WO2009068914A1 - Implantable device - Google Patents

Implantable device Download PDFInfo

- Publication number

- WO2009068914A1 WO2009068914A1 PCT/GB2008/051119 GB2008051119W WO2009068914A1 WO 2009068914 A1 WO2009068914 A1 WO 2009068914A1 GB 2008051119 W GB2008051119 W GB 2008051119W WO 2009068914 A1 WO2009068914 A1 WO 2009068914A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- layer

- housing

- restrictor

- moieties

- titanium

- Prior art date

Links

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61N—ELECTROTHERAPY; MAGNETOTHERAPY; RADIATION THERAPY; ULTRASOUND THERAPY

- A61N1/00—Electrotherapy; Circuits therefor

- A61N1/18—Applying electric currents by contact electrodes

- A61N1/32—Applying electric currents by contact electrodes alternating or intermittent currents

- A61N1/36—Applying electric currents by contact electrodes alternating or intermittent currents for stimulation

- A61N1/372—Arrangements in connection with the implantation of stimulators

- A61N1/375—Constructional arrangements, e.g. casings

Definitions

- This invention relates to implantable devices and particularly, although not exclusively, relates to implantable devices for implantation in a human body and a method of making such devices.

- implantable devices for implantation in a human body for applying a stimulus to a part of the body, for example a tissue, for a therapeutic purpose.

- implantable devices may be arranged to supply an electrical stimulus used in neurological therapy for stimulating nerves or muscle to combat pain or may be used as a heart pacemaker.

- Other applications include use in treating urinary urge incontinence by stimulating nerves close to the pelvic floor; and use in reduction of pressure sores by stimulating cavernous nerves.

- implantable devices are, in some cases, used to provide a chemical or mechanical stimulus.

- Implantable devices may, in general terms, comprise a housing which includes electronic circuitry and a power source.

- the housing defines an hermetically sealed environment so that its contents are protected from ingress of water which could be damaging. It has been known for over 30 years to make such housings out of titanium parts which are laser welded together to define a hermetically sealed container.

- housings made from plastics materials have been proposed but have generally been inadequate in use due to the inherent porosity of plastics materials. This problem has been addressed in commercial applications by filling a housing around its electronic circuitry with silicone in an attempt to protect the circuitry.

- silicone is also permeable to water and, accordingly, its use is an ineffective solution to the problem.

- an implantable device comprising a housing which comprises a polymeric material wherein said housing includes a restrictor layer for restricting passage of fluid into an interior region of the housing, wherein said restrictor layer comprises a material which includes titanium moieties.

- Said restrictor layer preferably directly contacts said polymeric material. There may therefore be no intermediate, for example adhesive, layer between said polymeric material and said restrictor layer.

- Said restrictor layer is suitably provided over at least 50%, preferably at least 75%, more preferably at least 90%, especially at least 95% of the outer surface area of the housing.

- said restrictor layer is provided over substantially the entire outer surface of the housing so that it substantially seals the housing from ingress of fluid, into the housing.

- the restrictor layer is arranged to restrict (more preferably substantially prevent) passage of an aqueous liquid, for example a body fluid, from a position outside the housing to a position within the housing.

- Said restrictor layer may have a thickness, for example an average thickness, of less than lOOO ⁇ m, suitably less than 500 ⁇ m, preferably less than 250 ⁇ m, more preferably less than lOO ⁇ m, especially less than 10 ⁇ m. In especially preferred embodiments the thickness may be less than 5 ⁇ m or even less than 2 ⁇ m.

- Said restrictor layer may have a thickness, for example an average thickness, of greater than 0. l ⁇ m, preferably greater than 0.5 ⁇ m, more preferably greater than 0.75 ⁇ m.

- Said restrictor layer may itself be made up of a plurality, preferably a multiplicity, of different layers.

- said restrictor layer may include at least five, preferably at least ten, more preferably at least fifteen, especially at least twenty different layers.

- the restrictor layer may include less than fifty different layers .

- the restrictor layer includes different layers, all of the layers may not have the same composition.

- at least one layer in the restrictor layer has a different structure or composition compared to the structure or composition of another layer of said restrictor layer.

- Layers of said restrictor layer are suitably selected to be complimentary to one another thereby to enhance the ability of the restrictor layer to restrict passage of fluid.

- one layer of said restrictor layer may have defects, for example microscopic openings, which would otherwise allow some fluid to pass therethrough.

- a layer adjacent said one layer may be arranged to compensate for the defects, for example by having a structure which blocks or otherwise cooperates with defects, for example openings, thereby to restrict passage of fluid through said one layer.

- said restrictor layer includes a first layer in contact with a second layer and there being a third layer in contact with the second layer, wherein the first, second and third layers are superimposed and wherein the second layer has a different structure or composition (preferably both a different structure and composition) compared to the structure and/or composition of the first and third layers.

- said restrictor layer includes at least five layers, more preferably at least ten layers, especially at least twenty layers wherein the layers are superimposed and adjacent layers have a different structure or composition (preferably both a different structure and different composition) .

- each of said five (or ten or twenty layers if provided) has an average thickness in the range lnm to 200nm, more preferably in the range 5nm to lOOnm.

- Said restrictor layer may include a plurality, preferably a multiplicity, of layers which include titanium moieties.

- Said restrictor layer may include at least one layer type (hereinafter referred to as a "first layer type”) which consists essentially of titanium moieties.

- said at least one first layer type may consist essentially of titanium metal.

- Said first layer type may have a thickness in the range lnm to 200nm, preferably in the range 5nm to lOOnm.

- Said restrictor layer may include a multiplicity, preferably at least three, more preferably at least seven, layers having the same composition and/or thickness as said first layer type as described.

- Said restrictor layer may include at least one layer type (hereinafter referred to as a "second layer type") which does not consist essentially of titanium moieties and therefore suitably does not consist essentially of titanium metal.

- Said second layer type may have a thickness in the range lnm to 200nm, preferably in the range 5nm to lOOnm.

- Said restrictor layer may include a multiplicity, preferably at least three, more preferably at least seven, layers having the same composition and/or thickness as said second layer type as described.

- Said second layer type may include titanium moieties.

- Said second layer type may also include non-metal moieties.

- Said second layer type may comprise a titanium compound for example a compound consisting of titanium moieties and a non-metal.

- a non-metal may be gaseous at stp; for example it may be oxygen or nitrogen.

- Said second layer type preferably includes nitrogen moieties.

- said second layer type preferably comprises, more preferably consists essentially of, titanium and nitrogen moieties and is preferably therefore a titanium nitride compound.

- the ratio of titanium moieties to nitrogen moieties in said second layer type may be in the range 0.3 to 3, preferably 0.5 to 2, more preferably 0.8 to 1.2.

- Said restrictor layer preferably includes first to sixth layers (preferably first to tenth layers) which are superimposed upon one another wherein adjacent layers have different compositions and each layer includes titanium moieties.

- Preferably alternate layers include both titanium and nitrogen moieties.

- Said restrictor layer preferably includes an outermost layer (which suitably defines an outer surface of the housing which may contact body fluids in use) which comprises titanium moieties and preferably consists essentially of titanium moieties.

- the outermost layer consists essentially of titanium metal.

- Said housing suitably includes a wall which is defined by said polymeric material (for example by said wall being produced by moulding, for example injection moulding, or the like) .

