US6822738B1 - Spectroscopic rotating compensator ellipsometer system with pseudo-achromatic retarder system - Google Patents

Spectroscopic rotating compensator ellipsometer system with pseudo-achromatic retarder system Download PDFInfo

- Publication number

- US6822738B1 US6822738B1 US10/034,800 US3480001A US6822738B1 US 6822738 B1 US6822738 B1 US 6822738B1 US 3480001 A US3480001 A US 3480001A US 6822738 B1 US6822738 B1 US 6822738B1

- Authority

- US

- United States

- Prior art keywords

- compensator

- sample

- wavelength

- zero

- wavelengths

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime, expires

Links

- 238000000034 method Methods 0.000 claims abstract description 107

- 238000004458 analytical method Methods 0.000 claims abstract description 12

- 239000000463 material Substances 0.000 claims description 247

- 230000005670 electromagnetic radiation Effects 0.000 claims description 113

- 238000011835 investigation Methods 0.000 claims description 94

- 239000011159 matrix material Substances 0.000 claims description 59

- 238000013178 mathematical model Methods 0.000 claims description 57

- 230000003287 optical effect Effects 0.000 claims description 34

- 239000000835 fiber Substances 0.000 claims description 25

- 230000010287 polarization Effects 0.000 claims description 24

- 230000003993 interaction Effects 0.000 claims description 23

- 238000012546 transfer Methods 0.000 claims description 22

- 238000013459 approach Methods 0.000 claims description 19

- 238000010606 normalization Methods 0.000 claims description 19

- 230000028161 membrane depolarization Effects 0.000 claims description 17

- 230000001939 inductive effect Effects 0.000 claims description 14

- 101000969581 Homo sapiens MOB kinase activator 1A Proteins 0.000 claims description 11

- 102100021437 MOB kinase activator 1A Human genes 0.000 claims description 11

- 238000004364 calculation method Methods 0.000 claims description 11

- 101001115732 Homo sapiens MOB kinase activator 2 Proteins 0.000 claims description 10

- 102100025000 MOB kinase activator 2 Human genes 0.000 claims description 10

- 239000002344 surface layer Substances 0.000 claims description 9

- 238000010276 construction Methods 0.000 claims description 8

- 229920000642 polymer Polymers 0.000 claims description 7

- 101100257994 Arabidopsis thaliana FAB2 gene Proteins 0.000 claims description 6

- 239000006185 dispersion Substances 0.000 claims description 6

- 230000002688 persistence Effects 0.000 claims description 5

- 239000013078 crystal Substances 0.000 claims description 2

- 230000001360 synchronised effect Effects 0.000 claims description 2

- 241000702021 Aridarum minimum Species 0.000 claims 4

- 241000163925 Bembidion minimum Species 0.000 claims 4

- 238000012544 monitoring process Methods 0.000 abstract 1

- 239000000523 sample Substances 0.000 description 166

- 230000006870 function Effects 0.000 description 48

- 229910052698 phosphorus Inorganic materials 0.000 description 15

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 15

- 230000000694 effects Effects 0.000 description 13

- 238000000572 ellipsometry Methods 0.000 description 12

- 238000011156 evaluation Methods 0.000 description 12

- 230000014509 gene expression Effects 0.000 description 10

- 235000012239 silicon dioxide Nutrition 0.000 description 10

- 239000010453 quartz Substances 0.000 description 9

- 230000005540 biological transmission Effects 0.000 description 7

- 230000009286 beneficial effect Effects 0.000 description 6

- 230000008901 benefit Effects 0.000 description 6

- 238000012937 correction Methods 0.000 description 5

- 235000021251 pulses Nutrition 0.000 description 5

- 230000035945 sensitivity Effects 0.000 description 5

- 102100038028 1-phosphatidylinositol 3-phosphate 5-kinase Human genes 0.000 description 4

- 101001025044 Homo sapiens 1-phosphatidylinositol 3-phosphate 5-kinase Proteins 0.000 description 4

- 238000003491 array Methods 0.000 description 4

- 229910052785 arsenic Inorganic materials 0.000 description 4

- 229910052799 carbon Inorganic materials 0.000 description 4

- 239000013256 coordination polymer Substances 0.000 description 4

- 238000013461 design Methods 0.000 description 4

- 239000010408 film Substances 0.000 description 4

- 238000005259 measurement Methods 0.000 description 4

- 229910052757 nitrogen Inorganic materials 0.000 description 4

- 239000012925 reference material Substances 0.000 description 4

- 239000000758 substrate Substances 0.000 description 4

- 229910052717 sulfur Inorganic materials 0.000 description 4

- 101150032645 SPE1 gene Proteins 0.000 description 3

- 101100233725 Saccharomyces cerevisiae (strain ATCC 204508 / S288c) IXR1 gene Proteins 0.000 description 3

- 101100291452 Saccharomyces cerevisiae (strain ATCC 204508 / S288c) MMS1 gene Proteins 0.000 description 3

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 3

- 230000008859 change Effects 0.000 description 3

- 239000002131 composite material Substances 0.000 description 3

- 238000009795 derivation Methods 0.000 description 3

- 230000009977 dual effect Effects 0.000 description 3

- 239000010445 mica Substances 0.000 description 3

- 229910052618 mica group Inorganic materials 0.000 description 3

- 101150028225 ordA gene Proteins 0.000 description 3

- 239000013074 reference sample Substances 0.000 description 3

- 229910052710 silicon Inorganic materials 0.000 description 3

- 239000010703 silicon Substances 0.000 description 3

- 239000000377 silicon dioxide Substances 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 239000010409 thin film Substances 0.000 description 3

- 101100162205 Aspergillus parasiticus (strain ATCC 56775 / NRRL 5862 / SRRC 143 / SU-1) aflI gene Proteins 0.000 description 2

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 2

- UHYPYGJEEGLRJD-UHFFFAOYSA-N cadmium(2+);selenium(2-) Chemical compound [Se-2].[Cd+2] UHYPYGJEEGLRJD-UHFFFAOYSA-N 0.000 description 2

- 238000004422 calculation algorithm Methods 0.000 description 2

- 238000012512 characterization method Methods 0.000 description 2

- 229910052681 coesite Inorganic materials 0.000 description 2

- 229910052906 cristobalite Inorganic materials 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 2

- 230000002999 depolarising effect Effects 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 230000010354 integration Effects 0.000 description 2

- 239000010410 layer Substances 0.000 description 2

- 239000013307 optical fiber Substances 0.000 description 2

- 230000005855 radiation Effects 0.000 description 2

- 238000001228 spectrum Methods 0.000 description 2

- 229910052682 stishovite Inorganic materials 0.000 description 2

- XOLBLPGZBRYERU-UHFFFAOYSA-N tin dioxide Chemical compound O=[Sn]=O XOLBLPGZBRYERU-UHFFFAOYSA-N 0.000 description 2

- 229910052905 tridymite Inorganic materials 0.000 description 2

- WUPHOULIZUERAE-UHFFFAOYSA-N 3-(oxolan-2-yl)propanoic acid Chemical compound OC(=O)CCC1CCCO1 WUPHOULIZUERAE-UHFFFAOYSA-N 0.000 description 1

- 238000012935 Averaging Methods 0.000 description 1

- 241001441571 Hiodontidae Species 0.000 description 1

- 244000046052 Phaseolus vulgaris Species 0.000 description 1

- 235000010627 Phaseolus vulgaris Nutrition 0.000 description 1

- UCKMPCXJQFINFW-UHFFFAOYSA-N Sulphide Chemical compound [S-2] UCKMPCXJQFINFW-UHFFFAOYSA-N 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- 230000008033 biological extinction Effects 0.000 description 1

- 229910052980 cadmium sulfide Inorganic materials 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 238000004590 computer program Methods 0.000 description 1

- 238000007405 data analysis Methods 0.000 description 1

- 238000012217 deletion Methods 0.000 description 1

- 230000037430 deletion Effects 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 description 1

- 238000012417 linear regression Methods 0.000 description 1

- 239000004973 liquid crystal related substance Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000037361 pathway Effects 0.000 description 1

- 239000002861 polymer material Substances 0.000 description 1

- 230000000063 preceeding effect Effects 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 238000000611 regression analysis Methods 0.000 description 1

- 230000000717 retained effect Effects 0.000 description 1

- 238000005070 sampling Methods 0.000 description 1

- 150000003346 selenoethers Chemical class 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 229960001866 silicon dioxide Drugs 0.000 description 1

- 230000003595 spectral effect Effects 0.000 description 1

- 238000000391 spectroscopic ellipsometry Methods 0.000 description 1

- 238000004611 spectroscopical analysis Methods 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

