WO2007002518A1 - Delayed release or extended-delayed release dosage forms of pramipexole - Google Patents

Delayed release or extended-delayed release dosage forms of pramipexole Download PDFInfo

- Publication number

- WO2007002518A1 WO2007002518A1 PCT/US2006/024665 US2006024665W WO2007002518A1 WO 2007002518 A1 WO2007002518 A1 WO 2007002518A1 US 2006024665 W US2006024665 W US 2006024665W WO 2007002518 A1 WO2007002518 A1 WO 2007002518A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- pramipexole

- release

- delayed

- pharmaceutical composition

- polymer

- Prior art date

Links

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/14—Particulate form, e.g. powders, Processes for size reducing of pure drugs or the resulting products, Pure drug nanoparticles

- A61K9/16—Agglomerates; Granulates; Microbeadlets ; Microspheres; Pellets; Solid products obtained by spray drying, spray freeze drying, spray congealing,(multiple) emulsion solvent evaporation or extraction

- A61K9/1605—Excipients; Inactive ingredients

- A61K9/1617—Organic compounds, e.g. phospholipids, fats

- A61K9/1623—Sugars or sugar alcohols, e.g. lactose; Derivatives thereof; Homeopathic globules

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/185—Acids; Anhydrides, halides or salts thereof, e.g. sulfur acids, imidic, hydrazonic or hydroximic acids

- A61K31/19—Carboxylic acids, e.g. valproic acid

- A61K31/195—Carboxylic acids, e.g. valproic acid having an amino group

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/185—Acids; Anhydrides, halides or salts thereof, e.g. sulfur acids, imidic, hydrazonic or hydroximic acids

- A61K31/19—Carboxylic acids, e.g. valproic acid

- A61K31/195—Carboxylic acids, e.g. valproic acid having an amino group

- A61K31/197—Carboxylic acids, e.g. valproic acid having an amino group the amino and the carboxyl groups being attached to the same acyclic carbon chain, e.g. gamma-aminobutyric acid [GABA], beta-alanine, epsilon-aminocaproic acid, pantothenic acid

- A61K31/198—Alpha-aminoacids, e.g. alanine, edetic acids [EDTA]

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/33—Heterocyclic compounds

- A61K31/395—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins

- A61K31/41—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins having five-membered rings with two or more ring hetero atoms, at least one of which being nitrogen, e.g. tetrazole

- A61K31/425—Thiazoles

- A61K31/428—Thiazoles condensed with carbocyclic rings

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/0012—Galenical forms characterised by the site of application

- A61K9/0053—Mouth and digestive tract, i.e. intraoral and peroral administration

- A61K9/006—Oral mucosa, e.g. mucoadhesive forms, sublingual droplets; Buccal patches or films; Buccal sprays

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/0012—Galenical forms characterised by the site of application

- A61K9/0053—Mouth and digestive tract, i.e. intraoral and peroral administration

- A61K9/0065—Forms with gastric retention, e.g. floating on gastric juice, adhering to gastric mucosa, expanding to prevent passage through the pylorus

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/14—Particulate form, e.g. powders, Processes for size reducing of pure drugs or the resulting products, Pure drug nanoparticles

- A61K9/16—Agglomerates; Granulates; Microbeadlets ; Microspheres; Pellets; Solid products obtained by spray drying, spray freeze drying, spray congealing,(multiple) emulsion solvent evaporation or extraction

- A61K9/1605—Excipients; Inactive ingredients

- A61K9/1629—Organic macromolecular compounds

- A61K9/1652—Polysaccharides, e.g. alginate, cellulose derivatives; Cyclodextrin

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/20—Pills, tablets, discs, rods

- A61K9/2072—Pills, tablets, discs, rods characterised by shape, structure or size; Tablets with holes, special break lines or identification marks; Partially coated tablets; Disintegrating flat shaped forms

- A61K9/2077—Tablets comprising drug-containing microparticles in a substantial amount of supporting matrix; Multiparticulate tablets

- A61K9/2081—Tablets comprising drug-containing microparticles in a substantial amount of supporting matrix; Multiparticulate tablets with microcapsules or coated microparticles according to A61K9/50

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/20—Pills, tablets, discs, rods

- A61K9/2072—Pills, tablets, discs, rods characterised by shape, structure or size; Tablets with holes, special break lines or identification marks; Partially coated tablets; Disintegrating flat shaped forms

- A61K9/2086—Layered tablets, e.g. bilayer tablets; Tablets of the type inert core-active coat

- A61K9/209—Layered tablets, e.g. bilayer tablets; Tablets of the type inert core-active coat containing drug in at least two layers or in the core and in at least one outer layer

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/20—Pills, tablets, discs, rods

- A61K9/28—Dragees; Coated pills or tablets, e.g. with film or compression coating

- A61K9/2806—Coating materials

- A61K9/2833—Organic macromolecular compounds

- A61K9/284—Organic macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polyvinyl pyrrolidone

- A61K9/2846—Poly(meth)acrylates

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/20—Pills, tablets, discs, rods

- A61K9/28—Dragees; Coated pills or tablets, e.g. with film or compression coating

- A61K9/2806—Coating materials

- A61K9/2833—Organic macromolecular compounds

- A61K9/2853—Organic macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polyethylene glycol, polyethylene oxide, poloxamers, poly(lactide-co-glycolide)

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/20—Pills, tablets, discs, rods

- A61K9/28—Dragees; Coated pills or tablets, e.g. with film or compression coating

- A61K9/2806—Coating materials

- A61K9/2833—Organic macromolecular compounds

- A61K9/286—Polysaccharides, e.g. gums; Cyclodextrin

- A61K9/2866—Cellulose; Cellulose derivatives, e.g. hydroxypropyl methylcellulose

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/20—Pills, tablets, discs, rods

- A61K9/28—Dragees; Coated pills or tablets, e.g. with film or compression coating

- A61K9/2886—Dragees; Coated pills or tablets, e.g. with film or compression coating having two or more different drug-free coatings; Tablets of the type inert core-drug layer-inactive layer

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/48—Preparations in capsules, e.g. of gelatin, of chocolate

- A61K9/4808—Preparations in capsules, e.g. of gelatin, of chocolate characterised by the form of the capsule or the structure of the filling; Capsules containing small tablets; Capsules with outer layer for immediate drug release

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/48—Preparations in capsules, e.g. of gelatin, of chocolate

- A61K9/4841—Filling excipients; Inactive ingredients

- A61K9/4858—Organic compounds

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/48—Preparations in capsules, e.g. of gelatin, of chocolate

- A61K9/4841—Filling excipients; Inactive ingredients

- A61K9/4866—Organic macromolecular compounds

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/48—Preparations in capsules, e.g. of gelatin, of chocolate

- A61K9/4891—Coated capsules; Multilayered drug free capsule shells

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/48—Preparations in capsules, e.g. of gelatin, of chocolate

- A61K9/50—Microcapsules having a gas, liquid or semi-solid filling; Solid microparticles or pellets surrounded by a distinct coating layer, e.g. coated microspheres, coated drug crystals

- A61K9/5005—Wall or coating material

- A61K9/5021—Organic macromolecular compounds

- A61K9/5026—Organic macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polyvinyl pyrrolidone, poly(meth)acrylates

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/48—Preparations in capsules, e.g. of gelatin, of chocolate

- A61K9/50—Microcapsules having a gas, liquid or semi-solid filling; Solid microparticles or pellets surrounded by a distinct coating layer, e.g. coated microspheres, coated drug crystals

- A61K9/5005—Wall or coating material

- A61K9/5021—Organic macromolecular compounds

- A61K9/5031—Organic macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polyethylene glycol, poly(lactide-co-glycolide)

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/48—Preparations in capsules, e.g. of gelatin, of chocolate

- A61K9/50—Microcapsules having a gas, liquid or semi-solid filling; Solid microparticles or pellets surrounded by a distinct coating layer, e.g. coated microspheres, coated drug crystals

- A61K9/5005—Wall or coating material

- A61K9/5021—Organic macromolecular compounds

- A61K9/5036—Polysaccharides, e.g. gums, alginate; Cyclodextrin

- A61K9/5042—Cellulose; Cellulose derivatives, e.g. phthalate or acetate succinate esters of hydroxypropyl methylcellulose