- the wall may have a thickness of less than 5mm, or less than 3mm, typically in the range l-3mm.

- the ratio of the thickness of the wall (e.g. the average thickness) to the thickness of the restrictor layer (e.g. average thickness) may be in the range 500-5000.

- Said implantable device may have a volume of less than 50cm 3 , preferably less than 35cm 3 , more preferably less than 25cm .

- the volume may be at least lcm .

- At least 75wt%, more preferably at least 90wt%, especially at least 95wt%, of said housing is made up of said polymeric material and said restrictor layer.

- said housing consists essentially of said polymeric material and said restrictor layer.

- Said housing preferably houses electronic components, for example arranged to produce a stimulus when part of a medical device for implantation in a human body.

- Said polymeric material may comprise a bio-compatible polymeric material.

- Said bio-compatible polymeric material may be any polymeric material which is non-toxic and not otherwise harmful when introduced into the human body.

- Said polymeric material may comprise a first polymer as described hereinafter.

- Said first polymer may have a Notched Izod Impact Strength (specimen 80mm x 10mm x 4mm with a cut 0.25mm notch (Type A), tested at 23 0 C, in accordance with ISO180) of at least 4KJm “2 , preferably at least 5KJm "2 , more preferably at least 6KJm “2 .

- Said Notched Izod Impact Strength measured as aforesaid, may be less than 10KJm "2 , suitably less than 8KJm "2 .

- the Notched Izod Impact Strength, measured as aforesaid, of the plastic material may be at least 3KJm “2 , suitably at least 4KJm “2 , preferably at least 5KJm "2 .

- Said impact strength may be less than 50 KJm “2 , suitably less than 30KJm "2 .

- Said first polymer suitably has a melt viscosity (MV) of at least 0.06 kNsm “2 , preferably has a MV of at least 0.09 kNsm “2 , more preferably at least 0.12 kNsm “2 , especially at least 0.15 kNsm “2 .

- MV melt viscosity

- MV is suitably measured using capillary rheometry operating at 400 0 C at a shear rate of 1000s "1 using a tungsten carbide die, 0.5x3.175mm.

- Said first polymer may have a MV of less than 1.00 kNsm , preferably less than 0.5 kNsm "2 .

- Said first polymer may have a MV in the range 0.09 to 0.5 kNsm "2 , preferably in the range 0.14 to 0.5 kNsm "2 .

- Said first polymer may have a tensile strength, measured in accordance with ISO527 (specimen type Ib) tested at 23 0 C at a rate of 50mm/minute of at least 20 MPa, preferably at least 60 MPa, more preferably at least 80 MPa.

- the tensile strength is preferably in the range 80-110 MPa, more preferably in the range 80-100 MPa.

- Said first polymer may have a flexural strength, measured in accordance with ISO178 (80mm x 10mm x 4mm specimen, tested in three-point-bend at 23 0 C at a rate of

- the flexural strength is preferably in the range 145-180MPa, more preferably in the range 145-164 MPa.

- Said first polymer may have a flexural modulus, measured in accordance with ISO178 (80mm x 10mm x 4mm specimen, tested in three-point-bend at 23 0 C at a rate of 2mm/minute) of at least 1 GPa, suitably at least 2 GPa, preferably at least 3 GPa, more preferably at least 3.5 GPa.

- the flexural modulus is preferably in the range 3.5- 4.5 GPa, more preferably in the range 3.5-4.1 GPa.

- Said first polymer may be amorphous or semi-crystalline. It is preferably semi-crystalline.

- the level and extent of crystallinity in a polymer is preferably measured by wide angle X-ray diffraction (also referred to as Wide Angle X-ray Scattering or WAXS), for example as described by Blundell and Osborn (Polymer 24, 953, 1983) .

- WAXS Wide Angle X-ray Scattering

- crystallinity may be assessed by Differential Scanning Calerimetry (DSC) .

- the level of crystallinity of said first polymer may be at least 1%, suitably at least 3%, preferably at least 5% and more preferably at least 10%. In especially preferred embodiments, the crystallinity may be greater than 25%.

- the main peak of the melting endotherm (Tm) of said first polymer (if crystalline) may be at least 300 0 C.

- Said first polymer may include a polymeric moiety which is: an acrylate (e.g. it comprises or consists of methylmethacrylate moieties); a urethane; a vinyl chloride; a silicone; a siloxane (eg comprising dimethylsiloxane moieties); a sulphone; a carbonate; a fluoroalkylene (e.g. a fluoroethylene) ; an acid (e.g. a glycolic acid or lactic acid); an amide (e.g. comprising nylon moieties); an alkylene (e.g. ethylene or propylene); an oxyalkylene (e.g. polyoxymethylene) ; an ester (e.g. polyethylene terephthalate) , an ether (e.g. an aryletherketone, an arylethersulphone (e.g. polyethersulphone or polyphenylenesulphone) or an ether imide) .

- Said first polymer may be selected from a polyalkylacrylate (e.g. polymethylmethacrylate), a polyfluoroalkylene (e.g. PTFE), a polyurethane, a polyalkylene (e.g. polyethylene or polypropylene), a polyoxyakylene (e.g. polyoxymethylene), a polyester (e.g. polyethylene terephthalate or polybutylene terephthalate) , a polysulphone, a polycarbonate, a polyacid (e.g. polyglycolic acid or polylactic acid), a polyalkylene oxide ester (e.g.

- a polyalkylacrylate e.g. polymethylmethacrylate

- a polyfluoroalkylene e.g. PTFE

- a polyurethane e.g. polyethylene or polypropylene

- a polyoxyakylene e.g. polyoxymethylene

- polyester e.g. polyethylene

- polyethylene oxide terephalate a polyvinylchloride, a silicone, a polysiloxane, a nylon, , a polyaryletherketone, a polarylethersulphone, a polyether imide and any copolymer which includes any of the aforementioned.

- said first polymer is selected from polyethylene, polypropylene, silicone and polyetheretherketone . More preferably, said polymeric material is selected from polyethylene, polypropylene, silicone and polyetheretheketone .

- Said first polymer may include a repeat unit of general formula

- A, B, C and D independently represent 0 or 1

- E and E' independently represent an oxygen or a sulphur atom or a direct link

- G represents an oxygen or sulphur atom, a direct link or a -O-Ph-0- moiety

- Ph represents a phenyl group

- m, r, s, t, v, w, and z represent zero or 1

- Ar is selected from one of the following moieties (i) to (v) which is bonded via one or more of its phenyl moieties to adjacent moieties

- a phenyl moiety has 1,4-, linkages to moieties to which it is bonded.

- Said first polymer may be a homopolymer which includes a repeat unit of IV or V or may be a random or block copolymer of at least two different units of IV and/or V.

- said first polymer may include a repeat unit of general formula

- A, B, C, and D independently represent 0 or 1 and E, E', G, Ar, m, r, s, t, v, w and z are as described in any statement herein.

- Said first polymer may be a homopolymer which includes a repeat unit of IV* or V* or a random or block copolymer of at least two different units of IV* and/or V*.

- said first polymer is a homopolymer having a repeat unit of general formula IV.

