US20050015888A1 - Wrinkle resistant composition - Google Patents

Wrinkle resistant composition Download PDFInfo

- Publication number

- US20050015888A1 US20050015888A1 US10/924,539 US92453904A US2005015888A1 US 20050015888 A1 US20050015888 A1 US 20050015888A1 US 92453904 A US92453904 A US 92453904A US 2005015888 A1 US2005015888 A1 US 2005015888A1

- Authority

- US

- United States

- Prior art keywords

- composition

- fabric

- water

- group

- polymers

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M23/00—Treatment of fibres, threads, yarns, fabrics or fibrous goods made from such materials, characterised by the process

- D06M23/06—Processes in which the treating agent is dispersed in a gas, e.g. aerosols

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M13/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment

- D06M13/10—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment with compounds containing oxygen

- D06M13/224—Esters of carboxylic acids; Esters of carbonic acid

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M13/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment

- D06M13/10—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment with compounds containing oxygen

- D06M13/224—Esters of carboxylic acids; Esters of carbonic acid

- D06M13/2243—Mono-, di-, or triglycerides

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/01—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with natural macromolecular compounds or derivatives thereof

- D06M15/03—Polysaccharides or derivatives thereof

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/19—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with synthetic macromolecular compounds

- D06M15/21—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- D06M15/263—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds of unsaturated carboxylic acids; Salts or esters thereof

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/19—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with synthetic macromolecular compounds

- D06M15/21—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- D06M15/263—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds of unsaturated carboxylic acids; Salts or esters thereof

- D06M15/267—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds of unsaturated carboxylic acids; Salts or esters thereof of unsaturated carboxylic esters having amino or quaternary ammonium groups

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/19—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with synthetic macromolecular compounds

- D06M15/21—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- D06M15/285—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds of unsaturated carboxylic acid amides or imides

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/19—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with synthetic macromolecular compounds

- D06M15/21—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- D06M15/356—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds of other unsaturated compounds containing nitrogen, sulfur, silicon or phosphorus atoms

- D06M15/3562—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds of other unsaturated compounds containing nitrogen, sulfur, silicon or phosphorus atoms containing nitrogen

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/19—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with synthetic macromolecular compounds

- D06M15/37—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- D06M15/53—Polyethers

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/19—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with synthetic macromolecular compounds

- D06M15/37—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- D06M15/564—Polyureas, polyurethanes or other polymers having ureide or urethane links; Precondensation products forming them

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/19—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with synthetic macromolecular compounds

- D06M15/37—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- D06M15/643—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds containing silicon in the main chain

- D06M15/647—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds containing silicon in the main chain containing polyether sequences

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M7/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made of other substances with subsequent freeing of the treated goods from the treating medium, e.g. swelling, e.g. polyolefins

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M2200/00—Functionality of the treatment composition and/or properties imparted to the textile material

- D06M2200/20—Treatment influencing the crease behaviour, the wrinkle resistance, the crease recovery or the ironing ease

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M2200/00—Functionality of the treatment composition and/or properties imparted to the textile material

- D06M2200/40—Reduced friction resistance, lubricant properties; Sizing compositions

Definitions

- the present invention relates to fabric care compositions and to a method for treating fabrics in order to improve various properties of fabrics, in particular in-wear wrinkle resistance.

- Wrinkles in textile fabrics are caused by the bending and creasing of the textile material which places an external portion of a filament in a yarn under tension while the internal portion of that filament in the yarn is placed under compression.

- the hydrogen bonding that occurs between the cellulose molecules contributes to keeping wrinkles in place.

- the wrinkling of fabric, in particular clothing, is therefore subject to the inherent tensional elastic deformation and recovery properties of the fibers which constitute the yam and fabrics.

- U.S. Pat. No. 5,532,023 discloses aqueous wrinkle control compositions containing non-volatile silicone and film-forming polymer.

- Preferred silicones include reactive silicones and amino-functional silicone, known as “amodimethicone”.

- the composition containing such silicones is applied to fabric from a spray dispenser. It is found that in the spray treatment, an appreciable amount of the aqueous composition misses the fabric, and instead falls on flooring surfaces, such as rugs, carpets, concrete floors, tiled floors, linoleum floors, bathtub floors, which leaves a silicone layer that is accumulated on and/or cured on and/or bonded to the flooring surfaces.

- U.S. Pat. No. 5,573,695 discloses an aqueous wrinkle removal composition containing a vegetable oil based cationic quaternary ammonium surfactant, and an anionic fluorosurfactant.

- U.S. Pat. No. 4,661,268 discloses a wrinkle removal spray comprising an aqueous alcoholic composition containing a dialkyl quaternary ammonium salt and a silicone surfactant and/or a fluoro surfactant.

- 5,100,566 discloses a method of reducing wrinkles in fabric by spraying the fabric with an aqueous alcoholic solution of an anionic siliconate alkali metal salt.

- U.S. Pat. No. 4,806,254 discloses fabric wrinkle removal aqueous alcoholic solution containing glycerine and a nonionic surfactant.

- WO98/04772 provides the treatment of fabric against fabric creasing by application of a composition comprising a polycarboxylic acid or derivative thereof; and then curing the composition using a domestic process.

- Starch is also a conventional ingredient of dewrinkling compositions. However, while starch provides a suitable visual benefit onto the treated fabrics, it also gives fabric with an undesired stiff or starchy feeling.

- a lubricant preferably a water-soluble one

- component having a deviation of fabric Wrinkle Recovery Angle (WRA) versus water of at least +15 fulfill such a need.

- WRA fabric Wrinkle Recovery Angle

- This finding is particularly surprising, especially when the component providing such deviation is a polymer.

- the combination of a lubricant, especially a water-soluble one, with polymer is often the cause of phase separation.

- polymer like starch on top of composition comprising a lubricant, preferably a water-soluble one was found to give even worse results on the in-wear performance.

- the addition of a component providing a deviation of fabric WRA of at least +15 overcome such problems.

- the present invention reduces wrinkles in fabrics, including clothing, dry cleanables, linens, bed clothes, and draperies, by ironing.

- the present invention can be used on damp or dry clothing to relax wrinkles and give clothes a ready to wear look with lasting benefits that is demanded by today's fast paced world.

- an additional benefit of the composition of the present invention is an improved garment shape, body and crispness.

- composition of the present invention acts as an excellent ironing aid.

- the present invention makes the task of ironing easier and faster by creating less iron drag.

- the compositions of the present invention help produce a crisp, smooth appearance.

- the present invention is a wrinkle reducing composition

- a wrinkle reducing composition comprising a lubricant, preferably a water-soluble one, and a component having a deviation of fabric Wrinkle Recovery angle (WRA) versus water of at least +15.

- WRA fabric Wrinkle Recovery angle

- an article of manufacture comprising the composition of the invention, such as a sprayer, an aerosol, a foam dispenser, an iron, a refill cartridge thereof which contains the composition.

- a method of treating fabrics for imparting benefits selected from the group consisting of: reducing wrinkles and imparting in-wear resistance to fabrics.

- the composition is sprayed onto a fabric and the fabric is ironed.

- an article of manufacture comprising a container and the composition of the invention in association with usage instructions, in particular, instructions to use in a method where the composition is sprayed onto the fabric and the fabric is ironed.

- One essential component of the invention is a lubricant, preferably a water-soluble one.

- a lubricant preferably a water-soluble one.

- water-soluble is defined as “a component which when dissolved in water at a level of 0.2% by weight, or less, at 25° C., forms a clear, isotropic liquid”.

- Typical water-soluble lubricants include components selected from nonionic silicone containing surfactants, sorbitan esters, ethoxylated sorbitan esters, and mixtures thereof.

- the water-soluble lubricants are preferably present in an amount of from 0.1% to 70% by weight of the composition, more preferably of from 1 to 10% % by weight of the composition for diluted composition and of from 20 to 50% by weight of the composition for concentrated compositions.

