Glyoxalated Polyacrylamides as Paper Strengthening Agents

BACKGROUND OF THE INVENTION 1.Field of the Invention

This invention relates to processes and compositions for providing paper products having desirable strength properties. In particular, the present invention relates to paper products having at least acceptable dry strength at reduced basis weights. The present invention also relates to maintaining or increasing dry strength of paper products while reducing the basis weight of the paper products and while achieving at least acceptable levels of opacity. Further, the present invention relates to paper products having at least acceptable dry strength using mechanical pulp. The present invention is also directed to adding glyoxalated polyacrylamide and opacifier to wet pulp to form a wet pulp mix. The wet pulp mix may be used to make paper products, and the present invention is also directed to the resulting paper products.

2. Discussion of Background

Paper products may be made from chemical pulp, mechanical pulp, and mixtures thereof. Chemical pulp is pulp that has been produced with a chemical to remove all or most of the lignin from the wood. Chemical pulping processes typically have a yield of about 40 to 50 wt% of the initial wood. In contrast, mechanical pulp is a relatively cheaper high yield pulp which has been mechanically treated such that lignin remains in the pulp. Examples of mechanical pulp include TMP (thermomechanical pulp), RMP (refiner mechanical pulp), and BCTMP (bleached chemithermomechanical pulp).

Glyoxalated polyacrylamides are especially known as additives for imparting wet strength to paper and paperboard. Although glyoxalated polyacrylamides are used in a variety of grades of paper products, their principal use is in tissue grades, specifically wet-strength toweling.

In general, glyoxalated polyacrylamide wet-strength resins are prepared by crosslinking a low molecular weight polyacrylamide with glyoxal. Polyacrylamides are normally prepared with cationic comonomer of the quaternary ammonium type to provide means for self- attachment of the finished resin to fiber. Polyacrylamides, however, may also be anionic, in which case a cationic retention agent may be utilized to attach the finished resin to fiber.

Evidence strongly suggests that glyoxalated polyacrylamide imparts wet strength to paper products primarily through covalent bond formation between resin and fibers. This bonding is

by hemiacetal formation involving addition of cellulose hydroxyl to free aldehyde groups on the resin. In practice, functional wet strength requires formation of fiber-resin-fiber covalent bonds. These bonds form where glyoxalated polyacrylamide is adsorbed onto fiber surfaces within fiber- to-fiber bonded area, and when papermaking and drying conditions favor the formation of an extensive amount of covalent bonding between resin networks and each of at least two contacting fibers.

It is also known that glyoxalated polyacrylamides can impart dry strength to paper products. Significant dry strength increases are believed to be derived from the unreacted amide groups on the resin. The dry strength appears to be largely independent of the wet-strength chemistry and is typical of that obtained with conventional polyacrylamide dry-strength resins.

Examples of commercially available glyoxalated polyacrylamides include "Parez 631" glyoxalated polyacrylamide available from Cytec Technology Corporation, Stamford,

Connecticut, and "Hercobond 1000" glyoxalated polyacrylamide available from Hercules

Incorporated, Wilmington, Delaware. An example of a composition which includes glyoxalated polyacrylamide is "Calloway 911" which is a physical mixture of glyoxalated polyacrylamide and polyamide wet strength resin, available from Calloway Chemical Company, Columbus, Georgia.

"Hercobond 1000" glyoxalated polyacrylamide is a cationic dry strength and temporary wet-strength resin which is designed to impart superior performance in the pH range of 4.5 to 7.5, while maintaining repulpability. "Hercobond 1000" glyoxalated polyacrylamide provides improvements in various strength properties in many paper and paperboard grades, and allows substitution of lower cost fibers. "Hercobond 1000" glyoxalated polyacrylamide is normally added at a point where it will be well distributed prior to sheet formation to ensure maximum retention on the longer fiber fraction of the furnish. Depending on overall system cleanliness, a promoter/charge control polymer such as "Reten 203" polyDADMAC or "Reten 201" dimethyl amine epichlorohydrin, both available from Hercules Incorporated, Wilmington, Delaware, may improve overall cost performance of "Hercobond 1000" glyoxalated polyacrylamide.

Glyoxalated polyacrylamides are disclosed in U.S. Patent No. 3,556,932 to COSCIA et al., the disclosure of which is herein incorporated by reference in its entirety, which discloses hydrophilic, thermosetting vinylamide polymers having a property of imparting wet strength and dry strength to paper.

U.S. Patent Application No. 09/136,855 to GEER et al., filed August 19, 1998 entitled "Dialdehyde-Modified Anionic and Amphoteric Polyacrylamides for Improving Dry Strength and

Wet Strength in Paper", the disclosure of which is herein incorporated by reference in its entirety, discloses compositions comprising crosslinked, thermosetting, water soluble polymer having nonionic moieties derived from acrylamide, methacrylamide or both; anionic moieties derived from a, β-unsaturated carboxylic acids having from 3 to 5 carbon atoms and salts thereof; and optionally cationic moieties derived from unsaturated monomers containing amino groups or quaternary ammonium groups, the polymer having aldehyde functionality.

