Hot water heating boiler log - Risk Engineering

Hot water heating boiler log - Risk Engineering

Hot water heating boiler log - Risk Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

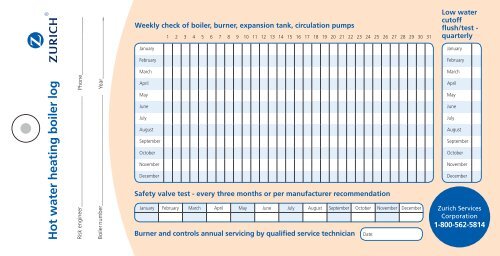

<strong>Hot</strong> <strong>water</strong> <strong>heating</strong> <strong>boiler</strong> <strong>log</strong><br />

<strong>Risk</strong> engineer_______________________________________ Phone_____________________<br />

Boiler number_______________________________________ Year_______________________<br />

Weekly check of <strong>boiler</strong>, burner, expansion tank, circulation pumps<br />

January<br />

February<br />

March<br />

April<br />

May<br />

June<br />

July<br />

August<br />

September<br />

October<br />

November<br />

December<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31<br />

Safety valve test - every three months or per manufacturer recommendation<br />

January February March April May June July August September October November December<br />

Burner and controls annual servicing by qualified service technician<br />

Date:<br />

Low <strong>water</strong><br />

cutoff<br />

flush/test -<br />

quarterly<br />

January<br />

February<br />

March<br />

April<br />

May<br />

June<br />

July<br />

August<br />

September<br />

October<br />

November<br />

December<br />

Zurich Services<br />

Corporation<br />

1-800-562-5814

Important: Follow manufacturer’s recommendations related to operation and testing.<br />

If there are any questions, contact your Zurich risk engineer.<br />

WARNING: DO NOT LEAVE THE BOILER UNATTENDED DURING TESTING OF LOW WATER CUTOFFS<br />

Low <strong>water</strong><br />

cutoffs:<br />

Float type:<br />

(monthly)<br />

Flush the float chamber until clear <strong>water</strong> runs to eliminate any sludge accumulation.<br />

A1-18390-A (07/09) 09-2392<br />

<strong>Hot</strong> <strong>water</strong> <strong>heating</strong> <strong>boiler</strong> <strong>log</strong><br />

Pumps &<br />

expansion tank<br />

Pressure relief<br />

devices<br />

(relief valves)<br />

Water<br />

treatment<br />

Burner controls<br />

& safety<br />

devices<br />

Probe type:<br />

(monthly)<br />

(monthly)<br />

Manual<br />

test:<br />

(quarterly)<br />

With the <strong>boiler</strong> in operation push the test button to simulate a low <strong>water</strong> condition<br />

(See manufacturer’s instructions). The burner should shut down.<br />

Inspect pumps and piping for signs of leaks, corrosion, or improper operation. Inspect expansion tank<br />

for proper <strong>water</strong> level. If problems are found, have a qualified repair firm make needed corrections.<br />

With the <strong>boiler</strong> in operation and at operating pressure, test the safety valve by pulling the test lever to a<br />

fully open position for a few seconds. Release the test lever allowing the valve to snap closed.<br />

CAUTION: If the valve is seized in the shut position or will not reseal correctly, it should be<br />

repaired or replaced immediately.<br />

Maintain your <strong>water</strong> softening system and regularly test and maintain your feed <strong>water</strong> treatment. Effective <strong>water</strong><br />

treatment will control scale accumulations in the <strong>boiler</strong> that have a significant effect on <strong>boiler</strong> efficiency and longevity.<br />

Ask your Zurich risk engineer if you have any questions.<br />

Annually have a qualified <strong>boiler</strong> burner/control technician test, adjust and maintain all the safety devices and controls<br />

on the <strong>boiler</strong>. If you are located in a jurisdiction that has adopted the CSD-1 standard, there are specific requirements<br />

that must be completed. Contact your local Zurich risk engineer if you have any questions.