- a preferred class of nonionic silicone containing surfactants are the polyalkylene oxide polysiloxanes having a dimethyl polysiloxane hydrophobic moiety and one or more hydrophilic polyalkylene side chains, and having the general formula: R1—(CH3)2SiO—(CH3)2SiO]a—[(CH3)(R1)SiO]b—Si(CH3)2—R1 wherein a+b are from about 1 to about 50, preferably from about 1 to about 30, more preferably from about 1 to about 25, and each R1 is the same or different and is selected from the group consisting of methyl and a poly(ethyleneoxide/propyleneoxide) copolymer group having the general formula: —(CH2)n O(C2 H4 O)c (C3 H6 O)d R2 with at least one R1 being a poly(ethyleneoxy/propyleneoxy) copolymer group, and wherein n is 3 or 4, preferably 3; total c (for all polyalkylene

- Nonlimiting examples of this type of surfactants are the Silwet® surfactants which are available OSI Specialties Inc., a Division of Witco, Danbury, Connecticut.

- Representative Silwet® surfactants which contain only ethyleneoxy (C2H4O) groups are as follows. Name Average MW Average a + b Average total c L-7608 600 1 8 L-7607 1,000 2 17 L-77 600 1 9 L-7605 6,000 20 99 L-7604 4,000 21 53 L-7600 4,000 11 68 L-7657 5,000 20 76 L-7602 3,000 20 29 L-7622 10,000 88 75

- Nonlimiting examples of Silwet® surfactants which contain both ethyleneoxy (C2 H4 O) and propyleneoxy (C3 H6 O) groups are as follows. Name Average MW EO/PO ratio L-720 12,000 50/50 L-7001 20,000 40/60 L-7002 8,000 50/50 L-7210 13,000 20/80 L-7200 19,000 75/25 L-7220 17,000 20/80

- the molecular weight of the polyalkyleneoxy group (R1) is less than or equal to about 10,000.

- the molecular weight of the polyalkyleneoxy group is less than or equal to about 8,000, and most preferably ranges from about 300 to about 5,000.

- the values of c and d can be those numbers which provide molecular weights within these ranges.

- the number of ethyleneoxy units (—C2H4O) in the polyether chain (R1) must be sufficient to render the polyalkylene oxide polysiloxane water-soluble. If propyleneoxy groups are present in the polyalkylenoxy chain, they can be distributed randomly in the chain or exist as blocks.

- Silwet® surfactants which contain both ethyleneoxy and propyleneoxy groups, are also preferred.

- Preferred Silwet® surfactants are the L-7001, L-7087, L-7200, L-7280, L-7600, L-7608, L-7622, L-7657.

- polyalkylene oxide polysiloxanes of the present invention can be prepared according to the procedure set forth in U.S. Pat. No. 3,299,112, incorporated herein by reference.

- polyalkylene oxide polysiloxanes of the surfactant blend of the present invention are readily prepared by an addition reaction between a hydrosiloxane (i.e., a siloxane containing silicon-bonded hydrogen) and an alkenyl ether (e.g., a vinyl, allyl, or methallyl ether) of an alkoxy or hydroxy end-blocked polyalkylene oxide).

- a hydrosiloxane i.e., a siloxane containing silicon-bonded hydrogen

- an alkenyl ether e.g., a vinyl, allyl, or methallyl ether

- reaction conditions employed in addition reactions of this type are well-known in the art and in general involve heating the reactants (e.g., at a temperature of from about 85° C. to 110° C.) in the presence of a platinum catalyst (e.g., chloroplatinic acid) and a solvent (e.g., toluene).

- a platinum catalyst e.g., chloroplatinic acid

- a solvent e.g., toluene

- Still other preferred water-soluble lubricants of the nonionic type are those from the class of sorbitan esters and/or alkylethoxylate sorbitan ester. These ethoxylated sorbitan esters are formed by ethoxylation of sorbitan or its cyclic derivative sorbitan, followed by esterification of one of the available hydroxy groups to introduce one long chain alkyl or alkenyl group, leaving the remaining hydroxy groups free.

- Water-insoluble lubricants are also useful herein. Suitable water-insoluble lubricants include cationic fabric softeners, silicones, and aliphatic and cycloaliphatic hydrocarbons.

- Suitable cationic fabric softening components for use herein include the water-insoluble quaternary-ammonium fabric softeners, the most commonly used having been di-long alkyl chain ammonium chloride or methyl sulfate.

- Preferred cationic softeners among these include the following:

- the quaternary ammonium compounds and amine precursors herein have the formula (I) or (II), below: wherein Q is selected from —O—C(O)—, —C(O)—O—, —O—C(O)—O—, —NR 4 —C(O)—, —C(O)—NR 4 —;

- Non-limiting examples of softener-compatible anions include chloride or methyl sulfate.

- the alkyl, or alkenyl, chain T 1 , T 2 , T 3 , T 4 , T 5 must contain at least 6 carbon atoms, preferably at least 11 carbon atoms, more preferably at least 16 carbon atoms.

- the chain may be straight or branched.

- Tallow is a convenient and inexpensive source of long chain alkyl and alkenyl material.

- the compounds wherein T 1 , T 2 , T 3 , T 4 , T 5 represents the mixture of long chain materials typical for tallow are particularly preferred.

- quaternary ammonium compounds suitable for use in the aqueous fabric softening compositions herein include:

- compounds 1-7 are examples of compounds of Formula (I); compound 8 is a compound of Formula (II).

- N,N-di(tallowoyl-oxy-ethyl)-N,N-dimethyl ammonium chloride where the tallow chains are at least partially unsaturated.

- the level of unsaturation of the tallow chain can be measured by the Iodine Value (IV) of the corresponding fatty acid, which in the present case should preferably be in the range of from 5 to 100 with two categories of compounds being distinguished, having a IV below or above 25.

- IV Iodine Value

- the anion is merely present as a counterion of the positively charged quaternary ammonium compounds.

- the nature of the counterion is not critical at all to the practice of the present invention.

- the scope of this invention is not considered limited to any particular anion.

- amine precursors thereof is meant the secondary or tertiary amines corresponding to the above quaternary ammonium compounds, said amines being substantially protonated in the present compositions due to the pH values.

- Still other water-insoluble lubricants include polyalkyl or polyaryl siloxanes with the following structure:

- the alkyl or aryl groups substituted on the siloxane chain (R) or at the ends of the siloxane chains (A) can have any structure as long as the resulting silicones remain fluid at room temperature.

- the silicones are hydrophobic, are neither irritating, toxic, nor otherwise harmful when applied to fabrics or when they come in contact with human skin, are compatible with other components of the composition, are chemically stable under normal use and storage conditions, and are capable of being deposited on fabric.

- the R group preferably is a phenyl, a hydroxy, an alkyl or an aryl.

- the two R groups on the silicone atom can represent the same group or different groups. More preferably, the two R groups represent the same group preferably a methyl, an ethyl, a propyl, a phenyl or a hydroxy group, q is prereably an integer from about 7 to about 8,000.

- A represents groups which block the ends of the silicone chains. Suitable A groups include hydrogen, methyl, methoxy, ethoxy, hydroxy, propoxy, and aryloxy.

- the preferred silicones are polydimethyl siloxanes; more preferred silicones are polydimethyl siloxanes having a viscosity of greater than about 10 000 centistokes (cst) at 25° C.

- Suitable methods for preparing these silicone materials are disclosed in U.S. Pat. Nos. 2,826,551 and 3,964,500, incorporated herein by reference. Silicones useful in the present invention are also commercially available. Suitable examples include silicones offered by Dow Corning Corporation.

- hydrocarbons for use herein include, in particular, linear or branched C 8 -C 40 paraffin hydrocarbons or mixtures of different hydrocarbons.

- An important factor in the selection of suitable hydrocarbons is that they should have a liquid to at most wax-like consistency at room temperature.

- a component having a deviation of fabric WRA of at least +15 is another essential component of the invention.

- these components are present in an amount of at least about 0.01%, preferably from about 0.1% to about 20% by weight of the composition, preferably to about 4% by weight of the diluted composition, preferably to about 12% by weight of the concentrated composition.

- the WRA Test method is taken from the AATCC 66-1990. This method is an American National Standard method designed for the determination of the wrinkle recovery of woven fabrics, whereby a test specimen, creased and compressed under controlled conditions of time and load, is suspended in the test instrument for a controlled recovery period, after which the recovery angle is measured. Experimental detail on how to measure this WRA is given in AATCC 66-1990, incorporated herein by reference.

- the WRA method is tested on 100% cotton, woven Oxford pinpoint fabric, free from wrinkles, cut in twelve specimens of 0.59 inch ⁇ 1.57 inch, six with their long dimension parallel to the warp, and six with their long dimensional parallel to the filling. The test is carried out on cloth conditioned for 24 hours at 21° C.