FARLEY, Wet-Strength Resins and Their Application. "Glyoxalated Polyacrylamide Resin", pp. 45-61 (1994), the disclosure of which is herein incorporated by reference in its entirety, is focused primarily on the use of resin in paper toweling and discloses that glyoxalated polyacrylamide (PAM) permits basis weights to be reduced while maintaining wet and dry strength. The reduction in basis weight is disclosed as being based on an increase in dry strength and that added dry strength is desirable in certain napkin and specialty creped grades. Further, it is disclosed that glyoxalated polyacrylamides permit the use of increased levels of weaker, less expensive fibers such as mechanical fibers without sacrificing the desired sheet strength properties. This document, however, discloses that the added dry strength may not always be desirable. For example, higher dry strength in consumer towel can have a negative impact on sheet softness or "handfeel".

Other glyoxalated polyacrylamides are disclosed in U.S. Patent No. 4,605,702 to GUERRO et al.; and U.S. Patent Nos. 4,954,538, 5,041,503, and 5,320,711 to DAUPLAISE et al., the disclosures of which are herein incorporated by reference in their entireties.

In view of the above, FARLEY discloses using glyoxalated polyacrylamide to reduce basis weight and to increase weak fiber levels. While the background art, such as FARLEY, discloses use of glyoxalated polyacrylamides for increasing wet and/or dry strength of paper products, the background art involving glyoxalated polyacrylamides is not concerned with opacity characteristics of paper products, especially reduced basis weight paper products. In this regard, the opacity of the paper product, e.g., newsprint, is particularly important when the paper product is used as a reading material. Therefore, there is a need for methods for producing low basis weight and/or high mechanical pulp content, high opacity paper products.

SUMMARY OF THE INVENTION This invention relates to processes and compositions for providing paper products having desirable strength properties.

The present invention also relates to paper products having at least acceptable dry strength, especially at reduced basis weights, and preferably in paper products having at least acceptable levels of opacity. The present invention also relates to maintaining or increasing dry strength of paper products while reducing the basis weight of the paper products and while achieving at least acceptable levels of opacity. By reducing the basis weight of the paper products, substantial cost savings can be achieved through the present invention. Further, the present invention relates to paper products having at least acceptable dry strength while containing mechanical pulp. The present invention also relates to maintaining or increasing dry strength of paper products, especially at reduced basis weights, while increasing mechanical pulp content and while achieving at least acceptable levels of opacity. By increasing the mechanical pulp content relative to more expensive pulps, substantial cost savings can be achieved through the present invention.

The present invention also relates to adding glyoxalated polyacrylamide and opacifier in the formation of paper products, especially in paper products having low basis weights and/or increased mechanical pulp, and yet having at least acceptable levels of dry strength and opacity. In accordance with one aspect, the present invention is directed to a method of making paper product, comprising: adding glyoxalated polyacrylamide and opacifier to wet pulp to form wet pulp mix, and forming paper product from the wet pulp mix. The present invention is also directed to paper product made by this method.

In accordance with another aspect, the present invention is directed to a method of making newsprint, comprising: adding glyoxalated polyacrylamide to wet pulp to form wet pulp mix; and forming newsprint from the wet pulp mix. The present invention is also directed to newsprint made by this method.

In accordance with still another aspect, the present invention is directed to a method of making wood containing paper, comprising: adding glyoxalated polyacrylamide and opacifier to wet pulp comprising mechanical pulp, and forming wood containing paper from the wet pulp, wherein the wood containing paper has a dry, machine direction tensile strength of at least about

6 lb/in width and an opacity of at least about 85%. The present invention is also directed to wood containing paper made by this method.

In accordance with one aspect, the wet pulp for the paper product comprises mechanical pulp.

In accordance with another aspect, the paper product comprises wood containing paper.

In accordance with another aspect, the opacifier comprises at least one of clay, precipitated calcium carbonate, TiO2, and alumino-silicate.

In accordance with still another aspect, the paper product, newsprint, or wood containing paper has a basis weight of preferably about 10 to 60 lb/3000 ft2, more preferably about 20 to 40 lb/3000 ft2. The newsprint may have a basis weight of about 20 to 33 lb/3000 ft2, more preferably 24 to 27 lb/3000 ft2. In accordance with yet another aspect, the paper product or newsprint has a dry, machine direction tensile strength of at least about 6 lb/in width.

In accordance with another aspect, the paper product, newsprint, or wood containing paper has an opacity of preferably at least about 85%, more preferably at least about 90%o.

In accordance with another aspect, the wet pulp for the paper product comprises at least about 10 wt% of mechanical pulp, and the paper product has an opacity of at least about 85%o.

In accordance with another aspect, the methods of making paper product and wood containing paper further comprise coating the paper product or wood containing paper.

In accordance with still another aspect, the glyoxalated polyacrylamide may comprise glyoxalated cationic polyacrylamide, glyoxalated amphoteric polyacrylamide, or glyoxalated anionic polyacrylamide.

In accordance with another aspect, the glyoxalated polyacrylamide is added in an amount of preferably about 0.05 to 1.5 wt%, more preferably about 0J to 0.8 wt%, and most preferably about 0J to 0.4 wt% based on dry pulp.

In accordance with yet another aspect, the opacifier is added in an amount of preferably about 1 to 20 wt%, more preferably about 1 to 10 wt%, and most preferably about 2 to 4 wt% based on dry pulp.

In accordance with another aspect, the method further comprises adding retention aid to the wet pulp.