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/48—Preparations in capsules, e.g. of gelatin, of chocolate

- A61K9/50—Microcapsules having a gas, liquid or semi-solid filling; Solid microparticles or pellets surrounded by a distinct coating layer, e.g. coated microspheres, coated drug crystals

- A61K9/5005—Wall or coating material

- A61K9/5021—Organic macromolecular compounds

- A61K9/5036—Polysaccharides, e.g. gums, alginate; Cyclodextrin

- A61K9/5042—Cellulose; Cellulose derivatives, e.g. phthalate or acetate succinate esters of hydroxypropyl methylcellulose

- A61K9/5047—Cellulose ethers containing no ester groups, e.g. hydroxypropyl methylcellulose

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/48—Preparations in capsules, e.g. of gelatin, of chocolate

- A61K9/50—Microcapsules having a gas, liquid or semi-solid filling; Solid microparticles or pellets surrounded by a distinct coating layer, e.g. coated microspheres, coated drug crystals

- A61K9/5073—Microcapsules having a gas, liquid or semi-solid filling; Solid microparticles or pellets surrounded by a distinct coating layer, e.g. coated microspheres, coated drug crystals having two or more different coatings optionally including drug-containing subcoatings

- A61K9/5078—Microcapsules having a gas, liquid or semi-solid filling; Solid microparticles or pellets surrounded by a distinct coating layer, e.g. coated microspheres, coated drug crystals having two or more different coatings optionally including drug-containing subcoatings with drug-free core

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/48—Preparations in capsules, e.g. of gelatin, of chocolate

- A61K9/50—Microcapsules having a gas, liquid or semi-solid filling; Solid microparticles or pellets surrounded by a distinct coating layer, e.g. coated microspheres, coated drug crystals

- A61K9/5084—Mixtures of one or more drugs in different galenical forms, at least one of which being granules, microcapsules or (coated) microparticles according to A61K9/16 or A61K9/50, e.g. for obtaining a specific release pattern or for combining different drugs

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/0002—Galenical forms characterised by the drug release technique; Application systems commanded by energy

- A61K9/0004—Osmotic delivery systems; Sustained release driven by osmosis, thermal energy or gas

Definitions

- a movement disorder is a neurological disturbance that involves one or more muscles or muscle groups. Movement disorders affect a significant portion of the population, causing disability as well as distress. Movement disorders include Parkinson's disease, Huntington's chorea, progressive supranuclear palsy, Wilson's disease, Tourette's syndrome, epilepsy, tardive dyskinesia, and various chronic tremors, tics and dystonias. Different clinically observed movement disorders can be traced to the same or similar areas of the brain. For example, abnormalities of basal ganglia (a large cluster of cells deep in the hemispheres of the brain) are postulated as a causative factor in diverse movement disorders.

- basal ganglia a large cluster of cells deep in the hemispheres of the brain

- Parkinson's disease is a common disabling disease of old age affecting about one percent of the population over the age of 60 in the United States. The incidence of Parkinson's disease increases with age and the cumulative lifetime risk of an individual developing the disease is about 1 in 40. It is a progressive neurodegenerative disorder of the extra pyramidal nervous system, and is associated with the depletion of dopamine from cells in the corpus striatum. The disease affects the mobility and control of the skeletal muscular system. Its characteristic features include resting tremor, bradykinetic movements, rigidity and postural change.

- Parkinson's disease A perceived pathophysiological cause of Parkinson's disease is progressive destruction of dopamine-producing cells in the basal ganglia which comprise the pars compartum of the substantia nigra, basal nuclei located in the brain stem. Loss of dopamineric neurons results in a relative excess of acetylcholine. See Jellinger, Post Mortem Studies in Parkinson 's Disease - Is It Possible to Detect Brain Areas For Specific Symptoms? J. Neural. Transm. 56(Supp): 1-29:1999. Parkinson's disease often begins with mild limb stiffness and infrequent tremors and progresses over a period often or more years to frequent tremors and memory impairment, to uncontrollable tremors and dementia.

- Pramipexole is a non-ergot potent dopamine receptor agonist and has been shown to be clinically effective in treating Parkinson's patients in early PD. It has preferential affinity for D3 receptor within the D2 subfamily of dopamine receptors and inhibits dopamine synthesis and release. It has been found effective as a monotherapy as well as an adjunct to levodopa therapy in patients with advance disabilities. Pramipexole is marketed as immediate release tablets by Pfizer under the trade name MIRAPEX ® .

- Tardive Dyskinesia is a chronic disorder of the nervous system, characterized by involuntary, irregular rhythmic movements of the mouth, tongue, and facial muscles. The upper extremities also may be involved. These movements may be accompanied, to a variable extent, by other involuntary movements and movement disorders. These include rocking, writhing, or twisting movements of the trunk (tardive dystonia), forcible eye closure (tardive blepharospasm), an irresistible impulse to move continually (tardive akathisia), jerking movements of the neck (tardive spasmodic torticollis), and disrupted respiratory movements (respiratory dyskinesia).

- TD TD cases are caused by the prolonged use of antipsychotic drugs (neuroleptics).

- a relatively small number are caused by the use of other medications, such as metoclopramide, that, like neuroleptics, block dopamine receptors.

- TD often manifests or worsens in severity after neuroleptic drug therapy is discontinued. Resumption of neuroleptic therapy will temporarily suppress the involuntary movements, but may aggravate them in the long run.

- TD affects approximately 15-20% of patients treated with neuroleptic drugs (Khot et al., Neuroleptics and Classic Tardive Dyskinesia, in Lang AE, Werner WJ (eds.): Drug Induced Movement Disorders, Futura Publishing Co., 1992, pp 121-166). Therefore, the condition affects hundreds of thousands of people in the United States alone. The cumulative incidence of TD is substantially higher in women, in older people, and in those being treated with neuroleptics for conditions other than schizophrenia, such as bipolar disorder (manic- depressive illness) (see, e.g., Hayashi et al, Clin. Neuropharmacol. 19: 390, 1996; Jeste et al., Arck Gen. Psychiatry 52: 756, 1995).

- TD does not respond in general to antiparkinson drugs (Decker et al, New Eng. J Med. Oct. 7, p. 861, 1971).

- Focal Dystonias (FD) are a class of related movement disorders involving the intermittent sustained contraction of a group of muscles. The prevalence of focal dystonias in one US county was estimated as 287 per million (Monroe County Study); this suggests that at least 70,000 people are affected in the US alone. The spasms of focal dystonia can last many seconds at a time, causing major disruption of the function of the affected area. Some of the focal dystonias are precipitated by repetitive movements; writer's cramp is the best known example.

- Focal dystonia can involve the face (e.g., blepharospasm, mandibular dystonia), the neck (torticollis), the limbs (e.g., writer's cramp), or the trunk.

- Dystonia can occur spontaneously or can be precipitated by exposure to neuroleptic drugs and other dopamine receptor blockers (tardive dystonia).

- neuroleptic drugs and other dopamine receptor blockers e.g., writer's cramp

- No systemic drug therapy is generally effective, but some drugs give partial relief to some patients. Those most often prescribed are anticholinergics, baclofen, benzodiazepines, and dopamine agonists and antagonists. The most consistently effective treatment is the injection of botulinum toxin into affected muscles.

- a tic is an abrupt repetitive movement, gesture, or utterance that often mimics a normal type of behavior.

- Motor tics include movements such as eye blinking, head jerks or shoulder shrugs, but can vary to more complex purposive-appearing behaviors such as facial expressions of emotion or meaningful gestures of the arms and head.

- the movement can be obscene (copropraxia) or self-injurious.

- Phonic or vocal tics range from throat clearing sounds to complex vocalizations and speech, sometimes with coprolalia (obscene speech) (Leckman et al, supra).

- Tics are irregular in time, though consistent regarding the muscle groups involved. Characteristically, they can be suppressed for a short time by voluntary effort.

- Tics are estimated to affect 1% to 13% of boys and 1% to 11% of girls, the male- female ratio being less than 2 to 1. Approximately 5% of children between the ages of 7 and 11 years are affected with tic behavior (Leckman et al, Neuropsychiatry of the Bas. Gang 20(4): 839-861, 1997). The estimated prevalence of multiple tics with vocalization, e.g., Tourette's syndrome, varies among different reports, ranging from 5 per 10,000 to 5 per 1,000.