- 230000000153 supplemental effect Effects 0.000 description 1

- -1 surface roughness Substances 0.000 description 1

- 230000003746 surface roughness Effects 0.000 description 1

- 230000009897 systematic effect Effects 0.000 description 1

- 239000011800 void material Substances 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01J—MEASUREMENT OF INTENSITY, VELOCITY, SPECTRAL CONTENT, POLARISATION, PHASE OR PULSE CHARACTERISTICS OF INFRARED, VISIBLE OR ULTRAVIOLET LIGHT; COLORIMETRY; RADIATION PYROMETRY

- G01J3/00—Spectrometry; Spectrophotometry; Monochromators; Measuring colours

- G01J3/28—Investigating the spectrum

- G01J3/447—Polarisation spectrometry

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01J—MEASUREMENT OF INTENSITY, VELOCITY, SPECTRAL CONTENT, POLARISATION, PHASE OR PULSE CHARACTERISTICS OF INFRARED, VISIBLE OR ULTRAVIOLET LIGHT; COLORIMETRY; RADIATION PYROMETRY

- G01J4/00—Measuring polarisation of light

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N21/00—Investigating or analysing materials by the use of optical means, i.e. using sub-millimetre waves, infrared, visible or ultraviolet light

- G01N21/17—Systems in which incident light is modified in accordance with the properties of the material investigated

- G01N21/21—Polarisation-affecting properties

- G01N21/211—Ellipsometry

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01J—MEASUREMENT OF INTENSITY, VELOCITY, SPECTRAL CONTENT, POLARISATION, PHASE OR PULSE CHARACTERISTICS OF INFRARED, VISIBLE OR ULTRAVIOLET LIGHT; COLORIMETRY; RADIATION PYROMETRY

- G01J3/00—Spectrometry; Spectrophotometry; Monochromators; Measuring colours

- G01J3/28—Investigating the spectrum

- G01J2003/2866—Markers; Calibrating of scan

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01J—MEASUREMENT OF INTENSITY, VELOCITY, SPECTRAL CONTENT, POLARISATION, PHASE OR PULSE CHARACTERISTICS OF INFRARED, VISIBLE OR ULTRAVIOLET LIGHT; COLORIMETRY; RADIATION PYROMETRY

- G01J3/00—Spectrometry; Spectrophotometry; Monochromators; Measuring colours

- G01J3/02—Details

- G01J3/0205—Optical elements not provided otherwise, e.g. optical manifolds, diffusers, windows

- G01J3/0224—Optical elements not provided otherwise, e.g. optical manifolds, diffusers, windows using polarising or depolarising elements

Definitions

- Spectroscopic Ellipsometer Systems utilize a Source which simultaneously provides a plurality of Wavelengths, which Source can be termed a “Broadband” Source of Electromagnetic radiation.

- the disclosed invention then has Priority to simultaneous use of 2 OMEGA and 4 OMEGA signals provided from a detector in a spectroscopic rotating compensator ellipsometer system which utilizes “Other-Than-Substantially Non-Achromatic” Compensators, namely “Substantially-Achromatic” or “Pseudo-Achromatic” Compensators, to characterize samples, emphasis added.

- the invention provides a Spectroscopic Rotating Compensator Ellipsometer System which comprises a Psuedo-Achromatic Compensator, and discloses alternative use of D.C. and A.C data normalization in various calibration steps, as well as use of un-normalized signals in determining Reflectance.

- the preferred invention Compensator provides that two of said per se., or effective Zero-Order Waveplate Compensators, be oriented with respect to one another such that the fast axes of the First per se. or effectively Zero-Order Compensator are rotated with respect to the Second per se. or effectively Zero-Order Compensator, away from zero or ninety degrees, and typically within some range around a nominal forty-five (45) degrees.

- Compensators are specifically designed to provide retardation values which never equal or exceed one-hundred-eighty (180) degrees, or even one-hundred-thirty-five (135) degrees at any utilized wavelength. It is noted that this is in direct contrast to the practice of Therma-wave rotating compensator systems as described in U.S. Pat. Nos. 6,320,657 B1, 6,134,012, 5,973,787 and 5,877,859 to Aspnes, wherein large chromaticities, (eg. at least 90-180 degrees retardation range over a range of wavelengths), in compensator systems utilized cover a range of retardations which the Specifications indicate can include 180 degrees therewithin, emphasis added.

- a compensator disposed in the path of the light beam, said compensator for inducing phase retardations in the polarization state of the light beam, said compensator having characteristics selected from the group consisting of:

- said detector means generating a time varying intensity output signal simultaneously comprising 2 ⁇ and 4 ⁇ component signals;

- the disclosed invention system preferably utilizes at least one compensator means which is described as a selection from the group consisting of:

- Spectroscopic Rotating Compensator Material System Investigation System (ie. Spectroscopic Ellipsometer) is used to investigate a Material System, (ie. Sample), present on said Stage for Supporting a Material System, (Sample), said Analyzer Means and Polarizer Means are maintained essentially fixed in position and at least one of said at least one Compensator(s) Means is/are caused to continuously rotate while a Polychromatic, (Broadband), Beam of Electromagnetic Radiation produced by said Source of a Polychromatic Beam of Electromagnetic Radiation is caused to pass through said Polarizer and said Compensator Means.

- Spectroscopic Rotating Compensator Material System Investigation System ie. Spectroscopic Ellipsometer

- detector means that measure the intensity of the beam after the interaction with the analyzer means at a plurality of wavelengths across the wavelength range of at least 200 to 800 nm;

- effective polarizer means azimuthal angle orientation

- analyzer means azimuthal angle orientation

- the Calibration Parameter containing Mathematical Equation provides a functional relationship, and, it is noted, can even be a constant value over a range of, for instance, Wavelengths and/or Polarizer Azimuthal Angle settings). (Note, said parameterized approach to mathematical regression based calibration parameter evaluation is better described supra herein under the Headings GLOBAL REGRESSION MODES 1, 2 and 3).

- Eq. 8 is a truncated Fourier Series, and could include additional, higher harmonic terms).

- Said Data Set can be obtained with the Ellipsometer in Material System, (Sample), present or Straight-through configuration, although some benefits are realized when a Material System, (Sample), is utilized, (discussed supra herein).

- the disclosed invention can be practiced utilizing Multiple-Data Sets.

- the Regression based Calibration procedure of the disclosed invention requires that an at least Two (2) Dimensional Data Set be experimentally obtained.

- said Two (2) Dimensional Data Set has as Independent Variables, Polarizer, (where the Rotating Compensator is placed after a Material System, (Sample)), Azimuthal Angle, and Wavelength.

- Polarizer where the Rotating Compensator is placed after a Material System, (Sample)

- Azimuthal Angle e.g., a Rotating Compensator is placed before a Material System, (Sample)

- N (fn(ALPHA 2 , BETA 2 , ALPHA 4 , BETA 4 ))/D.C.;

- a polychromatic beam of electromagnetic radiation produced by said broadband electromagnetic radiation source means of a polychromatic beam of electromagnetic radiation to pass through said polarizer means, interact with a material system (sample) caused to be in the path thereof, pass through said analyzer means, and interact with said dispersive optics such that a multiplicity of essentially single wavelengths are caused to simultaneously enter a corresponding multiplicity of detector elements in said at least one detector system, with said polychromatic beam of electromagnetic radiation also being caused to pass through said compensator(s) means positioned at a location selected from the group consisting of: (before said stage for supporting a material system, and after said stage for supporting a material system, and both before and after said stage for supporting a material system);

- M_actual ⁇ _compensator [ ⁇ 1 0 0 0 0 1 - c 0 0 0 0 cos ⁇ ⁇ ⁇ ⁇ ( 1 - b ) sin ⁇ ⁇ ⁇ ⁇ ( 1 - b ) 0 0 - sin ⁇ ⁇ ⁇ ⁇ ( 1 - b ) cos ⁇ ⁇ ⁇ ⁇ ( 1 - b ) ] 65

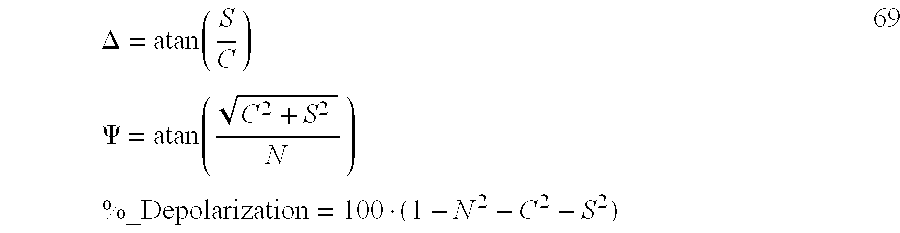

- Analyzer Azimuth ‘A’ is set to forty-five (45) degrees, and they can be calculated without even measuring the D.C. component of the signal, although the D.C. component remains necessary to enable calculating Depolarization, (as in Eq.