In accordance with still another aspect, the method further comprises adding alum to the wet pulp.

In accordance with another aspect, the wet pulp comprises preferably at least about 50 wt% of mechanical pulp, more preferably at least about 80 wt% of mechanical pulp.

In accordance with yet another aspect, the wet pulp mix has a pH of preferably about 3 to 10, more preferably about 4 to 7.

In accordance with still another aspect, the wood containing paper comprises newsprint. In accordance with another aspect, the wood containing paper has a stress intensity factor of preferably about 1 to 4 MPa(m) \ more preferably about 2 to 4 MPa(m) /:, and most preferably about 3 to 3.5 MPa(m)'J

In accordance with another aspect, the wood containing paper has a Mullen burst strength of preferably at least about 5 psi, more preferably about 6 to 15 psi, and most preferably about 10 to 14 psi. In accordance with still another aspect, the wood containing paper has a tensile energy absorbed (TEA) of preferably at least about 0.01 (in-lb)/in2, more preferably about 0.02 to 0.08 (in-lb)/in2, and most preferably about 0.03 to 0.07 (in-lb)/in2.

In accordance with another aspect, the wood containing paper has a density of about 0.4 to 0.8 g/cm3, more preferably about 0.5 to 0J g/cm3, and most preferably about 0.6 to 0.7 g/cm3.

DETAILED DESCRIPTION OF THE INVENTION The particulars shown herein are by way of example and for purposes of illustrative discussion of the various embodiments of the present invention only and are presented in the cause of providing what is believed to be the most useful and readily understood description of the principles and conceptual aspects of the invention. In this regard, no attempt is made to show details of the invention in more detail than is necessary for a fundamental understanding of the invention, the description making apparent to those skilled in the art how the several forms of the invention may be embodied in practice.

All percent measurements in this application, unless otherwise stated, are measured by weight based upon 100% of a given sample weight. Thus, for example, 30% represents 30 weight parts out of every 100 weight parts of the sample.

Unless otherwise stated, a reference to a compound or component, includes the compound or component by itself, as well as in combination with other compounds or components, such as mixtures of compounds. Before further discussion, a definition of the following terms will aid in the understanding of the present invention.

BASIS WEIGHT: weight of paper product per a given area of paper product, e.g., lb/3000 ft2 or lb/ream.

GRAMMAGE: grams of paper product per square meter (gsm).

DRY STRENGTH: strength of paper product in a dry state, i.e., less than about 10 wt% of moisture content.

OPACITY: property of paper product that obstructs passage of light and prevents seeing through the paper product objects on the opposite side. In this application, opacity is measured in accordance with Tappi T425 which is the same as ASTM D589.

OPACIFIER: a substance which may be used to increase the opacity of paper products by increasing the light scattering property of the paper product.

CHEMICAL PULP: wood pulp made by separating the fibers of wood chips by the action of chemicals, such as alkalies and acids.

MECHANICAL PULP: wood pulp produced by mechanically separating fibers, e.g., by grinding or mechanically refining. WOOD CONTAINING PAPER PRODUCT (MECHANICAL PRINTING PAPER

PRODUCT, GROUND WOOD PAPER PRODUCT): a paper product containing at least 10 wt% of mechanical pulp.

NEWSPRINT: non-coated wood containing printing paper having a brightness of less than about 62%o, as measured in accordance with Tappi T452 which is the same as ISO 2469, and a Parker print surf (PPS) roughness of greater than about 3 microns, as measured in accordance with Tappi T555 which is the same as ISO 8791-4.

As an overview, this invention relates to processes and compositions for providing paper products having desirable strength properties, especially paper products having at least acceptable dry strength at reduced basis weights. More specifically, the present invention relates to maintaining or increasing dry strength of paper products while reducing the basis weight of the paper products and while achieving at least acceptable levels of opacity. By reducing the basis weight of the paper products, substantial cost savings can be achieved through the present invention.

Further, the present invention relates to paper products having at least acceptable dry strength with mechanical pulp. In particular, the present invention relates to maintaining or increasing dry strength of paper products while increasing mechanical pulp content and while achieving at least acceptable levels of opacity. By increasing the mechanical pulp content relative

to more expensive pulps, such as chemical pulps, substantial cost savings can be achieved through the present invention.

The present invention is also related to adding glyoxalated polyacrylamide and opacifier to wet pulp to form a wet pulp mix. The wet pulp mix may be used to make paper products. Such paper products may have a low basis weight and/or increased mechanical pulp, and yet have at least acceptable levels of dry strength and opacity.

As noted above, the present invention utilizes glyoxalated polyacrylamides to obtain a reduction of basis weight and/or to permit an increase in mechanical pulp content. The glyoxalated polyacrylamide may be cationic, anionic, or amphoteric (i.e., containing both cationic and anionic sites with a net charge that is cationic). The glyoxalated polyacrylamide is preferably cationic or amphoteric. In particular, the glyoxalated polyacrylamide may be a glyoxal modified

DADMAC (diallyldimethylammonium chloride)-acrylamide resin.

Examples of glyoxalated polyacrylamides include those disclosed in U.S. Patent No.

