid. In a similar way, a blue shift (hypsochromic shift) was also observed with the phenylalanine binding to SNOWTEX-AK.

- In a further set of examples, pharmaceutical materials were adsorbed to carrier alumina particles and then selectively released from the carrier particles. In particular, separate 50 ml Solutions of Tetracycline and hydrocortisone agents (0.01 g) in water were prepared to which the alumina nanoparticle (SNOWTEX-AK) suspension (5 ml of 20% wt/wt) were added. A bathochromic shift (red shift) in the UV-VIS Lambda maxima was again observed, indicating strong binding of these pharmaceutical agents to the surface of the alumina particle. The following Table 3 shows the shift in the UV-VIS spectra recorded. Once the pharmaceutical agents had been bound to particles, they were selectively released by a controlled pH trigger mechanism. Thus, by changing the pH of the modified nanoparticle suspension to high pH values, the pharmaceutical agent was released as observed by a second red shift of the UV-VIS Lambda Maxima. In particular, the alkaline agent, dilute sodium hydroxide (0.1 N), was added in 0.5 ml amounts to the samples. The tetracycline was released from the alumina surface when the suspension of modified nanoparticles was altered to pH {fraction (9/10)} or greater. The noted shifts correspond to the absorption maximum of the free pharmaceutical agents.

TABLE 3 SAMPLE UV-VIS ABSORPTION (nm) Hydrocortisone in water 241 Hydrocortisone/SN-AK 234 Hydrocortisone/SN-AK with Base 244 Hydrocortisone with base 244 Tetracycline in water 357 Tetracycline/SN-AK 365 Tetracyclin/SN-AK with base 385 Tetracycline with base 385 - Therefore, these two examples of pharmaceutical agents demonstrate the capability of selectively releasing pharmaceutical agents from the carrier particles. By the use of a “pH trigger” the functional compounds can be released in a controlled manner when needed. It should be noted that such triggering of the delivery system may be accomplished through environmental changes such as infection which results in pH changes, taking advantage of inherent differences in pH depending on body locations, and the intentional act of introducing chemistries such as pH altering materials to the delivery systems to trigger the release of functional compounds. Chemistries that may be introduced to a delivery system include bicarbonates, carbonates and buffering salts which would result in a pH change on becoming wet with water or biological fluid. In yet another example, the delivery system would be incorporated into a tampon. Normal healthy vaginal fluid is acidic, typically in the 3-5 pH range. However, when infected with a yeast infection or other microbial infection, the pH changes to the basic range. This swing in pH would trigger the release of medication or buffering agents to restore the healthy pH of the vaginal fluid and flora.

- Silica Particle Binding and Release:

- The following examples illustrate the use of silica nanoparticles (as opposed to alumina particles) and the bonding of signal functional agents to the surface of the particles. The pH triggered release for silica coated particles is activated by adding acid and lowering the pH to the environment of the silica particles. Dilute acid is used in these examples.

- A method used to prepare silica nanoparticles having functional agents bonded to the surface included the following steps. The functional agent was dissolved into water with stirring. To this stirred solution was slowly added the silica nanoparticles and the resulting mixture stirred for about 5 to 10 minutes to allow the functional agent to bond to the surface of the nanoparticles. The UV-VIS spectrum of the water solution was obtained by taking an aliquot of the stirred mixture and placing it in a quartz cell. The UV-VIS spectra were obtained using the UV-VIS spectrophotometer Model UV-1601 with water as a reference. Zeta Potential and particle size measurements were determined using a ZetaPals Instrument (Brookhaven Instrument Company, Holtsville, N.Y.).

- A method used to release the bonded functional agent from the silica surface using a pH trigger included the following steps. The silica nanoparticle having the functional agent bonded to the surface was placed in aqueous solution (suspension) with stirring. To this stirred suspension was slowly added dilute hydrochloric acid (0.1N) dropwise and the pH measured. An aliquot of this suspension was taken and the UV-VIS spectrum measured. In this manner, the bonded functional agent's Lambda max peak can be observed to decrease with the free functional agent's Lambda max peak observed to appear and increase.

- In a similar fashion, the binding of active fragrance compounds to silica nanoparticles (SNOWTEX C, Nissan Chemicals America, Houston, Tex.) was demonstrated. Accordingly, to a solution (0.01 g of salicyclaldehyde in 50 ml of water) of salicylaldehyde (used in the perfume industry as a base fragrance) was added a dilute suspension (3 ml of 2% wt/wt) of silica nanoparticles (Snowtex C, Nissan Chemicals America, Houston Tex.) with stirring. The UV-VIS absorption of the salicylaldehyde underwent a red shift in its lambda max (see Table 4 below) and the characteristic fragrance disappeared. The red shift is characteristic of the binding of the aryl aldehyde functionality to the silica surface. Upon addition of dilute acid (hydrochloric acid), the aldehyde was released and the fragrance returned. The UV-VIS absorption also underwent a blue shift to return to that of the starting aldehyde. Such chemistry may be used in conjunction with a pharmaceutical to be released upon the change of an environmental condition to indicate/signal that the pharmaceutical material has been delivered. For instance, such signal agent may be adsorbed onto a silica particle. A pharmaceutical compound may be separately adsorbed onto an alumina particle. The particles may be combined and jointly used within a delivery vehicle or as part of a modified drug delivery device. The functional agents then would be triggered upon the occurrence of separate chemical events.

- In a similar manner, salicylaldoxime a metal sequestering agent, was also found to bind to the silica particle surface and undergo a pH triggered release. The structural formulas and exemplary data are illustrated in the following Table 4.