- Tweezers are used to place the test specimen between the leaves of the specimen holder (2 superimposed leaves 0.63 inch wide, but of different lengths and fastened together at one end) with one end directly under the 0.71-inch mark. With the tweezers, the exposed end of the specimen is lifted over and looped back to the 0.71-inch mark on the shorter, thin metal leaf and held with the left thumbnail.

- the holder with the specimen is inserted into a plastic press (2 superimposed leaves of equal length (3.74 inch) and 0.79 inch wide, fastened together at one end ) and a weight of 500 g is applied for 5 minutes so that a crease is formed.

- the plastic press can then be removed and the specimen holder combination can be inserted in the tester with the exposed end of the specimen holder in the mount on the face of the tester.

- the crease should line up with a spot at the center of the tester disk, and the dangling specimen leg should be lined up immediately with the vertical guide line.

- the wrinkle recovery value is read to the nearest degree from the scale. The sum is taken of the average recovery for all warp readings and all filling readings and compared with a cloth treated with water.

- the fabric WRA obtained with the tested component is compared with the fabric WRA obtained with water, thereby giving a deviation ⁇ .

- a component which provide a ⁇ of at least positive(+)15, preferably having a ⁇ within the range of 15-30 is a component suitable for the invention.

- Preferred components which have a deviation of fabric WRA versus water of at least 15 are selected from a) shape retention polymers, b) polymers comprising at least one unit which provide a dye transfer inhibiting benefit, c) polyurethanes, d) Isomaltooligosaccharide, e) polyamine polymers, f) amphoteric polymers, g) aminosilicones, h) curable silicones and mixtures thereof. Most preferred are the polymers which are water-soluble.

- the word “component” is meant to include compounds having a WRA deviation versus water of at least 15, mixtures of such components as well as mixtures of components which per se do not have a WRA deviation versus water of at least 15 but which, in combination do have a WRA deviation versus water of at least 15.

- One such component is disclosed and claimed in co-pending application EP 99870222.9-2413.

- Suitable shape retention polymers can be natural, or synthetic, and can act by forming a film, and/or by providing adhesive properties.

- the present invention can optionally use film-forming and/or adhesive polymer to impart shape retention to fabric, particularly clothing.

- adheresive it is meant that when applied as a solution or a dispersion to a fiber surface and dried, the polymer can attach to the surface.

- the polymer can form a film on the surface, or when residing between two fibers and in contact with the two fibers, it can bind the two fibers together.

- Other polymers such as Isomaltose Oligosaccharide can form a film and/or bond the fibers together when the treated fabric is pressed by a hot iron. Such a film will have adhesive strength, cohesive breaking strength, and cohesive breaking strain.

- Nonlimiting examples for natural polymers are Isomaltose Oligosaccharide and their derivatives, and chitins and their derivatives.

- the synthetic polymers useful in the present invention are comprised of monomers.

- monomers which can be used to form the synthetic polymers of the present invention include: low molecular weight C 1 -C 6 unsaturated organic mono-carboxylic and polycarboxylic acids, such as acrylic acid, methacrylic acid, crotonic acid, maleic acid and its half esters, itaconic acid, and mixtures thereof; esters of said acids with C 1 -C 12 alcohols, such as methanol, ethanol, 1-propanol, 2-propanol, 1-butanol, 2-methyl-1-propanol, 1-pentanol, 2-pentanol, 3-pentanol, 2-methyl-1-butanol, 1-methyl-i-butanol, 3-methyl-1-butanol, 1-methyl-1-pentanol, 2-methyl-i-pentanol, 3-methyl-i-pentanol, t-butanol, cyclohexanol, 2-

- Nonlimiting examples of said esters are methyl acrylate, ethyl acrylate, t-butyl acrylate, methyl methacrylate, hydroxyethyl methacrylate, methoxy ethyl methacrylate, and mixtures thereof; amides and imides of said acids, such as N,N-dimethylacrylamide, N-t-butyl acrylamide, maleimides; low molecular weight unsaturated alcohols such as vinyl alcohol (produced by the hydrolysis of vinyl acetate after polymerization), allyl alcohol; esters of said alcohols with low molecular weight carboxylic acids, such as, vinyl acetate, vinyl propionate; ethers of said alcohols such as methyl vinyl ether; aromatic vinyl such as styrene, alpha-methylstyrene, t-butylstyrene, vinyl toluene, polystyrene macromer, and the like; polar vinyl heterocyclics, such as vinyl pyrroli

- said monomers are selected from the group consisting of vinyl alcohol; acrylic acid; methacrylic acid; methyl acrylate; ethyl acrylate; methyl methacrylate; t-butyl acrylate; t-butyl methacrylate; n-butyl acrylate; n-butyl methacrylate; isobutyl methacrylate; 2-ethylhexyl methacrylate; dimethylaminoethyl methacrylate; N,N-dimethyl acrylamide; N,N-dimethyl methacrylamide; N-t-butyl acrylamide; vinylpyrrolidone; vinyl pyridine; adipic acid; diethylenetriamine; salts thereof and alkyl quaternized derivatives thereof, and mixtures thereof.

- said monomers form homopolymers and/or copolymers (i.e., the film-forming and/or adhesive polymer) having a glass transition temperature (Tg) of from about ⁇ 20° C. to about 150° C., preferably from about ⁇ 10° C. to about 150° C., more preferably from about 0° C. to about 100° C., most preferably, the adhesive polymer hereof, when dried to form a film will have a Tg of at least about 25° C., so that they are not unduly sticky, or “tacky” to the touch.

- said polymer is soluble and/or dispersible in water and/or alcohol.

- Said polymer typically has a molecular weight of at least about 500, preferably from about 1,000 to about 2,000,000, more preferably from about 5,000 to about 1,000,000, and even more preferably from about 30,000 to about 300,000 for some polymers.

- adipic acid/dimethylaminohydroxypropyl diethylenetriamine copolymer adipic acid/epoxypropyl diethylenetriamine copolymer

- polyvinyl alcohol polyvinylpyridine n-oxide; methacryloyl ethyl betaine/methacrylates copolymer; ethyl acrylate/methyl methacrylate/methacrylic acid/acrylic acid copolymer

- polyamine resins; and polyquaternary amine resins poly(ethenylformamide); poly(vinylamine) hydrochloride; poly(vinyl alcohol-co-6% vinylamine); poly(vinyl alcohol-co-12% vinylamine); poly(vinyl alcohol-co-6% vinylamine hydrochloride

- said copolymer and/or homopolymers are selected from the group consisting of adipic acid/dimethylaminohydroxypropyl diethylenetriamine copolymer; poly(vinylpyrrolidone/dimethylaminoethyl methacrylate); polyvinyl alcohol; ethyl acrylate/methyl methacrylate/methacrylic acid/acrylic acid copolymer; methacryloyl ethyl betaine/methacrylates copolymer; polyquaternary amine resins; poly(ethenylformamide); poly(vinylamine) hydrochloride; poly(vinyl alcohol-co-6% vinylamine); poly(vinyl alcohol-co-12% vinylamine); poly(vinyl alcohol-co-6% vinylamine hydrochloride); and poly(vinyl alcohol-co-12% vinylamine hydrochloride).

- adipic acid/dimethylaminohydroxypropyl diethylenetriamine copolymer poly(vinylpyrrol

- Preferred polymers useful in the present invention are selected from the group consisting of copolymers of hydrophilic monomers and hydrophobic monomers.

- the polymer can be linear random or block copolymers, and mixtures thereof.

- Such hydrophobicthydrophilic copolymers typically have a hydrophobic monomer/hydrophilic monomer ratio of from about 95:5 to about 20:80, preferably from about 90:10 to about 40:60, more preferably from about 80:20 to about 50:50 by weight of the copolymer.

- the hydrophobic monomer can comprise a single hydrophobic monomer or a mixture of hydrophobic monomers

- the hydrophilic monomer can comprise a single hydrophilic monomer or a mixture of hydrophilic monomers.

- hydrophobic is used herein consistent with its standard meaning of lacking affinity for water, whereas “hydrophilic” is used herein consistent with its standard meaning of having affinity for water.

- hydrophobic means substantially water insoluble; “hydrophilic” means substantially water-soluble.