- Gilles de Ia Tourette syndrome is the most severe tic disorder. Tourette's syndrome is 3-4 times more common in boys than girls and 10 times more common in children and adolescents than in adults (Leckman et al., Neuropsychiatry of the Bas. Gang 20(4): 839-861, 1997; Esper et al, Tenn. Med. 90: 18-20, 1997). Patients with TS have multiple tics, including at least one vocal (phonic) tic. TS becomes apparent in early childhood with the presentation of simple motor tics, for example, eye blinking or head jerks. Initially, tics may come and go, but in time tics become persistent and severe, and begin to have adverse effects on the child and the child's family.

- Phonic tics manifest, on average, 1 to 2 years after the onset of motor tics. By the age of 10, most children have developed an awareness of the premonitory urges that frequently precede a tic. Such premonitions may enable the individual to voluntary suppress the tic, yet premonition unfortunately adds to the discomfort associated with having the disorder. By late adolescence/early adulthood, tic disorders can improve significantly in certain individuals. However, adults who continue to suffer from tics often have particularly severe and debilitating symptoms. (Leckman et al., Neuropsychiatry of the Bas. Gang 20(4): 839-861, 1997).

- pramipexole therapy is usually associated with a number of undesirable side effects, and patient compliance is a significant obstacle for effective treatment.

- MIRAPEX ® tablets often have to be given three times a day in equally divided doses. Therefore, compliance is a major problem with patients.

- a second problem for the multiple dose regimen is that the daily "peak and trough" blood levels produced by multiple daily doses result in fluctuating stimulation of the dopaminergic neurons. These fluctuations may contribute to the pathogenesis of the motor complications in Parkinson disease.

- Commonly occurring adverse effects associated with MIRAPEX ® include nausea, vomiting / emesis, weakness, dizziness, fainting, agitation, confusion, hallucinations, muscle twitching, uncontrollable movements, a tingling sensation, chest pain, insomnia, somnolence, decreased appetite, dry mouth, sweating, headache, constipation and gastric intestinal complications.

- Episodes of sudden uncontrollable somnolence have been reported in 22% of PD patients receiving pramipexole in a dose related manner.

- pramipexole has been reported to include orthostatic hypotension, the incidence of which is dose- and peak-related.

- compulsive gambling behaviors see Dodd et al, Pathological Gambling Caused by Drugs Used to Treat Parkinson Disease, Archives of Neurology vol. 62, Sept. 2005; Driver- Dunckley et al., Pathological Gambling Associated With Dopamine Agonist Therapy in Parkinson's Disease, Neurology, Vol. 61, August 2003

- excessive shopping, overeating, and hypersexuality have also been linked to MIRAPEX ® treatment.

- MIRAPEX ® Although the main indication of MIRAPEX ® is PD treatment, MIRAPEX ® is also used in lower doses to treat other movement disorders such as restless legs syndrome ⁇ e.g. , 0.125 mg daily versus 4.5 mg daily for Parkinson's). It is also being used off-label to treat depression as well as some sleep disorders.

- the currently available immediate release pramipexole formulation is not ideal as it is associated with poor patient compliance as well as treatment-emergent side effects that lead to poor patient tolerance. Therefore, there remains a clear-cut need for new treatments and improved dosage forms for various movement disorders, such as using pramipexole in alleviating at least one adverse effect associated with the treatment of Parkinson's disease.

- pramipexole The pharmacokinetics of pramipexole is linear, with plasma concentrations increasing proportionate with increase in dosage. Pramipexole is rapidly absorbed, reaching peak concentration in approximately 2 hours. The absolute bioavailability of pramipexole is greater than 90%. It undergoes little presystemic metabolism and is excreted virtually unchanged in the urine. However, it is difficult to reach the upper limit of the dose range using the currently available immediate release formulation. This is partly because both gastrointestinal and CNS side effects are more frequent during the initial ascending phase of the plasma profile. Nausea was primarily reported at the moment of peak pramipexole plasma levels, and increased with increase in dose. Data from other studies suggest that pramipexole may induce a locally mediated nausea via gastric irritation as rapid onset of the nausea was observed prior to achieving peak plasma levels.

- the present invention is directed to pramipexole pharmaceutical compositions that allow for highly controlled, delayed administration, preferably once-daily administration that release pramipexole over an extended period of time.

- the delayed / extended release dosage form is preferably at least equivalent in effectiveness to the conventional immediate release, three-time daily regimen, and provides average steady-state blood levels of pramipexole over a course of treatment.

- a delayed and/or once-a-day administration of pramipexole is advantageous over thrice-a-day administration in terms of patient compliance and reduced adverse events, thus providing better treatment of the conditions for which the pramipexole is indicated.

- the invention provides an oral delayed immediate release (DIR or DR) or delayed extended release (DXR) dosage form that provides continuous and stable delivery of pramipexole over extended duration and maintains the desired therapeutic effects, while minimizing, if not eliminating, the undesired side effects and with improved patient compliance.

- DIR or DR delayed immediate release

- DXR delayed extended release

- pramipexole and/or its prodrug(s) and/or stereoisomers are released at a rate that results in reduction in the frequency or severity of at least one adverse effect associated with pramipexole therapy.

- the dosage form releases pramipexole and/or its prodrug and/or stereoisomer at a rate that results in reduction in the frequency or severity of at least one adverse event associated with current pramipexole therapies, or allows for a more convenient dosing regimen than current therapies.

- a delayed-release (DR) pramipexole pharmaceutical composition in an orally deliverable form, comprising an enteric coating, a pramipexole core, and one or more pharmaceutically acceptable carriers and excipients, wherein the enteric coating reduces or substantially eliminates the release and/or absorption of pramipexole in the upper gastrointestinal (GI) tract.

- DR delayed-release

- pramipexole is first released and/or absorbed in intestine.

- the enteric coating delays the release of pramipexole by at least about 1.5 - 2 hours, or 2-3 hours after ingestion.

- the enteric coating is selected from: cellulose acetate phthalate (CAP), hydroxypropyl methylcellulose phthalate (HPMCP), polyvinyl acetate phthalate (PVAP), hydroxypropyl methylcellulose acetate succinate (HPMCAS), cellulose acetate trimellitate, hydroxypropyl methylcellulose succinate, cellulose acetate succinate, cellulose acetate hexahydrophthalate, cellulose propionate phthalate, copolymer of methylmethacrylic acid and methyl methacrylate, copolymer of methyl acrylate, methylmethacrylate and methacrylic acid, copolymer of methylvinyl ether and maleic anhydride (Gantrez ES series), ethyl methyacrylate-methylmethacrylate- chlorotrimethylammonium ethyl acrylate copolymer, natural resins such as zein, shellac and copal collophorium, carboxymethyl

- the enteric coating becomes soluble at above pH 4.5, such as around pH 5.5-6.8.

- the pramipexole pharmaceutical composition comprises one or more pramipexole salts, derivatives and/or stereoisomers.

- the pramipexole salt is pramipexole dihydrochloride monohydrate.

- the pramipexole core is formulated as an immediate release (IR) composition.

- the pramipexole core is formulated as an extended release (XR) composition.

- XR extended release

- the XR composition is prepared by coating pramipexole- layered inert pellets with a release-controlling polymer.

- the release-controlling polymer is ethylcellulose-based.

- the release-controlling polymer is selected from: EUDRAGIT ® RL; EUDRAGIT ® RS; cellulose derivatives selected from: ethylcellulose aqueous dispersions (AQUACOAT ® , SURELEASE ® ), hydroxyethyl cellulose, hydroxypropyl cellulose, or hydroxypropyl methylcellulose; polyvinylpyrrolidone; polyvinylpyrrolidone / vinyl acetate copolymer; OPADRY ® , or equivalents thereof.

- the delayed-release pramipexole pharmaceutical composition is formulated to provide an effective dose over at least 4 - 24 hours after administration to the patient. In certain embodiments, the delayed-release pramipexole pharmaceutical composition is formulated to provide an effective plasma level over at least 8 - 16 hours after administration to the patient.

- the effective plasma level at a 0.375 mg dose is about 50 - 400 ⁇ g/mL for Parkinson's Disease treatment.

- the effective plasma levels may increase with an increase in dose levels, such as to 800-1800 pg/mL or even 400-4000 pg/mL.

- the pramipexole core comprises an XR portion and an IR portion.