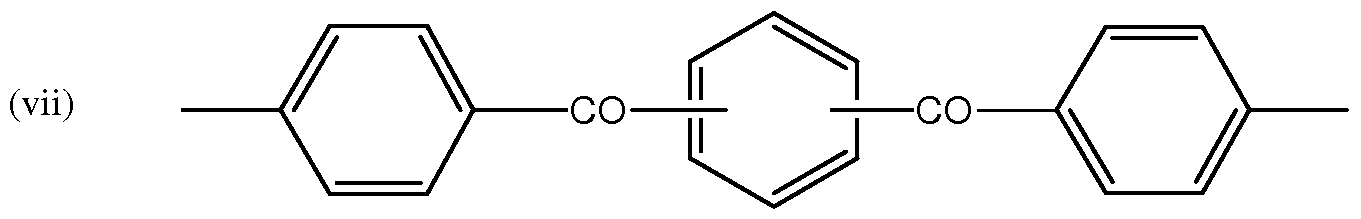

- Ar is selected from the following moieties (vi] to (x)

- the middle phenyl may be 1,4- or 1, 3-substituted. It is preferably 1, 4-substituted.

- Suitable moieties Ar are moieties (ii) , (iii), (iv) and (v) and, of these, moieties, (ii), (iii) and (v) are preferred.

- Other preferred moieties Ar are moieties (vii) , (viii), (ix) and (x) and, of these, moieties (vii) , (viii) and (x) are especially preferred.

- first polymers are polymers (or copolymers) which consist essentially of phenyl moieties in conjunction with ketone and/or ether moieties. That is, in the preferred class, the first polymer does not include repeat units which include -S-, - SO 2 - or aromatic groups other than phenyl.

- Preferred first polymers for example bio-compatible polymeric materials of the type described include:

- E' represent oxygen atoms

- G represents a direct link

- s represents 0, and

- a and B represent 1 (i.e. polyetheretherketone) .

- Said first polymer may consist essentially of one of units (a) to (f) defined above.

- said may comprise a copolymer comprising at least two units selected from (a) to (f) defined above.

- Preferred copolymers include units (a) .

- a copolymer may comprise units (a) and (f ) ; or may comprise units (a) and (e) .

- Said first polymer for example bio-compatible polymeric material preferably comprises, more preferably consists essentially of, a repeat unit of formula (XX)

- said first polymer is selected from polyetheretherketone, polyetherketone, polyetherketoneetherketoneketone and polyetherketoneketone . In a more preferred embodiment, said first polymer is selected from polyetherketone and polyetheretherketone. In an especially preferred embodiment, said first polymer is polyetheretherketone.

- At least 90wt%, preferably at least 95wt%, more preferably at least 98wt% of said polymeric material of said housing is made up of said first polymer.

- said housing includes a continuous coating of said restrictor layer on said first polymer, suitably over the entire outer surface of said first polymer, suitably so that substantially none of said first polymer is exposed to the outside and may contact fluid in use.

- the diffusion lag time of water through the restrictor layer as measured by ELS as described hereinafter is equal to or less than 10 ⁇ 10 m 2 /s, preferably equal to or less than 10 ⁇ 12 m 2 /s, more preferably equal to or less than ICT 14 m 2 /s, especially equal to or less than 1(T 16 m 2 /s.

- a method of making a housing of an implantable device comprising:

- At least part, preferably substantially the entirety, of said restrictor layer may be made by a physical vapour deposition (PVD) technique.

- the technique may be selected from magnetron sputtering, vacuum evaporation, cathodic arc evaporation, ion-plating, ion-beam sputtering and pulsed laser ablation.

- the PVD technique comprises magnetron sputtering.

- the layer is suitably prepared from a coating flux created as a vapour from a solid source under a partial vacuum. Said layer is suitably prepared in a sputtering process.

- Said method may include:

- Said method may include introducing another material into said vacuum chamber which may also be arranged to condense on the substrate.

- the other material may comprise a nitrogen-containing gas.

- the method may include varying conditions in said vacuum chamber to vary the structure and/or composition of material which may condense on said housing or parts thereof thereby to build up a plurality or multiplicity of layers which have different structures and/or compositions as described according to the first aspect.

- the method may include varying conditions so that one or more layers which are formed on the substrate consist essentially of titanium moieties.

- the method preferably involves selecting a housing (rather than simply parts thereof which may be formed into a housing) and forming said restrictor layer thereon.

- the housing may comprise two or more parts which have been secured together prior to formation of said restrictor layer .

- the housing may incorporate electronic components, for example arranged to produce a stimulus when part of a medical device for implantation in a human body, prior to formation of said restrictor layer.

- a method of restricting passage of fluid for example a liquid such as a body fluid, into a housing of an implantable device, the method comprising: providing a restrictor layer on said housing or parts which are arranged to form said housing, wherein said restrictor layer comprises a material which includes titanium moieties .

- the method of the third aspect may be carried out in accordance with the method of the second aspect .

- a method of applying a stimulus to a human body including associating an implantable device as described herein with the body to be stimulated.

- an implantable device as described herein for applying a stimulus to a human body.

- Figure 1 is a cross-section through an implantable device

- Figure 2 is an enlarged view of the area contained within region II of figure 1 ;

- Figure 3 is a schematic illustration of an arrangement used to expose coated substrates

- Figure 4 is a graph of water uptake against time for example 4 at 37 0 C;

- Figure 5 is a graph of water uptake against time for example 4 at 60 0 C;

- Figure 6 is a graph of water uptake against time for example 4 obtained by ELS;

- Figure 7 is a graph of water uptake against time for example 5 at 37 0 C;

- Figure 8 is a graph of water uptake verse against time for example 5 at 6O 0 C and

- Figure 9 is a graph of water uptake against time for example 5 obtained by ELS.

- an implantable device 2 comprises a housing 4 which comprises injection moulded (or machined) housing wall halves 6, 8 which define an enclosed interior region 10 within which a stimulator 12 and power source 14 are arranged.

- the housing also includes a coating 16 which covers substantially the entirety of the outer surfaces of the wall halves so as to hermetically seal the housing and substantially prevent ingress of moisture into the interior region 10, in use.

- the wall halves 6, 8 comprise polyetheretherketone polymer which is injection moulded to define the halves 6, 8.

- the halves may be secured together by a suitable means, for example by welding and/or as described in US2006/0259090.

- the polyetheretherketone polymer of the housing halves is coated, using plasma vapour deposition (PVD), to define a multiple layer (40 layer) coating which comprises alternate layers of titanium 20 and titanium nitride 22.

- the outer layer 20a comprises substantially pure titanium and suitably the sum of the number of titanium and titanium nitride layers is 40.

- Each titanium layer may have a thickness of 20nm, and each titanium nitride layer may have a thickness of IOnm.

- the overall thickness of the coating is l ⁇ m.

- each interface between titanium layers 20 and contiguous titanium nitride layers 32 there may not be a sharp distinction at each interface between titanium layers 20 and contiguous titanium nitride layers 32. There may be a gradual increase in the level of nitrogen contained in the layer on moving away from an interface into a titanium nitride layer; and a gradual decrease in the level of nitrogen contained in a layer on moving away from an interface into a titanium layer.

- ASTM C581 combined with the principles of ASTM D570 is a standard gravimetric practice for determination of the chemical resistance and diffusion behaviour of composites intended for use in liquids. During the experiments the samples were in an unstressed state. The baseline exposure conditions were a temperature of 37 0 C and a pressure of 1 bar.

- Figure 3 schematically illustrates the exposure arrangement used.