3,556,932 to COSCIA et al.; U.S. Patent No. 4,605,702 to GUERRO et al.; U.S. Patent Nos. 4,954,538, 5,041,503, and 5,320,71 1 to DAUPLAISE et al.; U.S. Patent Application No.

09/136,855 to GEER et al., filed August 19, 1998, entitled "Dialdehyde-Modified Anionic and

Amphoteric Polyacrylamides for Improving Dry Strength and Wet Strength in Paper"; and

FARLEY, Wet-Strength Resins and Their Application. "Glyoxalated Polyacrylamide Resin", pp.

45-61 (1994), the disclosures of which are herein incorporated by reference in their entireties. Preferred examples of glyoxalated polyacrylamides include "Hercobond 1000" glyoxalated polyacrylamide available from Hercules Incorporated, Wilmington, Delaware and

"Parez 631 " glyoxalated polyacrylamide available from Cytec Technology Corporation, Stamford,

Connecticut.

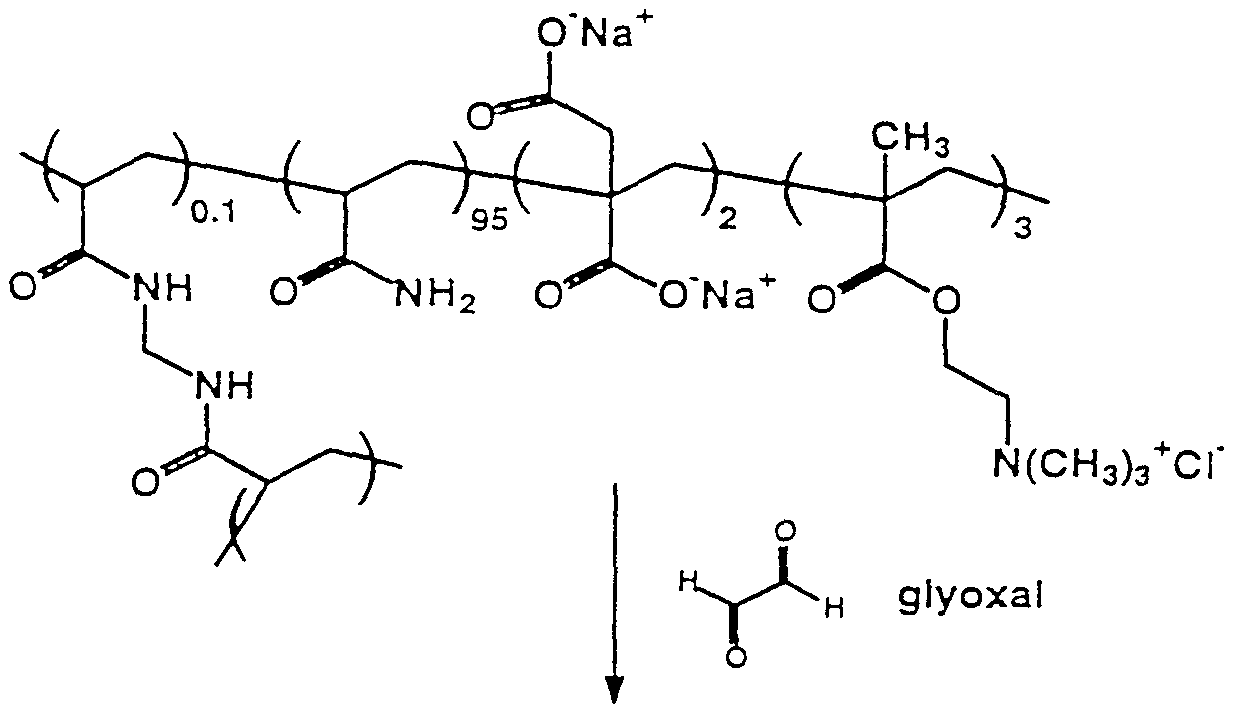

"Hercobond 1000" glyoxalated polyacrylamide can be formed by adding about 25 mol%o of glyoxal relative to acrylamide. In this process, about 33 to 50% of the glyoxal normally reacts with the acrylamide. The formula for "Hercobond 1000" glyoxalated polyacrylamide is shown in Formula (I) below:

The chemistry of a glyoxalated amphoteric polyacrylamide discussed in the above-noted U.S. Patent Application No. 09/136,855 to GEER et al., the disclosure of which is herein incorporated by reference in its entirety, is shown below with reference to Formulas (II) and (III):

itaconic acid

methylenebisacrylamide potassium bromate (MBA) sodium metabisulfite

Formula (II)

The chemistry of another glyoxalated polyacrylamide discussed in the above-noted U.S. Patent Application No. 09/136,855 to GEER et al., the disclosure of which is herein incorporated by reference in its entirety, is shown below with reference to Formulas (IV) and (V):

The chemistry of still another glyoxalated polyacrylamide, aldehyde azetidinium, is shown below with reference to Formulas (VI) and (VII). As shown below, aldehyde azetidinium is the reaction product of acrylamide-diallylamine hydrochloride copolymer with epichlorohydrin and glyoxal, with a mole ratio of acrylamide to diallylamine hydrochloride in the copolymer being about 40 to 60.