- the XR portion and the IR portion are both present as multiparticulate beads / pellets embedded within an inactive dissolvable / disintegratable matrix.

- the XR portion and the IR portion are each present as a section of the pramipexole core.

- the XR portion is partially or completely covered by a rate- controlling coating that controls the release rate of the XR portion.

- the delayed-release pramipexole pharmaceutical composition is formulated as a once-a-day composition.

- the once-a-day composition contains about 0.375 mg, 0.5 mg, 1.0 mg, 1.5 mg, 3.0 mg, or 4.5 mg of pramipexole dihydrochloride monohydrate, or equivalent thereof.

- the delayed-release pramipexole pharmaceutical composition further comprises a bioadhesive layer that adheres to the lower GI tract.

- the bioadhesive layer comprises polymeric materials selected from polyamides, polyalkylene glycols, polyalkylene oxides, polyvinyl alcohols, polyvinylpyrrolidone, polyglycolides, polyurethanes, polymers of acrylic and methacrylic esters, polylactides, poly(butyric acid), polyanhydrides, polyorthoesters, poly(fumaric acid), poly(maleic acid), polycarbonates, polyalkylenes, polyalkylene terephthalates, polyvinyl alcohols, polyvinyl ethers, polyvinyl esters, polyvinyl halides, polysiloxanes, polystyrene, poly(lactide-co-glycolide), chitosan, chitin, hyaluronic acid, hyaluronan, Carbopols, Corplex polymers, Polycarbophils-Cysteine (Thiomers), Chitosan-Thi

- the delayed-release pramipexole pharmaceutical composition upon administration to an individual, reduces or eliminates at least one undesirable side-effect selected from: nausea, emesis, insomnia, hallucination, somnolence, constipation, and gastric and/or intestinal complication as compared to treatment with a thrice-daily immediate release composition of the same overall dosage.

- the nausea or emesis results from a locally mediated gastric i ⁇ itation.

- the delayed-release pramipexole pharmaceutical composition provides substantially the same bioavailability and/or maximum blood concentration (C ma ⁇ ) compared to an immediate-release pramipexole pharmaceutical composition of the same dosage without the enteric coating.

- the delayed and/or extended release pharmaceutical composition provides a substantially reduced degree of fluctuation in plasma levels compared to an immediate release pharmaceutical composition of the pramipexole of the same dose administered three times daily.

- the delayed and/or extended release pharmaceutical composition is associated with reduced side effects (e.g., nausea, vomiting) compared to an immediate release pharmaceutical composition of the pramipexole of the same dose administered three times daily.

- the delayed-release pramipexole pharmaceutical composition is suitable for human treatment, or for veterinary treatment of a non-human mammal.

- Another aspect of the invention provides a method of preparing a pramipexole pharmaceutical composition, comprising coating a formulation comprising pramipexole with an enteric coating that reduces or substantially eliminates the release and/or absorption of pramipexole in the upper gastrointestinal (GI) tract.

- GI gastrointestinal

- Another aspect of the invention provides a method of treating Parkinson's Disease in an individual, comprising administering to the individual a delayed-release pramipexole pharmaceutical composition as set forth above.

- Embodiments described herein are contemplated to be combined with each other embodiments as appropriate. Embodiments described in detail under one aspect of the invention may be equally applicable for the other aspects of the invention.

- Figures IA - IJ are schematic drawings (not to scale) illustrating cross-sectional views of exemplary designs for the subject delivery device.

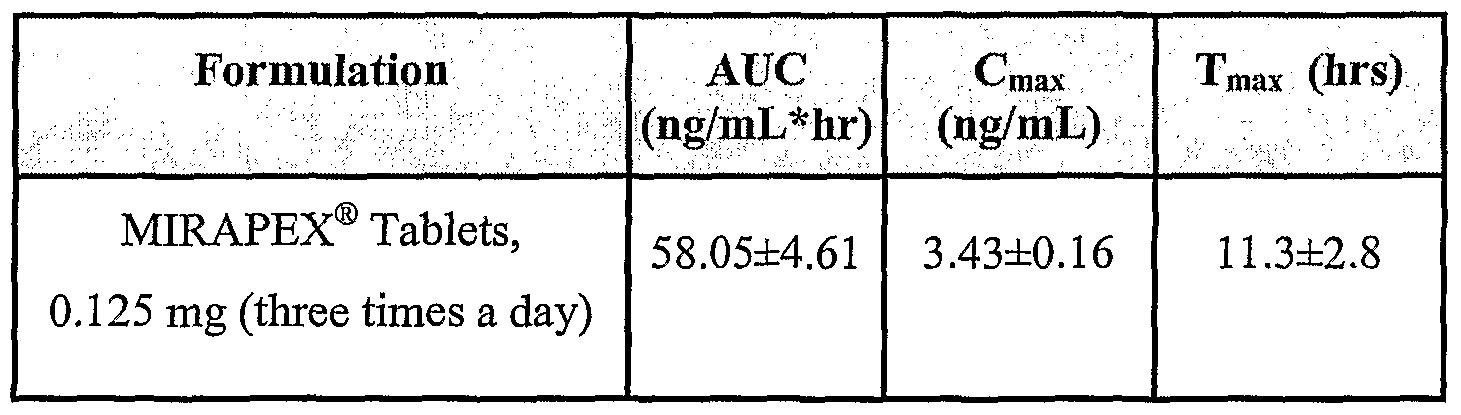

- Figure 2 shows the results of an exemplary experiment comparing concentration of MIRAPEX ® 0.125 mg tablets over time in fed and fasted Beagle dogs.

- Figure 3 shows the results of an exemplary experiment comparing enteric-coated MIRAPEX ® 0.125 mg tablets and plain MIRAPEX ® 0.125 mg tablets in fasted Beagle dogs.

- Figure 4 shows the dissolution profile of pramipexole 0.375 mg Extended-Release (ER) and delayed extended release (DER) formulations.

- ER Extended-Release

- DER delayed extended release

- Figure 5 shows the results of comparing pramipexole 0.375 mg Extended Release (ER) and Delayed Extended Release (DER) formulations in fasted Beagles.

- Figure 6 shows the results of comparing pramipexole 0.375 mg Extended Release multiparticulate-based capsules and matrix-based tablet formulations, with 0.375 mg MIRAPAX ® Tablets Given in a Three-In-a-Day (TID) Dosing Regimen (0.125 mg x 3) in fed Beagles.

- Figure 8 shows a comparison between pramipexole 0.375 mg Extended Release Multiparticulate-based capsules formulations vs. 0.375mg Mirapex tablets given in a TID dosing regimen (0.125 mg x 3) in beagles.

- Figures 9A-C show the mean human pramipexole plasma concentration comparing pramipexole 0.375 mg extended release multiparticulate formulations with Mirapex® tablets, 0.375 mg (0.125 mg x 3).

- Figure 1OA is the in vitro dissolution profile of pramipexole extended release tablet formulation, 0.375 mg [5% coating (80 parts Surelease and 20 parts OPADRY), obtained using a USP II apparatus.

- Figure 1OB shows the in vivo PK performance of a pramipexole extended release tablet, 0.375 mg [5% coating (80 parts Surelease + 20 parts OPADRY)] and pramipexole extended release capsules, 0.375mg [8.3 % Ethocel and 5% Spheromer III coated) in fasted beagle dogs.

- Figure 11 is a comparison of pramipexole ER Formulations with Mirapex (0.125) mg tablets administered in three times a day dosing regimen.

- Figure 12 is a schematic drawing (not to scale) illustrating a cross-sectional view of one design of the subject delivery device.

- Figure 13 is a schematic drawing (not to scale) illustrating a cross-sectional view of one design of the subject delivery device.

- Figure 14 is a schematic drawing (not to scale) illustrating a cross-sectional view of one design of the subject delivery device.

- Figure 15 is a schematic drawing (not to scale) illustrating a cross-sectional view of one design of the subject delivery device.

- the present invention relates to pharmaceutical compositions and methods for the treatment of disorders for which pramipexole is administered. Such disorders include some sleep disorders and certain movement disorders (such as Parkinson's disease and restless legs syndrome, etc.).

- the present invention also relates to the methods for protecting neural cells.

