CROSS-REFERENCE TO RELATED APPLICATIONS

-

This application claims benefit of U.S. Provisional Application No. 61/245,810, filed Sep. 25, 2009, U.S. Provisional Application No. 61/307,060, filed Feb. 23, 2010, U.S. Provisional Application No. 61/332,997, filed May 10, 2010, and U.S. Provisional Application No. 61/370,261, filed Aug. 3, 2010, each of which is hereby incorporated by reference.

STATEMENT AS TO GOVERNMENT SPONSORSHIP

-

This invention was made with government support under P10D0002, ROI HG005097-01, and 1RC2HG005613-01 awarded by the National Institutes of Health. The government has certain rights in the invention.

BACKGROUND OF THE INVENTION

-

The invention relates to the fields of high throughput nucleic acid sequencing and amplification.

-

High-throughput, cost-effective DNA and RNA sequencing promises to usher in a new era of personalized medicine. However, a dramatic reduction in cost and increase in speed are needed for mass-market genetic analysis to benefit human health.

-

Accordingly, there is a need for new methods, kits, reagents, and devices for rapid and accurate nucleic acid sequencing and amplification.

SUMMARY OF THE INVENTION

-

In general, the invention features methods and systems for sequencing of nucleic acids based on the measurement of the incorporation of fluorogenic nucleotides in microreactors. The invention provides numerous advantages over previous systems such as unambiguous determination of sequence, fast cycle time, long read lengths, low overall cost of reagents, low instrument cost, and high throughput. The invention also features methods and kits for nucleic acid amplification. The amplification and sequencing aspects of the invention may or may not be employed in conjunction with one another.

-

In one aspect, the invention provides a method for sequencing a nucleic acid by immobilizing a single target nucleic acid or a number of substantially identical copies of the target nucleic acid within a microreactor, then providing a mixture in solution phase to this microreactor, which is optionally sealed, e.g., with a water-immiscible liquid such as a silicone, hydrocarbon, or fluorocarbon oil or by pressing the microreactors against a membrane or solid substrate. This mixture includes a nucleic acid replicating catalyst (e.g., DNA polymerase, RNA polymerase, ligase, RNA-dependent RNA polymerase, or reverse transcriptase), and a first nucleotide species having a label that is substantially non-fluorescent until after incorporation of the first nucleotide into a nucleic acid based on complementarity to the target nucleic acid. The mixture in solution phase, e.g., having a volume of 0.0001 fL-100000 fL, is disposed in a microreactor, and template-dependent replication of the target nucleic acid is allowed to occur. The target nucleic acid is then sequenced by detecting, after a suitable time, fluorescence generated from this first label as a result of the incorporation of the first nucleotide during template-dependent replication. If this included nucleotide species is not complementary to the target nucleic acid sequence, negligible fluorescence is generated. However, if the target nucleic acid sequence contains multiple sequential bases that are complementary to this first nucleotide species, then the generated fluorescence signal will be larger than that expected for a single nucleotide incorporation. In this way homopolymer stretches in the target nucleic acid can be efficiently sequenced. After quantification of fluorescence signal, the solution within the microreactor is then exchanged for a different mixture in solution phase, which includes a nucleic acid replicating catalyst (e.g., DNA polymerase, RNA polymerase, ligase, RNA-dependent RNA polymerase, or reverse transcriptase), and a second nucleotide species having a label that is substantially non-fluorescent until after incorporation of the second nucleotide into a nucleic acid based on complementarity to the target nucleic acid. If this second nucleotide species is complementary to the target nucleic acid, fluorescent label is generated by the nucleic acid replicating catalyst, otherwise negligible signal is generated. These steps are repeated for all nucleotide species serially and repeatedly, allowing full determination of the target nucleic acid sequence. The labels attached to each different nucleotide employed in the methods may be the same or different. Liquid exchange may occur through unsealing sealed microreactors, removing the liquid contents, introducing a new mixture in solution phase, and resealing the microreactors.

-

In some embodiments, the nucleic acid replicating catalyst is tightly bound to the nucleic acids being sequenced, and therefore need not be reintroduced in subsequent cycles of sequencing.

-

The detection step may be repeated as desired to continue sequencing the target nucleic acid by detecting incorporation of the next nucleotide, e.g., for at least 10, 25, 100, 300, 1000, or 10,000 base pairs.

-

In certain embodiments, the mixture in solution phase further includes an activating enzyme that renders the label fluorescent. Examples of activating enzymes include an alkaline phosphatase, acid phosphatase, galactosidase, horseradish peroxidase, phosphodiesterase, phosphotriesterase, pyruvate kinase, lactic dehydrogenase, maltose phosphorylase, glucose oxidase, lipase, and combinations thereof. Activating enzymes may be immobilized on the surface of a microreactor or on a bead disposed in the microreactor.

-

In other embodiments, the mixture in solution phase further includes non-hydrolyzable nucleotide substrates that inhibit misincorporation of the labeled nucleotide substrate species by binding to the replicating catalyst, e.g., polymerase, on nucleic acid molecules, in which the template base is not complementary to the labeled nucleotide substrate. In this way, these non-hydrolyzable nucleotide substrates block the labeled substrate from binding with the replicating catalyst, e.g., polymerase, and thereby reduce or prevent misincorporation events. Non-hydrolyzable nucleotide analogs are well known in the art.

-

In other embodiments, a second mixture in solution phase containing an unlabeled nucleotide species including the first base is introduced into the microreactor and template-dependent replication is allowed to proceed until the sequencing cycle is complete. The second mixture may further include three non-hydrolyzable nucleotide species, with second, third, and fourth bases, where the first, second, third, and fourth bases are different.

-

In other embodiments, the label is photobleached after fluorescence detection. The label may also be a phosphate label that is cleaved from the nucleotide during incorporation.

-

DNA, RNA or combinations thereof may be sequenced in the methods of the invention. For DNA or RNA, a primer may be employed. The methods of the invention may also be multiplexed to determine the sequence of more than one target nucleotide at the same time or sequentially.

-

In certain embodiments, the nucleic acid is immobilized either to the microreactor or to a bead within the microreactor using any of a number of methods (such as biotin-streptavidin, antigen-antibody affinity, covalent attachment, or nucleic acid complementarity). For example, the nucleic acid may be attached to a micron-sized bead disposed in the microreactor or to a lid of the microreactor. When a bead is employed, it may be magnetic and immobilized in a microreactor using a magnetic field. The target nucleic acid or plurality of copies may be immobilized in a spatial pattern, e.g., via biotin, on a surface of a microreactor. The pattern may be formed by spatially selective exposure to air plasma and subsequent coupling of a binding moiety, e.g., biotin or an oligonucleotide, or my spatially selective application of such a binding moiety.

-

The methods of the invention may also be employed with reversibly terminated nucleotides and with enzymatic signal amplification techniques as described herein.

-

The mixture in solution phase may further include an exonuclease, where a plurality of first labels is produced as a result of incorporation of the nucleotide and subsequent excision by the exonuclease. In such embodiments, the nucleotide may not be capable of extension. In other embodiments, the nucleotide excised is replaced with a nucleotide that is resistant to exonuclease excision and optionally reversibly terminated, e.g., an optionally reversibly terminated α-phosphorothioate.

-

The target nucleic acid may be reversibly bound to a bead when it is introduced into the microreactor. In certain embodiments, the microreactors include bound oligonucleotides, and a nucleic acid complementary, e.g., a single copy, to the target nucleic acid and reversibly bound to a bead is introduced into the microreactor. The complementary nucleic acid binds to a bound oligonucleotide, which is extended via template-dependent replication, thereby immobilizing the target nucleic acid in the microreactor. Such embodiments may further include performing template dependent replication of the target nucleic acid to produce from the bound oligonucleotides a plurality of copies of the target nucleic acid bound to the microreactor. The bead may be removed once the complementary nucleic acid is bound to the microreactor.

-

In certain embodiments, the plurality of copies is produced by rolling circle amplification (with or without hyperbranching), which may be followed by PCR amplification. The plurality of copies also may or may not be a concatemer.

-

In other embodiment, the temperature of the microreactor is reduced, e.g., to 15° C. or lower, when a fluorogenic nucleotide species is introduced. Subsequently, the temperature of the microreactor may be raised, e.g., to 20° C. or higher, during incorporation of the nucleotide species in template-dependent replication. If a lid is present, it may be closed prior to an increase in temperature. Template-dependent replication may or may not employ thermocycling.

-

The sequencing methods may also be employed with a population of single target nucleic acids or a population of pluralities of copies of the target nucleic acids, wherein each single target nucleic acid or plurality of copies of the target nucleic acid is immobilized in one of a plurality of microreactors. The plurality of microreactors may be super-Poisson loaded with the population of single target nucleic acids or population of pluralities of copies of the target nucleic acids. In one method of super-Poisson loading, the pluralities of copies of the target nucleic acids are concatemers sized so that only one concatemer is disposed in one of the plurality of microreactors. In another method of super-Poisson loading, each single target nucleic acid or plurality of copies of the target nucleic acid is bound to a bead sized so that only one bead is disposed in one of the plurality of microreactors. In a further method of super-Poisson loading, at least two repetitions of Poisson loading the population of single target nucleic acids, or complement thereof, or population of pluralities of copies of the target nucleic acids or complement thereof into a subset of the plurality of microreactors so that subsequent loading of the subset is prevented are performed. For example, each repetition includes loading a nucleic acid complementary to the target nucleic acid to the subset of microreactors and extending substantially all (or at least 70%, 75%, 80%, 85%, 90%, 95%, or 99%) of an oligonucleotide bound to a surface of the subset of microreactors by template dependent replication to produce the target nucleic acids. In another example, each repetition includes adding the population of plurality of copies of the target nucleic acid to the subset of microreactors, wherein the copies comprise a binding moiety that binds to moieties bound to a surface of the microreactors, and wherein, for each plurality and microreactor, the number of copies is sufficient to bind to substantially all (or at least 70%, 75%, 80%, 85%, 90%, 95%, or 99%) of the moieties bound to the surface. Alternatively, a repetition may include binding a number of binding sites on the surface of the microreactor and then treating the microreactor to prevent further binding of nucleic acids.