- substantially water insoluble shall refer to a material that is not soluble in distilled (or equivalent) water, at 25° C., at a concentration of about 0.2% by weight, and preferably not soluble at about 0.1% by weight (calculated on a water plus monomer or polymer weight basis).

- substantially water-soluble shall refer to a material that is soluble in distilled (or equivalent) water, at 25° C., at a concentration of about 0.2% by weight, and are preferably soluble at about 1% by weight.

- soluble refers to the maximum concentration of monomer or polymer, as applicable, that can dissolve in water or other solvents to form a homogeneous solution, as is well understood to those skilled in the art.

- Nonlimiting examples of useful hydrophobic monomers are acrylic acid C 1 -C18 alkyl esters, such as methyl acrylate, ethyl acrylate, t-butyl acrylate; methacrylic C 1 -C18 alkyl esters, such as methyl methacrylate, 2-ethyl hexyl methacrylate, methoxy ethyl methacrylate; vinyl alcohol esters of carboxylic acids, such as, vinyl acetate, vinyl propionate, vinyl neodecanoate; aromatic vinyls, such as styrene, t-butyl styrene, vinyl toluene; vinyl ethers, such as methyl vinyl ether; vinyl chloride; vinylidene chloride; ethylene, propylene and other unsaturated hydrocarbons; and the like; and mixtures thereof.

- acrylic acid C 1 -C18 alkyl esters such as methyl acrylate, ethyl acrylate, t-

- Some preferred hydrophobic monomers are methyl acrylate, methyl methacrylate, t-butyl acrylate, t-butyl methacrylate, n-butyl acrylate, n-butyl methacrylate, and mixtures thereof.

- Nonlimiting examples of useful hydrophilic monomers are unsaturated organic mono-carboxylic and polycarboxylic acids, such as acrylic acid, methacrylic acid, crotonic acid, maleic acid and its half esters, itaconic acid; unsaturated alcohols, such as vinyl alcohol, allyl alcohol; polar vinyl heterocyclics, such as vinyl pyrrolidone, vinyl caprolactam, vinyl pyridine, vinyl imidazole; vinyl amine; vinyl sulfonate; unsaturated amides, such as acrylamides, e.g., N,N-dimethylacrylamide, N-t-butyl acrylamide; hydroxyethyl methacrylate; dimethylaminoethyl methacrylate; salts of acids and amines listed above; and the like; and mixtures thereof.

- unsaturated organic mono-carboxylic and polycarboxylic acids such as acrylic acid, methacrylic acid, crotonic acid, maleic acid and its half esters

- Some preferred hydrophilic monomers are acrylic acid, methacrylic acid, N,N-dimethyl acrylamide, N,N-dimethyl methacrylamide, N-t-butyl acrylamide, dimethylaamino ethyl methacrylate, vinyl pyrrolidone, salts thereof and alkyl quaternized derivatives thereof, and mixtures thereof.

- the shape retention copolymers contain hydrophobic monomers and hydrophilic monomers which comprise unsaturated organic mono-carboxylic and polycarboxylic acid monomers, such as acrylic acid, methacrylic acid, crotonic acid, maleic acid and its half esters, itaconic acid, and salts thereof, and mixtures thereof; and optionally other hydrophilic monomers.

- unsaturated organic mono-carboxylic and polycarboxylic acid monomers such as acrylic acid, methacrylic acid, crotonic acid, maleic acid and its half esters, itaconic acid, and salts thereof, and mixtures thereof; and optionally other hydrophilic monomers.

- hydrophilic unsaturated organic mono-carboxylic and polycarboxylic acid monomers are acrylic acid, methacrylic acid, crotonic acid, maleic acid and its half esters, itaconic acid, and mixtures thereof.

- Nonlimiting examples of the hydrophobic monomers are esters of the unsaturated organic mono-carboxylic and polycarboxylic acids cited hereinabove with C 1 -C 12 alcohols, such as methanol, ethanol, 1-propanol, 2-propanol, 1-butanol, 2-methyl-1-propanol, 1-pentanol, 2-pentanol, 3-pentanol, 2-methyl-i -butanol, 1-methyl-i -butanol, 3-methyl-1-butanol, 1-methyl-1-pentanol, 2-methyl-1-pentanol, 3-methyl-1-pentanol, t-butanol, cyclohexanol, 2-ethyl-1-butanol, and mixtures thereof, preferably methanol, ethanol, 1-propanol, 2-propanol, 1-butanol, 2-methyl-1-propanol, t-butanol, and mixtures thereof.

- Highly preferred adhesive and/or film-forming polymers that are useful in the composition of the present invention actually contain silicone moieties in the polymers themselves.

- These preferred polymers include graft and block copolymers of silicone with moieties containing hydrophilic and/or hydrophobic monomers described hereinbefore.

- the silicone-containing copolymers in the composition of the present invention provide shape retention, body, and/or good, soft fabric feel.

- Suitable silicone copolymers include the following:

- Preferred silicone-containing polymers are the silicone graft copolymers comprising acrylate groups described, along with methods of making them, in U.S. Pat. No. 5,658,557, Bolich et al., issued Aug. 19, 1997, U.S. Pat. No. 4,693,935, Mazurek, issued Sept. 15, 1987, and U.S. Pat. No. 4,728,571, Clemens et al., issued Mar. 1, 1988. Additional silicone-containing polymers are disclosed in U.S. Pat. Nos. 5,480,634, Hayama et al, issued Oct. 2, 1996, 5,166,276, Hayama et al., issued Nov. 24, 1992, 5,061,481, issued Oct.

- These polymers preferably include copolymers having a vinyl polymeric backbone having grafted onto it monovalent siloxane polymeric moieties, and components consisting of non-silicone hydrophilic and hydrophobic monomers.

- the silicone-containing monomers are exemplified by the general formula: X(Y) n Si(R) 3-m Z m wherein X is a polymerizable group, such as a vinyl group, which is part of the backbone of the polymer; Y is a divalent linking group; R is a hydrogen, hydroxyl, lower alkyl (e.g.

- Z is a monovalent polymeric siloxane moiety having an average molecular weight of at least about 500, is essentially unreactive under copolymerization conditions, and is pendant from the vinyl polymeric backbone described above; n is 0 or 1; and m is an integer from 1 to 3.

- the preferred silicone-containing monomer has a weight average molecular weight of from about 1,000 to about 50,000, preferably from about 3,000 to about 40,000, most preferably from about 5,000 to about 20,000.

- Nonlimiting examples of preferred silicone-containing monomers have the following formulas:

- Silicone-containing adhesive and/or film-forming copolymers useful in the present invention comprise from 0% to about 90%, preferably from about 10% to about 80%, more preferably from about 40% to about 75% of hydrophobic monomer, from about 0% to about 90%, preferably from about 5% to about 80% of hydrophilic monomer, and from about 5% to about 50%, preferably from about 10% to about 40%, more preferably from about 15% to about 25% of silicone-containing monomer.

- any particular copolymer will help determine its formulation properties.

- the copolymer can be optimized for inclusion in specific vehicles.

- polymers which are soluble in an aqueous formulation preferably contain from 0% to about 70%, preferably from about 5% to about 70% of hydrophobic monomer, and from about 30% to about 98%, preferably from about 30% to about 80%, of hydrophilic monomer, and from about 1% to about 40% of silicone-containing monomer.

- Polymers which are dispersible preferably contain from 0% to about 70%, more preferably from about 5% to about 70%, of hydrophobic monomer, and from about 20% to about 80%, more preferably from about 20% to about 60%, of hydrophilic monomer, and from about 1% to about 40% of silicone-containing monomer.

- the silicone-containing copolymers preferably have a weight average molecular weight of from about 10,000 to about 1,000,000, preferably from about 30,000 to about 300,000.

- the preferred polymers comprise a vinyl polymeric backbone, preferably having a Tg or a Tm as defined above of about ⁇ 20° C. and, grafted to the backbone, a polydimethylsiloxane macromer having a weight average molecular weight of from about 1,000 to about 50,000, preferably from about 5,000 to about 40,000, most preferably from about 7,000 to about 20,000.

- the polymer is such that when it is formulated into the finished composition, and then dried, the polymer phase separates into a discontinuous phase which includes the polydimethylsiloxane macromer and a continuous phase which includes the backbone.