- ELS Electrical Impedance Spectroscopy

- the equipment electrodes were connected to the polymer. If water diffuses through the coating, there will be a lag time for water uptake of the polymer. After the lag time, the solubility of water - and the diffusion of water into the polymer - will change the electrical impedance of the system. From this change, the diffusion and eventual chemical degradation characteristics can be derived.

- polyetheretherketone film obtainable from Victrex PIc, Thornton Cleveleys, UK, has a matt side (Ra 0.5 to l ⁇ m) and a glossy side (Ra about 0.1 ⁇ m) .

- Example 3 The samples of Examples 3 to 6 were assessed as described in Example 2.

- the example 3 material absorbed an excessive amount of water and therefore is unsuitable for use for a housing which is required to be substantially impermeable to water.

- the example 4 material exhibited an uptake as illustrated in figures 4 and 5.

- An ELS measurement was also carried out and results are provided in figure 6.

- the example 5 material exhibited an uptake as illustrated in figures 7 and 8.

- An ELS measurement was also carried out and results are provided in figure 9.

Abstract

An implantable device comprising a housing which comprises a polymeric material wherein said housing includes a restrictor layer for restricting passage of fluid into an interior region of the housing, wherein said restrictor layer comprises a material which includes titanium moieties, for example titanium nitride.

Description

Implantable Device

This invention relates to implantable devices and particularly, although not exclusively, relates to implantable devices for implantation in a human body and a method of making such devices.

It is well known to provide implantable devices for implantation in a human body for applying a stimulus to a part of the body, for example a tissue, for a therapeutic purpose. Such implantable devices may be arranged to supply an electrical stimulus used in neurological therapy for stimulating nerves or muscle to combat pain or may be used as a heart pacemaker. Other applications include use in treating urinary urge incontinence by stimulating nerves close to the pelvic floor; and use in reduction of pressure sores by stimulating cavernous nerves. In addition, implantable devices are, in some cases, used to provide a chemical or mechanical stimulus.

Implantable devices may, in general terms, comprise a housing which includes electronic circuitry and a power source. Preferably, the housing defines an hermetically sealed environment so that its contents are protected from ingress of water which could be damaging. It has been known for over 30 years to make such housings out of titanium parts which are laser welded together to define a hermetically sealed container. In addition, housings made from plastics materials have been proposed but have generally been inadequate in use due to the inherent porosity of plastics materials. This problem has been addressed in commercial applications by filling a housing around its electronic circuitry with silicone in an

attempt to protect the circuitry. However, silicone is also permeable to water and, accordingly, its use is an ineffective solution to the problem.

It is an object of the invention to address problems associated with implantable devices.

According to a first aspect of the invention, there is provided an implantable device comprising a housing which comprises a polymeric material wherein said housing includes a restrictor layer for restricting passage of fluid into an interior region of the housing, wherein said restrictor layer comprises a material which includes titanium moieties.

Said restrictor layer preferably directly contacts said polymeric material. There may therefore be no intermediate, for example adhesive, layer between said polymeric material and said restrictor layer.

Said restrictor layer is suitably provided over at least 50%, preferably at least 75%, more preferably at least 90%, especially at least 95% of the outer surface area of the housing. Preferably, said restrictor layer is provided over substantially the entire outer surface of the housing so that it substantially seals the housing from ingress of fluid, into the housing.

Suitably, the restrictor layer is arranged to restrict (more preferably substantially prevent) passage of an aqueous liquid, for example a body fluid, from a position outside the housing to a position within the housing.

Said restrictor layer may have a thickness, for example an average thickness, of less than lOOOμm, suitably less than 500μm, preferably less than 250μm, more preferably less than lOOμm, especially less than 10μm. In especially preferred embodiments the thickness may be less than 5μm or even less than 2μm.

Said restrictor layer may have a thickness, for example an average thickness, of greater than 0. lμm, preferably greater than 0.5μm, more preferably greater than 0.75μm.

Said restrictor layer may itself be made up of a plurality, preferably a multiplicity, of different layers. For example, said restrictor layer may include at least five, preferably at least ten, more preferably at least fifteen, especially at least twenty different layers. The restrictor layer may include less than fifty different layers .

Where the restrictor layer includes different layers, all of the layers may not have the same composition. Preferably, therefore, at least one layer in the restrictor layer has a different structure or composition compared to the structure or composition of another layer of said restrictor layer. Layers of said restrictor layer are suitably selected to be complimentary to one another thereby to enhance the ability of the restrictor layer to restrict passage of fluid. For example, one layer of said restrictor layer may have defects, for example microscopic openings, which would otherwise allow some fluid to pass therethrough. To combat this, a layer adjacent said one layer may be arranged to compensate for the defects, for example by having a structure which blocks or otherwise

cooperates with defects, for example openings, thereby to restrict passage of fluid through said one layer.

Preferably, said restrictor layer includes a first layer in contact with a second layer and there being a third layer in contact with the second layer, wherein the first, second and third layers are superimposed and wherein the second layer has a different structure or composition (preferably both a different structure and composition) compared to the structure and/or composition of the first and third layers. Preferably, said restrictor layer includes at least five layers, more preferably at least ten layers, especially at least twenty layers wherein the layers are superimposed and adjacent layers have a different structure or composition (preferably both a different structure and different composition) . Preferably each of said five (or ten or twenty layers if provided) has an average thickness in the range lnm to 200nm, more preferably in the range 5nm to lOOnm.

Said restrictor layer may include a plurality, preferably a multiplicity, of layers which include titanium moieties.

Said restrictor layer may include at least one layer type (hereinafter referred to as a "first layer type") which consists essentially of titanium moieties. Thus, said at least one first layer type may consist essentially of titanium metal. Said first layer type may have a thickness in the range lnm to 200nm, preferably in the range 5nm to lOOnm. Said restrictor layer may include a multiplicity, preferably at least three, more preferably at least seven, layers having the same composition and/or thickness as said first layer type as described.

Said restrictor layer may include at least one layer type (hereinafter referred to as a "second layer type") which does not consist essentially of titanium moieties and therefore suitably does not consist essentially of titanium metal. Said second layer type may have a thickness in the range lnm to 200nm, preferably in the range 5nm to lOOnm. Said restrictor layer may include a multiplicity, preferably at least three, more preferably at least seven, layers having the same composition and/or thickness as said second layer type as described.

Said second layer type may include titanium moieties. Said second layer type may also include non-metal moieties. Said second layer type may comprise a titanium compound for example a compound consisting of titanium moieties and a non-metal. A non-metal may be gaseous at stp; for example it may be oxygen or nitrogen.

Said second layer type preferably includes nitrogen moieties. Thus, preferably, said second layer type preferably comprises, more preferably consists essentially of, titanium and nitrogen moieties and is preferably therefore a titanium nitride compound. The ratio of titanium moieties to nitrogen moieties in said second layer type may be in the range 0.3 to 3, preferably 0.5 to 2, more preferably 0.8 to 1.2.

Said restrictor layer preferably includes first to sixth layers (preferably first to tenth layers) which are superimposed upon one another wherein adjacent layers have different compositions and each layer includes titanium

moieties. Preferably alternate layers include both titanium and nitrogen moieties.

Said restrictor layer preferably includes an outermost layer (which suitably defines an outer surface of the housing which may contact body fluids in use) which comprises titanium moieties and preferably consists essentially of titanium moieties. Thus, preferably, the outermost layer consists essentially of titanium metal.