-

The immobilizing step may include adding a nucleic acid complementary to the target nucleic acid to the microreactor and extending an oligonucleotide bound to a surface of the microreactor by template dependent replication to produce the target nucleic acid or adding the plurality of copies of the target nucleic acid to the microreactor, wherein the copies include a binding moiety that binds to moieties bound to a surface of the microreactor, and wherein the number of copies is sufficient to bind to substantially all of the moieties bound to the surface.

In methods where nucleic acids are bound to oligonucleotide on the surface of a microreactor, the oligonucleotide may be a PCR primer, or it may melt from a nucleic acid complementary to the target nucleic acid at 35° C. or higher.

-

The plurality of copies of the target nucleic acid may be employed in the sequencing and may be produced by any of the amplification methods described herein.

-

In one embodiment, the method for sequencing a nucleic acid includes immobilizing in a microreactor a single target nucleic acid or a plurality of copies of the target nucleic acid; cooling the microreactor to 15° C. or lower; introducing to the microreactor a mixture in solution phase including a nucleic acid replicating catalyst, and a single species of nucleotide having a first base and a first label that is substantially non-fluorescent until after incorporation of the nucleotide into a nucleic acid based on complementarity to the target nucleic acid; sealing the microreactor and heating the microreactor to 20° C. or higher; allowing template-dependent replication of the target nucleic acid or the plurality of copies of the target nucleic acid; sequencing the target nucleic acid by detecting incorporation of the nucleotide during template-dependent replication by detecting fluorescence emission resulting from the first label; repeating the previous steps sequentially with a second single nucleotide species having a second base and a second label that is substantially non-fluorescent until incorporation of the second nucleotide into the nucleic acid based on complementarity to the target nucleic acid, a third single nucleotide species having a third base and a third label that is substantially non-fluorescent until incorporation of the third nucleotide into the nucleic acid based on complementarity to the target nucleic acid; and a fourth single nucleotide species having a fourth base and a fourth label that is substantially non-fluorescent until incorporation of the fourth nucleotide into the nucleic acid based on complementarity to the target nucleic acid, wherein any two of the first, second, third and fourth labels are the same or different, and the first, second, third, and fourth bases are different.

-

In another aspect, the invention features a method of amplifying a nucleic acid by providing a single copy of a first nucleic acid (e.g., single or double stranded) having first and second ends; immobilizing the first nucleic acid via the first end to a bead; immobilizing the second end of the nucleic acid to a surface of a microreactor; and amplifying, e.g., by polymerase chain reaction or ligase chain reaction, the first nucleic acid to produce a plurality of amplicons having first and second ends, wherein the plurality of amplicons binds to the surface of the microreactor via the second ends or to the bead via the first ends. Alternatively, the nucleic acid may be immobilized to the microreactor without the use of a bead.

-

Alternatively, the invention features a method of amplifying a nucleic acid by providing a single copy of a first nucleic acid having first and second ends; optionally immobilizing the first nucleic acid via the first end to a bead; immobilizing the second end of the first nucleic acid to one of a plurality of complementary oligonucleotides bound to a surface of a microreactor; extending the oligonucleotide by template dependent replication to produce a second nucleic acid bound to the surface of the microreactor; and amplifying the second nucleic acid to produce a plurality of amplicons extended from said plurality of oligonucleotides bound to the surface of the microreactor. In this embodiment, the bead may be removed once the complementary oligonucleotide is delivered to microreactor. In certain embodiments, substantially all (or at least 70%, 75%, 80%, 85%, 90%, 95%, or 99%) of the oligonucleotides are extended. The oligonucleotide may be a PCR primer, or it may melt from a nucleic acid complementary to the target nucleic acid at 35° C. or higher. In another embodiment, the oligonucleotides not extended are treated to prevent extension, e.g., by degradation or cleavage from the surface.

-

Another amplification method includes providing a single copy of a first circular nucleic acid; immobilizing the first nucleic acid to one of a plurality of complementary oligonucleotides bound to a surface of a microreactor or a bead; extending the oligonucleotide by rolling circle amplification to produce a second nucleic acid bound to the surface of the microreactor or bead; and amplifying, e.g., by linear or nonlinear rolling circle amplification, the second nucleic acid to produce a plurality of amplicons extended from the plurality of oligonucleotides bound to said surface of said microreactor. This method may further include amplifying the product by PCR.

-

In embodiments of the amplification methods, a first oligonucleotide adaptor is coupled to the first end of the first nucleic acid, e.g., by ligation, and a second oligonucleotide adaptor is coupled to the second end of the first nucleic acid, e.g., by ligation, wherein the first adaptor includes a moiety that optionally binds to the bead, and the second adaptor includes a moiety that binds to the surface of the microreactor. The first and second adaptors may also include nucleotide sequences to which forward and reverse primers for PCR hybridize.

-

The bead may include an oligonucleotide having a sequence to which the first end of the first nucleic acid hybridizes. Similarly, the surface of the microreactor may include an oligonucleotide having a sequence to which the second end of the first nucleic acid hybridizes.

-

Amplifying may occur by any suitable method, e.g., PCR, LCR, RCA, or HRCA.

-

The first nucleic acid is, for example, isolated from a library or biological sample. The library or biological sample may be fragmented to produce a plurality of nucleic acids including the first nucleic acid. The method may also be repeated for a plurality of single copies of nucleic acids. For example, the method may occur simultaneously for a plurality of nucleic acids, wherein each nucleic acid is immobilized in a separate microreactor.

-

In certain embodiments, the microreactor and bead are sized so that only one bead is immobilized in the microreactor.

-

The amplicons may be bound to the surface of the microreactor or to the bead, and the bead may be removed from the microreactor after amplification.

-

The microreactor may be sealed after delivery of the nucleic acid, e.g., with a water-immiscible liquid or by pressing the microreactors against a membrane or solid substrate. In addition, single copies of nucleic acids may also be delivered to the microreactor by methods other than beads, e.g., solution phase delivery of a dilute solution.

-

In certain embodiments, additional target nucleic acids cannot be immobilized in the microreactor after amplification. These methods may be employed in super-Poisson loading of a plurality of microreactors. For example, single nucleic acids can be Poisson loaded in a subset of a plurality of microreactors and amplified, and this process can be repeated to achieve super-Poisson loading.

-

Any of the amplification methods described herein may be employed to produce a plurality of nucleic acids for use in the sequencing methods provided herein, e.g., employing fluorescent, chemiluminescent, or electrical detection. In preferred embodiments, the amplification and sequencing occur in the same microreactor.

-

The invention further features a system for sequencing a nucleic acid that includes a plurality of microreactors each of which is capable of holding a different set of immobilized, substantially identical target nucleic acids for sequencing, and a solution phase mixture of a nucleic acid replicating catalyst, and a nucleotide that has a label that is substantially non-fluorescent until after incorporation of that nucleotide into a nucleic acid based on complementarity to the target nucleic acid; and a fluorescent microscope for imaging the plurality of microreactors to sequence target nucleic acids in the microreactors by the methods described herein. The system may include a light source, e.g., the excitation source of the microscope, capable of photobleaching the label after detection.

-

The system may further include a fluidic delivery system capable of delivering liquids to each of the plurality of microreactors and/or a light source capable of eliciting fluorescence from the label for detection. This fluidic system may be capable of performing emulsion PCR (Dressman (2003) Proc. Natl. Acad. Sci. USA 100:8817; Brenner et al. (2000) Nat. Biotech. 18:630), bridge PCR (Bentley et al. Nature, 2008, 456, 54), other solid-phase PCR, or linear nucleic acid amplification to generate distinct populations of substantially identical nucleic acids and immobilize them within a microreactor. This fluidic system may also be capable of purifying and amplifying nucleic acids from cells for sequencing. For example, the system may be capable of isolating a single cell, purifying RNA or DNA from the cell, and amplifying this nucleic acid for subsequent sequencing. This fluidic system may also be capable of sealing the array of microreactors using applied pressure. In particular, the plurality of microreactors may further include a control layer, pressurization of which conformally seals the microreactors against a flat surface. In such embodiments, the system further includes a pressure source. The system may also include a temperature controller capable of reducing the temperature of the microreactors below room temperature and capable of increasing the temperature of the microreactors to perform template dependent nucleic acid replication. The temperature controller may also be capable of thermocycling the plurality of microreactors so that nucleic acids present are amplified. The system may further include computer software (on a physical memory) or hardware to control the operation of the individual components. In particular, computer software or hardware may be present that controls the temperature of the microreactors during introduction of a labeled nucleotide, e.g., to 15° C. or below; during sealing of the array; during template dependent replication, e.g., to 20° C. or above; and any combination thereof.