- Exemplary silicone grafted polymers for use in the present invention include the following, where the composition of the copolymer is given with the approximate weight percentage of each monomer used in the polymerization reaction to prepare the copolymer: N,N-dimethylacrylamide/isobutyl methacrylate/(PDMS macromer ⁇ 20,000 approximate molecular weight) (20/60/20 w/w/w), copolymer of average molecular weight of about 400,000; N,N-dimethylacrylamide/(PDMS macromer ⁇ 20,000 approximate molecular weight) (80/20 w/w), copolymer of average molecular weight of about 300,000; and t-butylacrylate/N,N-dimethylacrylamide/(PDMS macromer ⁇ 10,000 approximate molecular weight) (70/10/20), copolymer of average molecular weight of about 400,000.

- Highly preferred shape retention copolymers of this type contain hydrophobic monomers, silicone-containing monomers and hydrophilic monomers which comprise unsaturated organic mono- and polycarboxylic acid monomers, such as acrylic acid, methacrylic acid, crotonic acid, maleic acid and its half esters, itaconic acid, and salts thereof, and mixtures thereof. These preferred polymers surprisingly provide control of certain amine type malodors in fabrics, in addition to providing the fabric wrinkle control benefit.

- a nonlimiting example of such copolymer is n-butylmethacrylate /acrylic acid/(polydimethylsiloxane macromer, 20,000 approximate molecular weight) copolymer of average molecular weight of about 100,000, and with an approximate monomer weight ratio of about 70/10/20.

- a highly preferred copolymer is composed of acrylic acid, t-butyl acrylate and silicone-containing monomeric units, preferably with from about 20% to about 90%, preferably from about 30% to about 80%, more preferably from about 50% to about 75% t-butyl acrylate; from about 5% to about 60%, preferably from about 8% to about 45%, more preferably from about 10% to about 30% of acrylic acid; and from about 5% to about 50%, preferably from about 10% to about 40%, more preferably from about 15% to about 30% of polydimethylsiloxane of an average molecular weight of from about 1,000 to about 50,000, preferably from about 5,000 to about 40,000, most preferably from about 7,000 to about 20,000.

- Nonlimiting examples of acrylic acid/tert-butyl acrylate/polydimethyl siloxane macromer copolymers useful in the present invention, with approximate monomer weight ratio, are: t-butylacrylate/acrylic acid/(polydimethylsiloxane macromer, 10,000 approximate molecular weight) (70/10/20 wlwiw), copolymer of average molecular weight of about 300,000; t-butyl acrylate/acrylic acid/(polydimethylsiloxane macromer, 10,000 approximate molecular weight) (63/20/17), copolymer of average molecular weight of from about 120,000 to about 150,000; and n-butylmethacrylate/acrylic acid/ (polydimethylsiloxane macromer ⁇ 20,000 approximate molecular weight) (70/10/20 wlwiw), copolymer of average molecular weight of about 100,000.

- a useful and commercially available copolymer of this type is Diahold® ME from Mitsubishi Chemical Corp., which is a t-butyl acrylate/acrylic acid/ (polydimethylsiloxane macromer, 12,000 approximate molecular weight) (60/20/20), copolymer of average molecular weight of about 128,000.

- silicone block copolymers comprising repeating block units of polysiloxanes.

- silicone-containing block copolymers examples include U.S. Pat. No. 5,523,365, to Geck et al., issued Jun. 4, 1996; U.S. Pat. No. 4,689,289, to Crivello, issued Aug. 25, 1987; U.S. Pat. No. 4,584,356, to Crivello, issued Apr. 22, 1986; Macromolecular Design, Concept & Practice, Ed: M. K. Mishra, Polymer Frontiers International, Inc., Hopewell Jct., N.Y. (1994), and Block Copolymers, A. Noshay and J. E. McGrath, Academic Press, N.Y. (1977), which are all incorporated by reference herein in their entirety.

- Other silicone block copolymers suitable for use herein are those described, along with methods of making them, in the above referenced and incorporated U.S. Pat. No. 5,658,577.

- the silicone-containing block copolymers useful in the present invention can be described by the formulas A-B, A-B-A, and —(A-B) n — wherein n is an integer of 2 or greater.

- A-B represents a diblock structure

- A-B-A represents a triblock structure

- —(A-B) n — represents a multiblock structure.

- the block copolymers can comprise mixtures of diblocks, triblocks, and higher multiblock combinations as well as small amounts of homopolymers.

- the silicone block portion, B can be represented by the following polymeric structure —(SiR 2 O) m —, wherein each R is independently selected from the group consisting of hydrogen, hydroxyl, C 1 -C 6 alkyl, C 1 -C 6 alkoxy, C 2 -C 6 alkylamino, styryl, phenyl, C 1 -C 6 alkyl or alkoxy-substituted phenyl, preferably methyl; and m is an integer of about 10 or greater, preferably of about 40 or greater, more preferably of about 60 or greater, and most preferably of about 100 or greater.

- the non-silicone block, A comprises monomers selected from the monomers as described hereinabove in reference to the non-silicone hydrophilic and hydrophobic monomers for the silicone grafted copolymers. Vinyl blocks are preferred co-monomers.

- the block copolymers preferably contain one or more non-silicone blocks, and up to about 50%, preferably from about 10% to about 20%, by weight of one or more polydimethyl siloxane blocks.

- sulfur-linked silicone containing copolymers including block copolymers.

- the term “sulfur-linked” means that the copolymer contains a sulfur linkage (i.e., —S—), a disulfide linkage (i.e., —S—S—), or a sulfhydryl group (i.e., —SH).

- A is a vinyl polymeric segment formed from polymerized free radically polymerizable monomers.

- the selection of A is typically based upon the intended uses of the composition, and the properties the copolymer must possess in order to accomplish its intended purpose. If A comprises a block in the case of block copolymers, a polymer having AB and/or ABA architecture will be obtained depending upon whether a mercapto functional group —SH is attached to one or both terminal silicon atoms of the mercapto functional silicone compounds, respectively.

- the weight ratio of vinyl polymer block or segment, to silicone segment of the copolymer can vary.

- the preferred copolymers are those wherein the weight ratio of vinyl polymer segment to silicone segment ranges from about 98:2 to 50:50, in order that the copolymer possesses properties inherent to each of the different polymeric segments while retaining the overall polymer's solubility.

- the preferred polymers comprising at least one unit which provide a dye transfer inhibiting benefit are water-soluble polymers.

- the polymers comprising at least one unit which provide a dye transfer inhibiting benefit useful in the present invention have the formula: [—P(D) m —] n wherein the unit P is a polymer backbone which comprises units which are homopolymeric or copolymeric. D units are defined herein below.

- the term “homopolymeric” is defined as “a polymer backbone which is comprised of units having the same unit composition, i.e., formed from polymerization of the same monomer”.

- copolymeric is defined as “a polymer backbone which is comprised of units having a different unit composition, i.e., formed from the polymerization of two or more monomers”.

- P backbones preferably comprise units having the formula: [—CR 2 —CR 2 ]— or —[(CR 2 ) x —L]— wherein each R unit is independently hydrogen, C 1 -C 12 alkyl, C 6 -C 12 aryl, and D units as described herein below; preferably C 1 -C 4 alkyl.

- Each L unit is independently selected from heteroatom-containing moieties, non-limiting examples of which are selected from the group consisting of: polysiloxane having the formula: wherein the index p is from 1 to about 6; units which have dye transfer inhibition activity: and mixtures thereof; wherein R 1 is hydrogen, C 1l -C 12 alkyl, C 6 -C 12 aryl, and mixtures thereof.

- R 2 is C 1 -C 12 alkyl, C 1 -C 12 alkoxy, C 6 -C 12 aryloxy, and mixtures thereof; preferably methyl and methoxy.

- R 3 is hydrogen C 1 -C 12 alkyl, C 6 -C 12 aryl, and mixtures thereof; preferably hydrogen or C 1 -C 4 alkyl, more preferably hydrogen.

- R 4 is C 1 -C 12 alkyl, C 6 -Cl 2 aryl, and mixtures thereof.

- the backbones of the polymers of the present invention comprise one or more D units which are units which comprise one or more units which provide a dye transfer inhibiting benefit.

- the D unit can be part of the backbone itself as represented in the general formula: [—P(D) m —] n or the D unit may be incorporated into the backbone as a pendant group to a backbone unit having, for example, the formula:

- the number of D units depends upon the formulation. For example, the number of D units will be adjusted to provide water solubility of the polymer as well as efficacy of dye transfer inhibition.