- the pharmaceutical compositions and methods of the invention relate to the use of pramipexole either alone or in combination with other active agents or pharmaceutical compositions suitable for the treatment of such diseases or the prevention or inhibition of diseases using pramipexole as a neuroprotectant.

- the invention relates to particular pramipexole dosage forms (e.g., a delayed release, preferably once-a-day dosage form) that provide release profiles that are effective for the intended therapeutic use (e.g., ameliorating or overcoming symptoms of a movement disorder, such as Parkinson's disease), while reducing or avoiding at least one undesirable side-effect associated with conventional pramipexole treatment.

- a delayed release preferably once-a-day dosage form

- release profiles that are effective for the intended therapeutic use (e.g., ameliorating or overcoming symptoms of a movement disorder, such as Parkinson's disease), while reducing or avoiding at least one undesirable side-effect associated with conventional pramipexole treatment.

- pramipexole in the upper GI tract may cause local irritation and lead to at least one undesirable side effect of pramipexole treatment, including emesis and nausea.

- one or more undesirable side effects traditionally associated with administering pramipexole to an individual can be alleviated or even eliminated by delaying the release of pramipexole until the drug is in the lower GI tract, such as in the intestine (e.g., the small intestine, the colon, and/or the rectum).

- one way to reduce or eliminate the release of pramipexole in the stomach is to utilize an enteric coating, such that pramipexole is not substantially released in the acidic environment of the stomach.

- an enteric coating such that pramipexole is not substantially released in the acidic environment of the stomach.

- pramipexole is released either as an immediate release (IR) dosage form or as an extended release (XR) dosage form, or a mixture thereof. Since such dosage forms are also delayed-release dosage forms, they are referred to as delayed immediate release (DIR or DR) or delayed extended release (DXR) dosage forms, respectively.

- the DXR dosage form achieves the therapeutic benefit of the conventional thrice-a-day pramipexole regimen and yet is administered as a single daily administration, e.g., which contains substantially the same total dosage of pramipexole, yet releases the drug in a controlled manner and over an extended period of time, thus improving patient compliance, and alleviating and/or eliminating the undesirable daily "peak and trough" blood levels produced by multiple daily doses, and the associated fluctuating stimulation of the dopaminergic neurons.

- the dosage form may include bioadhesive layers that adhere to the lower GI tract, such as intestinal walls, to prolong the release of pramipexole in the lower GI tract.

- the bioadhesive layer may be inside or outside the enteric coating.

- the presence of the bioadhesive layer e.g., as a partial coating that is continuous or discontinuous

- the presence of the bioadhesive layer preferably does not substantially impede the release of pramipexole.

- the presence of the bioadhesive layer ⁇ e.g., as a partial coating that is continuous or discontinuous

- Pramipexole is not acid-sensitive, and thus need not be protected from the relative acidic environment of the upper GI tract per se. Indeed, in certain embodiments, pramipexole needs to be delivered to the lower GI tract, for example, for targeted treatment of certain colon diseases.

- the present invention is based in part on the unexpected discovery that by by-passing the release of pramipexole in the upper GI tract (e.g., the stomach) it is possible to avoid one or more undesirable side effects typically associated with pramipexole treatments, such as nausea and/or emesis.

- compositions of the present invention maybe in the form of, among others, a granule, tablet (including matrix or osmotic), pellet, powder, sachet, capsule, gel, dispersion, solution or suspension.

- a granule, tablet including matrix or osmotic

- pellet powder

- sachet capsule

- gel dispersion

- solution or suspension a granule, tablet or osmotic

- the dosage forms be composed in such a manner as to achieve the profiles set forth herein.

- Another aspect of the invention provides a method for making the pharmaceutical compositions with one or more features as described above.

- Another aspect of the invention provides a method for using the pharmaceutical compositions with one or more features as described above, in treating a movement disorder, such as Parkinson's disease.

- Another aspect of the invention provides the use of a pharmaceutical composition with one or more features as described above in manufacturing medicaments for the treatment of a movement disorder, such as Parkinson's disease.

- the subject preparations and methods can be used as part of treatments for human and/or other animal subjects.

- other animal subjects to which the invention is applicable extend to both domestic animals and livestock, raised either as laboratory animals, pets or zoo animals, or for commercial purposes. Examples are rodents such as mice, rats, hamsters, or rabbits; dogs; cats; cattle; horses; sheep; hogs; and goats.

- water-soluble herein means having solubility of at least about 10 mg/ml.

- solubility herein means solubility in water at 20-25 0 C at any physiologically acceptable pH, for example at any pH in the range of about 4 to about 8.

- reference herein to solubility in water pertains to the salt, not to the free base form of pramipexole.

- Solid fraction is the ratio of absolute to apparent density of a compact of the starch.

- a “compact” herein is a compressed tablet, prepared for example on a tablet press, consisting only of a sample of starch for which it is desired to measure tensile strength.

- a “solid fraction representative of the tablet” is a solid fraction selected to be similar to the solid fraction of tablets prepared according to the invention. Typically a solid fraction of about 0.75 to about 0.85, illustratively 0.8, will be selected.

- oral means suitable for oral, including peroral and intra-oral (e.g., sublingual or buccal) administration, but tablets of the present invention are adapted primarily for peroral administration, i.e., for swallowing, typically whole (or, in certain embodiments, broken), with the aid of water or other drinkable fluid.

- a “subject” herein is an animal of any species, preferably mammalian, most preferably human.

- Conditions and disorders in a subject for which a particular agent is said herein to be “indicated” are not restricted to conditions and disorders for which the agent has been expressly approved by a regulatory authority, but also include other conditions and disorders known or believed by a physician to be amenable to treatment with the agent.

- Treatment herein embraces prophylactic treatment unless the context requires otherwise.

- adrenergic refers to neurotransmitters or neuromodulators chemically related to adrenaline (epinephrine) or to neurons which release such adrenergic mediators. Examples are dopamine, norepinephrine, and epinephrine. Such agents are also referred to as catecholamines, which are derived from the amino acid tyrosine.

- catechol moiety refers to a moiety with the following generic structure:

- a polymer may be functionalized by covalently attaching catechol moieties or compounds comprising catechol moieties.

- a compound comprising a catechol moiety may be blended with a polymer to form a simple mixture with no covalent association between the catechol moieties and the polymer.

- catecholamines refers to neurotransmitters that have a catechol ring (e.g., a 3, 4-dihydroxylated benzene ring). Examples are dopamine, norepinephrine, and epinephrine.

- cholinergic refers to neurotransmitters or neuromodulators chemically related to choline or to neurons which release such cholinergic mediators.

- dopaminergic refers to neurotransmitters or neuromodulators chemically related to dopamine or to neurons which release such dopaminergic mediators.

- dopamine refers to an adrenergic neurotransmitter, as is known in the art.

- ED50 means the dose of a drug which produces 50% of its maximum response or effect.

- an "effective amount" of, e.g., a movement disorder pharmaceutical composition, with respect to the subject method of treatment refers to an amount of the pharmaceutical composition in a preparation which, when applied as part of the subject dosage regimen brings about the desired correction / suppression of the movement disorder (e.g., dyskinesis and/or bradykinesis) according to clinically acceptable standards.

- the desired correction / suppression of the movement disorder e.g., dyskinesis and/or bradykinesis

- LD 5 0 means the dose of a drug which is lethal in 50% of test subjects.

- lethal therapeutic index refers to the therapeutic index of a drug defined as

- metabolites refers to active derivatives produced upon introduction of a compound into a biological milieu, such as a patient.

- a "patient,” “individual,” or “subject” to be treated by the subject method can mean either a human or non-human animal.

- prevent means reducing the probability / risk of developing a condition in a subject (e.g., a human), or delaying the onset of a condition in the subject, or lessening the severity of one or more symptoms of a condition (e.g., a movement disorder) that may develop in the subject, or any combination thereof.

- a condition e.g., a movement disorder

- prodrug is intended to encompass compounds which, under physiologic conditions, are converted into the therapeutically active agents of the present invention.

- a common method for making a prodrug is to include one or more selected moieties which are hydrolyzed under physiologic conditions to reveal the desired molecule.

- the prodrug is converted by an enzymatic activity of the host animal.

- protecting group as used herein means temporary substituents which protect a potentially reactive functional group from undesired chemical transformations. Examples of such protecting groups include esters of carboxylic acids, silyl ethers of alcohols, and acetals and ketals of aldehydes and ketones, respectively.