- ⁇ I ⁇ I 0 ⁇ ( D ⁇ ⁇ C + a2 ⁇ cos ⁇ ( 2 ⁇ ⁇ ⁇ ⁇ t ) + b2 ⁇ sin ⁇ ( 2 ⁇ ⁇ ⁇ ⁇ t ) + ⁇ a4 ⁇ cos ⁇ ( 4 ⁇ ⁇ ⁇ ⁇ t ) + b4 ⁇ sin ⁇ ( 4 ⁇ ⁇ ⁇ ⁇ t ) )

- At least one of said at least two, at least one-dimensional data set(s) being obtained utilizing one material system (MS) placed on said stage (STG) for supporting a material system (MS), and at least one of said at least two at least one-dimensional data set(s) being obtained utilizing one material system (MS) placed on said stage (STG) for supporting a material system (MS); and

- FIG. 7 demonstrates a “Straight-through” configuration of a Spectroscopic Rotating Compensator Material System Investigation System.

- FIG. 8 a shows lined diffraction grating dispersion Optics geometry.

- FIG. 9 b shows a Fiber Optic which is essentially circular shaped along the entire length thereof, and which provides input to a “Slit” per se.

- FIG. 9 f demonstrates construction of a Zero-Order Quartz Waveplate from two Multiple Order waveplates.

- FIGS. 9 g 1 , 9 h and 9 i demonstrates construction of a preferred compensator system constructed from first and second effective Zero-Order Waveplates, each of which effective Zero-Order Waveplates is a constructed composite of two Multiple Order waveplates, the fast axes of which at least two composite effective Zero-Order Waveplates are oriented away from zero or ninety degrees, and at a nominal forty-five degrees, with respect to one another.

- Optional additional third element(s) are indicated by dashed lines.

- FIG. 9 g 2 shows three Zero Order Plates are contacted to one another instead of having space thereinbetween.

- Three element Compensators configured as suggested by FIGS. 9 g 1 , 9 g 2 and 9 j can comprise a “Psuedo Achromatic” which can provide Retardation vs. Wavelength characteristics such as those presented in FIG. 10 g 2 .

- FIG. 9 j demonstrates functional construction of another preferred compensator system constructed from first and second actual per se.

- Zero-Order Waveplates each of which actual per se.

- Zero-Order Waveplate is an effective signle plate, the fast axes of which at least two composite actual per se.

- Zero-Order Waveplates are oriented away from zero or ninety degrees, and at a nominal forty-five degrees, with respect to one another.

- FIG. 9 l shows a “polka-dot” beam splitter.

- FIG. 10 a shows a plot of a compensator retardation characteristic which depends as (1/wavelength), (dashed line), as well as a compensator charactristic, (solid line).

- FIGS. 10 f and 10 g 1 show that changing waveplate selection for a FIG. 9 g 1 compensator configuration, and the angle between fast axes thereof, provides alternative retardation plots over various wavelength ranges.

- FIG. 10 g 2 shows retardation vs. wavelength for a three (3) Zero Order plate compensator.

- the retardation varies between about 47 degrees and 130 degrees over a wavelength range of 190 to 1700 nm.

- Said three (3) element compensator comprises a 422 nm quartz Zero Order waveplate sandwiched by two 633 nm quartz Zero Order waveplates.

- Rotating Compensator Ellipsometer uses a “Stepper Motor” to cause Compensator rotation, and a common signal synchronizes both the Compensator and Detector.

- An alternative technique is to use a signal derived from the motor to synchronize the detector. It is further noted that fixing the Polarizer Means (P) and Analyzer Means (A) in use provides another benefit in that polarization state sensitivity to input and output optics during data acquisition is essentially non-existent. This allows use of Optic Fibers, Mirrors, Beam Splitters, Lenses etc. for input/output.

- FIG. 2 also shows the presence of a Beam Splitter (BS) and a Cross Hair containing Reticule (CH) in the Detector Elements (DE's) containing Photo Array Detector System (DET). If the Beam Splitter (BS), the Dispersive Optics (DO), the Focusing Element (FE), the Detector Elements (DE's) containing Photo.

- BS Beam Splitter

- DO Dispersive Optics

- FE Focusing Element

- DE's Detector Elements

- the fast axes (FAA 2 ) & (FAB 2 ) of said second effective Zero-Order Waveplate (ZO 2 ) are oriented away from zero or ninety degrees, (eg. in a range around a nominal forty-five degrees such as between forty and fifty degrees), with respect to the fast axes (FAA 1 ) & (FAB 1 ) of said first effective Zero-Order Waveplate (ZO 1 ).

- 9 g 1 is a cross-sectional side view of a preferred compensator (PC) constructed from a first effective zero-order plate (ZO 1 ) which is constructed from two multiple order plates (MOA 1 ) and (MOB 1 ), and a second effective zero-order plate (ZO 2 ) which is constructed from two multiple order plates (MOA 2 ) and (MOB 2 ).

- An entered electromagnetic beam (EMBI) emerges as electromagnetic beam (EMBO) with a retardation entered between orthogonal components thereof with a Retardation vs. Wavelength such as demonstrated in FIGS. 15 a - 15 e.

- FIGS. 9 h and 9 i are views looking into the left and right ends of the preferred Compensator Means (PC) as shown in FIG.

- FIG. 9 g 1 show that the Fast Axes (FAA 2 ) and (FAB 2 ) of the second effective Zero-Order Waveplate (ZO 2 ) are rotated away from zero or ninety degrees and are ideally oriented at forty-five degrees, with respect to the Fast Axes (FAA 1 ) & (FAB 1 ) of the first effective Zero-Order Waveplate (ZO 1 ).

- the fast axis (FAA 1 ) of the first effective Zero-Order Waveplate (ZO 1 ) is shown as a dashed line in FIG. 9 i, for reference).

- FIG. 9 j demonstrates functional construction of another preferred compensator which is constructed from two per se.

- a compensator means system can be comprised of at least one Zero-Order waveplate and at least one effectively Zero-Order waveplate in combination, as well as combinations comprised of two actual Zero-Order waveplates or two effectively Zero-Order waveplates.

- a compensator can comprise more than two Zero-Order waveplate and/or effectively Zero-Order waveplates.

- FIGS. 9 g 1 and 9 j demonstrate in dashed lines the presence of additional Zero-Order waveplate and/or effectively Zero-Order waveplates. It is specifically noted that the dashed lines in FIG. 9 g 1 can represent a true single plate Zero-Order waveplate and the dashed lines in FIG.

- a preferred disclosed invention embodiment comprises at least one of said at least one compensator means (C) (C′) (C′′), which is selected from the group consisting of:

- said effective zero-order wave plate, ((ZO 2 ) or (ZO 1 )) being comprised of two multiple order waveplates which are combined with the fast axes thereof oriented at a nominal ninety degrees to one another, the fast axes of the multiple order waveplates in said effective zero-order wave plate, ((ZO 2 ) or (ZO 1 )), being rotated to a position away from zero or ninety degrees with respect to the fast axis of the zero-order waveplate, ((MOA) or (MOB));

- a Compensator Means (C), (C′), (C′′) utilized therein can provide a Retardance which varies with Wavelength and still be usable.

- the Rotating Compensator Material System Investigation System can also, of course, be Calibrated utilizing more than one Data Set and such a procedure is reported in U.S. Pat. No. 5,706,212, wherein a Rotating Compensator Material System Investigation System utilized in the Infra-red band of wavelengths, requires that two (2) Data Sets be present, (eg. selected with the Rotating Compensator Material System Investigation System oriented in a manner selected from the group: (“Straight-Through”, “Material System, (Sample), Present”, “Alternative Material System, (Sample), Present”)). Both Data Sets are simultaneously utilized in a Regression Procedure to evaluate numerous Calibration Coefficients in a Mathematical Model which is described in the 212 Patent.

- a second data set can be obtained utilizing a sample which provides a large Ellipsometric PSI value, and an Ellipsometric DELTA value of between thirty (30) and one-hundred-fifty (150) degrees. Internal reflections from the hypotenuse of a right angle prism, either uncoated or coated with aluminum, or an optically thick metallic film, will provide such characteristics.

- FIGS. 1, 3 , 4 and 5 demonstrate sample present data set gathering configurations of a Rotating Compensator Ellipsometer System.

- a third data set can be obtained with the ellipsometer system configured in a “straight-through” configuration, (see FIG. 7 ), wherein the effective sample PSI is forty-five (45) degrees and the effective sample DELTA is zero (0.0) degrees.

- Preferred calibration procedure practise provides that data be normalized to A.C. where determining compensator means retardation (R), polarizer means azimuth (P) and compensator means fast axis azimuth (C) are fit, and that data be normalized to D.C where optical element Depolarization/Meuller Matrix values are fit.