Said housing suitably includes a wall which is defined by said polymeric material (for example by said wall being produced by moulding, for example injection moulding, or the like) . The wall may have a thickness of less than 5mm, or less than 3mm, typically in the range l-3mm. The ratio of the thickness of the wall (e.g. the average thickness) to the thickness of the restrictor layer (e.g. average thickness) may be in the range 500-5000.

Said implantable device may have a volume of less than 50cm3, preferably less than 35cm3, more preferably less than 25cm . The volume may be at least lcm .

Preferably at least 75wt%, more preferably at least 90wt%, especially at least 95wt%, of said housing is made up of said polymeric material and said restrictor layer. Preferably, said housing consists essentially of said polymeric material and said restrictor layer.

Said housing preferably houses electronic components, for example arranged to produce a stimulus when part of a medical device for implantation in a human body.

Said polymeric material may comprise a bio-compatible polymeric material.

Said bio-compatible polymeric material may be any polymeric material which is non-toxic and not otherwise harmful when introduced into the human body.

Said polymeric material may comprise a first polymer as described hereinafter.

Said first polymer may have a Notched Izod Impact Strength (specimen 80mm x 10mm x 4mm with a cut 0.25mm notch (Type A), tested at 230C, in accordance with ISO180) of at least 4KJm"2, preferably at least 5KJm"2, more preferably at least 6KJm"2. Said Notched Izod Impact Strength, measured as aforesaid, may be less than 10KJm"2, suitably less than 8KJm"2.

The Notched Izod Impact Strength, measured as aforesaid, of the plastic material may be at least 3KJm"2, suitably at least 4KJm"2, preferably at least 5KJm"2. Said impact strength may be less than 50 KJm"2, suitably less than 30KJm"2.

Said first polymer suitably has a melt viscosity (MV) of at least 0.06 kNsm"2, preferably has a MV of at least 0.09 kNsm"2, more preferably at least 0.12 kNsm"2, especially at least 0.15 kNsm"2.

MV is suitably measured using capillary rheometry operating at 4000C at a shear rate of 1000s"1 using a tungsten carbide die, 0.5x3.175mm.

Said first polymer may have a MV of less than 1.00 kNsm , preferably less than 0.5 kNsm"2.

Said first polymer may have a MV in the range 0.09 to 0.5 kNsm"2, preferably in the range 0.14 to 0.5 kNsm"2.

Said first polymer may have a tensile strength, measured in accordance with ISO527 (specimen type Ib) tested at 230C at a rate of 50mm/minute of at least 20 MPa, preferably at least 60 MPa, more preferably at least 80 MPa. The tensile strength is preferably in the range 80-110 MPa, more preferably in the range 80-100 MPa.

Said first polymer may have a flexural strength, measured in accordance with ISO178 (80mm x 10mm x 4mm specimen, tested in three-point-bend at 230C at a rate of

2mm/minute) of at least 50 MPa, preferably at least 100

MPa, more preferably at least 145 MPa. The flexural strength is preferably in the range 145-180MPa, more preferably in the range 145-164 MPa.

Said first polymer may have a flexural modulus, measured in accordance with ISO178 (80mm x 10mm x 4mm specimen, tested in three-point-bend at 230C at a rate of 2mm/minute) of at least 1 GPa, suitably at least 2 GPa, preferably at least 3 GPa, more preferably at least 3.5 GPa. The flexural modulus is preferably in the range 3.5- 4.5 GPa, more preferably in the range 3.5-4.1 GPa.

Said first polymer may be amorphous or semi-crystalline. It is preferably semi-crystalline.

The level and extent of crystallinity in a polymer is preferably measured by wide angle X-ray diffraction (also referred to as Wide Angle X-ray Scattering or WAXS), for example as described by Blundell and Osborn (Polymer 24, 953, 1983) . Alternatively, crystallinity may be assessed by Differential Scanning Calerimetry (DSC) .

The level of crystallinity of said first polymer may be at least 1%, suitably at least 3%, preferably at least 5% and more preferably at least 10%. In especially preferred embodiments, the crystallinity may be greater than 25%.

The main peak of the melting endotherm (Tm) of said first polymer (if crystalline) may be at least 3000C.

Said first polymer may include a polymeric moiety which is: an acrylate (e.g. it comprises or consists of methylmethacrylate moieties); a urethane; a vinyl chloride; a silicone; a siloxane (eg comprising dimethylsiloxane moieties); a sulphone; a carbonate; a fluoroalkylene (e.g. a fluoroethylene) ; an acid (e.g. a glycolic acid or lactic acid); an amide (e.g. comprising nylon moieties); an alkylene (e.g. ethylene or propylene); an oxyalkylene (e.g. polyoxymethylene) ; an ester (e.g. polyethylene terephthalate) , an ether (e.g. an aryletherketone, an arylethersulphone (e.g. polyethersulphone or polyphenylenesulphone) or an ether imide) .

Said first polymer may be selected from a polyalkylacrylate (e.g. polymethylmethacrylate), a polyfluoroalkylene (e.g. PTFE), a polyurethane, a polyalkylene (e.g. polyethylene or polypropylene), a polyoxyakylene (e.g. polyoxymethylene), a polyester (e.g. polyethylene terephthalate or polybutylene

terephthalate) , a polysulphone, a polycarbonate, a polyacid (e.g. polyglycolic acid or polylactic acid), a polyalkylene oxide ester (e.g. polyethylene oxide terephalate) a polyvinylchloride, a silicone, a polysiloxane, a nylon, , a polyaryletherketone, a polarylethersulphone, a polyether imide and any copolymer which includes any of the aforementioned.

Preferably, said first polymer is selected from polyethylene, polypropylene, silicone and polyetheretherketone . More preferably, said polymeric material is selected from polyethylene, polypropylene, silicone and polyetheretheketone .

Said first polymer may include a repeat unit of general formula

or a repeat unit of general formula

wherein A, B, C and D independently represent 0 or 1,

E and E' independently represent an oxygen or a sulphur atom or a direct link, G represents an oxygen or sulphur

atom, a direct link or a -O-Ph-0- moiety where Ph represents a phenyl group, m, r, s, t, v, w, and z represent zero or 1 and Ar is selected from one of the following moieties (i) to (v) which is bonded via one or more of its phenyl moieties to adjacent moieties

Unless otherwise stated in this specification, a phenyl moiety has 1,4-, linkages to moieties to which it is bonded.

Said first polymer may be a homopolymer which includes a repeat unit of IV or V or may be a random or block copolymer of at least two different units of IV and/or V.

As an alternative to a first polymer comprising units IV and/or V discussed above, said first polymer may include a repeat unit of general formula

or a homopolymer having a repeat unit of general formula

wherein A, B, C, and D independently represent 0 or 1 and E, E', G, Ar, m, r, s, t, v, w and z are as described in any statement herein.

Said first polymer may be a homopolymer which includes a repeat unit of IV* or V* or a random or block copolymer of at least two different units of IV* and/or V*.

Preferably, said first polymer is a homopolymer having a repeat unit of general formula IV.

Preferably Ar is selected from the following moieties (vi] to (x)

In (vii), the middle phenyl may be 1,4- or 1, 3-substituted. It is preferably 1, 4-substituted.

Suitable moieties Ar are moieties (ii) , (iii), (iv) and (v) and, of these, moieties, (ii), (iii) and (v) are preferred.