Acrylamide + Diallylamine Hydrochloride

Aldehyde-azetϊdinium resin, azetidinium-rϊch composition, (structure shows reactive functionality only)

As noted above, glyoxalated polyacrylamide may be added to increase strength properties to allow a reduction of basis weight and/or an increase in mechanical pulp content. The paper- product can have a basis weight of preferably about 10 to 60 lb/3000 ft2 (about 16 to 98 gsm), more preferably about 20 to 40 lb/3000 ft2 (about 33 to 65 gsm). For newsprint, the basis weight is preferably about 20 to 33 lb/3000 ft2 (about 33 to 54 gsm), more preferably about 24 to 30 lb/3000 ft2 (about 39 to 49 gsm), and most preferably about 24 to 27 lb/3000 ft2 (about 39 to 44 gsm).

The pulp mix can have a mechanical pulp content of preferably at least about 10 wt%, more preferably at least about 30 wt%, even more preferably at least about 50 wt%, and most preferably at least about 80 wt%. For newsprint, the mechanical pulp content in the pulp mix is preferably at least about 80 wt%, more preferably at least about 90 wt%, and most preferably at least about 95 wt%. The paper product may have a mechanical pulp content of preferably at least about 10 wt%, more preferably at least about 30 wt%>, even more preferably at least about 50 wt%, and most preferably at least about 80 wt%. For newsprint, the mechanical pulp content in the newsprint is preferably at least about 80 wt%, more preferably at least about 90 wt%, and most preferably at least about 95 wt%. Increasing the amount of mechanical pulp relative to more expensive pulps may result in substantial cost savings, but may also result in reduced paper product strength.

To maintain or increase strength properties in paper products having such basis weights and mechanical pulp contents, the glyoxalated polyacrylamide may be added in an amount of preferably about 0.05 to 1.5 wt%, more preferably about 0J to 0.8 wt%, and most preferably about 0J to 0.4 wt% based on dry pulp. In this regard, a substantial amount of strength is imparted when as little as about 0.1 wt% is used. The strengthening effect further increases up to at least about 2.0 wt%. The glyoxalated polyacrylamides of the present invention are conveniently employed in the manufacture of paper products as dilute aqueous solutions of preferably about 7 to 10 wt%, more preferably about 8.5 wt%. The solutions can be applied to preformed paper products by the "tub" or impregnation method, but more preferably are applied by adding the solutions directly to papermaking fibrous suspensions at any point in the papermaking system where strengthening agents may be added.

An opacifier may be added to obtain paper products having an opacity of at least about 85%), more preferably at least about 90%o, with ranges of preferably about 90 to 98%, and most

preferably about 93 to 97%, as measured in accordance with Tappi T425 which is the same as ASTM D589. The opacifiers have a particle size of preferably less than about 3 microns, more preferably less than about 2 microns, and most preferably less than 1 micron. The opacifiers have a surface area of preferably greater than 6 nr/g, more preferably greater than 12 m2/g, and most preferably greater than 16 m2/g, with ranges of preferably about 3 to 6 m 2/g, more preferably about 6 to 12 m2/g, and most preferably about 12 to 24 m2/g.

Examples of opacifiers include calcined clay, precipitated calcium carbonate, kaolin clay, TiO2, and alumino-silicates. The opacifier is preferably calcined clay or precipitated calcium carbonate. A preferred example of the calcined clay is "Hycal" calcined clay available from Huber Engineered Minerals, Macon, Georgia. A preferred example of precipitated calcium carbonate is "Albacar HO" precipitated calcium carbonate available from Specialty Minerals, Bethlehem, Pennsylvania.

To achieve an opacity of at least about 85% in paper products having the above-noted basis weights and mechanical pulp contents, the opacifier is added in an amount of preferably about 1 to 20 wt%, more preferably about 1 to 10 wt%, and most preferably about 2 to 4 wt% based on dry pulp.

Further additives may also be added to the wet pulp. The additives may be any additive, such as those which are normally used in paper making, such as retention aids, biocides, defoamer, and sizing agents which control the penetration of aqueous liquids. Regarding preferred additives, when anionic glyoxalated polyacrylamides are used, a retention agent is usually added. For example, there may be employed cationic retention aids, such as the melamine-formaldehyde acid colloid of U.S. Patent No. 2,345,543 to WOHNSIEDLER et al., the disclosure of which is herein incorporated by reference in its entirety, the adipic acid-diethylenetriamine-epichlorohydrin resin of U.S. Patent No. 2,926,154 to KEIM, the disclosure of which is herein incorporated by reference in its entirety, polyethyleneimine, and polyvinylpyridine quaternized with butyl bromide. Other examples of retention aids include low molecular weight quaternary amines having medium to high charge density such as "Reten 203" polyDADMAC and "Reten 201" dimethyl amine epichlorohydrin. Retention aid may be added in an amount of preferably about 0.012 to 0.4 wt%>, more preferably about 0.025 to 0.2 wt%>, and most preferably about 0.05 to 0.1 wt% based on dry pulp.

In addition to glyoxalated polyacrylamide, other wet strength and dry strength resins may also be used as additives. Examples of such additives include polyaminopolyamide-epi resin

(such as "Kymene 557H" wet-strength resin available from Hercules Incoφorated), cationic starch, polyamine-epi resins (such as "Reten 204" resin available from Hercules Incoφorated), and polyethyleneimine.