-

Microreaders may be fabricated from poly(dimethylsiloxane) (PDMS) or a combination of PDMS and glass. These devices may be coated with a fluorocarbon polymer (e.g., CYTOP) and a polyethyleneoxide-polypropyleneoxide block copolymer, such as a poloxamer (e.g., Pluronic F-108) or poloxamine. Alternatively, the reactor surface may be coated with protein-based passivation agents (e.g., bovine serum albumen or casein). PDMS microreactors may also be treated with a fluorocarbon fluid such as Fluorinert (e.g., FC-43 or FC-770). Glass surfaces may be silanized for surface passivation (e.g., 1H, 1H, 2H, 2H-perfluorooctyltrichlorosilane or [tris(trimethylsiloxy)silylethyl]dimethylchlorosilane) and/or to allow surface conjugation of the nucleic acid or other components of the mixture (e.g., using 3-mercaptopropyltrimethoxysilane). Additionally, the reactor surface may be passivated by covalent coupling of polyethylene glycol (PEG) to the surface.

-

The microreactors may be patterned with a binding moiety, e.g., biotin or an oligonucleotide.

-

The system may also include a stage that is capable of moving the plurality of microreactors relative to the fluorescence microscope, so that a first portion of the plurality of microreactors is imaged. The fluidic delivery system may also be capable of delivery fluids to a second portion of the plurality of microreactors while the first portion of the plurality of microreactors is imaged. In other embodiments, a third portion of the plurality of microreactors is undergoing template-dependent replication, while fluids are delivered to the second portion of the plurality of microreactors, and the first portion of the plurality of microreactors is imaged.

-

The invention also features kits including a nucleic acid replicating catalyst (e.g., DNA polymerase, RNA polymerase, ligase, RNA-dependent RNA polymerase, or reverse transcriptase), four nucleotides each having a label that is substantially non-fluorescent until after incorporation of the nucleotide into a nucleic acid based on complementarity to the target nucleic acid, and an activating enzyme that renders the label fluorescent (e.g., an alkaline phosphatase, acid phosphatase, galactosidase, horseradish peroxidase, phosphodiesterase, phosphotriesterase, pyruvate kinase, lactic dehydrogenase, maltose phosphorylase, glucose oxidase, lipase, or combination thereof). The four nucleotides are typically sufficient to allow complete sequencing of a naturally occurring nucleic acid, e.g., including A, T or U, C, and G. Each nucleotide may have a distinct label, or any two or more of the nucleotides may include the same label.

-

In a related aspect, the invention provides a kit including a plurality of microreactors that are each capable of holding an immobilized single target nucleic acid, a mixture in solution phase of reagents for template dependent replication of the single target nucleic acid, and a bead functionalized to bind to the single target nucleic acid; a plurality of beads that are each capable of binding a nucleic acid and being disposed within one of the microreactors; and reagents for template dependent replication of the nucleic acid. The kit may also include a water-immiscible liquid for sealing the microreactors. The microreactors may include bound oligonucleotides or a spatially patterned binding moiety, e.g., biotin. Other exemplary microreactors, beads, and reagents are described herein.

-

The invention also provides a compound having the formula:

-

-

wherein n is 0 to 4, R is a nucleoside base, X is H, OH, or OMe, and Y is H or Cl, or a salt thereof.

-

The invention also features a compound having the formula:

-

-

wherein n is 0 to 4, R is a nucleoside base, and X is H, OH, or OMe, or a salt thereof.

-

By “adaptor” is meant a chemical moiety capable of covalently binding to the 5′ or 3′ end of a nucleic acid and having a binding moiety capable of covalently or noncovalently attaching the nucleic acid to a solid surface, e.g., bead or microreactor.

-

By “amplicon” is meant a product of template-dependent nucleic acid replication. Depending on the technique employed, an amplicon may have the same sequence or the complementary sequence of a nucleic acid being replicated. Amplicons may also include only a portion of the sequence or complement of the nucleic acid being replicated or additional moieties not found in the nucleic acid being replicated, e.g., via primers or nucleotides employed in replication.

-

By “amplifying” is meant producing a plurality of copies of a nucleic acid, either substantially identical in sequence, complementary in sequence, or both, by a template-dependent replicating process.

-

By “bead” is meant any particle that does not dissolve during nucleic acid sequencing or amplification and that is capable of binding a nucleic acid, either covalently or noncovalently. Beads may be magnetic or nonmagnetic.

-

By “biological sample” is meant any sample of biological origin containing nucleic acid. Sources of sample include whole organisms (e.g., single cellular organisms and viruses), tissues, and culture samples.

-

By “capable of extension” is meant capable of having a nucleotide added through template-dependent replication. For example, a DNA or RNA nucleotide is capable of extension. Once a reversibly terminated or dideoxy nucleotide is incorporated into a primer-template nucleic acid molecule, subsequent primer extension is not possible.

-

By “fluorogenic” or “substantially non-fluorescent” is meant not emitting a significant amount of fluorescence at a given wavelength until after a chemical reaction has occurred.

-

By “incorporation” of a nucleotide into a nucleic acid is meant the formation of a chemical bond, e.g., a phosphodiester bond, between the nucleotide and another nucleotide in the nucleic acid. For example, a nucleotide may be incorporated into a replicating strand of DNA via formation of a phosphodiester bond. Other types of bonds may be formed if non-naturally occurring nucleotides are employed.

-

By a “microreactor” is meant a vessel having a volume such that a light microscope can detect the buildup of a freely diffusing fluorophore using a photon detector.

-

By “nucleotide” is meant a natural or synthetic ribonucleosidyl, 2′-deoxyribonucleosidyl radical, 2′-O-methyl ribonucleosidyl, Locked Nucleic Acid, peptide nucleic acid, glycerol nucleic acid, morpholino nucleic acid, or threose nucleic acid connected, e.g., via the 5′, 3′ or 2′ carbon of the radical, to a phosphate group and a base. The nucleotide may include a purine or pyrimidine base, e.g., cytosine, guanine, adenine, thymine, uracil, xanthine, hypoxanthine, inosine, orotate, thioinosine, thiouracil, pseudouracil, 5,6-dihydrouracil, and 5-bromouracil. The purine or pyrimidine may be substituted as is known in the art, e.g., with halogen (i.e., fluoro, bromo, chloro, or iodo), alkyl (e.g., methyl, ethyl, or propyl), acyl (e.g., acetyl), or amine or hydroxylprotecting groups. In certain embodiments when DNA is being sequenced, the nucleotides employed are dATP, dCTP, dGTP, and dTTP. In other embodiments when RNA is being sequenced, the nucleotides employed are ATP, CTP, GTP, and UTP. A target DNA sequence can also be sequenced with riboside bases using RNA polymerase, and a target RNA sequence can also be sequenced with deoxyriboside bases using reverse transcriptase. The term includes moieties having a single base, e.g., ATP, and moieties having multiple bases, e.g., oligonucleotides.

-

By “nucleotide replicating catalyst” is meant any catalyst, e.g., an enzyme, that is capable of producing a nucleic acid that is complementary to a target nucleic acid. Examples include DNA polymerases, RNA polymerases, reverse transcriptases, ligases, and RNA-dependent RNA polymerases.

-

By “rolling circle amplification” is meant amplification of a circular nucleic acid with a strand-displacing nucleic acid replicating catalyst.

-

By “sequencing” a nucleic acid is meant identification of one or more nucleotides in, or complementary to, a target nucleic acid. Sequencing may include determination of the individual bases in sequence, determination of the presence of an oligonucleotide sequence, or determination of the class of nucleotide present, e.g., member of A-T, A-U, or G-C pair, or purine base or pyrimidine base.

-

Other features and advantages of the invention will be apparent from the following drawings, detailed description, and the claims.

BRIEF DESCRIPTION OF THE DRAWINGS

-

FIG. 1: Fluorogenic sequencing using a coupled enzyme assay. A) A strand of immobilized DNA with a polymerase bound, ready to add the next base to the primer strand of the DNA. This strand represents one of the population of substantially identical strands of DNA immobilized in the reaction chamber. Phosphates are represented by small circles, and fluorophores are represented by large circles. Semi-transparent circles are dark because they are conjugated to one or more phosphates. B) The polymerase recognizes the correct, complementary nucleotide to add to the primer strand and binds it. C) The polymerase adds the nucleotide, generating a natural incorporated base as well as a dark fluorophore conjugated to two phosphates. D) A phosphatase cleaves one of these two phosphates, and then E) cleaves the other, generating a fluorescent molecule that can be detected. F) Upon detection of this incorporated base, the fluorescent tag and phosphates exit the reaction volume. The phosphatase and polymerase are also optionally exchanged (signified by their transparency). G) buffer containing another base, along with polymerase and phosphatase, is introduced to probe the next base in the sequence. H) steps A)-G) are repeated serially with each species of nucleotide, allowing full sequencing of the immobilized DNA.

-

FIG. 2A: Valve-based sealing of PDMS microreactors. The PDMS microreactor includes a control layer (A) which allowed for reversible sealing of the reaction chambers upon application of pressure (B).

-

FIG. 2B: Two-layer PDMS microfluidic device for on-chip PCR consisting of a microreactor array-containing flow layer and a pressurizable control layer with a membrane for sealing the array. Both the control layer and the flow layer can be pressurized with water to prevent evaporation of the microrcactors during thermocycling.