- FIG. 5 shows that Wavelengths in said Orders (+ORD 2 , +ORD 1 , ⁇ ORD 1 and ⁇ ORD 2 ) can be intercepted by Detector elements (DE's) in Photo Arrays (PA).

- DE's Detector elements

- PA Photo Arrays

- FIG. 5 also shows the presence of Filters (F 1 ). It is noted that Wavelengths for adjacent Orders overlap, and said Filters (F 1 ) allow a user to pass only desired Wavelengths, as well as reduce background radiation entry to Photo Arrays (PA's). Typically a Focusing Element is not present in a FIG. 5 embodiment.

- FIG. 10 b shows calculated retardation vs. wavelength curves for two compensators which demonstrate (1/wavelength) retardation characterics, (long and short dashed lines), and the retardation curve, (solid line), of an assembly configuration as demonstrated in FIG. 9 g 1 which is arrived at by combining said two retarders with a 45 degree angle between the fast axes thereof.

- FIGS. 10 d and 10 e show results calculated for a compensator means as demonstrated in FIG. 9 g 1 , wherein one waveplate is selected at 266 NM and the other at 633 NM., and wherein the fast axes are oriented at 45 degrees with respect to one another.

- the wavelength range is from 190 to 730 NM, (ie. deep UV to Visable).

- FIG. 10 d shows the calculated effective fast axis orientation of a two plate compensator means and

- FIG. 10 e shows the calculated effective rotary power.

- an arbitrary sequence of retarder elements can be mathematically represented by a single compensator means with “effective” retardance, fast axis and rotary power.

- wavelength characteristic retardation range is less than Ninety (90) degrees over a range bounded by Thirty (30.0) to less than one-hundred-thirty-five (135) degrees, over a range of wavelengths specified from a MINW of one-hundred-ninety (190), and a MAXW of seventeen-hundred (1700) nanometers, hence, even though the range of its retardation is between about 47 and 130 degrees, it is covered by Claim language which recited boundaries of 30 and less than 135 degrees.

- the described invention easily avoids the limitation inherrent in the Patent to Aspnes, U.S. Pat. No. 5,877,589, which Patent was identified in the Background Section of this Disclosure, while providing excellent materials system investigation results. Further, the described invention also avoids utilization of “substantially-non-achromatic” compensator means with at least a ninety (90) degree range of retardance variance of an applicable wavelength range, hence avoids the limitations in the Aspnes et al. U.S. Pat. Nos. 6,320,657 B1 and 6,134,012, respectively, again while providing excellent materials system investigation results.

- a Mathematical Model developed to represent a Spectroscopic Rotating Compensator Material System Investigation System can be expressed as explicit equations for Intensity Transfer Function, or as equations for Coefficients of Terms which comprise such as a Transfer Function.

- Spectroscopic Ellipsometer ie. Spectroscopic Ellipsometer

- a Mathematical Model can “Effectively” provide such equations. That is, a computer program need not calculate a Transfer Function per se. to utilize mathematical relationships inherent therewithin.

- the described invention is considered to be particularly impressive as it is relatively easily constructed utilizing commercially available “Off-The-Shelf” Diode Array Spectrometer Systems, and non-ideal Compensators.

- the described invention conveniently provides, in a commercially realizable format, that which was thought to be, prior thereto and the version thereof presented in the Parent U.S. Pat. No. 5,872,630, essentially impossibly to provide in other than a prohibitively expensive, (and perhaps difficult to calibrate and utilize), single unit format.

- Compensator means is to be interpreted sufficiently broadly to include one or more than one compensator(s), and that that for the purposes of this Specification and Claim interpretation, that as applied to a Compensator or Compensator Means:

Abstract

Disclosed is a spectroscopic Ellipsometer having pseudo-achromatic compensator(s) having fast axes which vary with wavelength and which provide, a range of retardations, (that is, maximum retardance minus minimum retardance), of less than 90 degrees over a range of wavelengths, said range of retardations being bounded by a minimum of preferably at least 30 degrees, to a maximum of less than 135 degrees. Calibration is achieved by a Mathematical Regression based technique involving, where desirable, Parameterization of Calibration Parameters. Various Dimensional Data Set(s) obtained with the Spectroscopic Ellipsometer configured in a Sample, present” or in a Straight-through” configuration, are variously normalized to D.C., A.C. or combination D.C. and A.C. components. Sample analysis using a detector provided intensity signal simultaneously comprising 2ω and 4ω signals simultaneously, and use of un-normalized A.C. and/or D.C. signals in reflectance monitoring are also disclosed.

Description

This Application is a Continuation-In-Part of:

Co-pending application Ser. No. 09/945,962 filed Sep. 4, 2001; and

application Ser. No. 09/496,011 filed Feb. 1, 2000 now U.S. Pat. No. 6,353,477;

which is a CIP from application Ser. No. 09/246,888 filed Feb. 8, 1999, (now U.S. Pat. No. (6,084,675);

which is a CIP from application Ser. No. 08/912,211 filed Aug. 15, 1997, (now U.S. Pat. No. 5,872,630);

which is a CIP from application Ser. No. 08/530,892 filed Sep. 20, 1995, (now U.S. Pat. No. 5,666,201);

and is a CIP of application Ser. No. 08/618,820 filed Mar. 20, 1996, (now U.S. Pat. No. 5,706,212);

This Application is, via the Co-Pending application Ser. No. 09/496,011 and application Ser. No. 09/246,888 further a Continuation-In-Part of applications Ser. No. 09/225,118 (now U.S. Pat. No. 6,084,674); Ser. No. 09/223,822 (now U.S. Pat. No. 6,118,537); Ser. No. 09/232,257 (now U.S. Pat. No. 6,141,102); Ser. No. 09/225,371 (now U.S. Pat. No. 6,100,981); Ser. No. 09/225,076 (now U.S. Pat. No. 5,963,325); which Applications depend from application Ser. No. 08/997,311 filed Dec. 23, 1997, now U.S. Pat. No. 5,946,098.

This invention relates to ellipsometers and polarimeters and the like, and more particularly is a Spectroscopic Rotating Compensator Ellipsometer System including a Pseudo-Achromatic Compensator providing, over a range of wavelengths, a range of retardations, (ie. maximum retardance minus minimum retardance), of less than 90 degrees, said range of retardations being bounded by a minimum of preferably at least 30 degrees, to a maximum of less than 135 degrees. Said System also comprises a detector means for simultaneously detecting a Multiplicity of Wavelengths, which Spectroscopic Rotating Compensator Ellipsometer System is calibrated by a Mathematical Regression based technique involving, where beneficial and desired, Parameterization of Calibration Parameters. Prefered embodiments provide a preferred fast axes offset, dual or triple zero-order, or dual or triple effective zero-order, or combination zero-order and effective zero-order waveplate compensator means system; alternative use of D.C. or A.C, and combination A.C. and D.C. data normalizing bases in various calibration steps and use of un-normalized signals to determine reflectance, as well as use of various samples during calibration data acquisition. Said invention system can be realized utilizing off-the-shelf, non-ideal, waveplates combined to provide a compensator which presents a fast axis azimuth which varies with wavelength.

Ellipsometry is a well known means by which to monitor material systems, (samples). In brief, a polarized beam of electromagnetic radiation of one or more wavelengths is caused to impinge upon a material system, (sample), along one or more angles of incidence and then interact with a material system, (sample). Beams of electromagnetic radiation can be considered as comprised of two orthogonal components, (ie. “P” and “S”), where “P” identifies a plane which contains both an incident beam of electromagnetic radiation, and a normal to an investigated surface of a material system, (sample), being investigated, and where “S” identifies a plane perpendicular to the “P” plane and parallel to said surface of said material system, (sample). A change in polarization state in a polarized beam of electromagnetic radiation caused by said interaction with a material system, (sample), is representative of properties of said material system, (sample). (Note Polarization State basically refers to a magnitude of a ratio of orthogonal component magnitudes in a polarized beam of electromagnetic radiation, and a phase angle therebetween.) Generally two well known angles, (PSI and DELTA), which characterize a material system, (sample), at a given Angle-of-Incidence, are determined by analysis of data which represents change in polarization state. Additional sample identifying information is often also obtained by application of ellipsometry, including layer thicknesses, (including thicknesses for multilayers), optical thicknesses, sample temperature, refractive indicies and extinction coefficients, index grading, sample composition, surface roughness, alloy and/or void fraction, parameter dispersal and spectral dependencies on wavelength, vertical and lateral inhomogenieties etc.

Continuing, Ellipsometer Systems generally include a source of a beam of electromagnetic radiation, a Polarizer means, which serves to impose a linear state of polarization on a beam of electromagnetic radiation, a Stage for supporting a material system, (sample), and an Analyzer means which serves to select a polarization state in a beam of electromagnetic radiation after it has interacted with a material system, (sample), and pass it to a Detector System for analysis therein. As well, one or more Compensator(s) can be present and serve to affect a phase angle change between orthogonal components of a polarized beam of electromagnetic radiation.