- the field of protecting group chemistry has been reviewed (Greene, T. W.; Wuts, P.G.M. Protective Groups in Organic Synthesis, 2nd ed.; Wiley: New York, 1991).

- SeU5o means the dose of a drug which is produces a particular side-effect in 50% of test subjects.

- side-effect therapeutic index refers to the therapeutic index of a drug defined as SeDso/EDso.

- statically significant means that the obtained results are not likely to be due to chance fluctuations at the specified level of probability.

- the level of significance equal to 0.05 and 0.01 means that the probability of error is 5 out of 100 and 1 out of 100, respectively.

- treat means to counteract a medical condition (e.g., a movement disorder) to the extent that the medical condition is improved according to clinically acceptable standard(s).

- a medical condition e.g., a movement disorder

- to treat a movement disorder means to improve the movement disorder or relieve symptoms of the particular movement disorder in a patient, wherein the improvement and relief are evaluated with a clinically acceptable standardized test (e.g., a patient self-assessment scale) and/or an empirical test (e.g., PET scan).

- a clinically acceptable standardized test e.g., a patient self-assessment scale

- an empirical test e.g., PET scan

- Cmax means maximum plasma concentration of pramipexole achieved by the ingestion of the composition of the invention or the t.i.d comparator (Mirapex IR tablets).

- Cmin means minimum plasma concentration of pramipexole achieved by the ingestion of the composition of the invention or the t.i.d comparator (Mirapex IR tablets).

- Cavg means average plasma concentration of pramipexole achieved by the ingestion of the composition of the invention or the t.i.d comparator (Mirapex IR tablets). Cavg is calculated by AUC over a 24 hours intervals divided by 24.

- Tmax means the time to achieve maximum plasma concentrations produced by ingestion of of the composition of the invention or the t.i.d comparator (Mirapex IR tablets).

- AUC as used herein means the area under the plasma concentration-time curve, as calculated by the trapezoidal rule over the 24 hour interval for all the formulations.

- DFL Degree of Fluctuation

- Cmin and “trough levels” should be considered synonyms.

- Cmax and “peak levels” should be considered synonyms.

- Pramipexole (formula I below) is a dopamine D2 receptor agonist useful in treatment of Parkinson's disease and complications associated therewith.

- Pramipexole as its dihydrochloride salt is commercially available in the United States as MIRAPEX ® tablets of Pharmacia & Upjohn / Pfizer. These are marketed as immediate-release tablets in 0.125 mg, 0.25 mg, 0.5 mg, 1.0 mg and 1.5 mg strengths, designed for thrice-a-day oral administration of a single tablet each to provide a daily dose of 0.375 to 4.5 mg. See Physicians' Desk Reference 57th edition (2003), 2768-2772.

- pramipexole dihydrochloride monohydrate unless otherwise specified; e.g., 1.0 mg pramipexole dihydrochloride monohydrate is equivalent to about 0.7 mg pramipexole base.

- Other salt forms can be readily converted from the amount of pramipexole base contained therein.

- pramipexole or a salt thereof herein embraces racemates, enantiomers, polymorphs, hydrates and solvates thereof.

- Pramipexole (I) is used preferably in the form of its S-enantiomer, (S)-2-amino-4,5,6,7-tetrahydro-6-(propylamino)- benzothiazole.

- a preferred salt of pramipexole is the dihydrochloride salt, most preferably in the form of the monohydrate.

- Pramipexole compositions of the invention are preferably suitable for administration no more than once daily. Such compositions are useful in treatment of any CNS condition or disorder for which pramipexole has therapeutic utility, but especially Parkinson's disease and complications associated therewith.

- Pramipexole and its salts useful herein can be prepared by processes known per se, including processes disclosed in patents and other literature pertaining to pramipexole.

- the amount of the pramipexole salt present in a composition of the invention is sufficient to provide a daily dose in one to a small plurality, for example one to about 4, of tablets to be administered at one time.

- the full daily dose is delivered in a single tablet.

- An amount of pramipexole salt, expressed as pramipexole dihydrochloride monohydrate equivalent, of about 0.1 to about 10 mg per tablet, or about 0.05% to about 5% by weight of the composition will generally be suitable.

- an amount of about 0.2 to about 6 mg, more preferably an amount of about 0.3 to about 5 mg, per tablet is present.

- immediate release composition a dosage form that is formulated to release substantially all the active ingredient on administration with no enhanced, delayed or extended release effect.

- a composition may be in the form of a pellet (a term used interchangeably with “bead” or “beadlet” herein).

- the immediate release pellet can serve as a precursor to an extended or delayed release pellet, or be used with an extended or delayed release pellet.

- an immediate release pellet can be prepared by mixing pramipexole with a bulking agent. Additionally, one can add disintegrating agents, antiadherents and glidants to the formulation.

- Bulking agents employable in these compositions may be chosen from, among others: microcrystalline cellulose, for example, AVICEL® (FMC Corp.) or EMCOCEL ® (Mendell Inc.), which also has binder properties; dicalcium phosphate, for example, EMCOMPRESS ® (Mendell Inc.); calcium sulfate, for example, COMPACTROL ® (Mendell Inc.); and starches, for example, Starch 1500; and polyethylene glycols (CARBOWAX ® ).

- Such bulking agents are typically present in the range of about 5% to about 75% (w/w), with a preferred range of about 25% to about 50% (w/w).

- Suitable disintegrants include, but are not limited to: crosslinked sodium carboxymethyl cellulose (AC-DI-SOL ® ), sodium starch glycolate (EXPLOTAB ® , PRIMO JEL ® ) and crosslinked polyvinylpolypyrrolidone (PLASONE-XL ® ). Disintegrants are used to facilitate disintegration of the pellet upon administration and are typically present in an amount of about 3% to about 15% (w/w), with a preferred range of about 5% to about 10% (w/w).

- Antiadherents and glidants employable in such formulations can include talc, cornstarch, silicon dioxide, sodium lauryl sulfate, colloidal silica dioxide, and metallic stearates, among others.

- the immediate release composition may contain one or more binders to give the pellets cohesiveness.

- binders are well known in the art, and include such substances as microcrystalline cellulose, polyvinyl pyrrolidone, starch, maltrin, methylcellulose, hydroxypropyl methylcellulose, carboxymethyl cellulose, sucrose solution, dextrose solution, acacia, tragacanth and locust bean gum, which may be applied wet.

- the binding agent may be present in the composition in an amount of from about 0.2 wt % to about 40 wt %, preferably from about 5 wt % to about 30 wt %, or from about 10 wt % to about 15 wt %.

- the pellets can be made by, for example, simple granulation such as wet granulation or dry granulation, followed by sieving; extrusion and marumerization (spheronization); rotogranulation; or any agglomeration process that results in a pellet of reasonable size and robustness.

- simple granulation such as wet granulation or dry granulation, followed by sieving

- extrusion and marumerization spheronization

- rotogranulation or any agglomeration process that results in a pellet of reasonable size and robustness.

- the drug and other additives are granulated by addition of a binder solution.

- the wet mass is passed through an extruder equipped with a certain size screen, and the extrudates are spheronized in a marumerizer.

- the resulting pellets are dried and sieved for further applications.

- the granules are kneaded after wetting by the combined actions of mixing and milling.

- the resulting granules or pellets are dried and sieved for further applications.

- the immediate release beadlets or pellets are prepared by solution or suspension layering, whereby a drug solution or dispersion, with or without a binder and optionally an anti-tacking agent such as talc, is sprayed onto a core or starting seed (either prepared or a commercially available product) in a fluid bed processor or other suitable equipment.

- the cores or starting seeds can be, for example, sugar spheres or spheres made from microcrystalline cellulose.

- the binder in the formula can be present in amounts ranging from about 0% to about 5% by weight, and preferably about 0.5% to about 2% by weight.

- the amount of anti-tacking agent used can be from about 0% to about 5%, preferably about 0.5% to about 2% by weight.

- the drug thus is coated on the surface of the starting seeds.

- the drug may also be layered onto the drug-containing pellets described above, if desired. Following drug layering, the resulting drug-loaded pellets are dried for further applications.

- a protective layer, or overcoating, may be desired to ensure that the drug-loaded pellets do not aggregate during processing or upon storage.