Further, additives may be used to control charge and to control the pH of the wet pulp mix. The preferred cationic glyoxalated polyacrylamides of the present invention are rapidly and substantively adsorbed by the papermaking fibers at pH values ranging from about 3.5 to about 8 and the use of retention aids is usually unnecessary. While the best wet strength results are achieved at low pH, very satisfactory results may be achieved with neutral pulps. In view of the above, the wet pulp mix has a pH of preferably about 3 to 10, and more preferably about 4 to 7. An example of an additive for controlling charge and pH is alum which may be added in an amount of preferably about 0J5 to 2 wt%, more preferably about 0.5 to 1 wt% of the wet pulp mix.

The wet pulp may be substantially any kind of wet pulp and mixtures thereof. In particular, the wet pulp preferably includes mechanical pulp, and even more preferably includes enough mechanical pulp to form a wood containing paper. Other examples of the components of the wet pulp include softwood, hardwood, sawdust, secondary (i.e., from recycled paper materials including ash containing fibers), and machine broke fibers. The fibers may have been produced in a kraft or sulfite pulping process.

From the wet pulp mix is formed the paper product in a conventional manner. In this regard, the paper product may be made by adding glyoxalated polyacrylamide and opacifier to a wet pulp involving cellulose papermaking fibers in an aqueous suspension, forming the suspension into a water-laid web, and drying the web thereby developing the paper product.

The resulting paper product may be any type of paper product, which may be coated or non-coated. The coating process may be done in a conventional manner and may involve coatings such as a pigment in a binder such as clay in latex. For example, the paper product is preferably a wood containing paper. Wood containing paper is also known as mechanical printing paper and groundwood paper. A preferred type of paper product is newsprint.

As noted above, the present invention is directed to low basis weight paper products and/or mechanical pulp paper products having at least acceptable strength and opacity. In particular, the method of the present invention has been able to reduce newsprint basis weight by 6% relative to conventional newsprints while obtaining at least acceptable levels of dry strength and opacity.

Thus, the paper product has improved dry strength to allow reduction in basis weight. In particular, the paper product preferably has a machine direction (MD) dry tensile strength of at least about 6 lb/in width, more preferably at least about 10 lb/in width, with ranges of preferably about 10 to 18 lb/in width, and more preferably about 12 lb/in width to 15 lb/in width, as measured in accordance with Tappi T494 which is the same as ASTM D828.

The paper product preferably has a stress intensity factor (SIF) of about 1 to 4 MPa(m)J. more preferably about 2 to 4 MPa(m) 2, and most preferably about 3 to 3.5 MPa(m) 'A: The puφose of this test is to determine the fracture strength of paper or paperboard using linear elastic models. In this application, SIF is measured by using a "T/A EJ A 1000 Tester" analytical device available from Thwing-Albert Instrument Company, Philadelphia, Pennsylvania. The speed is set for 2 mm/min. The jaws have 4 inch grips. Instead of using a rotating suspending arm in the upper position, a solid, rigid arm is used. This rigid arm is produced from a single piece of metal to the dimensions of the rotating arm for the puφose of maintaining the grips parallel. The jaws are set for 14 cm apart as measured from the inside edges of the jaws. It is important to ensure that the tops and bottoms of the jaws are parallel to each other prior to the testing.

The samples to be tested are cut into rectangular strips that are 9 cm wide and 20 cm long. In these strips, on each side a 2.5 cm slit is cut into the 20 cm long edges of the strip at a position which is 9 cm from either the top or bottom on each side to produce a 4 cm wide section of paper product. The two 2.5 cm slits are in the form of straight lines that are peφendicular to the 14 cm long edges of the paper product. The samples should be conditioned for at least 24 hours at 74 ± 2°C and 50 ± 2% relative humidity.

The caliper of each sample is then measured. After the caliper is measured, the samples to be tested are placed in the jaws of the tensile tester such that the samples are aligned peφendicular to the jaws. The test is then initiated and allowed to run on the "T/A EJA/1000

Tester" analytical device.

Once this test is run, to calculate the MPa force, the cross-sectional area of the paper product is divided into the tensile load in Newtons obtained during the test to thereby obtain σf. SIF is calculated by using the known equation: SIF = Kc = βσ^πa)'72, where β is a geometric factor which equals 1J012, σf is as discussed above, π is 3J4159..., and a is the slit length (a = 0.025 m in the procedure discussed above).

The paper product preferably has a Mullen burst strength of at least about 5 psi, more preferably about 6 to 15 psi, and most preferably about 10 to 14 psi, as measured in accordance with Tappi T403 which is the same as ASTM D774.

The paper product preferably has a tensile energy absorbed (TEA) of at least about 0.01 (in-lb)/in2, more preferably about 0.02 to 0.08 (in-lb)/in2, and most preferably about 0.03 to 0.07

(in-lb)/in2.

The paper product preferably has a density of about 0.4 to 0.8 g/cm3, more preferably about 0.5 to 0J g/cm3, and most preferably about 0.6 to 0J g/cm3.

The present invention will be further illustrated by way of the following Examples. These examples are non-limiting and do not restrict the scope of the invention.

Unless stated otherwise, all percentages, parts, etc. presented in the examples are by weight.

EXAMPLES 1-9 AND COMPARATIVE EXAMPLES 1-8 These Examples and Comparative Examples show improvement in dry strength resulting from use of glyoxalated polyacrylamides in wood containing paper.