-

FIG. 3: A fluorescence image of dye trapped in oil covered PDMS microreactors (5 μm diameter).

-

FIG. 4: One reversibly terminated nucleotide (with red polygons representing the reversible terminator moiety on the 3′ end) is incorporated into a homopolymeric DNA sequence, generating a fluorescent label (A-F). However, upon incorporation of the reversible terminator, no subsequent incorporations of the base are possible, even though they are complementary to the template strand. Upon removal of the nucleotides and the reversible terminator moiety (G), further incorporation of nucleotides into the homopolymeric region can occur (H), one nucleotide at a time.

-

FIG. 5: Small red polygons in the backbone of the DNA represent linkages that are resistant to the action of the exonuclease (for example phosphorothioate linkages). Fluorogenic nucleotides are incorporated into the DNA generating fluorescent product (A-F). Exonuclease then digests this newly incorporated base (G) leading to subsequent incorporations of the fluorogenic nucleotide (H) and generation of multiple fluorescent labels (I). The solution is then replaced with nucleotides which, when incorporated, generate DNA that is resistant to exonuclease digestion (J). One of these nucleotides is incorporated (K), and sequencing of the next base, with enzymatic amplification, can occur (L).

-

FIG. 6: Scheme for scanning microreactors in a rectilinear pattern.

-

FIG. 7: Scheme for simultaneous detection of microreactors in a rectilinear pattern.

-

FIG. 8: Scheme for amplification of a single copy of a nucleic acid in a microreactor.

-

FIG. 9: Scheme for amplification of a single copy of a nucleic acid in a microreactor.

-

FIG. 10: Scheme for pre-amplification by linear, rolling circle amplification and in-microreactor amplification with PCR.

-

FIG. 11: Scheme for hyperbranched rolling circle amplification.

-

FIG. 12: Scheme for rolling circle amplification for direct sequencing with PCR amplification.

-

FIGS. 13A-C: Schematic depictions of surface preparations for super-Poisson loading of microreactors.

-

FIG. 14: Work flow for thermocycle fluorogenic DNA sequencing in PDMS microreactors. In this case, DNA template-coated beads are immobilized in each microreactor.

-

FIGS. 15A-E: A) A schematic depiction of a thermocycler for use with the invention; B) exemplary thermal cycles achievable with this device; and C)-E) photographs of a thermocycler with a PDMS microreactor array seated on it.

-

FIG. 16: An exemplary microreactor fabrication procedure. Polystyrene beads are close-packed onto a flat glass surface. Polydimethylsiloxane (PDMS) is poured and cured onto these beads and then removed. The impregnated beads are removed mechanically, and the coupled-enzyme reaction mixture is placed between the patterned PDMS and a PDMS-coated coverslip. Upon application of pressure, sealed microreactors are formed and can be imaged from below with a light microscope.

-

FIG. 17: Schematic depiction of photolithographic fabrication of microreactors in PDMS.

-

FIG. 18: Microreactors with spatially patterned biotin surfaces. PDMS was patterned with PEG-Biotin and otherwise treated as described in Example 2. Streptavidin-coated 1 micron diameter beads were introduced and bound to the inside of the chambers and not the walls separating the chambers.

-

FIGS. 19A-B: Demonstration of homogeneous fluorogenic assay for DNA polymerase activity in PDMS microreactors. A) Bright field transmission image (left) of 5 μm diameter microreactors one of which contains a polystyrene bead coated with ˜100 DNA molecules and fluorescence image (right) of the same field-of-view 5 minutes after sealing the poly-C-DNA template-coated bead, φ29 (exo-) DNA polymerase, dGTP-γ-resorufin substrate, and shrimp alkaline phosphatase (SAP). B) Bright field transmission image (left) of 1.5 μm diameter microreactors two of which contain polystyrene beads coated with ˜100 DNA molecules and fluorescence image (right) of the same field-of-view 3 minutes after sealing the poly-C-DNA template-coated beads, Klenow fragment (exo-) DNA polymerase, dGTP-γ-resorufin substrate, and SAP. One of the two microreactors contains more than one bead, and the corresponding fluorescence signal is considerably higher.

-

FIG. 20: Demonstration of the detection of the signal generated from the incorporation of a single dG4P-3′-O-methyl-fluorescein-5(6)-carboxylic acid substrate from approximately 10,000 DNAs. These DNAs were immobilized on 1 micron streptavidin coated beads that are in turn immobilized in 5 micron microreactors made of PDMS. The image was acquired after 2 minutes of fluorescence signal buildup. Left is the bright field showing the reactors and immobilized beads, and right is the fluorescence image acquired with brightfield fluorescence microscopy. Upon unsealing and resealing the device, no further signal was generated, indicating the reaction has gone to completion.

-

FIG. 21: Microreactors with spatially patterned biotin surface. PDMS was patterned with PEG-Biotin and otherwise treated as described in Example 5. Streptavidin-coated 1 micron diameter beads were introduced and bound to the inside of the chambers and not the walls separating the chambers.

-

FIG. 22: 1 micron streptavidin-coated magnetic beads immobilized in microreactors spatially patterned with biotin.

-

FIG. 23: Images of fluorogenic sequencing according to the invention.

-

FIG. 24: Images of fluorogenic sequencing of a mixture of nucleic acids according to the invention.

-

FIG. 25: Fluid handling system for a microfluidic sequencing device. Four pressurized reagent reservoirs, each containing a polymerization reaction mixture for one of four fluorogenic nucleotides along with a wash buffer reservoir, are connected to a manifold of hydraulic valves. Each hydraulic valve is connected to a port on a rotary selector valve which has a single output. The selector valve is motorized and can rotate allowing the selection of a single reagent with minimal mixing and dead volume. The selector valve output is connected to a microfluidic device containing PDMS microreactors. Both the hydraulic valve manifold and the selector valve are computer controlled.

-

FIG. 26: Fluorescence intensity (after background subtraction) for each sequencing probe cycle corresponding to a microreactor containing a homopolymeric DNA template. The fluorescence intensity was proportional to the length of the homopolymer. Little or no signal was observed in probe cycles that do not correspond to the correct base in the template.

-

FIG. 27: Fluorescence intensity (after background subtraction) for each sequencing probe cycle corresponding to a microreactor containing a random DNA template. The fluorescence intensity was proportional to the length of homopolymeric sequences in the template. Little or no signal was observed in probe cycles that do not correspond to the correct base in the template.

-

FIGS. 28A-B: Fluorescence micrographs showing selective patterning of microreactors. A) A micrograph of the reactors focused at a plane level with the opening of the microreactors and B) A micrograph of the deepest part of the microreactors reactors.

-

FIGS. 29A-B: Fluorescence micrographs showing selective patterning of microreactors with DNA. A) A micrograph of the reactors focused at a plane level with the opening of the microreactors B) A micrograph of the reactors focused at the deepest part of the microreactors.

-

FIG. 30: Schematic depiction of a device including microreactors for sequencing nucleic acids.

-

FIGS. 31A-B: A) Fluorescence intensity (after background subtraction) for each sequencing probe cycle corresponding to a microreactor containing a random DNA template and B) calculated sequence based on thresholding of the fluorescence intensity.

-

FIG. 32: Fabrication of a PDMS microreactor array on a glass coverslip with an ultra-thin PDMS coat using a PDMS micropillar array master.

-

FIG. 33: Fluorescence image of a fluorophore-filled PDMS microreactor array mounted on a glass coverslip and sealed with a PDMS slab. Many of the fluorophores contained in microreactors in the lower left corner of the array have been photobleached. Because the individual microreactors are sealed, the photobleached region is not replenished by unbleached fluorophores from the other microreactors.

-

FIGS. 34A-B: Amplification with microreactor PCR. A) Homogeneous end-point fluorescent Taqman signal from PDMS microreactors that were thermocycled with a PCR reaction mixture that did not contain a DNA template. B) Non-uniform end-point fluorescent Taqman signal from PDMS microreactor that were thermocycled with a PCR reaction mixture with a very dilute DNA template sample such that most microreactors would initially contain zero, one, or two template molecules. The bright microreactors contain PCR product.

-

FIG. 35: Normalized, background-subtracted fluorescence intensity from a single microreactor (top) and base-calling resulting from intensity thresholding (bottom). In both graphs, the black bars are derived from the experimental sequencing data, and the dots represent the theoretical result. In this case, an error-free, 30-base read is obtained from Template A.

-

FIG. 36: Normalized, background-subtracted fluorescence intensity from a single microreactor (top) and base-calling resulting from intensity thresholding (bottom). In both graphs, the black bars are derived from the experimental sequencing data, and the dots represent the theoretical result. In this case, a 30-base read is obtained from Template B with a single error.

-

FIG. 37: Normalized, background-subtracted fluorescence intensity from a single microreactor (top) and base-calling resulting from intensity thresholding (bottom). In both graphs, the black bars are derived from the experimental sequencing data, and the dots represent the theoretical result. In this case, an error-free, 39-base read is obtained from Template C.

-

FIG. 38: Fluorescence image of labeled DNA hybridized to a DNA oligomer that is covalently attached to the inner walls of PDMS microreactors.

-

FIG. 39A-B: A) Fluorescence image of a labeled-primer that was complementary to a surface-immobilized 5′-benzaldehyde functionalized oligonucleotide that was covalently patterned on the inner walls of PDMS microreactors. B) Fluorescence image of a PDMS microreactor array that was covalently patterned with the same primer as in A), but that was probed with a non-complementary labeled oligonucleotide.