- the molecular weight of the polymers of the present invention are from about 500, preferably from about 1,000, more preferably from about 10,000 most preferably from 200,000 to about 6,000,000, preferably to about 2,000,000, more preferably to about 1,000,000, yet more preferably to about 500,000, most preferably to about 360,000 daltons. Therefore the value of the index n is selected to provide the indicated molecular weight, and providing for a water solubility of at least 100 ppm, preferably at least about 300 ppm, and more preferably at least about 1,000 ppm in water at ambient temperature which is defined herein as 25° C.

- Non-limiting examples of preferred D units are D units which comprise an amide moiety.

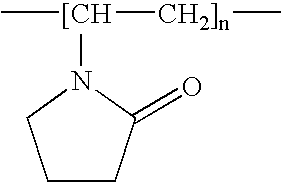

- Examples of polymers wherein an amide unit is introduced into the polymer via a pendant group includes polyvinylpyrrolidone having the formula: polyvinyloxazolidone having the formula: polyvinylmethyloxazolidone having the formula: polyacrylamides and N-substituted polyacrylamides having the formula: wherein each R′ is independently hydrogen, C 1 -C 6 alkyl, or both R′ units can be taken together to form a ring comprising 4-6 carbon atoms; polymethacrylamides and N-substituted polymethacrylamides having the general formula: wherein each R′ is independently hydrogen, C 1 -C 6 alkyl, or both R′ units can be taken together to form a ring comprising 4-6 carbon atoms; poly(N-acrylylglycinamide) having the formula: wherein each R′ is independently hydrogen, C 1 -C 6 alkyl, or both R′ units can

- D unit wherein the nitrogen of the dye transfer inhibiting moiety is incorporated into the polymer backbone is a poly(2-ethyl-2-oxazoline) having the formula: wherein the index n indicates the number of monomer residues present.

- the amino-functional polymers of the present invention can comprise any mixture of dye transfer inhibition units which provides the product with suitable properties.

- the preferred polymers which comprise D units which are amide moieties are those which have the nitrogen atoms of the amide unit highly substituted so the nitrogen atoms are in effect shielded to a varying degree by the surrounding non-polar groups. This provides the polymers with an amphiphilic character.

- Non-limiting examples include polyvinyl-pyrrolidones, polyvinyloxazolidones, N,N-disubstituted polyacrylamides, and N,N-disubstituted polymethacrylamides.

- a detailed description of physico-chemical properties of some of these polymers are given in “Water-Soluble Synthetic Polymers: Properties and Behavior”, Philip Molyneux, Vol. 1, CRC Press, (1983) included herein by reference.

- the amide containing polymers may be present partially hydrolyzed and/or crosslinked forms.

- a preferred polymeric compound for the present invention is polyvinylpyrrolidone (PVP). This polymer has an amphiphilic character with a highly polar amide group conferring hydrophilic and polar-attracting properties, and also has non-polar methylene and methine groups, in the backbone and/or the ring, conferring hydrophobic properties. PVP is readily soluble in aqueous and organic solvent systems.

- PVP is available ex ISP, Wayne, New Jersey, and BASF Corp., Parsippany, N.J., as a powder or aqueous solutions in several viscosity grades, designated as, e.g., K-12, K-15, K-25, and K-30. These K-values indicate the viscosity average molecular weight, as shown below: PVP viscosity average molecular weight (in thousands of daltons) K-12 K-15 K-25 K-30 K-60 K-90 2.5 10 24 40 160 360 PVP K-12, K-15, and K-30 are also available ex Polysciences, Inc.

- PVP K-15, K-25, and K-30 and poly(2-ethyl-2-oxazoline) are available ex Aldrich Chemical Co., Inc., Milwaukee, Wis.

- PVP K30 (40,000) through to K90 (360,000) are also commercially available ex BASF under the tradename Luviskol or commercially available ex ISP.

- Still higher molecular PVP like PVP 1.3MM, commercially available ex Aldrich is also suitable for use herein.

- PVP-type of material suitable for use in the present invention are polyvinylpyrrolidone-co-dimethylaminoethylmethacrylate, commercially available ex ISP in a quaternised form under the tradename Gafquat® or commercially available ex Aldrich Chemical Co.

- N-oxide units having the formula: wherein R 1 , R 2 , and R 3 can be any hydrocarbyl unit (for the purposes of the present invention the term “hydrocarbyl” does not include hydrogen atom alone).

- the N-oxide unit may be part of a polymer, such as a polyamine, i.e., polyalkyleneamine backbone, or the N-oxide may be part of a pendant group attached to the polymer backbone.

- An example of a polymer which comprises an the N-oxide unit as a part of the polymer backbone is polyethyleneimine N-oxide.

- Non-limiting examples of groups which can comprise an N-oxide moiety include the N-oxides of certain heterocycles inter alia pyridine, pyrrole, imidazole, pyrazole, pyrazine, pyrimidine, pyridazine, piperidine, pyrrolidine, pyrrolidone, azolidine, morpholine.

- a preferred polymer is poly(4-vinylpyriding N-oxide, PVNO).

- the N-oxide unit may be pendant to the ring, for example, aniline oxide.

- N-oxide comprising polymers of the present invention will preferably have a ratio of N-oxidized amine nitrogen to non-oxidized amine nitrogen of from about 1:0 to about 1:2, preferably to about 1:1, more preferably to about 3:1.

- the amount of N-oxide units can be adjusted by the formulator.

- the formulator may co-polymerize N-oxide comprising monomers with non N-oxide comprising monomers to arrive at the desired ratio of N-oxide to non N-oxide amino units, or the formulator may control the oxidation level of the polymer during preparation.

- the amine oxide unit of the polyamine N-oxides of the present invention have a Pk a less than or equal to 10, preferably less than or equal to 7, more preferably less than or equal to 6.

- the average molecular weight of the N-oxide comprising polymers which provide a dye transfer inhibitor benefit to polymers is from about 500 daltons, preferably from about 10,000 daltons, more preferably from about 20,000 daltons to about 6,000,000 daltons, preferably to about 2,000,000 daltons, more preferably to about 360,000 daltons.

- a further example of polymers which have dye transfer inhibition benefits are polymers which comprise both amide units and N-oxide units as described herein above.

- Non-limiting examples include co-polymers of two monomers wherein the first monomer comprises an amide unit and the second monomer comprises an N-oxide unit.

- oligomers or block polymers comprising these units can be taken together to form the mixed amide/N-oxide polymers.

- the resulting polymers must retain the water solubility requirements described herein above.

- Polymers of the urethane type are also suitable components for use herein.

- a typical disclosure of polyurethane polymer can be found in EP844274A1 as well as in EP839903.

- Isomaltooligosaccharides (including mixtures), the individual components of said mixtures, substituted versions thereof, derivatised versions thereof, and mixtures thereof are suitable components for use herein.

- IMO is used as corn syrup.

- cellulosic fibers/fabrics such as cotton, rayon, ramie, jute, flax, linen, polynosic-fibers, Lyocell (Tencel®), polyester/cotton blends, other cotton blends, and the like, especially cotton, rayon, linen, polyester/cotton blends, and mixtures thereof.

- Suitable fabric improving actives that are useful in the present invention include oligosaccharides with a degree of polymerization (DP) of from about 1 to about 15, preferably from about 2 to about 10, and wherein each monomer is selected from the group consisting of reducing saccharide containing 5 and/or 6 carbon atoms, including isomaltose, isomaltotriose, isomaltotetraose, isomaltooligosaccharide, fructooligosaccharide, levooligosaccharides, galactooligosaccharide, xylooligosaccharide, gentiooligosaccharides, disaccharides, glucose, fructose, galactose, xylose, mannose, arabinose, rhamnose, maltose, sucrose, lactose, maltulose, ribose, lyxose, allose, altrose, gulose, idose, talose, tre

- Oligosaccharides containing b-linkages are also preferred.

- Preferred oligosaccharides are acyclic and have at least one linkage that is not an ⁇ -1,4-glycosidic bond.