These Examples and Comparative Examples were run on a pilot paper machine. The pilot paper machine included a "headbox" to distribute pulp slurry onto a moving wire fabric, a vacuum dewatering device under the wire, 2 straight through press nips, electrically heated dryer cylinders, and a 5 nip calender stack prior to reeling.

In each of these Examples and Comparative Examples, the pilot paper machine was run under the following conditions: the pulp content of the slurry was about 0.25 wt%>, the pulp slurry temperature was at 30 to 50°C, the speed was 12 ft/minute, the presses were at 60 psig of pressure, the dryer cylinders were at 90 to 95°C, and the calender stack pressure was at 55 PLI (pounds per linear inch). Under these conditions, the sheet was dried to 6 to 7 wt%> of moisture at the reel.

The conditions and results of each of these Examples and Comparative Examples are summarized in Table 1 below. The target basis weights were 28 lb/3000 ft2 (47 gsm) and 25 lb/3000 ft2 (42 gsm) which is a 12-13% difference. The runs were targeted at a paper density of 0.48 g/cm3 to minimize variation in caliper. All runs were made with 5 wt%o softwood kraft with the remainder being repulped blank newsprint stock. Although most of the runs involved a pH of 4.5 with 1 wt% of alum, some of the runs involved a pH of 7 as noted in Table 1 below. In all

runs, 0.01 wt%ι of "Reten 157" cationic flocculent available from Hercules Incoφorated, Wilmington, Delaware, was used. The Comparative Examples included control runs of 28 lb/3000 ft2 and 25 lb/3000 ft2 with or without 2 wt% of clay. The clay used in these Examples and Comparative Examples was "Hycal" calcined clay available from Huber Engineered Minerals, Macon, Georgia.

In Table 1, "Aid. Azet Resin" refers to the aldehyde azetidinium as shown in Formula (VII) above. "Ash xrf ' refers to the ash content as measured by the x-ray fluorescence method. The Mullen index is the mean dry Mullen per grammage in units of kN/m2/grammage. The Tensile Index is the mean dry MD tensile strength per grammage in units of N/m/grammage. The adjusted values of Table 1 are normalized to either 28 lb/3000 ft2 (47 gsm) or 25 lb/3000 ft2 (42 gsm), depending upon the target basis weight.

TABLE 1

The results of Table 1 are summarized in Table 2 below. In each case, the change in Mullen burst strength was obtained from the mean dry Mullen aged 18 days, the tensile strength was obtained from the mean dry MD tensile, and the TEA was obtained from the mean dry MD TEA. For aldehyde-azetidinium resin at pH 7, the averages of these properties at 0.2 wt% and 0.4 wt% dosage levels were compared with the respective values of these properties of Comparative Example 4. For "Parez 631 " glyoxalated polyacrylamide and aldehyde azetidinium resin at pH 4.5, the averages of these properties at 0J wt% and 0.4 wt% level were compared with the respective values of these properties of Comparative Example 8. For example, the increase in tensile strength resulting from "Parez 631 " glyoxalated polyacrylamide was calculated as follows:

((((8.39+8.34)/2)-7.78)/7.78) x 100 = 7.5%.

TABLE 2

As seen from Table 2, the best results were obtained by using "Parez 631 " glyoxalated polyacrylamide. Also as seen from Table 2, the aldehyde-azetidinium resin performed better at pH 7 than at pH 4.5. In view of these results, the aldehyde-azetidinium resin may be particularly useful for newsprint furnishes run at pH 7 or higher. However, most newsprints are made under acidic conditions.

EXAMPLES 10-20 AND COMPARATIVE EXAMPLES 9-12 These Examples and Comparative Examples show that dry strength can be maintained or increased by using glyoxalated polyacrylamides in wood containing paper even when basis weight is reduced. These Examples and Comparative Examples also show the effect of adding opacifier to paper product.

These Examples and Comparative Examples were run on the same pilot paper machine as used in Examples 1-9 and Comparative Examples 1-8. In each of these Examples and Comparative Examples, the pulp content of the slurry, the pulp slurry temperature, speed, press pressure, dryer cylinder temperature, and calender stack pressure were set the same as in Examples 1-9 and Comparative Examples 1-8.

The conditions and results of each of these Examples and Comparative Examples are summarized in Tables 3 and 4 below. The target basis weights were 28 lb/3000 ft2 (47 gsm) and 25 lb/3000 ft2 (42 gsm) which is a 12-13%o difference. The runs were targeted at 0.48 g/cm3 density to minimize variation in caliper. All runs were made with 5 wt% softwood kraft with the remainder being repulped blank newsprint stock. During these runs, it was found that refining the TMP (thermomechanical paper) from 200 to 150 CSF (Canadian standard freeness) seemed to improve strength, formation, and runnability. The pH for these runs was 4.5 with 1 wt%> of alum being added. The Comparative Examples involved control runs of 28 lb/3000 ft2 and 25 lb/3000 ft2 with or without 2 wt% of clay. The clay used in these Examples and Comparative Examples was "Hycal" calcined clay available from Huber

Engineered Minerals, Macon, Georgia.