-

FIG. 40: Fluorescence image of PDMS microreactor array after 10 cycles of TaqMan PCR with rolling circle pre-amplification.

-

FIG. 41: Schematic of a microfluidic device for on-chip PCR.

-

FIG. 42: Left: Fluorogenic nucleotide signal generated from immobilized DNA generated from PCR on the walls of a PDMS device. Right: Signal after opening and resealing this device.

DETAILED DESCRIPTION OF THE INVENTION

-

We have developed methods and systems for detecting the synthesis of single nucleic acids or an ensemble of substantially identical nucleic acids using fluorogenic nucleotides that are substrates for nucleic acid replicating catalysts and that become able to emit light as a result of incorporation of the nucleotide into a nucleic acid. We have further developed techniques to amplify single molecules of nucleic acids. The invention typically employs microreactors to contain the sequencing or amplification reaction. This invention overcomes limitations of previously proposed techniques.

Nucleic Acid Sequencing

-

Advantages of the sequencing methods include:

-

- 1) Use of fluorogenic substrates eliminates background from unincorporated labeled nucleotides.

- 2) Synchronous, ensemble sequencing allows for multiple fields of view to be observed after a single cycle of incorporation, increasing throughput.

- 3) Large amount of fluorescent product generated allows for simple and economical detection scheme.

- 4) Allows for a regular, dense array of microreactors enabling high-throughput, parallel nucleic acid sequencing.

- 5) Reduction in the amount and the cost of reagents (enzyme, labeled nucleotide, nucleic acid, etc.) required for high-throughput sequencing.

- 6) Phosphate-labeled nucleotides allow for synthesis of natural DNA or RNA, allowing for the sequencing of thousands of nucleotides, in principle.

- 7) Use of terminal phosphate-labeled nucleotides eliminates the need for chemical modification of DNA following incorporation, decreasing the cycle time.

-

The methods are employed in connection with sequencing by synthesis, in which the incorporation of an individual nucleotide, e.g., including a single base or multiple bases, into a nucleic acid during replication is detected. As nucleotides are incorporated into a nucleic acid that is complementary to the target nucleic acid, the label is rendered able to emit light, e.g., by cleavage from the incorporated nucleotide (e.g., when bound to the terminal phosphate of a nucleotide) (FIG. 1). Preferably, the label is substantially non-emitting when diffusing free in solution to reduce background that could interfere with real time detection of incorporation. Because signal is only generated upon incorporation of the probe nucleotide, the technique distinguishes between incorporation and false binding, i.e., temporary hybridization not resulting in bond formation, and no zero-order waveguide is required. Sequencing may be performed with linear or circular nucleic acids. Sequencing may also be employed isothermally or with thermocycling. Reagents and conditions for amplification, described herein, may also be adapted for sequencing by synthesis.

-

Incorporation typically results in the cleavage of a portion of the nucleotide, e.g., pyrophosphate, and the label is typically bound to the cleaved portion, i.e., does not form part of the nucleic acid after incorporation. The label may not be immediately fluorescent upon cleavage from the nucleotide. In these embodiments, chemical modification of the label or groups pendant on the label must first occur. For example, certain dyes are non-fluorescent when conjugated to a phosphate group; removal of the phosphate group, e.g., via a phosphatase, then renders the label fluorescent. Other chemical mechanisms that may be involved include acid and base catalyzed reactions and other catalytic processes described herein. Labels may alternatively become able to emit merely as a result of cleavage from the growing nucleic acid. For example, a label may be quenched or otherwise rendered non-emitting by proximity to the nitrogenous base of a nucleotide or a moiety associated with the base.

-

Preferably, the rate of generation of a fluorophore is more rapid than incorporation of a nucleotide into a nucleic acid. Additionally, any activating catalyst (e.g., alkaline phosphatase) preferably acts rapidly on the fluorogenic label, yielding a fluorophore quickly in comparison to the rate of incorporation.

-

When each nucleotide is added to the synthesized strand, the nucleotide added is preferably identified. One method of determining the identity of a particular nucleotide is to attach a single label to each nucleotide being added, typically A, T, C, and G, or A, U, C, and G. By sequentially replacing the solution in the microreactor with a solution containing only one of these labeled nucleotide species at a time, microreactors with nucleic acid that is complementary to the added nucleotide species will generate fluorescent label, while other reactors will not. In this manner, the entire sequence of the nucleic acids in all microreactors can be determined.

-

Because only one labeled nucleotide species is available to the replicating catalyst, e.g., polymerase, at any one time, some catalysts, polymerases, may incorporate the labeled nucleotide species when it is not complementary to the template strand nucleic acid. This misincorporation may remove the nucleic acid strand from subsequent sequencing-by-synthesis cycles, and, over time, reduce the signal generated from each microreactor. To reduce the propensity of the catalyst, e.g., polymerase for misincorporation, non-hydrolyzable nucleotide species may be added to the reaction mixture to compete with the binding of the non-complementary labeled nucleotide species, thereby inhibiting misincorporation. For example, if C is the current base being probed in the microreactor array, the reaction mixture would include fluorogenically labeled dC substrate capable of generating a fluorescent product upon incorporation, as well as non-hydrolyzable nucleotide species that bind to the polymerase in a similar manner to dATP, dTTP, and dGTP. For example, for a dATP analog, dApCpp or dApNHpp might be used, and these non-hydrolyzable dATP structures can serve as examples of other non-hydrolyzable nucleotide analog species by changing the adenosine base moieties to thymine, guanine, uracil, or cytosine. If an activating enzyme is used in the reaction mixture, these non-hydrolyzable nucleotide analogs must be inert to the activities of the activating enzyme. For example, if a phosphatase is used as an activating enzyme, the non-hydrolyzable nucleotide analogs must have their terminal phosphates blocked with, for example, an alkyl group, to eliminate the possibility of a reaction with the phosphatase. Exemplary structures for dNTP analogs are shown below:

-

-

where n=0, 1, 2, 3, or 4, R is a is a nucleoside base, Q1 and Q2 are independently hydrogen or hydroxyl, X is a functional group or atom that prevents hydrolysis of the nucleoside analog by a polymerase enzyme, such as methylene or amine, and Y is a substituted or unsubstituted alkyl or aromatic group that prevents digestion of the nucleoside analog by a phosphatase enzyme.

-

These non-hydrolyzable nucleotide analogs can also be used in conjunction with natural nucleotides to ensure that each cycle of the sequencing reaction reaches completion through the use of a “chase” wash step. For example, after a sequencing cycle that has involved the incorporation of a labeled dATP substrate, non-hydrolyzable nucleotide species that bind to the replicating catalyst, e.g., polymerase, in a similar manner to dCTP, dTTP, and dGTP, along with dATP itself can be introduced to the microreactors. Because the incorporation of labeled nucleotides is typically much slower kinetically than the incorporation of native nucleotides, this chase step will ensure that all appropriate nucleic acid molecules have incorporated dATP and are ready to be probed by the addition of another labeled nucleotide species. The inclusion of non-hydrolyzable nucleotide species that bind to the replicating catalyst, e.g., polymerase, in a similar manner to dCTP, dTTP, and dGTP ensures that the native dATP will not be misincorporated into nucleic acids in which dATP is not complementary to the template strand. If misincorporation is not a significant problem for a specific genus of nucleic acid replicating catalyst, then this chase step can simply include the natural nucleotide analog of the previously used fluorogenic nucleotide analog, allowing for efficient and rapid synchronization of the DNA population.

-

Sequencing may also be performed using ligase, in which oligonucleotides hybridized adjacent to one another on a template strand are ligated together. Each oligonucleotide employed may be uniquely labeled. Oligonucleotides having the sequence complementary to a region of repeated sequence may be added sequentially using the methods of the invention, and the number of repeats determined by the number of oligonucleotides ligated.

-

Many proteins and enzymes require metallic co-factors such as divalent metal cations (Mg2+, Mn2+, Zn2+, etc.). For example, magnesium ions may be required for nucleic acid polymerase and alkaline phosphatase activity; manganese ions may be required to enhance the ability of the nucleic acid polymerase to incorporate modified nucleotide substrates (as described in U.S. Pat. No. 7,125,671 and Tabor S., Richardson C. C., Proc. Natl. Acad. Sci. USA, 1989, 86, 4076-4080); and zinc ions may be required for alkaline phosphatase activity. The presence of metal ions at high concentrations can complicate protein-protein interactions, protein-nucleic acid interactions, and surface passivation. In addition, divalent cations can destabilize polyphosphate compounds. Buffer components such as ammonium sulfate and chelating agents can be used to tune intermolecular interactions and control the effective concentration of metal ions. Many nucleic acid polymerizing replicating catalysts also require a reducing environment to perform optimally. There are many classes of reducing agents such as thiols (such as 2-mercaptoethanol or dithiothreitol) and phosphines (such as tris(2-carboxyethyl)phosphine (TCEP)), which are compatible with physiological buffers.

-

An individual sequencing reaction may be controlled by the introduction of Mg or Mn ions, nucleotides, and other co-factors necessary to effect replication. Other methods for controlling replication include changing the temperature or introducing or removing substances that promote or discourage complex formation between the target and catalyst. The catalyst or target may also be rendered inoperative to end sequencing, e.g., through denaturation or cleavage.