- the protective coating layer may be applied immediately outside the core, either a drug-containing core or a drug-layered core, by conventional coating techniques such as pan coating or fluid bed coating using solutions of polymers in water or suitable organic solvents or by using aqueous polymer dispersions.

- OPADRY ® , OPADRY II ® (Colorcon) and corresponding color and colorless grades from Colorcon can be used to protect the pellets from being tacky and provide colors to the product.

- Different anhydride-based polymers e.g., sebacic/fumaric copolymers such as Spheromer I or Spheromer II from Spherics, Inc.

- the suggested levels of protective or color coating are from about 1% to about 6%, preferably about 2% to about 3% (w/w).

- ingredients can be incorporated into the overcoating formula, for example to provide a quicker immediate release, such as plasticizers: acetyltriethyl citrate, triethyl citrate, acetyltributyl citrate; dibutylsebacate, triacetin, polyethylene glycols, propylene glycol and the others; lubricants: talc, colloidal silica dioxide, magnesium stearate, calcium stearate, titanium dioxide, magnesium silicate, and the like.

- the immediate release composition may be prepared as an uncoated tablet, or a tablet core prior to coating, comprising starch and a hydrophilic polymer acting as a matrix for a water-soluble drug or prodrug requires to have a certain minimum hardness in order to be able to resist breakage and/or attrition due to mechanical stresses imposed during a high-speed tableting operation (including all steps up to and including filling of the tablets into containers).

- the minimum acceptable hardness will depend on a number of factors, including the severity of the mechanical stresses, but is typically at least about 20 SCU, preferably at least about 22 SCU, more preferably at least about 24 SCU (about 17 kp).

- Hardness can be increased by increasing the compression force applied by the tablet press, but only up to a certain level. At least in the case of tablets as described herein, above a certain compression force, further increases in compression force give little or no further increase in tablet hardness. There is, in other words, a maximum hardness achievable by compression of a particular starch / hydrophilic polymer / active agent composition. A starch providing a maximum hardness inadequate to withstand the mechanical stresses of a highspeed tableting operation is unsuitable for the present purpose. Certain pregelatinized starches provide a maximum hardness of 20 SCU or less; these are starches having low tensile strength (0.1 kN cm "2 or less).

- immediate release pellets are contemplated as being used in combination with extended release pellets and/or delayed release pellets in a single dosage form, and/or being modified to generate extended release (XR) pellets, delayed release (DR) pellets, and/or delayed and extended release (DXR) pellets in a single dosage form.

- XR extended release

- DR delayed release

- DXR delayed and extended release

- the delayed-release component has a coat applied to the surface of the active pellet that delays the release of the drug from the pellet after administration for a certain period of time. This delayed release can be accomplished by applying a coating of enteric materials.

- enteric materials are polymers that are substantially insoluble in the acidic environment of the stomach, but are predominantly soluble in intestinal fluids at various specific pH's, such as pH 4.5 or higher.

- the enteric materials are non-toxic, pharmaceutically acceptable polymers, and include, for example, cellulose acetate phthalate (CAP), hydroxypropyl methylcellulose phthalate (HPMCP), polyvinyl acetate phthalate (PVAP), hydroxypropyl methylcellulose acetate succinate (HPMCAS), cellulose acetate trimellitate, hydroxypropyl methylcellulose succinate, cellulose acetate succinate, cellulose acetate hexahydrophthalate, cellulose propionate phthalate, copolymer of methylmethacrylic acid and methyl methacrylate, copolymer of methyl acrylate, methylmethacrylate and methacrylic acid, copolymer of methylvinyl ether and maleic anhydride (Gantrez ES series), ethyl me

- coating materials can be employed in coating the surfaces in a range of from about 1.0% (w/w) to about 50% (w/w) of the pellet composition. Preferably, these coating materials are in the range of from about 10-20% (w/w).

- the pellets may be coated in a fluidized bed apparatus or pan coating, for example, in a conventional manner.

- the pramipexole With the enteric-coated pellets, there is no substantial release of pramipexole in the acidic stomach environment of below about pH 4.5.

- the pramipexole becomes available when the pH-sensitive enteric layer dissolves at a higher pH in the GI tract, after a certain delayed time, or after the unit passes through the stomach.

- the preferred delay time is in the range of about 0.5 to about 6 hours, but more preferable is about 0.5 to about 4 hours.

- certain DR pellets may be coated with EUDRAGIT ® L30D-55, which dissolves at about pH 5.5-6.0, i.e., in the upper intestines.

- the DR pellets may be coated with EUDRAGIT ® FS30D, which dissolves at about pH 7.0, i.e., in the lower intestine and colon.

- the XR pellet described above may be additionally coated with the enteric material to generate delayed and extended release (DXR) pellets.

- DXR delayed and extended release

- Such a dosage form is delayed release until the drug reaches non-acidic environment, such as the upper and/or lower intestine, 1 and thereupon releasing drugs over an extended period of time.

- Extended Release Composition (XR) Pramipexole extended release pellets can be prepared in many different ways to achieve an extended release profile.

- the subject pramipexole XR pellets can be prepared by coating drug layered inert pellets with release-controlling polymers.

- the inert pellet is coated with the drug layer, or a drug loaded granule is prepared, as described above.

- the active (drug loaded) pellet is coated with a release-controlling polymeric membrane.

- the release-controlling coating layer may be applied immediately outside the core (such as a drug-containing core or a drug-layered core), by conventional coating techniques, such as pan coating or fluid bed coating, using solutions of polymers in water or suitable organic solvents, or by using aqueous polymer dispersions.

- the release controlling membrane can separate additional drug layers on the core; for instance, after coating with the release controlling substance, another drug layer can be applied, which is followed by another release controlling layer, etc.

- Suitable materials for the release-controlling layer include EUDRAGIT ® RL, EUDRAGIT ® RS, cellulose derivatives such as ethylcellulose aqueous dispersions (AQUACOAT ® , SURELEASE ® ), hydroxyethyl cellulose, hydroxypropyl cellulose, hydroxypropyl methylcellulose, polyvinylpyrrolidone, polyvinylpyrrolidone/vinyl acetate copolymer, OPADRY ® ), and the like.

- the thickness of the coating affects the release profile, and so this parameter can be used to customize the profile.

- the suggested coating levels are from about 1% to about 40%, about 5% to about 30% (w/w), or about 20% or about 25% in other embodiments.

- a hydrophilic polymer matrix core can be inadequate to provide sustained release of sufficiently long duration to permit once daily administration. It is believed that such salts are readily leached out of the hydrophilic matrix when contacted by an aqueous medium such as gastrointestinal fluid.

- a release-controlling coating around the tablet to produce an extended-release (XR) tablet.

- XR extended-release

- Such a coating may comprise a hydrophobic or water-insoluble polymer component such as ethylcellulose together with a hydrophilic or water-soluble pore- forming component such as HPMC.

- a coating step exposure to mechanical stresses is also greatly increased.

- the composition is found to be especially suited to a high-speed tableting operation that includes a step of coating the tablet with a release-controlling layer.

- ethylcellulose and HPMC as components of a release coating layer

- cellulosic polymers ⁇ e.g., methylcellulose, hydroxypropylcellulose, hydroxyethylcellulose, carboxymethylcellulose sodium, cellulose esters such as cellulose acetate, etc.

- polyvinyl acetate polyvinyl pyrrolidone

- polymers and copolymers of acrylic acid and methacrylic acid and esters thereof polyethylene glycol, carrageenan and other gums, etc.

- a release-controlling layer typically constitutes about 1% to about 15%, preferably about 2.5% to about 10%, by weight of the tablet as a whole.

- the hydrophobic or water-insoluble component preferably comprising ethylcellulose, typically constitutes about 1% to about 10%, preferably about 2% to about 7%, by weight of the tablet as a whole.

- the pore-forming component preferably comprising HPMC, is typically present in an amount of about 5% to about 50%, preferably about 10% to about 40%, by weight of the water- insoluble or hydrophobic component.

- a release-controlling layer in an amount of about 2.5% to about 5% by weight of the tablet core comprises an ethylcellulose-based material ⁇ e.g., SURELEASE ® of Colorcon) and an HPMC-based pore-forming material (e.g., OPADRY ® of Colorcon) in a weight ratio of about 3: 1 to about 4: 1.