It is noted that Spectroscopic Ellipsometer Systems utilize a Source which simultaneously provides a plurality of Wavelengths, which Source can be termed a “Broadband” Source of Electromagnetic radiation.

A number of types of ellipsometer systems exist, such as those which include rotating elements and those which include modulation elements. Those including rotating elements include Rotating Polarizer (RP), Rotating Analyzer (RA) and Rotating Compensator (RC). The presently disclosed invention comprises a Rotating Compensator Ellipsometer System. It is noted that Rotating Compensator Ellipsometer Systems do not demonstrate “Dead-Spots” where obtaining data is difficult. They can read PSI and DELTA of a Material System, (Sample), over a full Range of Degrees with the only limitation being that if PSI becomes essentially zero (0.0), one can't then determine DELTA as there is not sufficient PSI Polar Vector Length to form the angle between the PSI Vector and an “X” axis. In comparison, Rotating Analyzer and Rotating Polarizer Ellipsometers have “Dead Spots” at DELTA's near 0.0 or 180 Degrees and Modulation Element Ellipsometers also have “Dead Spots” at PSI near 45 Degrees. The utility of Rotating Compensator Ellipsometer Systems should then be apparent. Another benefit provided by fixed Polarizer (P) and Analyzer (A) positions is that polarization state sensitivity to input and output optics during data acquisition is essentially non-existent. This enables relatively easy use of optic fibers, mirrors, lenses etc. for input/output.

A Search for relevant Patents has Identified very little. Most important is a Patent to Johs et al., U.S. Pat. No. 5,872,630, from which the present Application is derived as a CIP. Said 630 Patent describes:

A spectroscopic rotating compensator material system investigation system comprising a source of a polychromatic beam of electromagnetic radiation, a polarizer, a stage for supporting a material system, an analyzer, a dispersive optics and at least one detector system which contains a multiplicity of detector elements, said spectroscopic rotating compensator material system investigation system further comprising at least one compensator(s) positioned at a location selected from the group consisting of:

before said stage for supporting a material system;

after said stage for supporting a material system; and

both before and after said stage for supporting a material system;

such that when said spectroscopic rotating compensator material system investigation system is used to investigate a material system present on said stage for supporting a material system, said analyzer and polarizer are maintained essentially fixed in position and at least one of said at least one compensator(s) is caused to continuously rotate while a polychromatic beam of electromagnetic radiation produced by said source of a polychromatic beam of electromagnetic radiation is caused to pass through said polarizer and said compensators, said polychromatic beam of electromagnetic radiation being also caused to interact with said material system, pass through said analyzer and interact with said dispersive optics such that a multiplicity of essentially single wavelengths are caused to simultaneously enter a corresponding multiplicity of detector elements in said at least one detector system.

Said 630 Patent also, amongst other disclosure, describes a Mathematical Regression based Calibration procedure which makes possible the use of essentially any compensator regardless of non-achromatic characteristics.

Another Patent to Johs, from which the 630 Patent was Continued-in Part, is U.S. Pat. No. 5,666,201, filed Sep. 20, 1995. The focus in said 201 Patent comprises a detector arrangement in which multiple orders of a dispersed beam of electromagnetic radiation are intercepted by multiple detector systems. However, Claim 8 in the 201 Patent, in combination with a viewing the Drawings therein, provide conception of the Spectroscopic Rotating Compensator Ellipsometer, as Claimed in Claim 1 of the JAW 630 Patent and, in fact, the the 630 Patent issued in view of a Terminal Disclaimer based upon the 201 Patent.

Also disclosed is U.S. Pat. No. 5,706,212, Issued Jan. 6, 1998, and Filed Mar. 20, 1996 for an Infrared Ellipsometer System Regression based Calibration Procedure. Said 212 Patent describes use of an Substantially Achromatic Rotating Compensator and application of Mathematical Regression in a Calibration procedure which evaluates calibration parameters in both rotating and stationary components. The 212 Patent describes that 2 OMEGA and 4 OMEGA associated terms are generated by a detector of a signal which passes through a compensator caused to rotate at a rate of OMEGA. Said 630 Patent was Continued-in-Part therefrom, as is the present Application via an intervening Patent Application. It is noted that the 212 Patent Application was filed four months prior to the earliest priority Patent Application, of Aspnes et al. Patents, (ie. U.S. Pat. Nos. 6,320,657 B1, 6,134,012, 5,973,787 and 5,877,859), the later of which was Filed on Jul. 24, 1996.

Relevant Patents to Aspnes et al. are U.S. Pat. Nos. 6,320,657 B1, 6,134,012, 5,973,787 and 5,877,859. These Patents describe a Broadband Spectroscopic Rotating Compensator Ellipsometer System wherein the Utility is found in the use of a “substantially Non-Achromatic” compensator, (see Claim 1 in the 657 Patent), and selecting a Wavelength Range and Compensator so that “an effective phase retardation value is induced covering at least from 90 degrees to 180 degrees”, (012 Patent), over a range of wavelengths of at least 200-800 nm. The 787 and 859 recite that at least one wavelength in said wavelength Range has a retardation imposed of between 135 and 225 Degrees, and another wavelength in the wavelength Range has a retardation imposed which is outside that retardation Range. The Utility of the Therma-wave Patents derives from the identified conditions being met so that at least one of a 2 OMEGA and a 4 OMEGA coefficient provided by a detector provides usable information at a wavelength, even when said coefficient does not provide usable information at other wavelengths. Again, the identified Aspnes et al. Patents recite directly, or describe the presence of a “substantially-non-Achromatic” compensator, while, it is noted at this point, the invention disclosed in this Application utlizes what are properly termed substantially-achromatic or Psuedo-Achromatic compensators. It is further noted that the U.S. Pat. No. 5,716,212 Patent Application, from which this Application Continues-in-Part, was filed prior to Jul. 24, 1976 filing date of the 859 Aspnes et al. priority Patent Application. The disclosed invention then has Priority to simultaneous use of 2 OMEGA and 4 OMEGA signals provided from a detector in a spectroscopic rotating compensator ellipsometer system which utilizes “Other-Than-Substantially Non-Achromatic” Compensators, namely “Substantially-Achromatic” or “Pseudo-Achromatic” Compensators, to characterize samples, emphasis added.

A recently published PCT Application is No. WO 01/90687 A2, which is based on U.S. application Ser. No. 09/575,295 filed May 3, 2001. This Application was filed by Thermavave Inc. and specifically describes separate use of a 2ω and a 4ω term to provide insight to sample thickness and temperature.

Another Patent, U.S. Pat. No. 4,053,232 to Dill et al. describes a Rotating-Compensator Ellipsometer System, which operates utilizes monochromatic light.

Two Patents which identify systems which utilize Polychromatic light in investigation of material systems, U.S. Pat. Nos. 5,596,406 and 4,668,086 to Rosencwaig et al. and Redner, respectively, were also identified.

Also identified is a Patent to Woollam et al, U.S. Pat. No. 5,373,359 as it describes a Rotating Analyzer Ellipsometer System which utilizes white light. Patents continued from the 359 Woollam et al. Patent are, U.S. Pat. No. 5,504,582 to Johs et al. and U.S. Pat. No. 5,521,706 to Green et al. Said 582 Johs et al. and 706 Green et al. Patents describe use of polychromatic light in a Rotating Analyzer Ellipsometer System.

A Patent to Bernoux et al., U.S. Pat. No. 5,329,357 is identified as it describes the use of optical fibers as input and output means in an ellipsometer system.

A Patent to Chen et al., U.S. Pat. No. 5,581,350 is identified as it describes the application of regression in calibration of ellipsometer systems.

Additionally, Patents pertaining to optical elements, and particularly to compensators/retarders per se are:

U.S. Pat. No. 4,917,461 to Goldstein, describes an achromatic infrared retarder comprised of two identical prisms in combination with a rflective surface;

U.S. Pat. No. 4,772,104 to Buhrer which describes an achromatic optical filter comprised of two birefringent disks;

U.S. Pat. No. 4,961,634 to Chipman describes an infrared achromatic retarder comprised of Cds and CdSe plates aligned with the fast axes thereof perpendicular to one another;

U.S. Pat. No. 5,946,098 to Johs, Herzinger and Green, which describes numerous optical elements. In addition Patents to Johs et al. U.S. Pat. Nos. 6,084,674; 6,118,537; 6,100,981; 6,141,102; 6,100,981; 5,963,325; 6,084,674 and to Herzinger et al. U.S. Pat. No. 6,084,675, which Applications depend from application Ser. No. 08/997,311 filed Dec. 23, 1997, now said U.S. Pat. No. 5,946,098;

Additional Patents which describe Compensators are U.S. Pat. No. 548,495 to Abbe; U.S. Pat. No. 4,556,292 to Mathyssek et al.; U.S. Pat. No. 5,475,525 Tournois et al.; U.S. Pat. No. 5,016,980 Waldron; and U.S. Pat. No. 3,817,624 to Martin and U.S. Pat. No. 2,447,828 to West;

And, Patents to Robert et al., U.S. Pat. Nos. 4,176,951 and 4,179,217 are also disclosed as they describe rotating Birefringent elements in Ellipsometers which produce 2ω and 4ω components.