-

Multiplexing, i.e., detection of more than one replication at a time, may also be employed to increase throughput.

Fluorogenic Labels

-

Any label that becomes able to emit light as a result of incorporation of a nucleotide to a synthesized nucleic acid may be employed in the methods of the invention. Labels can be attached to nucleotides at a variety of locations. Attachment can be made either with or without a bridging linker to the nucleotide. The label may be attached to the base, sugar, or phosphate of the nucleotide. Preferably, the label is attached to the terminal phosphate, so it is cleaved from the nucleotide during replication. Labels may also be attached to non-naturally occurring portions of a nucleotide, e.g., to the delta or epsilon phosphate in a tetra- or pentaphosphate containing nucleotide. Alternatively, labels may be attached to the alpha phosphate and displaced during incorporation of a nucleotide in a synthesized strand. For clarity, fluorogenic labels, as employed in the invention, do not include fluorophore-quencher pairs, in which a quenching moiety appended to a nucleotide prevents fluorescence by resonance energy transfer from the fluorophore. Some quenching by the base, sugar, or phosphate in a nucleotide may occur with a fluorogenic label.

-

In certain embodiments, the label is destroyed (or rendered non detectable) once detected. One method for destroying the label is photobleaching. Another method is to wash out this label by opening the microreactors and allowing buffer exchange through fluid flow and diffusion.

-

Bulk nucleic acid sequencing reactions rely upon enzymatic amplification of nucleic acid molecules to generate large numbers of fluorescently labeled molecules for each sequenced base. The large number of labels detected relaxes constraints on the chemical stability, photostability, brightness, and protein-dye interactions, as well as spectral separation between different labels.

-

Nucleic acid sequencing reactions also typically occur in a narrow range of conditions in which the replicating catalyst, e.g., polymerase, and associated enzymes (such as alkaline phosphatase) operate optimally. These conditions vary considerably depending on the particular enzymes involved. One critical parameter with respect to fluorogenic label selection is the pH under which the sequencing reaction will take place (typically within the physiological pH range of 6 to 9), because the absorption and emission spectra of the product fluorophores are often strongly pH-dependent. For example, it is desirable for fluorogenic substrates that produce phenolic fluorophores to have pKa's below 7.

-

Below we list preferred criteria for fluorogenic labels for use in high-fidelity, fluorogenic sequencing:

-

1) No reactivity or detrimental interaction with buffer components, enzymes, nucleic acids, or other dyes or substrates.

-

Sequencing can involve a complicated set of proteins including nucleic acid replicating enzymes, activating enzymes to digest fluorogenic substrates resulting from the incorporation of labeled nucleotides (such as alkaline phosphatase), blocking proteins for surface passivation, and oxygen scavenger enzymes for mitigating photodamage. Nonspecific interactions between fluorogenic substrates/fluorophores with proteins can result in quenching via electron transfer, energy transfer, or chemical reactions that result in spectrally modified fluorophores. Such interactions can compromise nucleic acid sequencing by damaging the substrate, reducing fluorescence emission, or altering protein function. For example, many fluorophores have complicated interactions with reducing agents. In addition, proteins commonly have solvent exposed residues containing thiol moieties. The ground and excited states of several commonly used fluorogenic dyes such as resorufin and 7-hydroxy-9H-(1,3-dichloro-9,9-dimethylacridin-2-one) (DDAO) are susceptible to nucleophilic attack by thiols. Fluorescein analogs with certain patterns of halogenation are similarly vulnerable. Fluorogenic substrates may also be susceptible to nucleophilic attack by buffer components, despite the resistance of the corresponding fluorescent product. Fluorogenic substrates and fluorophores that react and interact minimally with the components of the sequence reaction are preferred for fluorogenic sequencing. Chemical modification can be rationally employed on the fluorogenic labels/fluorophores to impart resistance to these effects (see, e.g., U.S. Pat. Nos. 7,432,372, 6,162,931, and 6,229,055 and WO 2005/108994 A1).

-

2) Fluorogenic labels are preferably resistant to photodamage and preferably do not emit significantly in the detection band(s).

-

To maximize signal to noise of the method, fluorogenic molecules within the detection volume are preferably substantially non-fluorescent when exposed to the excitation wavelengths. Preferably, these fluorogenic molecules have a very small extinction coefficient at these excitation wavelengths, such that they do not absorb photons when excited. Alternately, the fluorogenic molecules may have measurable absorbance at the excitation wavelengths of the fluorescent label, but thermal relaxation is the dominant process moving the substrate from the excited state to the ground state, substantially eliminating the possibility of fluorescence emission. In another embodiment, the substrate may absorb appreciably at the excitation wavelengths of the fluorescent label but emit fluorescence that is spectrally separated from the fluorescence generated by the fluorescent label. It is preferable for the fluorogenic substrate not to absorb the excitation light significantly, to limit time spent in the excited state, reducing the potential for any excited-state chemistry or bleaching.

-

3) Preferably, fluorophores produce a high photon flux at visible wavelengths. Preferred fluorescent labels generate large photon fluxes (with high quantum efficiency) at wavelengths well-separated from the excitation wavelength and bleach into breakdown products that are substantially unreactive. In order to increase signal, triplet state quenchers, such as those described in US 2007/0161017 A1, may be used.

-

The presence of molecular oxygen in the reaction chamber can also bleach fluorophores, reducing the average total number of photons generated during detection. A variety of methods for eliminating molecular oxygen from a reaction sample (including enzymatic systems of catalase and glucose oxidase or protocatechuate 3,4-dioxygenase) are known in the art (see, e.g., US 2007/0161017 A1).

-

Transient interactions with a surface (e.g. the surface of the microreactor) or buffer components, such as proteins at high concentration in the sequencing mixture, may quench fluorescence, creating spurious signal variations. Because high protein concentration in solution can cause nonspecific quenching of fluorescence, an example of a protein-free system for reducing nonspecific adsorption to surfaces is also described herein.

-

Exemplary labels include resorufin and 91′-(1,3-dichloro-9,9-dimethylacridin-2-one) (DDAO). Additional labels are known in the art, e.g., in U.S. Pat. Nos. 7,041,812, 7,052,839, 7,125,671, 7,223,541, and 7,244,566.