- a preferred oligosaccharide is a mixture containing IMO: from 0 to about 20% by weight of glucose, from about 10 to about 65% of isomaltose, from about 1% to about 45% of each of isomaltotriose, isomaltetraose and isomaltopentaose, from 0 to about 3% of each of isomaltohexaose, isomaltoheptaose, isomaltooctaose and isomaltononaose, from about 0.2% to about 15% of each of isomaltohexaose and isomaltoheptaose, and from 0 to about 50% by weight of said mixture being isomaltooligosaccharides of

- Oligosaccharide mixtures are either prepared by enzymatic reactions or separated as natural products from plant materials.

- the enzymatic synthesis of oligosaccharides involves either adding monosaccharides, one at a time, to a di- or higher saccharide to produce branched oligosaccharides, or it can involve the degradation of polysaccharides followed by transfer of saccharides to branching positions.

- Oligosaccharide Mixtures I and II are prepared by enzymatic hydrolysis of starch to maltooligosaccharides, which are then converted to isomaltooligosaccharides by a transglucosidase reaction.

- Oligosaccharide Mixture III for example, is a mixture of oligosaccharides isolated from soybean. Soybean oligosaccharides such as Mixture III, are of pure natural origin.

- Substituted and/or derivatised materials of the oligosaccharides listed hereinabove are also suitable in the present invention.

- Nonlimiting examples of these materials include: carboxyl and hydroxymethyl substitutions (e.g., glucuronic acid instead of glucose); amino oligosaccharides (amine substitution, e.g., glucosamine instead of glucose); cationic quaternized oligosaccharides; C 1 -C 6 alkylated oligosaccharides; acetylated oligosaccharide ethers; oligosaccharides having amino acid residues attached (small fragments of glycoprotein); oligosaccharides containing silicone moieties.

- substituted and/or derivatised oligosaccharides can provide additional benefits, such as: carboxyl and hydroxymethyl substitutions can introduce readily oxidizable materials on and in the fiber, thus reducing the probability of the fiber itself being oxidized by oxidants, such as bleaches; amine substitution can bind and/or condense with oxidatively damaged regions of the fiber to rejuvenate aged fabrics; acetylated sugar ethers can serve as bleach activators in subsequent processes where hydrogen peroxide is present; oligosaccharides having amino acid residues can improve delivery of fabric care benefits for fabrics containing proteinaceous fibers, e.g., wool and silk; and silicone-derivatised oligosaccharides can provide additional fabric softness and lubricity.

- C 6 alkyl oligosaccharide is disclosed (along with other higher, viz., C 6 -C 30 , alkyl polysaccharides) in U.S. Pat. No. 4,565,647.

- Typical disclosure of C 1 -C 6 alkylated oligosaccharides can also be found in U.S. Pat. No. 4,488,981. These patents are incorporated herein by reference.

- One preferred isomaltooligosaccharide is IMO 900 commercially available from Showa Sangyo Co.

- Polyvinylamines polymers are also suitable component giving a deviation of fabric WRA of at least 15.

- Typical polyvinylamines polymers include the quaternized and non-quaternized polyvinylamines having the formula: wherein R is hydrogen, C1-C12 linear or branched alkyl, benzyl, or alkyleneoxy having the formula (R1O)zY, wherein R1 is C1-C6 linear or branched alkylene, Y is hydrogen or an anionic unit, non-limiting examples of which include, —(CH2)fCO2M, —C(O)(CH2)fCO2M, —(CH2)fPO3M, —(CH2)fOPO3M, —(CH2)fSO3M, —CH2(CHSO3M)—(CH2)fSO3M, —CH2(CHSO2M)(CH2)fSO3M, —C(O)CH2CH(SO3M)CO2M, C(O)CH2CH(

- the index x has the value from about 50 to about 1,500; preferably the index x has a value such that the resulting polymeric suds stabilizer has an average molecular weight of from about 2,500, preferably from about 10,000, more preferably from about 20,000 to about 150,000, preferably to about 90,000, more preferably to about 80,000 daltons.

- Most preferred polymers for use in the present invention are water-soluble, including IMO 900 (Isomaltose Oligosaccharide ex. Showa Sangyo Co.), Avalure AC 120 (Polyacrylate ex. BF Goodrich), Luviskol K30, K60 and K85 (Polyvinylpyrrolidone MW 40.000, 400.000 and 1.250.000 ex. BASF), Luvitec VPC 55K65W (copolymer Vinylpyrrolidone & Vinylcaprolactam ex. BASF), Luvitec Quat 73W (copolymer 1-methyl-3-vinyl-imidazolium-methylsulfate & 1-vinyl-2-pyrrolidone ex.

- IMO 900 Isomaltose Oligosaccharide ex. Showa Sangyo Co.

- Avalure AC 120 Polyacrylate ex. BF Goodrich

- Luviskol K30, K60 and K85 Polyvinylpyrrolidone MW 40.000, 400.000 and 1.25

- Luviquat FC 905 copolymer Vinylimidazolium methochloride & Vinylpyrrolidone ex. BASF

- Sedipur 520 modified Polyacrylamide ex. BASF

- Chitanide 222 Chitosan succinamide ex. MIP

- Mirasil ADM-E Amphomer HC (Acrylate/Octylacrylamide copolymer ex. National Starch), and mixtures thereof.

- the water-soluble lubricant and the component, preferably polymer, having a deviation of fabric WRA of at least +15 are present in weight ratios of water-soluble lubricant to component of from 10:1 to 1:1. Indeed, it has been found that within these ratio ranges the resulting composition provides best in wear wrinkle benefit.

- amphoteric polymers i.e., polymers comprising at least one anionic moiety and one cationic moiety, and optionally a non-ionic moiety.

- the anionic moiety comprises a group which is a deprotonated anion of an acid group when the polymer is dissolved/dispersed in water at a pH of about 7 and which can be protonated to form a nonionic acid group when the polymer is dissolved/dispersed in water at an acidic pH.

- Representative examples of such groups include carboxylate, phosphonate, phosphate, phosphite, sulfonate, sulfate groups, and combinations thereof.

- each moiety may be further complexed with a separate, cationic counterion other than hydrogen.

- a separate, cationic counterion other than hydrogen include Na + , Li + , K + , NH4 + or combinations thereof.

- the cationic moiety comprises a protonated cation when the polymer is dissolved/dispersed in water at a pH of about 7 or below and can be deprotonated to a nonionic form when the polymer is dissolved/dispersed in water at a basic pH.

- the cationic moiety comprises a group which is a quaternized group.

- the protonated group include the ammonium functionality, phosphonium functionality, sulfonium functionality, and combinations thereof.

- ammonium refers to a moiety including a nitrogen atom linked to a plurality of moieties (either H, alkyl or aryl groups) by four bonds when dissolved/dispersed in water at a pH of 7.

- sulfonium refers to a moiety including a sulfur atom linked to three other moieties (either H, alkyl or aryl groups) when dispersed in water at a pH of about 7.

- phosphonium refers to a moiety including a phosphorous atom linked to four other moieties (either H, alkyl or aryl groups) when dispersed in water at a pH of about 7.

- ammonium, phosphonium and sulphonium functionality may be presented by the following formulae, respectively:

- R1 represents the polymer backbone and R2 represents hydrogen, alkyl or aryl substituents.

- R2 represents hydrogen, alkyl or aryl substituents.

- all R2 groups represents alkyl or aryl substituents, excluding hydrogen.

- each such second functional group may be further complexed with a separate, anionic counterion.

- counterion include chlorides, sulfates, carbonates, nitrates, formiates, perchlorates, or combinations thereof.

- amphoteric polymers herein comprise a non-ionic moiety.

- a preferred class of amphoteric polymers for use herein are polymers composed of both cationic and anionic vinylmonomers.

- Suitable anionic vinylmonomers for use herein include salts of acrylic acid, methacrylic acid, crotonic acid, maleic acid, fumaric acid, itaconic acid and vinylsulphonic acid.