Other preferred moieties Ar are moieties (vii) , (viii), (ix) and (x) and, of these, moieties (vii) , (viii) and (x) are especially preferred.

An especially preferred class of first polymers are polymers (or copolymers) which consist essentially of phenyl moieties in conjunction with ketone and/or ether moieties. That is, in the preferred class, the first polymer does not include repeat units which include -S-, - SO2- or aromatic groups other than phenyl. Preferred first polymers, for example bio-compatible polymeric materials of the type described include:

(a) a polymer consisting essentially of units of formula IV wherein Ar represents moiety (v) , E and

E' represent oxygen atoms, m represents 0, w represents 1, G represents a direct link, s represents 0, and A and B represent 1 (i.e. polyetheretherketone) .

(b) a polymer consisting essentially of units of formula IV wherein E represents an oxygen atom, E' represents a direct link, Ar represents a moiety of structure (ii) , m represents 0, A represents 1, B represents 0 (i.e. polyetherketone) ;

(c) a polymer consisting essentially of units of formula IV wherein E represents an oxygen atom, Ar represents moiety (ii) , m represents 0, E' represents a direct link, A represents 1, B represents 0, (i.e. polyetherketoneketone) .

(d) a polymer consisting essentially of units of formula IV wherein Ar represents moiety (ii), E and E' represent oxygen atoms, G represents a direct link, m represents 0, w represents 1, r represents 0, s represents 1 and A and B represent

1. (i.e. polyetherketoneetherketoneketone) .

(e) a polymer consisting essentially of units of formula IV, wherein Ar represents moiety (v) , E and E' represents oxygen atoms, G represents a direct link, m represents 0, w represents 0, s, r, A and B represent 1 (i.e. polyetheretherketoneketone) .

(f) a polymer comprising units of formula IV, wherein Ar represents moiety (v) , E and E' represent oxygen atoms, m represents 1, w represents 1, A represents 1, B represents 1, r and s represent 0 and G represents a direct link (i.e. polyether- diphenyl-ether-phenyl-ketone-phenyl-) .

Said first polymer may consist essentially of one of units (a) to (f) defined above. Alternatively, said may comprise a copolymer comprising at least two units selected from (a) to (f) defined above. Preferred copolymers include units (a) . For example, a copolymer may comprise units (a) and (f ) ; or may comprise units (a) and (e) .

Said first polymer for example bio-compatible polymeric material preferably comprises, more preferably consists essentially of, a repeat unit of formula (XX)

where tl, and wl independently represent 0 or 1 and vl represents 0, 1 or 2. Preferred first polymers have a said repeat unit wherein tl=l, vl=0 and wl=0; tl=0, vl=0 and wl=0; tl=0, wl=l, vl=2; or tl=0, vl=l and wl=0. More preferred have tl=l, vl=0 and wl=0; or tl=0, vl=0 and wl=0. The most preferred has tl=l, vl=0 and wl=0.

In preferred embodiments, said first polymer is selected from polyetheretherketone, polyetherketone, polyetherketoneetherketoneketone and polyetherketoneketone . In a more preferred embodiment, said first polymer is selected from polyetherketone and polyetheretherketone. In an especially preferred embodiment, said first polymer is polyetheretherketone.

Suitably at least 90wt%, preferably at least 95wt%, more preferably at least 98wt% of said polymeric material of said housing is made up of said first polymer.

Preferably, said housing includes a continuous coating of said restrictor layer on said first polymer, suitably over the entire outer surface of said first polymer, suitably so that substantially none of said first polymer is exposed to the outside and may contact fluid in use.

Suitably, the diffusion lag time of water through the restrictor layer as measured by ELS as described hereinafter is equal to or less than 10~10 m2/s, preferably equal to or less than 10~12 m2/s, more preferably equal to

or less than ICT14 m2/s, especially equal to or less than 1(T16 m2/s.

According to a second aspect of the invention, there is provided a method of making a housing of an implantable device, the method comprising:

(a) selecting a housing or parts of a housing, wherein said housing or parts comprises a polymeric material;

(b) forming a restrictor layer on said housing or parts of said housing, wherein said restrictor layer comprises a material which includes titanium moieties.

At least part, preferably substantially the entirety, of said restrictor layer may be made by a physical vapour deposition (PVD) technique. The technique may be selected from magnetron sputtering, vacuum evaporation, cathodic arc evaporation, ion-plating, ion-beam sputtering and pulsed laser ablation. Preferably, the PVD technique comprises magnetron sputtering. The layer is suitably prepared from a coating flux created as a vapour from a solid source under a partial vacuum. Said layer is suitably prepared in a sputtering process.

Said method may include:

(a) arranging a substrate comprising titanium moieties in a vacuum chamber;

(b) causing titanium moieties to be sputtered from said substrate;

(c) arranging said housing or parts of said housing in the vacuum chamber on which the titanium moieties may condense .

Said method may include introducing another material into said vacuum chamber which may also be arranged to condense on the substrate. The other material may comprise a nitrogen-containing gas.

The method may include varying conditions in said vacuum chamber to vary the structure and/or composition of material which may condense on said housing or parts thereof thereby to build up a plurality or multiplicity of layers which have different structures and/or compositions as described according to the first aspect.

The method may include varying conditions so that one or more layers which are formed on the substrate consist essentially of titanium moieties.

The method preferably involves selecting a housing (rather than simply parts thereof which may be formed into a housing) and forming said restrictor layer thereon. The housing may comprise two or more parts which have been secured together prior to formation of said restrictor layer .

The housing may incorporate electronic components, for example arranged to produce a stimulus when part of a medical device for implantation in a human body, prior to formation of said restrictor layer.

According to a third aspect of the invention, there is provided a method of restricting passage of fluid, for example a liquid such as a body fluid, into a housing of an implantable device, the method comprising: providing a restrictor layer on said housing or parts which are arranged to form said housing, wherein said restrictor layer comprises a material which includes titanium moieties .

The method of the third aspect may be carried out in accordance with the method of the second aspect .

According to a fourth aspect of the invention, there is provided a method of applying a stimulus to a human body, the method including associating an implantable device as described herein with the body to be stimulated.

According to a fifth aspect of the invention, there is provided the use of an implantable device as described herein for applying a stimulus to a human body.

Any feature of any aspect of any invention or embodiment described herein may be combined with any feature of any aspect of any other invention or embodiment described herein mutatis mutandis.

Specific embodiments of the invention will now be described, by way of example, with reference to the accompanying schematic drawings, in which:

Figure 1 is a cross-section through an implantable device;

Figure 2 is an enlarged view of the area contained within region II of figure 1 ;

Figure 3 is a schematic illustration of an arrangement used to expose coated substrates;

Figure 4 is a graph of water uptake against time for example 4 at 370C;

Figure 5 is a graph of water uptake against time for example 4 at 600C;

Figure 6 is a graph of water uptake against time for example 4 obtained by ELS;

Figure 7 is a graph of water uptake against time for example 5 at 370C;

Figure 8 is a graph of water uptake verse against time for example 5 at 6O0C and

Figure 9 is a graph of water uptake against time for example 5 obtained by ELS.

Referring to figures 1 and 2, an implantable device 2 comprises a housing 4 which comprises injection moulded (or machined) housing wall halves 6, 8 which define an enclosed interior region 10 within which a stimulator 12 and power source 14 are arranged. The housing also includes a coating 16 which covers substantially the entirety of the outer surfaces of the wall halves so as to hermetically seal the housing and substantially prevent ingress of moisture into the interior region 10, in use.