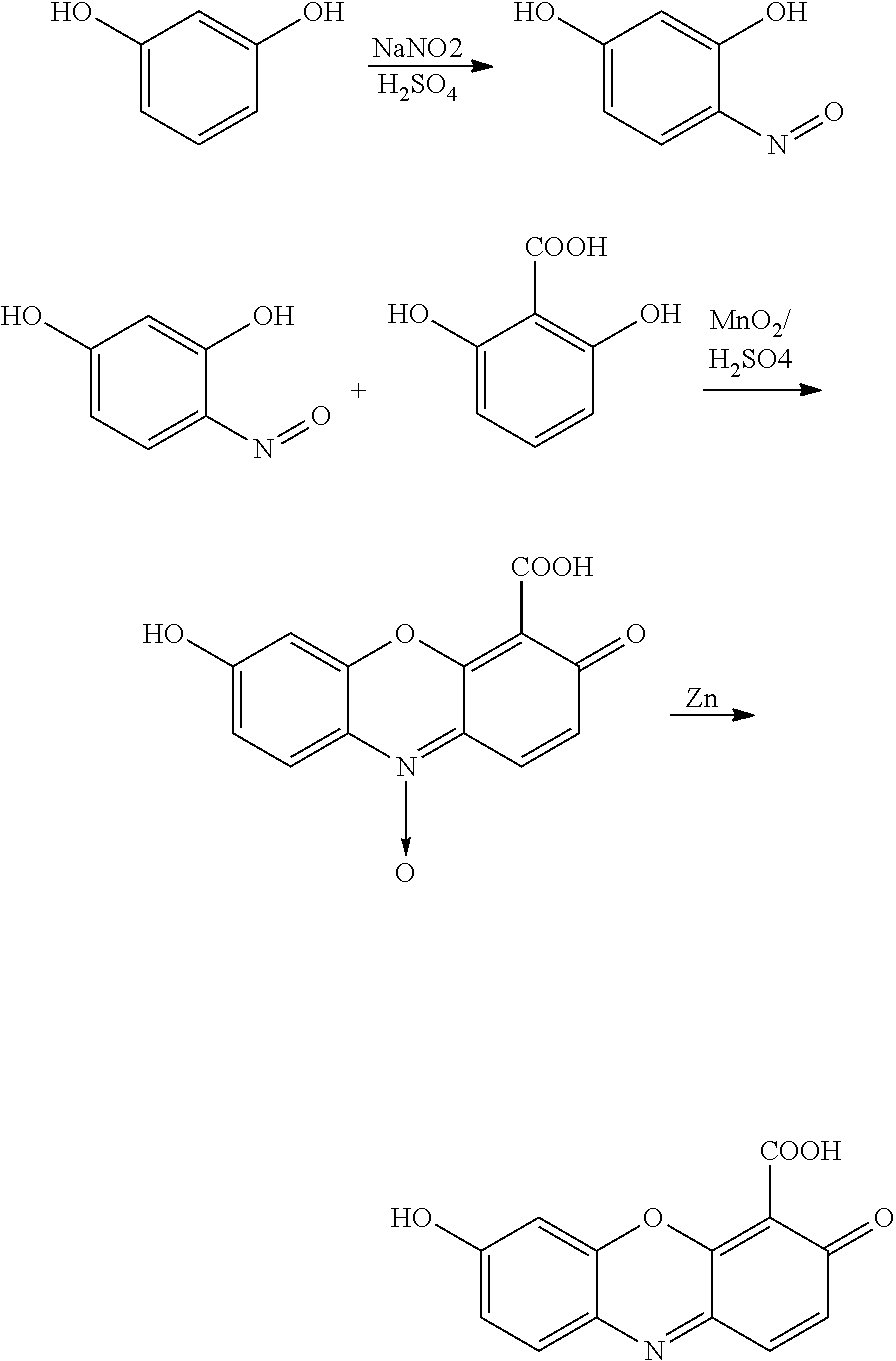

-

Previous embodiments of fluorogenic nucleic acid sequencing have relied on a relatively narrow class of fluorogenic dyes for labeling nucleotide substrates (e.g., U.S. 2004/015119 and U.S. Pat. No. 7,125,671). In particular, phenolic dyes such as fluoresceins, phenoxazines (such as resorufin), acridines (such as DDAO), and coumarins may be used in fluorogenic substrates. The chemistry of fluorogenic nucleic acid substrates based on phenolic dyes is relatively straightforward because the phenolic oxygen is esterified to a phosphate group. This substrate chemistry excludes the use of other potentially useful fluorogenic dyes such as those containing amines (e.g., rhodamine and its derivatives, cresyl violet, etc.). Once a DNA polymerase incorporates a labeled dNTP, cleaving between the α- and β-phosphates of the nucleotide, the liberated fluorophore becomes fluorescent, either directly upon cleavage from the dNTP, or after further enzymatic action of other enzymes (Sood et al. J. Am. Chem. Soc., 2005, 127, 2394-2395 and Kumar et al. Nucleotides, Nucleosides, and Nucleic Acids, 2005, 24, 401-408) (through a coupled enzyme assay discussed further below). These newly fluorescent molecules are then detected using standard fluorescence detection techniques (English et al. Nat. Chem. Biol., 2006, 2, 87-946) (such as total internal reflection fluorescence, epifluorescence, or confocal microscopy).

-

-

Resorufin is not fluorescent when conjugated to dNTPs, while for DDAO the fluorescence and absorption spectra change significantly when it is conjugated to dNTPs. Upon cleavage from the dNTP, e.g., through the action of DNA polymerase, these molecules still have phosphate groups covalently linked to the fluorophore, which must be removed before the molecule becomes fluorescent.

-

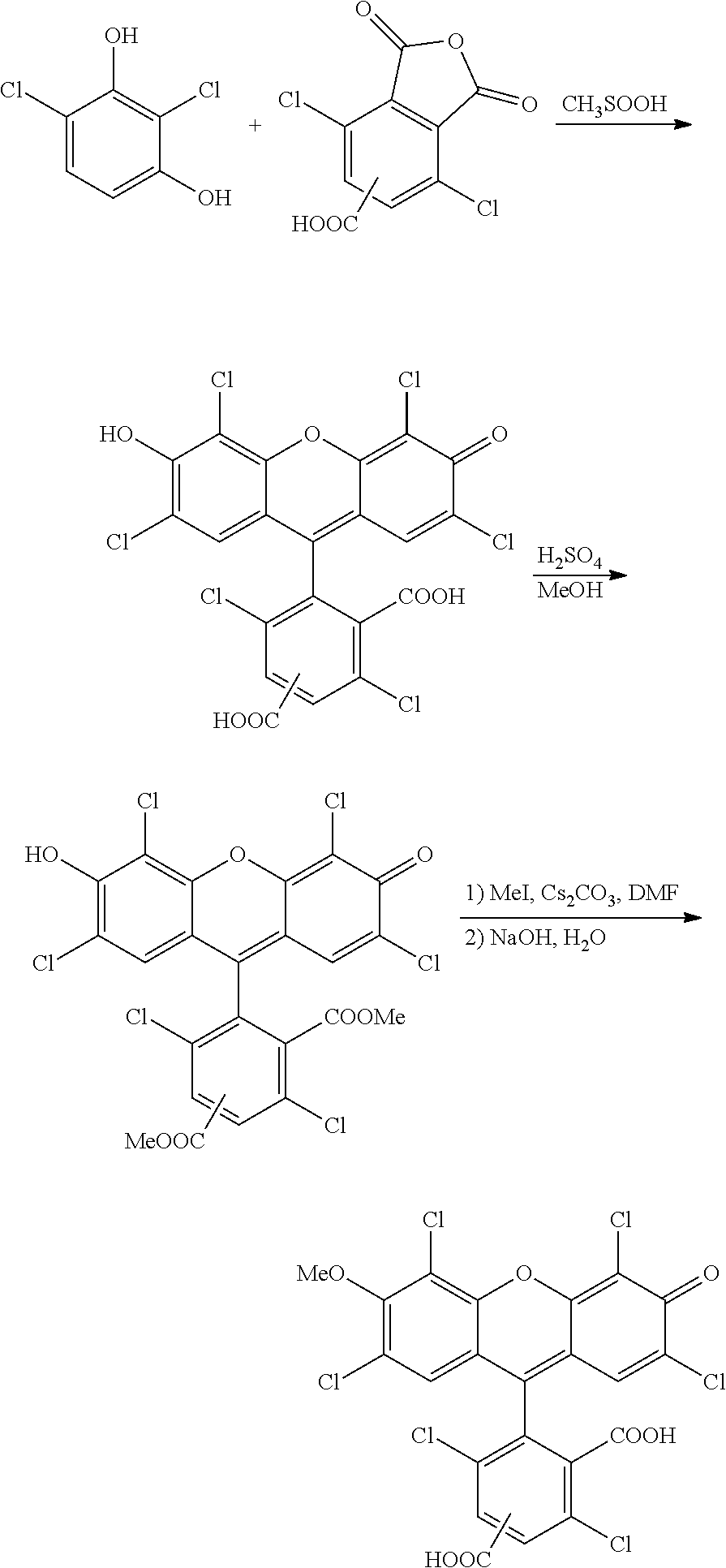

Additional labeled nucleotides employ a fluorescein-based fluorophore:

-

-

where R is a nucleoside base, as described herein, n is 0 to 4, and X is a blocking group that serves to minimize the fluorescence emission of the substrate molecule. This blocking group is, for example, an alkyl group (e.g., such as methyl, ethyl, propyl, isopropyl, and butyl), an acyl group (e.g., acetyl), an amide group (e.g., C(O)NRARB, where RA and RB are independently C1-C6 alkyl or RA and RB together for a 3-8-membered heterocycle, optionally containing additional nitrogen, oxygen, or sulfur atoms, e.g., morpholine), sulfonyl (e.g., SO2R, where R is C1-C6 alkyl), an alkyl group interrupted with one or more heteroatoms (e.g., O, N, S, or P), haloalkyl group (e.g., perfluorinated alkyl), cycloalkyl (e.g., with 3-6 ring carbons), carboxy substituted alkyl, sulfonyl substituted alkyl, or any other functional group that prevents the electronic structure of the attached oxygen from imparting significant fluorescence to the substrate molecule (see, e.g., WO 2005/108994). The functional groups R1-R10 are chosen to enhance the properties of the fluorogenic substrate and corresponding fluorophore to satisfy the requirements for nucleic acid sequencing described above. These groups may be selected from hydrogen, halogen (e.g., F or Cl), sulfonate (i.e., SO3H), carboxy, acyl, alkyl, alkoxy, alkylthio, aryl, heteroaryl (e.g., containing one or more O, N, or S), nitro, and hydroxyl (see also U.S. Pat. Nos. 7,432,372, 6,162,931, and 6,229,055 and WO 2005/108994 A1). Particular examples of fluorogenic nucleotide substrates with these modifications are as follows. Structures of fluorescein-based fluorogenic nucleotide substrates for fluorogenic nucleic acid sequencing where R is a nucleotide base, n is 0 to 4, and X is a blocking group designed to minimize the absorption and fluorescence emission of the fluorogenic substrate, and n is an integer between 0 and 4. A) Substrate based on 6-carboxyfluorescein (6-FAM). B) Substrate based on 6-carboxyhexachlorofluorescein (6-HEX). C) Substrate based on 6-carboxytetrachlorofluorescein (6-TET). D) Substrate based on 6-carboxy-4′,5′-dichloro-2′,7′-dimethoxyfluorescein (6-JOE). E) Substrate based on Oregon Green™ 488. F) Substrate based on Oregon Green™ 514. G) Substrate based on 2,7-dichlorofluorescein.

-

-

Another class of fluorogenic substrates has the general formula:

-

-

with R, X, and R1-R10 as described above. The fluorogenic dyes used in these substrates can be synthesized using methods known in the art (U.S. Pat. No. 6,130,101, U.S. 2005/0026235, and Pongev et al., Rus. J. Gen. Chem, 2001), and the corresponding substrates can be generated using the procedure described in WO 2010/017487.