- Suitable cationic vinylmonomers for use herein include salts of unsaturated amines such as the hydrochloride salt of vinylamine, salts of N,N′-dialkylaminoalkyl (meth) acrylates and N,N′-dialkylaminoalkyl (meth) acrylamides such as the hydrochloride salt of dimethylaminoethylmethacrylate (DMAEMA.HCl) or dimethylaminopropylacrylamide; alkyl quaternized aminoalkyl (meth) acrylates and aminoalky (meth) acrylamides such as trimethylammoniumethyl methacrylatechloride, trimethylammoniumpropyl acrylamidemethylsulfate, alkyl quaternized polar vinyl heterocyclics such

- a non-ionic comonomer can be incorporated, such as amides and imides of organic acids, such as acrylamide, N,N-dialkylacrylarnide, N-t-butylacrylamide, maleimides, vinylformamide, aromatic vinyl monomers such as styrene, vinyltoluene, t-butylstyrene; polar vinyl heterocyclics such as vinyl pyrrolidone, vinyl caprolactam, vinyl pyridine, vinylimidazole; low molecular weight unsaturated hydrocarbons and derivatives such as ethylene, propylene, butadiene, cyclohexadiene, vinylchloride and mixtures thereof.

- organic acids such as acrylamide, N,N-dialkylacrylarnide, N-t-butylacrylamide, maleimides, vinylformamide, aromatic vinyl monomers such as styrene, vinyltoluene, t-butylstyrene; polar vinyl heterocyclics such

- a preferred polymer of this class is based on poly(vinylamine-co-acrylic acid), in molar ratios varying between 1:100 to 100:1, preferably 90:10 to 40:60.

- Polymers of this class preferably have a molecular weight between 20.000 and 5.000.000 preferably between 30.000 and 1.000.000, more preferably between 50.000 and 300.000.

- a second class of polymers which are preferred for use herein are anionically modified polyethyleneimines.

- anionically modified polyethyleneimines include polyethyleneimines grafted with acrylic acid, methacrylic acid, maleic acid, fumaric acid, crotonic acid, itaconic acid, or carboxymethylated.

- anionically modified polyethyleneimines are well known. They can be prepared by reacting ⁇ , ⁇ -unsaturated carboxylic acids ( C ⁇ C—COOH) like acrylic or maleic acid with polyethyleneimine (Michael-type reaction) or by carboxymethylation. The carboxymethylation is carried out by reacting polyethyleneimine either with chloroacetic acid or with formaldehyde and sodium cyanide and subsequent saponification of the resultant aminonitrile. The latter procedure is well-known as the “Strecker Synthesis”.

- Polymers of this class have a degree of substitution of between 5 and 95, preferably 20 and 80, and a molecular weight between 5000 and 2 000 000, preferably 20 000 and 1 000 000.

- the amphoteric polymers can be provided to the clothes in amounts of from 1 ⁇ 10 ⁇ 7 g/g fabric to 0.3 g/g fabric, preferably from 1 ⁇ 10 ⁇ 5 g/g fabric to 0.1 g/g fabric; more preferably from 1 ⁇ 10 ⁇ 3 g/g fabric to 1 ⁇ 10 ⁇ 2 g/g fabric.

- aminosilicones preferably those comprising an amine comprising a sterically hindered functional group.

- any known aminosilicone can be used to treat clothes so as to provide the desired benefit.

- Aminosilicones used in a domestic context have been described in numerous publications, for instance U.S. Pat. No. 5,062,971 and U.S. Pat. No. 5,064,543 as ironing aid; in WO 00/24853, WO/9201773 and EP 300 525 in fabric conditioners, EP 150 867 and EP 150 872 in detergents and there is no need to redescribe such aminosilicones herein.

- aminosilicones can be used to treat clothes, but only in limited amounts such that the yellowing phenomenon does not become too visible, thereby limiting the performance of the composition.

- aminosilicones comprising a sterically hindered functional group.

- aminosilicones have been described in U.S. Pat. No. 5,540,952, EP 659 930, WO 00/5315, U.S. Pat. No. 5,688,889, WO 96/16110, WO 96/16124, WO 96/16127, WO 96/18667 and U.S. Pat. No. 5,792,825, the contents of which are incorporated herein.

- the present invention utilizes amino silicones comprising a sterically hindered functional group, i.e. polyorganosiloxanes having, per mole, at least one unit of general formula: ( R ) a ⁇ ⁇ ( X ) b ⁇ ⁇ Z ⁇ ⁇ Si ⁇ ( O ) 3 - ( a + b ) 2 in which:

- R are identical or different and represent a monovalent hydrocarbon radical chosen from linear or branched alkyl radicals having from 1 to 4 carbon atoms, the phenyl radical, the benzyl radical and the 3,3,3-trifluoropropyl radical;

- X are identical or different and represent a monovalent radical chosen from a hydroxyl group and a linear or branched alkoxy radical having from 1 to 3 carbon atoms;

- U represents —O— or —NR 9 —

- R 9 being a radical chosen from a hydrogen atom, a linear or branched alkyl radical having from 1 to 6 carbon atoms, a divalent radical —R 1 — having the meaning indicated above, one of the valency bonds being connected to the nitrogen of —NR 9 — and the other being connected to a silicon atom and a divalent radical of the formula —R 10 —N(R 1 )—S in which R 1 has the meaning indicated above

- R 10 represents a linear or branched alkylene radical having from 1 to 12 carbon atoms, one of the valency bonds (that of R 10 ) being connected to the nitrogen atom of —NR 9 — and the other (that of R 1 ) being connected to a silicon atom.

- S represents a monovalent group, in which:

- the secondary or tertiary amine function in S is incorporated in a piperidyl group.

- the polyorganosiloxane used can additionally comprise (an) other siloxyl unit(s).

- Such amino silicones comprising a sterically hindered functional group which are suitable for use herein are commercially available from Rhodia under the trade name Rhodorsil ®, in particular Rhodorsil ® H 21645 or Rhodorsil ® H 21650 or Silicex ®, in particular Silicex ® 263.

- the aminosilicones comprising a sterically hindered amino functional group can be provided to the clothes in amounts from 1 ⁇ 10 ⁇ 7 g/g fabric to 0.3 g/g fabric, preferably from 1 ⁇ 10 ⁇ 5 g/g fabric to 0.1 g/g fabric; more preferably from 1 ⁇ 10 ⁇ 3 g/g fabric to 1 ⁇ 10 ⁇ 2 g/g fabric, i.e. in amounts which are greater than the amounts in which other amino silicones can be used.

- a greater benefit can be obtained without observing fabric yellowing.

- curable silicones are also suitable for use herein. “Curable” silicone molecules have the ability to reach one with each other to yield a polymeric elastomer of a much higher molecular weight compared to the original molecule. Thus, “curing” often occurs when two curable silicone molecules or curable silicone polymers react yielding a polymer of a higher molecular weight. This “cure” reaction is define herein as the formation of new silicon-oxygen, silicon-carbon, and/or carbon-carbon linkages. Curable silicones can be cross-linked to some degree before application. That means that the curable silicone has cured to some degree before application but that can still further cure during and after application. Cross-linked curable silicones are preferred.

- curable silicones examples include vinyl-, allyl-, silane-, epoxy-, alkoxy-, and/or silanol-modified polydimethylsiloxanes, and mixtures thereof.

- Some curable silicones may required the cooperative use of a catalyst to induce curing, as in the case of vinyl-,hydrogen-modified silicones which cure via a hydrosilation process catalyzed by platinum compounds or radical catalysts.

- More preferred in this invention are curable silicone able to cure without the addition of a catalysts, such as epoxy-, alkoxy-, and/or silanol-modified polydimethylsiloxanes.

- a catalysts such as epoxy-, alkoxy-, and/or silanol-modified polydimethylsiloxanes.

- silanol-stopped polydimethyl-siloxanes emulsions are preferred.

- Curable silicones can have other organic group modifications as for example, although not restricting, amino or polyalkyleneoxide groups. Curable silicones may content reinforcing fillers. By reinforcing fillers we mean small particles made of inorganic or organic materials added to the curable silicone as additives or intimately linked to silicone molecules via covalent bonds.

- reinforcing fillers we mean small particles made of inorganic or organic materials added to the curable silicone as additives or intimately linked to silicone molecules via covalent bonds.

- silica particles sized from 10 to 100 nanometers present in 10% to 100% by weight based on the weight of the silicone.

- curable silicones are formulated as oil-in-water emulsions.

- Curable silicone emulsions are commercially available; e.g., GE-Bayer SM2112 Silicone Emulsions or Dow Corning Syl-Off® 7922 Catalyst Emulsion.

- curable silicones cure during or/and after application to the fabrics producing a network which will prevent the formation of wrinkles.

- Suitable film-forming polymers for use herein are durable press polymers.

- Durable press polymers are optional components of the invention.

- These polymers can be a cross-linking resin having the property of being cationic.