Regarding Articles, an article by Johs, titled “Regression a Calibration Method For Rotating Element Ellipsometers”, which appeared in Thin Film Solids, Vol. 234 in 1993 is also identified as it predates the Chen et al. Patent and describes an essentially similar approach to ellipsometer calibration.

An article by Jellison Jr. titled “Data Analysis for Spectroscopic Ellipsometry”, Thin Film Solids, 234, (1993) is identified as it describes a method for determining the accuracy with which certain data points can be measured, which information allows adding a weighting factor to a curve fitting regression procedure as applied to a multiplicity of data points, said weighting factor serving to emphasize the effect of more accurate and precise data.

An article by Collins titled “Automated Rotating Element Ellipsometers: Calibration, Operation, and Real-Time Applications”, Rev. Sci. Instrum. 61(8), August 1990 is identified as it provides insight into rotating element ellipsometers.

An article by Kleim et al. titled “Systematic Errors in Rotating-Compensator Ellipsometry” published in J. Opt. Soc. Am./Vol. 11, No. 9, September 1994 is identified as it describes calibration of rotating compensator ellipsometers.

An Article by An and Collins titled “Waveform Analysis With Optical Multichannel Detectors: Applications for Rapid-Scan Spectroscopic Ellipsometer”, Rev. Sci. Instrum., 62 (8), August 1991 is also identified as it discusses effects such as Detection System Error Characterization, Stray Light, Image Persistence etc., and calibration thereof.

Further identified as authority for Matrix Mathematics is a paper by Jones titled “A New Calculus For The Treatment Of Optical Systems”, J.O.S.O., Vol. 31, (July 1941).

Identified as describing application of Mueller Matricies in Rotating Compensator Ellispometers which utilize imperfect compensators, is a paper by Hauge titled “Mueller Matrix Ellipsometry With Imperfect Compensators”, J. Opt. Soc. Am., Vol. 68, No. 11, (November 1978).

A paper titled “Analysis of Specular and Textured SnO2:F Films by High Speed Four-Parameter Stokes Vector Spectroscopy”, Rovira & Collins, J. App. Phys., Vol. 85, No. 4, (1999).

Papers by Schubert and Schubert et al. which describe “Generalized Ellipsometry” are disclosed as they provide insight as how to Mathematically treat depolarizing Elements. Said Articles are: “Polarization Dependent Parametes of Arbitrary Anisotropic Homogeneous Epitaxial Systems”, Phys. Rev. B 53, (1996); “Generalized Transmission Ellipsometry For Twisted Biaxial Dielectric Media: Application to Chiral Liquid Crystals”, J. Opt. Soc. Am A, Vol 13, No. 9 (1996); and “Extrension of Rotating-Analyzer Ellipsometry to Generalized Ellipsometry: Determination of the Dielectric Function Tensor From Uniaxial TiO2”, J. Opt. Soc. Am. A. 13, (1996).

A book by Azzam and Bashara titled “Ellipsometry and Polarized light” North-Holland, 1977 is disclosed and incorporated herein by reference for general theory.

As well, identified for authority regarding regression, is a book titled Numerical Recipes in “C”, 1988, Cambridge University Press.

Even in view of the foregoing, a need remains for improved Spectroscopic Rotating Compensator Ellipsometer Systems, including a Photo Array, for simultaneously detecting a Multiplicity of Wavelengths, and which can be realized utilizing off-the-shelf, non-ideal, compensators and diode array spectrometers. As will be better disclosed in the Disclosure of the invention Section of this Specification, the invention provides a Spectroscopic Rotating Compensator Ellipsometer System which comprises a Psuedo-Achromatic Compensator, and discloses alternative use of D.C. and A.C data normalization in various calibration steps, as well as use of un-normalized signals in determining Reflectance.

First, it should be appreciated that the purpose of this Application is to achieve a Patent which clarifies the boundaries of what the Patents to Aspnes et al., U.S. Pat. Nos. 6,320,657 B1, 6,134,012, 5,973,787 and 5,877,859, (all assigned to Thermawave Inc.), cover as constrasted to what U.S. Pat. Nos. 5,706,212 and 5,872,630, and a Patent to Issue based on application Ser. No. 09/496,011 filed Feb. 1, 2000; (all assigned to J.A. Woollam Co. Inc.), cover. It is directly stated that it is believed that Thermawave has rights for application of “Substantially- Non-Achromatic” Compensators in Spectroscopic Rotating Compensator Ellipsometers, while the J.A. Woollam Co. Inc. has rights for application of “Substantially-Achromatic/Psuedo-Achromatic” Compensators in Spectroscopic Rotating Compensator Ellipsometers. This is partially based in that the priority of the Thermawave 859 Patent, (which discloses a Substantially-Non-Achromatic Retarder which provides a retardation range that passes through 180 degrees), is approximately 4 months later than the priority of the J.A. Woollam Co. 212 Patent, (which discloses a Substantially-Achromatic/Psuedo-Achromatic Retarder). The distinction between Achromatic and Substantially-Achromatic/Psuedo-Achromatic is that an Achromatic Retarder ideally provides the same retardation in all wavelengths over a range of wavelengths, while a Substantially Achromatic/Psuedo-Achromatic Retarder provides retardance over a range of wavelengths, which varies. The distinction between “Substantially-Non-Achromatic” and “Substantially-Achromatic/Psuedo-Achromatic” Retarders is that the former provide a retardation range which is, over a range of wavelengths, more than that provided by the later. It is believed that a good delineation line between Substantially-Non-Achromatic and Substantially-Achromatic/Psuedo-Achromatic Retarders is provided by the recitation in the Thermawave 012 Patent wherein it is stated that “an effective phase retardation value is induced covering at least from 90 decrees to 180 degrees”, over a range of wavelengths. In the present Specification the terminology Substantially-Achromatic/Psuedo-Achromatic is used to identify a Compensator that provides a range of retardations, over a range of wavelengths, which range of retardations, (ie. maximum retardation minus minimum retardation), is less than 90 degrees. And the distinction between Substantially-Achromatic and Psuedo-Achromatic, for the purposes of this Specification is considered to be that the former provides a range of retardation values, over a range of wavelengths, greater than 0.0 degrees and merging into the range of a Psuedo-Achromatic Compensator which, for the purposes of this Specification can be considered as providing a magnitude of retardations less than the magnitude of “at least from 90 to 180 degrees”, (eg. the retardation provided by a J.A. Woollam Co. Psuedo-Achromatic Compensator varies with wavelength over a range, (that is, maximum-minimum retardation), of less than 90 degrees, with a preferred lower boundary value retardation being at least 30 degrees, and an upper boundary value of retardation being less than 135 degrees). It is believed that the Thermawave Patents do not provide priority support for Claiming, in the context of a Rotating Compensator Spectroscope Ellipsometer, a retarder with other than Substantially-Non-Achromatic characteristics, while the J.A. Woollam Co. has priority support for Claiming Substantially-Achromatic/Psuedo-Achromatic Compensators applied in the context of a Rotating Compensator Spectroscopic Ellipsometer from the 212 and 630 Patents, with refined definition for Psuedo-Achromatic being provided by, for instance, the Allotted but still Co-pending application Ser. No. 09/496,011, which was filed Feb. 1, 2000.

Moving along, as described in the 630 Patent, prior thereto it was generally considered that while Rotating Compensator Ellipsometers Systems provide many benefits, (eg. Material System, (Sample), PSI and DELTA investigation limiting “dead-spots” are not present), that in the absence of essentially Achromatic “ideal” Compensators it would be prohibitively difficult and expensive to build, calibrate and utilize a “Spectroscopic” Rotating Compensator Ellipsometer Material System Investigating System. This is to be understood in light of the fact that Compensator Means which are essentially Achromatic, (ie. provide essentially constant retardation, (ie. very small retardation range), over a large range of Wavelengths, such as from, less than or equal to 190, to 1000 or higher (eg. 1800 nm), nanometers), are not generally and economically available as off-the-shelf items, (this being particulalry true where a Compensator is rotated during use).