- a release-controlling layer or coating is preferably applied at a relatively uniform thickness to provide even control of release rate of the pramipexole.

- the sustained-release tablet of the invention comprises a nonfunctional coating.

- a nonfunctional coating can comprise a polymer component, for example HPMC, optionally with other ingredients, for example one or more plasticizers, colorants, etc.

- HPMC polymer component

- other ingredients for example one or more plasticizers, colorants, etc.

- nonfunctional in the present context means having no substantial effect on release properties of the tablet, and does not imply that the coating serves no useful purpose.

- such a coating can impart a distinctive appearance to the tablet, provide protection against attrition during packaging and transportation, improve ease of swallowing, and/or have other benefits.

- a nonfunctional coating should be applied in an amount sufficient to provide complete coverage of the tablet.

- Uncoated tablets and cores of coated tablets of the invention can optionally contain one or more pharmaceutically acceptable excipients in addition to the starch and hydrophilic polymer components described above.

- excipients include without limitation glidants and lubricants.

- Other conventional excipients known in the art can also be included.

- a glidant can be used to improve powder flow properties prior to and during tableting and to reduce caking. Suitable glidants include colloidal silicon dioxide, magnesium trisilicate, powdered cellulose, starch, talc, tribasic calcium phosphate and the like.

- colloidal silicon dioxide is included as a glidant in an amount up to about 2%, preferably about 0.2% to about 0.6%, by weight of the tablet.

- a lubricant can be used to enhance release of a tablet from apparatus on which it is formed, for example by preventing adherence to the face of an upper punch ("picking") or lower punch ("sticking").

- Suitable lubricants include magnesium stearate, calcium stearate, canola oil, glyceryl palmitostearate, hydrogenated vegetable oil, magnesium oxide, mineral oil, poloxamer, polyethylene glycol, polyvinyl alcohol sodium benzoate, sodium lauryl sulfate, sodium stearyl fumarate, stearic acid, talc, hydrogenated vegetable oil, zinc stearate and the like.

- magnesium stearate is included as a lubricant in an amount of about 0.1 % to about 1.5%, preferably about 0.3% to about 1%, by weight of the tablet.

- coated extended-release (XR) tablets of pramipexole dihydrochloride of the invention are prepared using the composition shown in the table below:

- Tablet cores were prepared as following: all ingredients except the lubricant (magnesium stearate) were screened to remove lumps and were blended thoroughly in a low- shear mixer operating at 24 rpm for 10-30 minutes. The lubricant was then screened into the mixer and the materials were blended for a further 2-5 minutes. The resulting lubricated mixture was compressed into 350 mg tablets using a GlobePharma Manual Tablet Compaction Machine.

- lubricant magnesium stearate

- pramipexole was layered onto the lactose particles to achieve its uniform dispersion.

- a coating solution was prepared as follows: OPADRY ® HPMC-based material in an amount of 8.002 g was added to 171.735 g water and mixed for 45 minutes to provide an HPMC mixture. Next, 128.032 g SURELEASE ® ethylcellulose-based material was added to the HPMC mixture and mixed for an additional 30 minutes to provide a coating solution.

- Coating to a 5% total weight gain and curing of the coated tablets were performed as following: the coating solution was applied to the tablet cores in an amount providing a 5% weight gain.

- the resulting coated tablets were cured using a 12 inch (about 30 cm) Vector LCDS or 24 inch (about 60 cm) Thomas Accela-Coata coating pan for about 15 minutes at a bed temperature of at least about 70 0 C. After curing, temperature was ramped down over a period of about 8 minutes to an exhaust temperature of about 45°C.

- the extended release pellets typically contain the same amount of total pramipexole used for thrice-a-day conventional treatment, e.g., about 0.375 mg for the 0.125 mg regimen.

- compositions of the present invention can be in a number of different forms, such as tablets, powders, suspensions, solutions, etc.

- the composition is preferably in pellet/beadlet form, which can be incorporated into hard gelatin or other kinds of capsules, either with additional excipients, or alone.

- the dosage formulations described herein may contain one or more excipients, carriers or diluents. These excipients, carriers or diluents can be selected, for example, to control the disintegration rate of a tablet or drug eluting device to fit the desired release profile according to the instant invention.

- the one or more carriers (additives) and/or diluents may be pharmaceutically acceptable.

- pharmaceutically acceptable carrier means a pharmaceutically acceptable material, composition or vehicle, such as a liquid or solid filter, diluent, excipient, solvent or encapsulating material, involved in carrying or transporting the subject regulators from one organ, or portion of the body, to another organ, or portion of the body.

- a pharmaceutically acceptable material, composition or vehicle such as a liquid or solid filter, diluent, excipient, solvent or encapsulating material, involved in carrying or transporting the subject regulators from one organ, or portion of the body, to another organ, or portion of the body.

- Each carrier must be “acceptable” in the sense of being compatible with the other ingredients of the formulation and not injurious to the patient.

- materials which can serve as pharmaceutically acceptable carriers include (1) sugars, such as lactose, glucose and sucrose; (2) starches, such as corn starch and potato starch; (3) cellulose, and its derivatives, such as sodium carboxymethyl cellulose, ethyl cellulose and cellulose acetate; (4) powdered tragacanth; (5) malt; (6) gelatin; (7) talc; (8) excipients, such as cocoa butter and suppository waxes; (9) oils, such as peanut oil, cottonseed oil, safflower oil, sesame oil, olive oil, corn oil and soybean oil; (10) glycols, such as propylene glycol; (11) polyols, such as glycerin, sorbitol, mannitol and polyethylene glycol; (12) esters such as ethyl oleate and ethyl laurate; (13) agar; (14) buffering agents, such as magnesium hydroxide and aluminum hydroxide; (15)

- Typical excipients to be added to a capsule formulation include, but are not limited to: fillers such as microcrystalline cellulose, soy polysaccharides, calcium phosphate dihydrate, calcium sulfate, lactose, sucrose, sorbitol, or any other inert filler.

- fillers such as microcrystalline cellulose, soy polysaccharides, calcium phosphate dihydrate, calcium sulfate, lactose, sucrose, sorbitol, or any other inert filler.

- there can be flow aids such as fumed silicon dioxide, silica gel, magnesium stearate, calcium stearate or any other materials that impart good flow properties.

- a lubricant can also be added if desired, such as polyethylene glycol, leucine, glyceryl behenate, magnesium stearate or calcium stearate.

- the formulations can conveniently be presented in unit dosage form and can be prepared by any of the methods well known in the art of pharmacy. All methods include bringing into association the drug with the carrier or diluent which constitutes one or more accessory ingredients. In general, the formulations are prepared by uniformly and intimately bringing into association the agent with the carriers and then, if necessary, dividing the product into unit dosages thereof. It will be understood by those skilled in the art that any vehicle or carrier conventionally employed and which is inert with respect to the active agent, and preferably does not interfere with bioadhesion in embodiments employing a bioadhesive coating, may be utilized for preparing and administering the pharmaceutical compositions of the present invention. Illustrative of such vehicles and carriers are those described, for example, in Remington's Pharmaceutical Sciences, 18th ed. (1990), the disclosure of which is incorporated herein by reference.

- Examples of carriers and diluents include pharmaceutically accepted hydrogels such as alginate, chitosan, methylmethacrylates, cellulose and derivatives thereof (microcrystalline cellulose, hydroxypropyl cellulose, hydroxypropyl methyl cellulose, carboxymethylcellulose, ethylcellulose), agarose and POVIDONETM, kaolin, magnesium stearate, starch, lactose, sucrose, density-controlling agents such as barium sulfate and oils, dissolution enhancers such as aspartic acid, citric acid, glutamic acid, tartartic acid, sodium bicarbonate, sodium carbonate, sodium phosphate, glycine, tricine, Tromethamine, and TRIS.

- pharmaceutically accepted hydrogels such as alginate, chitosan, methylmethacrylates, cellulose and derivatives thereof (microcrystalline cellulose, hydroxypropyl cellulose, hydroxypropyl methyl cellulose, carboxymethylcellulose, ethylcellulose),

- excipients, carriers or diluents can also be selected to control the time until a dosage form detaches from a mucosal membrane.

- the addition of one or more disintegrating agents will reduce the time until a tablet or drug eluting device detaches.

- an agent that interferes with the mucosa-tablet / device adhesion can be used to control the time until detachment occurs.