Referring to figure 2, the wall halves 6, 8 comprise polyetheretherketone polymer which is injection moulded to define the halves 6, 8. After stimulator 12 and power source 14 (and any other components which are to be contained in interior region 10) have been arranged between the wall halves 6, 8, the halves may be secured together by a suitable means, for example by welding and/or as described in US2006/0259090. Then to provide a hermetically sealed housing, the polyetheretherketone polymer of the housing halves is coated, using plasma vapour deposition (PVD), to define a multiple layer (40 layer) coating which comprises alternate layers of titanium 20 and titanium nitride 22. The outer layer 20a comprises substantially pure titanium and suitably the sum of the number of titanium and titanium nitride layers is 40. Each titanium layer may have a thickness of 20nm, and each titanium nitride layer may have a thickness of IOnm. Thus, the overall thickness of the coating is lμm.

In view of the PVD method used, there may not be a sharp distinction at each interface between titanium layers 20 and contiguous titanium nitride layers 32. There may be a gradual increase in the level of nitrogen contained in the layer on moving away from an interface into a titanium nitride layer; and a gradual decrease in the level of nitrogen contained in a layer on moving away from an interface into a titanium layer.

It is found that the combination of polymer and a multilayer coating provides an outstanding barrier to passage of water as illustrated further below.

Example 1 - General procedure for provision of multiple layer coatings

Multiple layer coatings were prepared using a PVD process in a Closed Field Unbalanced Magnetron Sputter Ion Plating process using a Teer CFUBMSIP system provided by Teer Coatings Limited, UK. In the process, an approximately 40nm titanium layer is applied to a polyetheretherketone substrate by PVD followed by an approximately IOnm layer of titanium nitride followed by further respective 40nm and IOnm layers of titanium and titanium nitride to build up a multilayer coating having a thickness of about lμm. The maximum temperature the substrate may be subjected to during the coating process may be less than 16O0C.

Example 2 - General procedure for assessment of coated substrates

Samples prepared as described hereinafter were exposed to water according to the methodology described in ASTM C581.

ASTM C581 combined with the principles of ASTM D570 is a standard gravimetric practice for determination of the chemical resistance and diffusion behaviour of composites intended for use in liquids. During the experiments the samples were in an unstressed state. The baseline exposure conditions were a temperature of 370C and a pressure of 1 bar.

To obtain insight into the temperature dependence and chemical degradation behaviour, a second set of measurements were made at 6O0C.

Figure 3 schematically illustrates the exposure arrangement used.

After exposure to water for the specified time, samples were removed and dried in a vacuum oven at 5O0C until a constant dry weight was achieved. Results are summarised in graphs provided hereinafter.

Electrical Impedance Spectroscopy (ELS) was also carried out to validate the findings obtained using the above gravimetric method. In the ELS method, the coated side of the samples were continuously exposed to water with a humidity of 90% at 250C. The non-coated side was protected from direct contact with atmospheric moisture during the test method.

To measure the electrical impedance of the polymer, the equipment electrodes were connected to the polymer. If water diffuses through the coating, there will be a lag time for water uptake of the polymer. After the lag time, the solubility of water - and the diffusion of water into the polymer - will change the electrical impedance of the system. From this change, the diffusion and eventual chemical degradation characteristics can be derived.

Examples 3 to 6 - Samples tested

Various samples were prepared for testing as described in the table below. It should be noted that polyetheretherketone film, obtainable from Victrex PIc, Thornton Cleveleys, UK, has a matt side (Ra 0.5 to lμm) and a glossy side (Ra about 0.1 μm) .

Results and Discussion

The samples of Examples 3 to 6 were assessed as described in Example 2. The example 3 material absorbed an excessive amount of water and therefore is unsuitable for use for a housing which is required to be substantially impermeable to water.

The example 4 material exhibited an uptake as illustrated in figures 4 and 5. An ELS measurement was also carried out and results are provided in figure 6.

The example 5 material exhibited an uptake as illustrated in figures 7 and 8. An ELS measurement was also carried out and results are provided in figure 9.

Comparing the results for the example 4 and 5 materials, it will be noted that whilst the example 4 material provides some restriction to water ingress, the example 5 material is superior and this is graphically illustrated by comparing figures 6 and 9. The example 5 arrangement is found to have a diffusivity of ICT16 m2/s or less.

In tests on the example 6 sample, results comparable to that described for example 5 were achieved.

The invention is not restricted to the details of the foregoing embodiment (s) . The invention extends to any novel one, or any novel combination, of the features disclosed in this specification (including any accompanying claims, abstract and drawings), or to any novel one, or any novel combination, of the steps of any method or process so disclosed.

Claims

1. An implantable device comprising a housing which comprises a polymeric material wherein said housing includes a restrictor layer for restricting passage of fluid into an interior region of the housing, wherein said restrictor layer comprises a material which includes titanium moieties.

2. A device according to claim 1, wherein said restrictor layer is provided over at least 90% of the outer surface area of the housing.

3. A device according to claim 1 or claim 2, wherein said restrictor layer has a thickness of less than lOOOμm.

4. A device according to any preceding claim, wherein said restrictor layer is itself made up of a multiplicity of different layers.

5. A device according to any preceding claim, wherein the restrictor layer includes a multiplicity of layers, not all of which have the same composition.

6. A device according to any preceding claim, wherein said restrictor layer includes a first layer in contact with a second layer and there being a third layer in contact with the second layer, wherein the first, second and third layers are superimposed and wherein the second layer has a different structure or composition compared to the structure and/or composition of the first and third layers .

7. A device according to any preceding claim, wherein said restrictor layer includes at least one layer type (hereinafter referred to as a "first layer type") which consists essentially of titanium moieties, wherein said restrictor layer includes a multiplicity of layers having the same composition as said first layer type.

8. A device according to claim 7, wherein said restrictor layer includes at least one layer type (hereinafter referred to as a "second layer type") which does not consist essentially of titanium moieties.

9. A device according to claim 8, wherein said restrictor layer including a multiplicity of layers having the same composition as said second layer type.

10. A device according to claim 8 or claim 9, wherein said second layer type includes titanium moieties and also includes non-metal moieties.

11. A device according to any of claims 8 to 10, wherein said second layer type includes nitrogen moieties.

12. A device according to any of claims 8 to 11, wherein said second layer type comprises a titanium nitride compound.

13. A device according to any preceding claim, wherein said restrictor layer includes an outermost layer which comprises titanium moieties.

14. A device according to any preceding claim, wherein said housing houses electronic components arranged to produce a stimulus when part of a medical device for implantation in a human body.

15. A device according to any preceding claim, wherein said polymeric material comprises a bio-compatible polymeric material.

16. A device according to any preceding claim, wherein said polymeric material comprises a first polymer which comprises a repeat unit of formula (XX)

where tl and wl independently represent 0 or 1 and vl represents 0, 1 or 2.

17. A device according to any preceding claim, wherein said polymeric material comprises a first polymer which is polyetheretherketone .

18. A device according to any preceding claim, wherein said housing includes a continuous coating of said restrictor layer over the entire outer surface of said polymeric material.

19. A device according to any preceding claim, wherein the diffusion lag time of water through the restrictor layer as measured by ELS is equal to or less than ICT10 m2/s.