In the terminology of the 630 Patent, the disclosed invention system is, however, an affordable, easy to calibrate and utilize Spectroscopic Rotating Compensator Material System Investigation System comprising a Source of a Polychromatic Beam of Electromagnetic Radiation, a Polarizer, a Stage for Supporting a Material System, (Sample), an Analyzer, a Dispersive Optics and at least one Photo Array Detector Element System which contains a multiplicity of Detector Elements, which Spectroscopic Rotating Compensator Material System Investigation System further comprises at least one Compensator(s) positioned at a location selected from the group consisting of: (before said stage for supporting a Material System, (Sample), and after said stage for supporting a Material System, (Sample), and both before and after said stage for supporting a Material System (Sample).

While the preferred embodiment of the disclosed invention utilizes Psuedo-Achromatic Compensators, technically of interest is the fact that said at least one Compensator(s) utilized in the disclosed invention can technically be essentially any available, reasonably priced, off-the-shelf Retardation providing system, including non-Achromatic Berek-type, Zero-Order Waveplate, Multiple-Order Waveplate, Zero-Order Waveplate constructed from Multiple Multiple-Order Waveplates, Sequential Systems of Multiple Zero-Order Waveplates, each of which can be constructed from Multiple Multiple-Order Waveplates, Polymer Retarder, Mica Waveplate, Freshnel Rhomb, Achromatic, and Pseudo-Achromatic, etc. For general information, it is noted that a Berek-type Compensator is a uniaxially anisotropic plate of material in which the Optical Axis is oriented perpendicularly to a plate surface thereof. When a Polarized Beam of Electromagnetic Radiation is caused to be incident other than along the Optical Axis, orthogonal components thereof encounter different effective Indicies of Refraction, thereby effecting retardation therebetween. Polymer Compensators are made of a polymer material and can provide true Zero-Order retardance which, as do many Compensators, provides an inverse wavelength functional Retardance Characteristic. Essentially Achromatic (Pseudo-Achromatic) Compensators can be constructed by stacking appropriately chosen Polymer and Crystal waveplates.

Sequential Systems of Multiple Zero-Order Waveplates allow achieving flattened Retardance vs. wavelength characteristics, (ie. smaller retardation range), and it is noted, are the preferred disclosed invention Compensator type. To ellaborate, the preferred Compensator system comprises a system of at least two (eg. First and Second), Zero-Order Waveplates, each of which Zero-Order Waveplates can be a single plate, (eg. mica or polymer), or constructed from an effective combination of Multiple-Order Waveplates, (eg. two quartz plates or bicrystaline waveplates such as Cadmium Sulfide or Cadmium Selenide). As further insight, an effective Zero-Order Waveplate can be functionally constructed by combining two Multi-Order (eg. Quartz) Waveplates which have Optical Axes oriented at a nominal ninety (90) degrees with respect to one another. That is, two Multi-Order waveplates are selected and combined so that the difference in retardation entered by each gives rise to an overall Zero-Order Waveplate retardance characteristic. In particular, the prefered invention Compensator embodiment provides that each of said First and Second effectively Zero Order Waveplates be formed by physically optically combining two Multiple Order Waveplates, such that the net result of passing a beam of electromagnetic radiation therethrough is essentially equivalent to the result which would achieved by passing said electromagnetic beam through a single plate Zero-Order Waveplate. The reason that such effective Zero-Order Waveplates, which are formed by physically combining two Multiple Order Waveplates are preferred, is that such effectively Zero-Order Waveplates are readily and economically available in the marketplace, and that true single plate Zero-Order Waveplates are typically physically delicate and difficult to utilize. Continuing, the preferred invention Compensator provides that two of said per se., or effective Zero-Order Waveplate Compensators, be oriented with respect to one another such that the fast axes of the First per se. or effectively Zero-Order Compensator are rotated with respect to the Second per se. or effectively Zero-Order Compensator, away from zero or ninety degrees, and typically within some range around a nominal forty-five (45) degrees. In use, a beam of electromagnetic radiation utilized to investigate a material system, is caused to pass through both of said First and Second Compensators with the result achieved being that a disclosed invention preferred Compensator configuration provides a pseudo-achromatic retardation range, (ie. max-min), of less than 90 degrees within a range of retardations bounded by a lower bound of at least thirty (30) and an upper bound of less one-hundred-thirty-five (135) degrees, over relatively large wavelength ranges within, for instance, one-hundred-ninety (190 NM) to eighteen-hundred (1800 NM). That is, preferred invention Compensators are specifically designed to provide retardation values which never equal or exceed one-hundred-eighty (180) degrees, or even one-hundred-thirty-five (135) degrees at any utilized wavelength. It is noted that this is in direct contrast to the practice of Therma-wave rotating compensator systems as described in U.S. Pat. Nos. 6,320,657 B1, 6,134,012, 5,973,787 and 5,877,859 to Aspnes, wherein large chromaticities, (eg. at least 90-180 degrees retardation range over a range of wavelengths), in compensator systems utilized cover a range of retardations which the Specifications indicate can include 180 degrees therewithin, emphasis added.

In terminology similar to that used in the Aspnes et al. Patents, which describe spectroscopic ellipsometer systems comprising substantially non-achromatic compensators, the presently disclosed invention can be described as:

A spectroscopic ellipsometer for evaluating a sample comprising:

a broadband light source generating a beam having wavelengths extending over a range of at least 200 to 800 nm;

a polarizer disposed in the path of the light beam;

a compensator disposed in the path of the light beam, said compensator for inducing phase retardations in the polarization state of the light beam, said compensator having characteristics selected from the group consisting of:

being substantially achromatic;

being pseudo-achromatic; and

being other than substantially non-achromatic;

so that the amount of phase retardation varies with wavelength, over a range of wavelengths, less than is the case were a substantially-non-achromatic compensator utilized, said compensator means being rotated at an angular frequency of ω;

an analyzer that interacts with the light beam after the beam interacts with the sample and with the compensator;

a detector means that measure the intensity of the light beam after the interaction with the analyzer at a plurality of wavelengths across the wavelength range of at least 200 to 800 nm;

said detector means generating a time varying intensity output signal simultaneously comprising 2ω and 4ω component signals; and

optionally a processor for evaluating the sample based on simultaneous use of the intensity output signal 2ω and 4ω components.

(It is to be noted that the present Application is a CIP from application Ser. No. 08/618,820 filed Mar. 20, 1996, (now U.S. Pat. No. 5,706,212), which disclosed a spectroscopic ellipsometer sytem which was disclosed as preferably comprising a substantially achromatic compensator).

Another recitation of the presently disclosed invention, which focuses on the presence of a Psuedo-Achromatic Compensator, is:

A spectroscopic ellipsometer for evaluating a sample comprising:

polychromatic electromagnetic radiation source means generating a beam having wavelengths extending over a range of at least 200 to 800 nm;

polarizer means disposed in the path of said beam;

compensator(s) means disposed in the path of the beam, said compensator for inducing phase retardations in the polarization state of the light beam, said compensator(s) means being:

pseudo-achromatic;

in that the amount of phase retardation varies more with wavelength than is the case if a substantially achromatic compensator is utilized but in that the amount of phase retardation varies less than is the case if a substantially non-achromatic compensator is utilized, said compensator means being rotated at an angular frequency of ω;

analyzer means that interacts with the beam after the beam interacts with the sample and the compensator means;

detector means that measure the intensity of the beam after the interaction with the analyzer at a plurality of wavelengths across the wavelength range of at least 200 to 800 nm;

said detector means generating a time varying intensity output signal simultaneously comprising 2ω and 4ω component signals, said 2ω and 4ω signals being simultaneously present at all wavelengths measured unless the 2ω signal is forced to 0.0 by a sample presenting with an ellipsometric DELTA of 0.0, as opposed to being caused to be 0.0 by said compensator means; and

optionally a processor for evaluating the sample based on simultaneous use of the intensity output signal 2ω and 4ω components.

Further, for the purposes of this Specification, the definition of “other than substantially non-achromatic” includes the requirement that the range of retardations entered to wavelengths over a range of wavelengths does not include one-hundred-eights (180) degrees.

(Note in both the foregoing recitations, in contrast to the teachings of the Aspnes et al. U.S. Pat. Nos. 6,320,657 B1, 6,134,012, 5,973,787 and 5,877,859, the compensator means in a disclosed invention system can not force the 2ω signal to (0.0), as it is selected to provide, at any wavelength, far less than 180 degrees retardation, (eg, greater than 30 up to 120 degrees; or 35 to less than 125; or 45 degrees to less than 135 degrees etc.), regardless of which wavelength in the polychromatic range of wavelengths of at least 200 to 800 nm, (eg. 190-1800 nm), is investigated. Note, in any case the range of retardation values entered to wavelengths over a range thereof is less than ninety (90) degrees and does not include 180 degrees. Further, it is to be understood the terminology “Compensator” means include the case of a disclosed invention system being comprised of a Single Compensator or Multiple Compensator Elements).