-

A third class of fluorogenic compounds has the following structure:

-

Base-Sugar-Phosphate-[Self-reacting Component],

-

where Base is any nucleotide base as described herein, Sugar is any sugar or other such group in a nucleotide as described herein, Phosphate is a polyphosphate, and Self-reacting Component is a moiety that undergoes an intramolecular reaction upon cleavage of the phosphate to which it is connected to form a fluorophore. These compounds are substantially non-fluorescent at the wavelengths where the corresponding fluorophore emits and typically absorb very little at the absorption maximum of the corresponding fluorophore. The Self-reacting Component is of two forms. In one, this component includes a self-immolative linker conjugated to a fluorophore, wherein the conjugation renders the fluorophore substantially non-fluorescent. When the phosphate group is cleaved from the self-immolative linker, it spontaneously reacts, resulting in release of the fluorophore, which is fluorescent again. In another form, this component includes a proto-fluorophore, which is substantially nonfluorescent. Cleavage of the phosphate group from the proto-fluorophore results in an intramolecular reaction, e.g., lactonization, that forms a fluorophore. It will be understood that the compounds depicted above will be linked as is known in the art to produce a nucleotide, as defined herein, having a fluorogenic label.

-

An example of a fluorogenic substrate having a self-immolative linker is as follows:

-

-

where R1 is a nucleotide base, L is a self-immolative linker, n is an integer ranging from 0 to 4, and R2 is a fluorogenic moiety.

-

Self-immolative linkers are known in the art (see, e.g., Zhou et al., ChemBioChem, 2008, 9, 714-718; Levine et al., Molecules, 2008, 13, 204-211; Lavis et al., ChemBioChem, 2006, 7, 1151-1154; Richard et al., Bioconjugate Chemistry, 2008, 19, 1707-1718; U.S. 2005/0147997; and U.S. 2006/0003383). An example of a self-immolative linker is the trimethyl lock linker (Levine et al., Molecules, 2008, 13, 204-211 and Lavis et al., ChemBioChem, 2006, 7, 1151-1154):

-

-

where R is an enzyme substrate moiety (e.g., phosphate), and X—NH2 is a fluorophore. A fluorogenic nucleotide substrate having the trimethyl lock has the general structure:

-

-

One class of amine-containing fluorophores includes rhodamine derivatives, where the corresponding nucleotide substrate has the general structure:

-

-

where R is a nucleotide base, n is an integer ranging from 0 to 4, and X is a blocking group (as discussed above, e.g., C(O)-morpholinyl) that serves to minimize the fluorescence emission of the chromophore when it is conjugated to the substrate. The groups R1-R4 and R6-R11 are all hydrogen atoms in the case of rhodamine but can be modified to form derivatives with different chemical, spectral, and photophysical properties. R1-R4 and R6-R11 can be hydrogen, halogen (e.g., F or Cl), sulfonate, carboxy, acyl, alkyl, alkoxy, alkylthio, aryl, heteroaryl (e.g., containing one of O, N, or S), nitro, or hydroxyl, which may be substituted as described herein. Exemplary rhodamine dyes include rhodamine B, rhodamine 19, rhodamine 110, rhodamine 116, sulforhodamine B, and carboxyrhodamine.

-

Derivatives of oxazine dyes can also be employed in a similar fashion:

-

-

where R is a nucleoside base, n is an integer between 0 and 4, X is a blocking group (as discussed above) that serves to minimize the fluorescence emission of the chromophore when it is conjugated to the substrate, and R1-R5 and R7 represent functional groups as discussed for rhodamine. An exemplary oxazine dye is 3-imino-3H-phenoxazin-7-amine (oxazine).

-

Benzophenoxazine dyes, such as cresyl violet and its derivates, can also be employed:

-

-

where R is a nucleoside base, n is an integer between 0 and 4, X is a blocking group (as discussed above) that serves to minimize the fluorescence emission of the chromophore when it is conjugated to the substrate, and R1-R8 represent the functional groups as discussed for rhodamine. An example of a benzophenoxazine dye is 9-imino-9H-benzo[a]phenoxazine-5-amine.

-

These compounds will be incorporated by a nucleic acid replicating catalyst into a nucleic acid and yield a polyphosphate chain terminated by the self-immolative linker conjugated to the fluorophore:

-

-

where X—NH2 is a fluorophore. A phosphatase can then be used to cleave the polyphosphate chain leading to the generation of the following species:

-

-

resulting in the generation of an amine-containing fluorophore.

-

The Self-reacting Component may also result in spontaneous generation of a fluorophore, e.g., through cyclization reactions in response to enzymatic digestion. Fluorogenic nucleotide substrates based on self-generating fluorophores with the general structure given below can be used for nucleic acid sequencing:

-

-

where R1 is a nucleotide base, n is an integer between 0 and 4, and R2 is a moiety that undergoes an intramolecular reaction to form a fluorophore upon removal of the phosphate. An example of these compounds results in generation of a coumarin fluorophore (see, e.g., Wang et al., Methods in Molecular Medicine, 1998, 23, 71; Wang et al., Bioorganic and Medicinal Chemistry Letters, 1996, 6, 945-950; and U.S. Pat. No. 6,214,330):

-

-

where R represents any suitable substituent for the amine leaving group. Examples of structures of coumarin-generating fluorogenic nucleotide substrates for fluorogenic nucleic acid sequencing where R1 is a nucleotide base are A) substrate based on 7-hydroxycoumarin; B) substrate based on coumarin 102; C) substrate based on 6,8-difluoroumbelliferone; and D) substrate based on coumarin.

-

-

Additional fluorogenic nucleotide substrates are described in U.S. 2010/0036110 and WO 2010/017487, both of which are incorporated by reference. It will also be understood that the sugar moiety depicted in any of the above structures, i.e., 2′-deoxyribose, may be replaced with any other appropriate group, as described herein (for example, the nucleotide may be a ribonucleotide).

Microreactors

-

Massively parallel nucleic acid sequencing requires a method of capturing, spatially arranging, and, in most cases, amplifying a target nucleic acid sample for sequencing. The microreactor array offers not only a reaction confinement method for fluorogenic sequencing but also a natural platform for nucleic acid capture and amplification. Accordingly, the reagents for sequencing and/or amplification of nucleic acids are disposed in a microreactor. Exemplary microreactors hold volumes of 0.0001 fL, to 100000 fL, although larger volumes are possible. Conducting fluorogenic sequencing and/or amplification in a microreactor imparts several advantages as described herein. A single microreactor may be employed, or a device having numerous microreactors may be employed, e.g., a solid substrate having 10, 50, 100, 500, or more microreactors arranged as desired, e.g., an ordered array.

-

For sequencing, an ensemble of identical nucleic acids (generally clonally amplified from a single nucleic acid) is immobilized in each microreactor. The activating catalyst, or replicating catalyst may also be immobilized within the microreactor. Methods for immobilizing nucleic acids or catalysts are well known in the art and include biotin-streptavidin, antibody-antigen interactions, covalent attachment, or attachment to complementary nucleic acid sequences.

-

A target nucleic acid, activating catalyst, or replicating catalyst may be immobilized to beads (magnetic, paramagnetic, polystyrene, glass, etc.) using immobilization techniques well known in the art. When the nucleic acid is immobilized to a bead, these beads can then be trapped in microreactors, and the nucleic acid can be directly amplified or sequenced according to the invention. Affinity capture beads may also be used to capture relevant nucleic acids, e.g., eukaryotic RNA can be specifically extracted by annealing poly-dT coated beads to the poly-A tail of the mRNAs.

-

In order to trap a population of substantially identical nucleic acids within a microreactor, spatial patterning of the microreactor with non-covalent or covalent reactive groups may be employed so that nucleic acid binds only to the interior of the microreactor.

-

Materials that are useful in forming the microreactors include glass, glass with surface modifications, silicon, metals, semiconductors, high refractive index dielectrics, crystals, gels, lipids, and polymers (e.g., poly(dimethylsiloxane) (PDMS)). Mixtures of materials may also be employed.

-

An exemplary method of fabricating microreactors in PDMS is described herein (FIG. 2). Other materials for microreactor fabrication include polytetrafluoroethylene, perfluoropolyethers, and parylene. Additionally, lipid vesicles can be generated using standard lipid extrusion techniques (Okumus et al. Biophys. J. 2004, 87(4), 2798-2806) and used to confine the reaction. Another method of generating microreactors is the creation of an emulsion of the reaction mixture in an immiscible solvent such as mineral oil or silicon oil. These and other methods for manufacturing microreactors are known in the art, e.g., U.S. Pat. Nos. 7,081,269, 6,225,109, 6,225,109, and 6,585,939.

-

An ensemble of substantially identical target nucleic acids (or replicating catalyst) can be delivered to a microreactor using methods known in the art. One method employs emulsion PCR to generate a population or colony of substantially identical nucleic acids on a bead (Dressman (2003) Proc. Natl. Acad. Sci. USA 100:8817; Brenner et al. (2000) Nat. Biotech. 18:630). Another method for delivery is to provide a dilute solution of nucleic acid so that each microreactor, on average, holds fewer than one molecule. Using this approach some microreactors will have no target nucleic acid, some will have a single target nucleic acid, and a very small number will have more than one. As further described herein, single molecules of nucleic acid can be delivered to microreactors via beads. Then solid-phase PCR, rolling circle amplification, or other amplification technique, can be conducted on these immobilized single molecules, building up a population or colony of substantially identical nucleic acids. When employing beads, amplification may occur with or without the bead in the microreactor. Fluorophores and fluorogenic labels are preferably trapped in the microreactor during the course of a sequencing run. If either the generated fluorophore or the fluorogenic-label escapes the reactor, then information regarding the sequencing of the nucleic acid may be lost. Materials and methods for retaining fluorophores and fluorogenic substrates within a reactor are described herein.

-