20. A method of making a housing of an implantable device, the method comprising: (a) selecting a housing or parts of a housing, wherein said housing or parts comprise a polymeric material;

(b) forming a restrictor layer on said housing or parts of said housing, wherein said restrictor layer comprises a material which includes titanium moieties.

21. A method according to claim 20, wherein said method includes :

(a) arranging a substrate comprising titanium moieties in a vacuum chamber;

(b) causing titanium moieties to be sputtered from said substrate;

(c) arranging said housing or parts of said housing in the vacuum chamber on which the titanium moieties may condense .

22. A method according to claim 20 or claim 21, wherein said method includes introducing another material into said vacuum chamber which may also be arranged to condense on the substrate.

23. A method according to any of claims 20 to 22, wherein said housing incorporates electronic components prior to formation of said restrictor layer.

24. A method of restricting passage of fluid, for example a liquid such as a body fluid, into a housing of an implantable device, the method comprising: providing a restrictor layer on said housing or parts which are arranged to form said housing, wherein said restrictor layer comprises a material which includes titanium moieties .

25. A method of applying a stimulus to a human body, the method including associating an implantable device according to any of claims 1 to 19 with the body to be stimulated.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| GB0723170.7 | 2007-11-27 | ||

| GBGB0723170.7A GB0723170D0 (en) | 2007-11-27 | 2007-11-27 | Implantable device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2009068914A1 true WO2009068914A1 (en) | 2009-06-04 |

Family

ID=38926083

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/GB2008/051119 WO2009068914A1 (en) | 2007-11-27 | 2008-11-26 | Implantable device |

Country Status (2)

| Country | Link |

|---|---|

| GB (1) | GB0723170D0 (en) |

| WO (1) | WO2009068914A1 (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2018220002A1 (en) | 2017-05-30 | 2018-12-06 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung eingetragener Verein | Coated substrate having a titanium-containing coating and a modified titanium oxide coating |

| WO2023119013A1 (en) * | 2021-12-20 | 2023-06-29 | Medtronic, Inc. | Implantable medical device and method of forming same |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4041955A (en) * | 1976-01-29 | 1977-08-16 | Pacesetter Systems Inc. | Implantable living tissue stimulator with an improved hermetic metal container |

| US5876424A (en) * | 1997-01-23 | 1999-03-02 | Cardiac Pacemakers, Inc. | Ultra-thin hermetic enclosure for implantable medical devices |

| WO2001012246A1 (en) * | 1999-08-17 | 2001-02-22 | St. Jude Medical, Inc. | Medical devices with metal/polymer composites |

| US20030109903A1 (en) * | 2001-12-12 | 2003-06-12 | Epic Biosonics Inc. | Low profile subcutaneous enclosure |

| US20060251875A1 (en) * | 2005-05-06 | 2006-11-09 | The University Of Chicago | Hermetic bio-inert coatings for bio-implants fabricated using atomic layer deposition |

-

2007

- 2007-11-27 GB GBGB0723170.7A patent/GB0723170D0/en not_active Ceased

-

2008

- 2008-11-26 WO PCT/GB2008/051119 patent/WO2009068914A1/en active Application Filing

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4041955A (en) * | 1976-01-29 | 1977-08-16 | Pacesetter Systems Inc. | Implantable living tissue stimulator with an improved hermetic metal container |

| US5876424A (en) * | 1997-01-23 | 1999-03-02 | Cardiac Pacemakers, Inc. | Ultra-thin hermetic enclosure for implantable medical devices |

| WO2001012246A1 (en) * | 1999-08-17 | 2001-02-22 | St. Jude Medical, Inc. | Medical devices with metal/polymer composites |

| US20030109903A1 (en) * | 2001-12-12 | 2003-06-12 | Epic Biosonics Inc. | Low profile subcutaneous enclosure |

| US20060251875A1 (en) * | 2005-05-06 | 2006-11-09 | The University Of Chicago | Hermetic bio-inert coatings for bio-implants fabricated using atomic layer deposition |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2018220002A1 (en) | 2017-05-30 | 2018-12-06 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung eingetragener Verein | Coated substrate having a titanium-containing coating and a modified titanium oxide coating |

| DE102017111784A1 (en) | 2017-05-30 | 2018-12-06 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Coated substrate with titanium-containing coating and modified titanium oxide coating |

| WO2023119013A1 (en) * | 2021-12-20 | 2023-06-29 | Medtronic, Inc. | Implantable medical device and method of forming same |

Also Published As

| Publication number | Publication date |

|---|---|

| GB0723170D0 (en) | 2008-01-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Cieślik et al. | Silane–parylene coating for improving corrosion resistance of stainless steel 316L implant material | |

| EP3507335B1 (en) | Polymer coatings | |

| Nemati et al. | Magnetron-sputtered TixNy thin films applied on titanium-based alloys for biomedical applications: Composition-microstructure-property relationships | |

| EP1534356B1 (en) | Medical device exhibiting improved adhesion between polymeric coating and substrate | |

| Hasebe et al. | Fluorinated diamond‐like carbon as antithrombogenic coating for blood‐contacting devices | |

| WOLLIN et al. | Bacterial biofilm formation, encrustation, and antibiotic adsorption to ureteral stents indwelling in humans | |

| EP2723409A2 (en) | Polymeric materials | |

| US20090216104A1 (en) | Use of acid derivatives of fluoropolymers for fouling-resistant surfaces | |

| US20040086569A1 (en) | Active agent delivery systems, medical devices, and methods | |

| US20040033251A1 (en) | Active agent delivery system including a polyurethane, medical device, and method | |

| US20090123521A1 (en) | Medical devices having coatings for controlled therapeutic agent delivery | |

| US20050064038A1 (en) | Active agent delivery systems including a single layer of a miscible polymer blend, medical devices, and methods | |

| WO1995013313A1 (en) | Hydrocyclosiloxane membrane prepared by plasma polymerization process | |

| MXPA06006470A (en) | Implantable medical devices with fluorinated polymer coatings, and methods of coating thereof. | |

| CA2494188A1 (en) | Active agent delivery system including a hydrophobic cellulose derivative | |

| JP2005521477A (en) | 40-O- (2-hydroxy) ethyl-rapamycin coated stent | |

| Mohandesnezhad et al. | Enhanced bioactivity of 316L stainless steel with deposition of polypyrrole/hydroxyapatite layered hybrid coating: Orthopedic applications | |

| Gopi et al. | Hydroxyapatite coating on selectively passivated and sensitively polymer-protected surgical grade stainless steel | |

| WO2009068914A1 (en) | Implantable device | |

| KR20070112463A (en) | Wet lubricant surface coating having excellent durability, method for surface coating, and a medical device having the surface coating | |

| US9289540B2 (en) | Surface modification for coating | |

| Osaki et al. | Controlled drug release through a plasma polymerized tetramethylcyclo-tetrasiloxane coating barrier | |

| Przykaza et al. | Wettability of chitosan-modified and lipid/polypeptide-coated peek surfaces | |

| US7708774B1 (en) | Polyethylene oxide and silicone copolymers and their usage on medical devices | |

| Zeniieh et al. | Parylene-C thin film for biocompatible encapsulations with very strong adhesion and superior barrier properties |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 08853430 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 08853430 Country of ref document: EP Kind code of ref document: A1 |