Continuing, the disclosed invention system preferably utilizes at least one compensator means which is described as a selection from the group consisting of:

being comprised of at least two zero-order waveplates, said zero-order waveplates having their respective fast axes rotated to a position offset from zero or ninety degrees with respect to one another;

being comprised of a combination of at least a first and a second effective zero-order wave plate, said first effective zero-order wave plate being comprised of two multiple order waveplates which are combined with the fast axes thereof oriented at a nominal ninety degrees to one another, and said second effective zero-order wave plate being comprised of two multiple order waveplates which are combined with the fast axes thereof oriented at a nominal ninety degrees to one another; the fast axes of the multiple order waveplates in said second effective zero-order wave plate being rotated to a position at a nominal forty-five degrees to the fast axes of the multiple order waveplates in said first effective zero-order waveplate;

being comprised of a combination of at least a first and a second effective zero-order wave plate, said first effective zero-order wave plate being comprised of two multiple order waveplates which are combined with the fast axes thereof oriented at a nominal ninety degrees to one another, and said second effective zero-order wave plate being comprised of two multiple order waveplates which are combined with the fast axes thereof oriented at a nominal ninety degrees to one another; the fast axes of the multiple order waveplates in said second effective zero-order wave plate being rotated to a position away from zero or ninety degrees with respect to the fast axes of the multiple order waveplates and in said first effective zero-order waveplate;

being comprised of at least one zero-order waveplate and one effective zero-order waveplate, said effective zero-order wave plate being comprised of two multiple order waveplates which are combined with the fast axes thereof oriented at a nominal ninety degrees to one another, the fast axes of the multiple order waveplates in said effective zero-order wave plate being rotated to a position away from zero or ninety degrees with respect to the fast axis of the zero-order waveplate.

(Note, zero-order and effective zero-order waveplates are of, for instance, single plate and multiple waveplate construction respectively).

(It is also noted that generally the more elements combined to form a compensator, the smaller can be made the range over which retardation values vary with wavelength, over a range of wavelengths. For instance three (3) elements are utilized in some J.A. Woollam CO. Psuedo-Achromatic Compensators which operate over a major part of the range of 190-1700 nm).

Continuing, because the preferred disclosed invention Compensators do not provide an exact Ninety (90) Degrees of Retardation at all wavelengths over a relatively large range of Wavelengths, the presently disclosed invention, as described herein, utilizes a Regression based Calibration procedure which compensates for said non-ideal Compensator Retardation characteristics. And while it is true that the sensitivity and accuracy of a Rotating Compensator Material System investigation System degrades as the Retardance provided by a utilized Compensator approaches zero (0.0) or one-hundred-eighty (180) degrees, again, it has been found that Compensators which demonstrate a Retardation range of less than Ninety (90) degrees (max-min) over a range of utilized Wavelengths, within in a range bounded by at least Thirty (30) and less than one-hundred-thirty-five (135) degrees, (thereby avoiding the U.S. Pat. Nos. 6,320,657 B1, 6,134,012, 5,973,787 and 5,877,859 to Aspnes et al.), are available, or can be constructed from readily available components, which are very acceptable for use in the disclosed invention Rotating Compensator Ellipsometer System, and said Compensators enable achieving very impressive results over a demonstrated relatively large range of wavelengths, (eg. at least two-hundred-fifty (250) to one-thousand (1000) or more nanometers). One embodiment of the spectroscopic rotating compensator material system investigation system typically comprises at least one compensator(s) which produces a retardance of, preferably, between seventy-five (75) and one-hundred-thirty (130) degrees over a range of wavelengths defined by a selection from the group consisting of:

a. between one-hundred-ninety (190) and seven-hundred-fifty (750) nanometers;

b. between two-hundred-forty-five (245) and nine-hundred (900) nanometers;

c. between three-hundred-eighty (380) and seventeen-hundred (1700) nanometers;

d. within a range of wavelengths defined by a maximum wavelength (MAXW) and a minimum wavelength (MINW) wherein the ratio of (MAXW)/(MINW) is at least one-and-eight-tenths (1.8).

Acceptable practice however, provides for the case wherein at least one of said at least one compensator(s) provides range of Retardation of less than Ninety (90) degrees (max-min) over a range of utilized Wavelengths between MINW and MAXW, within in a range bounded by at least Thirty (30) and less than one-hundred-thirty-five (135) degrees, said wavelength range being specified by a selection from the group consisting of:

a. MINW less than/equal to one-hundred-ninety (190) and MAXW greater than/equal to seventeen-hundred (1700) nanometers;

b. MINW less than/equal to two-hundred-twenty (220) and MAXW greater than/equal to one-thousand (1000) nanometers;

c. within a range of wavelengths defined by a maximum wavelength (MAXW) and a minimum wavelength (MINW) range where (MAXW)/(MINW) is at least four-and-one-half (4.5).

(NOTE, the specified values and ranges can not be achieved by At single plates with Substantially Non-Achromatic, (eg. 1/wavelength), retardation characteristics, but can be achieved by two (2) and three (3) plate Compensator designs).

Continuing, when the disclosed invention Spectroscopic Rotating Compensator Material System Investigation System, (ie. Spectroscopic Ellipsometer), is used to investigate a Material System, (ie. Sample), present on said Stage for Supporting a Material System, (Sample), said Analyzer Means and Polarizer Means are maintained essentially fixed in position and at least one of said at least one Compensator(s) Means is/are caused to continuously rotate while a Polychromatic, (Broadband), Beam of Electromagnetic Radiation produced by said Source of a Polychromatic Beam of Electromagnetic Radiation is caused to pass through said Polarizer and said Compensator Means. Said Polychromatic Beam of Electromagnetic Radiation is also caused to interact with said Material System, (Sample), pass through said Analyzer Means and interact with said Dispersive Optics such that a Multiplicity of Essentially Single Wavelengths are caused to simultaneously enter a corresponding multiplicity of Detector Elements in said Detector System Photo Array.

In language again similar to that in the Aspnes et al. Patents, a method of calibrating a Spectroscopic Ellipsometer System can comprise the steps of:

a. providing a spectroscopic ellipsometer for evaluating a sample comprising:

broadband electromagnetic radiation source means generating a beam having wavelengths extending over a range of at least 200 to 800 nm;

polarizer means disposed in the path of said beam;

compensator means disposed in the path of the beam, said compensator for inducing phase retardations in the polarization state of the light beam, said compensator means having characteristics other than substantially non-achromatic, said compensator means being rotated at an angular frequency of ω;

analyzer means that interact with the beam after the beam interacts with the sample and the compensator means;

detector means that measure the intensity of the beam after the interaction with the analyzer means at a plurality of wavelengths across the wavelength range of at least 200 to 800 nm;

said detector means generating a time varying intensity signal simultaneously comprising 2ω and 4ω component signals, said 2ω and 4ω signals being simultaneously present at all wavelengths measured unless the 2ω signal is forced to 0.0 by a sample presenting with an ellipsometric DELTA of 0.0 as opposed to being caused to be 0.0 by said compensator means;

b. developing a mathematical model of said spectroscopic ellipsometer system which comprises as calibration parameter(s) at least one selection from the group consisting of:

effective polarizer means azimuthal angle orientation;

present sample PSI (Ψ), as a function of angle of incidence and a thickness;

present sample DELTA (Δ), as a function of angle of incidence and a thickness;

retardations of said compensator means as a function of wavelength;

compensator means azimuthal angle orientation;

matrix components of said compensator means; and

analyzer means azimuthal angle orientation;

which mathematical model is effectively a transfer function which enables calculation of electromagnetic beam magnitude detected by a detector element, given magnitude provided by said broadband electromagnetic radiation source means generating a beam having wavelengths extending over a range of at least 200 to 800 nm;

c. causing a polychromatic beam of electromagnetic radiation produced by said broadband electromagnetic radiation source means, to pass through said polarizer means, interact with a sample caused to be in the path thereof, pass through said analyzer means, and enter detector elements in said detector means, with said polychromatic beam of electromagnetic radiation also being caused to pass through said compensator means;

d. obtaining data as described by a selection from the group consisting of:

at least one multi-dimensional data set(s); and

least two, at least one-dimensional data sets;

said data set(s) being magnitude values vs. parameter(s) selected from the group consisting of:

wavelength;

angle-of-incidence of said polychromatic beam of electromagnetic radiation with respect to a present material system;

effective or actual azimuthal angle orientation of one element selected from the group consisting of:

said polarizer; and

said analyzer;

obtained over time, while at least one of said at least one compensator is caused to continuously rotate;

said at least at least one, multi-dimensional data set(s) being obtained utilizing a selection from the group consisting of:

all of said at least one multi-dimensional data set(s), being obtained utilizing a single sample;

at least one of said at least one multi-dimensional data sets being obtained utilizing one sample, with another of said at least one multi-dimensional data sets being obtained utilizing another sample; and