In Tables 3 and 4, "R 203" refers to "Reten 203" polyDADMAC, and "R 201" refers to "Reten 201" dimethyl amine epichlorohydrin, both available from Hercules Incoφorated, Wilmington, Delaware. "HB 1000" refers to "Hercobond 1000" glyoxalated polyacrylamide and "HB 2000" refers to "Hercobond 2000" anionic polyacrylamide-acrylic acid, both available from Hercules Incoφorated, Wilmington, Delaware, and "GlyAmpPAC" refers to the glyoxalated amphoteric polyacrylamide shown in Formula (V) above. "Form" refers to formation which is a measure of visual appearance as measured by an M&K formation tester available from M&K Systems Inc., Danvers, Massachusetts. The adjusted values of Tables 3 and 4 are normalized to either 28 lb/3000 ft2 (47 gsm) or 25 lb/3000 ft2 (42 gsm), depending upon the target basis weight.

TABLE 3

TABLE 4

) )

The results of Tables 3 and 4 are summarized in Table 5 below. For each composition, the values listed are the averages for the respective properties. For example, the values for "Hercobond 1000" glyoxalated polyacrylamide involve the average of each property for Examples 10-12.

TABLE 5

As seen from Tables 3-5, "Hercobond 1000" glyoxalated polyacrylamide outperformed

"Hercobond 2000" anionic polyacrylamide-acrylic acid and the glyoxalated polyacrylamide of Formula (V). Further, 42 gsm paper treated with "Hercobond 1000" had higher dry strength properties than the 45 gsm control paper of Comparative Example 9.

EXAMPLES 21-23 AND COMPARATIVE EXAMPLES 13-14

These Examples and Comparative Examples show improvement in dry strength by using the glyoxalated amphoteric polyacrylamide of Formula (III) in groundwood newsprint furnish.

Paper was prepared on a continuous papermaking former from a 95:5 blend based on weight of repulped groundwood newsprint (unrefined) and softwood bleached kraft pulp refined to about 410 ml (CSF) Canadian standard freeness. Sheets were generated having 42 gsm basis weight at a papermaking pH of about 4.5 with 1 wt%> of alum. Control runs (no additives) were prepared at 42 and 45 gsm basis weight for comparison. Ingredients and results are summarized in Table 6.

TABLE 6

As shown in Table 6, this glyoxalated amphoteric polyacrylamide increased dry strength of the 42 gsm sheet to a level which was higher than that obtained with a heavier (45 gsm) sheet without such resin. Further, higher levels of resin resulted in higher strength.

EXAMPLES 24-39 AND COMPARATIVE EXAMPLES 15-16 These Examples and Comparative Examples show that short fibers, e.g., mechanical pulp, can be substituted for long fibers, e.g., chemical pulp, without sacrificing dry strength by using glyoxalated polyacrylamides. These Examples and Comparative Examples also show the effect of adding opacifier to paper product.

These Examples and Comparative Examples were run on the same pilot paper machine as used in Examples 1-9 and Comparative Examples 1-8. In each of these Examples and Comparative Examples, the pulp content of the slurry, the pulp slurry temperature, speed, press pressure, dryer cylinder temperature, and calender stack pressure were set the same as in Examples 1-9 and Comparative Examples 1-8.

The conditions and results of each of these Examples and Comparative Examples are summarized in Table 7 below. The runs were targeted at 0.48 density to minimize variation in caliper. The pH for these runs was 4.5 with 1.2 wt% of alum. In some of the runs, "Hydrex" alumino-silicate available from Huber Engineered Minerals, Macon, Georgia, was added. Other additives included 0.75 wt% based on dry fiber of cationic starch as well as 0J lb/ton based on dry fiber of "Nalco 8671 " silica and 0.2 lb/ton based on dry fiber of "Nalco 7530" retention aid, both available from Nalco Chemical Company, Naperville, Illinois.

In Table 7, "R 203" refers to "Reten 203" polyDADMAC, and "R 201 " refers to "Reten 201 " dimethyl amine epichlorohydrin, both available from Hercules Incoφorated, Wilmington, Delaware. "HB 1000" refers to "Hercobond 1000" glyoxalated polyacrylamide and "HB 2000" refers to "Hercobond 2000" anionic polyacrylamide-acrylic acid, both available from Hercules Incoφorated. Wilmington, Delaware, "GlyAmpPAC" refers to the glyoxalated amphoteric polyacrylamide shown in Formula (V) above, and "K557H" refers to "Kymene 557H" wet-strength resin available from Hercules Incoφorated, Wilmington, Delaware. "Form" refers to formation which is a measure of visual appearance as measured by an M&K formation tester available from M&K Systems Inc., Danvers, Massachusetts. "Pulp blend" refers to the content of groundwood/sulfite/kraft pulps, respectively.

TABLE 7

As shown in Table 7, addition of glyoxalated polyacrylamides is able to increase the strength of 65/35 based paper to the strength of 60/40 based paper. Thus, addition of glyoxalated polyacrylamide allows substitution of short fibers, e.g., mechanical pulp, for long fibers, e.g., chemical pulp.

While the invention has been described in connection with certain preferred embodiments so that aspects thereof may be more fully understood and appreciated, it is not intended to limit the invention to these particular embodiments. On the contrary, it is intended to cover all alternatives, modifications and equivalents as may be included within the scope of the invention as defined by the appended claims.